ASTM D5043-04(2009)

(Practice)Standard Practice for Field Identification of Coatings (Withdrawn 2018)

Standard Practice for Field Identification of Coatings (Withdrawn 2018)

SIGNIFICANCE AND USE

Information about the generic type of coating on a surface is required to select compatible coatings for repainting and can be used when evaluating the performance of a coating in an environment in decisions on upgrading or replacing a coating system. This guide provides a systematic procedure for identifying the generic type of a coating. The procedure can be performed in the field by personnel with limited laboratory experience, and requires a minimum of equipment and materials.

SCOPE

1.1 This practice describes procedures and portable apparatus for determining the generic type of coating films most likely to be encountered on structures. The coating can either be weathered from exposure or be freshly applied.

1.2 Most commonly used coatings can be divided into the broad categories and subgroups shown in Table 1 on the basis of the nonvolatile component (generic types) of their vehicle (film forming resin, binder). Although the curing of some coatings involves more than one process and coatings may contain more than one type of resin, they can usually be assigned to one of the basic classes and generic types listed in Table 1.

1.3 For field exposed coatings, it is suggested that these test methods be used as part of a complete evaluation of a coated surface as it is frequently helpful to consider the environment of exposure and how the coating has performed in the environment when drawing conclusions from these tests.

1.4 These procedures will not result in the identification of components of a coating beyond general classification of the coating by generic type and are not appropriate if more detailed analysis is required, for example, as a part of failure analysis or to identify between different manufacturers of the same type of coating. They also may not be definitive enough to identify complex systems that include multiple layers of different generic types of coatings.

1.5 The evaluation of results is quite subjective. Practice and experience are required to minimize misinterpretation. Repeat tests may be required.

1.6 None of the test is to be taken alone as grounds for identifying the generic type. Only the combination of results from several or all of the tests is to be used in conclusions regarding generic types.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for in formation only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see 5.3.4, 6.3.1, 6.3.3, 7.4, and 8.4.

WITHDRAWN RATIONALE

This practice describes procedures and portable apparatus for determining the generic type of coating films most likely to be encountered on structures. The coating can either be weathered from exposure or be freshly applied.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this practice was withdrawn in January 2018 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5043 −04 (Reapproved 2009)

Standard Practice for

1

Field Identification of Coatings

This standard is issued under the fixed designation D5043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice describes procedures and portable appara-

responsibility of the user of this standard to establish appro-

tus for determining the generic type of coating films most

priate safety and health practices and determine the applica-

likely to be encountered on structures. The coating can either

bility of regulatory limitations prior to use. For specific hazard

be weathered from exposure or be freshly applied.

statements see 5.3.4, 6.3.1, 6.3.3, 7.4, and 8.4.

1.2 Most commonly used coatings can be divided into the

broad categories and subgroups shown in Table 1 on the basis

2. Summary of Practice

of the nonvolatile component (generic types) of their vehicle

2.1 Samples of coatings films are tested with solvents and

(film forming resin, binder). Although the curing of some

chemicals and subjected to pyrolysis to provide evidence of

coatings involves more than one process and coatings may

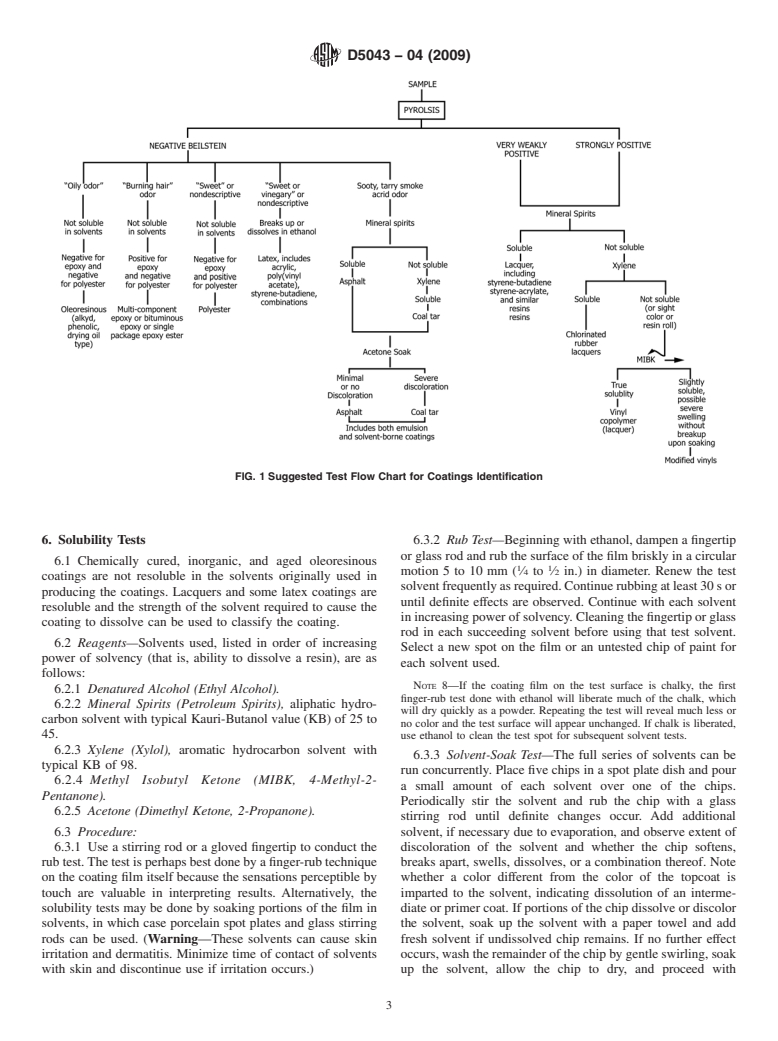

theirgenerictype.Fig.1showsaflowchartforsuggestedorder

contain more than one type of resin, they can usually be

of tests and classification of results.

assigned to one of the basic classes and generic types listed in

Table 1.

3. Significance and Use

1.3 For field exposed coatings, it is suggested that these test

3.1 Information about the generic type of coating on a

methods be used as part of a complete evaluation of a coated

surface is required to select compatible coatings for repainting

surface as it is frequently helpful to consider the environment

and can be used when evaluating the performance of a coating

of exposure and how the coating has performed in the

in an environment in decisions on upgrading or replacing a

environment when drawing conclusions from these tests.

coating system.This guide provides a systematic procedure for

1.4 These procedures will not result in the identification of

identifying the generic type of a coating. The procedure can be

components of a coating beyond general classification of the

performed in the field by personnel with limited laboratory

coatingbygenerictypeandarenotappropriateifmoredetailed

experience, and requires a minimum of equipment and mate-

analysis is required, for example, as a part of failure analysis or

rials.

to identify between different manufacturers of the same type of

coating. They also may not be definitive enough to identify 4. Sampling

complex systems that include multiple layers of different

4.1 The sample of coating is obtained by chipping or

generic types of coatings.

scraping with a knife or by sanding and then brushing the

1.5 The evaluation of results is quite subjective. Practice

material into a specimen container or clean envelope. Care

and experience are required to minimize misinterpretation. should be taken not to cut into substrates, such as plastic or

Repeat tests may be required.

asphalt, that contain polymeric or bituminous materials. Small

portions of untreated wood, masonry, or steel do not ordinarily

1.6 None of the test is to be taken alone as grounds for

interferewiththetests.Sometestscanbeconducteddirectlyon

identifying the generic type. Only the combination of results

the coating surface. If a liquid sample of coating is to be

from several or all of the tests is to be used in conclusions

evaluated, a film of the coating should first be cast on a glass

regarding generic types.

plate or similar surface from which it can conveniently be

1.7 The values stated in SI units are to be regarded as the

removed after drying.

standard. The values given in parentheses are for in formation

NOTE 1—To develop familiarity with the subjective evaluations that

only.

follow, it is good practice to make films of known resin composition by

applying control paints to glass plates or similar surfaces from which they

can be readily removed after drying.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.46 on Industrial Protective Coatings. 5. Pyrolysis

Current edition approved Dec. 1, 2009. Published December 2009. Originally

5.1 Summary of Test Procedure—A sample of coating

approved in 1990. Last previous edition approved in 2004 as D5043 – 04. DOI:

10.1520/D5043-04R09. placed in a small glass test tube is burned o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.