ASTM C516-08(2013)e1

(Specification)Standard Specification for Vermiculite Loose Fill Thermal Insulation

Standard Specification for Vermiculite Loose Fill Thermal Insulation

ABSTRACT

This specification covers the chemical and physical property requirements and acceptability testing procedures of expanded or exfoliated vermiculite loose fill thermal insulation. This also includes vermiculite that has been surface-treated to produce water repellency for use in installations where liquid moisture may be a factor. Vermiculite insulation is specified by two types according to treatments and five classes according to the range of particle size distribution. The insulation should conform to the specified values of bulk density, grading, water properties, thermal resistance, moisture absorption, combustibility, and surface-burning characteristics. Tests to determine the physical properties should also be in accordance with the specified test procedures.

SCOPE

1.1 This specification covers the composition and physical properties of expanded or exfoliated vermiculite loose fill insulation. The specification also includes the testing procedures by which the acceptability of the material shall be determined. These testing procedures deal primarily with material performance in the temperature range associated with the thermal envelope of buildings; however, the commercially usable temperature range for this insulation is from −119 to 850°F (−84 to 454°C). For specialized applications, refer to manufacturer's instructions.

1.2 The specification also covers the composition and properties of vermiculite that has been surface-treated to produce water repellency for installations.

1.3 When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems, the manufacturer shall provide the user with appropriate current information regarding any known problems associated with the recommended use of the company's products, and shall also recommend protective measures to be employed in their safe utilization.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 12.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C516 −08 (Reapproved 2013)

Standard Specification for

Vermiculite Loose Fill Thermal Insulation

This standard is issued under the fixed designation C516; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—11.1, 12.1, 12.2.2, and Table 3 were editorially corrected in April 2014.

1. Scope 2. Referenced Documents

1.1 This specification covers the composition and physical 2.1 ASTM Standards:

properties of expanded or exfoliated vermiculite loose fill C136Test Method for Sieve Analysis of Fine and Coarse

insulation. The specification also includes the testing proce- Aggregates

dures by which the acceptability of the material shall be C168Terminology Relating to Thermal Insulation

determined. These testing procedures deal primarily with C177Test Method for Steady-State Heat Flux Measure-

material performance in the temperature range associated with ments and Thermal Transmission Properties by Means of

the thermal envelope of buildings; however, the commercially the Guarded-Hot-Plate Apparatus

usable temperature range for this insulation is from−119 to C390Practice for Sampling and Acceptance of Thermal

850°F (−84 to 454°C). For specialized applications, refer to Insulation Lots

manufacturer’s instructions. C518Test Method for Steady-State Thermal Transmission

Properties by Means of the Heat Flow Meter Apparatus

1.2 The specification also covers the composition and prop-

C520Test Methods for Density of Granular Loose Fill

erties of vermiculite that has been surface-treated to produce

Insulations

water repellency for installations.

E84Test Method for Surface Burning Characteristics of

1.3 When the installation or use of thermal insulation

Building Materials

materials, accessories, and systems may pose safety or health

E136Test Method for Behavior of Materials in a Vertical

problems, the manufacturer shall provide the user with appro-

Tube Furnace at 750°C

priate current information regarding any known problems

associated with the recommended use of the company’s

3. Terminology

products, and shall also recommend protective measures to be

3.1 Definitions—Refer to Terminology C168 for definitions

employed in their safe utilization.

relating to insulation.

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

as standard. The values given in parentheses are mathematical

4. Classification

conversions to SI units that are provided for information only

4.1 Vermiculite insulation is classified by type and grade

and are not considered standard.

designations, as follows:

1.5 The following safety hazards caveat pertains only to the

4.1.1 Type I—Product that results from the expanding or

test methods portion, Section 9, of this specification:This

exfoliatingofnaturalvermiculiteorebygradingandheatingto

standard does not purport to address all of the safety concerns,

meet the requirements of this specification.

if any, associated with its use. It is the responsibility of the user

4.1.2 Type II—Expanded vermiculite that has been surface-

of this standard to establish appropriate safety and health

treated to produce water repellency and limit absorption of

practices and determine the applicability of regulatory limita-

moisture from both liquid and vapor phase.

tions prior to use.For specific hazard statements, see Section

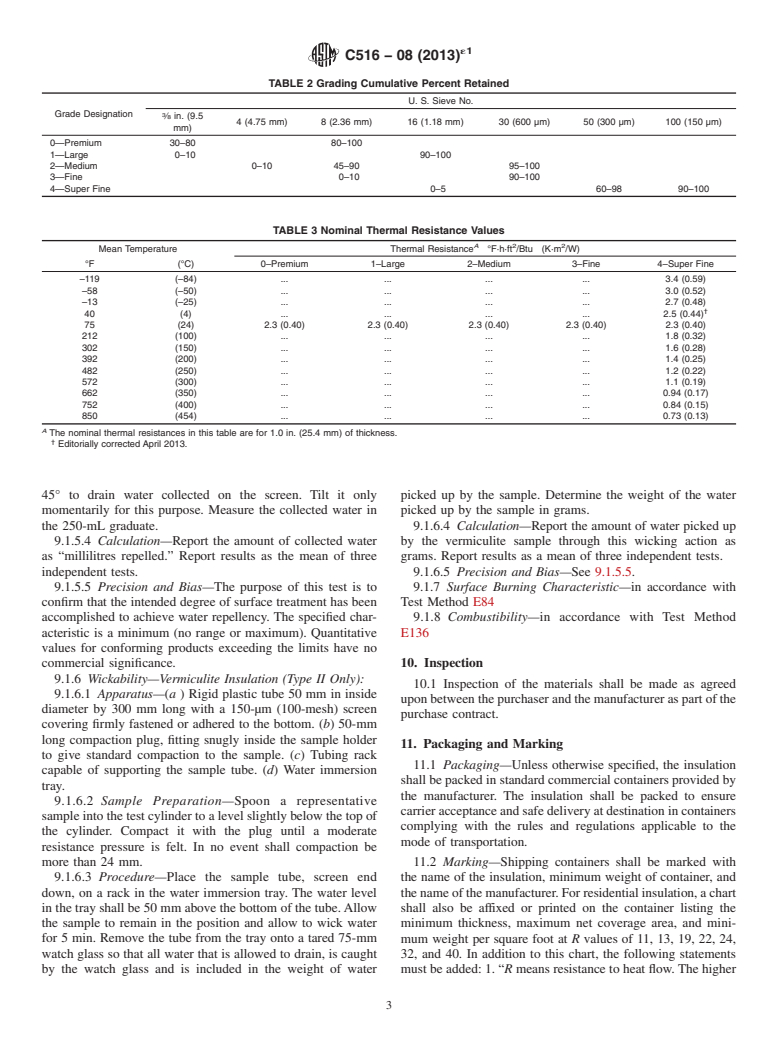

4.1.3 Grade designations established by range of particle

12.

size distribution and bulk density are shown in Table 1 and

Table 2.

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

Blanket and Loose Fill Insulation. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2013. Published April 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1963. Last previous edition approved in 2008 as C516–08. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0516-08R13E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C516−08 (2013)

TABLE 1 Density Specifications

9.1.2 Grading—Test Method C136, except that when a

3 3

Bulk Density, lb/ft (kg/m ) mechanical sieving device is used, the sieving time shall be 5

Grade Designation

min max min and the test specimen shall be 50 g of material.

0—Premium 3.0 (48) 5.0 (80)

9.1.3 Thermal Resistance—Testsforthermalresistancemay

1—Large 3.7 (59) 5.5 (88)

be made in accordance with Test Methods C177 or C518. Test

2—Medium 4.0 (64) 6.0 (96)

at the design density. The thermal resistance of the various

3—Fine 4.5 (72) 7.0 (112)

4—Super Fine 5.5 (88) 8.0 (128)

typesshallnotbelowerthanthevalueslistedinTable3,except

that the average thermal resistance of any four specimens may

fall up to 5% below the value in the table. Determine the

5. Ordering Information

thermal resistance (R-value) at mean temperature of 75°F

(24°C) and 40°F (4°C), at design density and in accordance

5.1 All purchase orders shall designate both type and grade

ofinsulationdesired.Iftypedesignationisomitted,TypeIwill with the current editions of Test Methods C177 or C518.

Report the direction of heat flow. Thermal resistance at other

be furnished. The type and grade classifications in this speci-

ficationdifferfromtheclassificationsinearlierissues.Purchas- mean temperatures may be determined if required.

ersreferencingthisspecificationshallincludethedateofissue.

9.1.4 Water Vapor Sorption—The test specimen shall be a

sample of approximately 50 g. Loose fill the sample and level

6. Materials and Manufacture

into a sample holder 9 by 9 by 5 in. (228 by 228 by 127 mm)

6.1 Vermiculite is a micaceous mineral which is mined and

deep.

processed to produce a high-purity concentrate. The

9.1.4.1 Condition with minimum air movement across the

concentrate, in the form of flakes of varying size and thickness

sample surface. Condition at 50 6 2% relative humidity and

3 3

weighing 55 lb/ft (880 kg/m ), is expanded in high-

120 6 5°F (48.9 6 3°C) to constant weight and record. State

temperature furnaces to densities in the range from 3.0 to 8.0

the density of the sample conditioned to constant weight in the

3 3

lb/ft (48 to 128 kg/m ).As a naturally occurring mineral, it is

report of results.

classifiable as an elementary building material. It is noncom-

9.1.4.2 Increase the relative humidity to 90 6 2% relative

bustible as determined by Test Method E136. Material shall

humidity and 120 6 5°F (48.9 6 3°C) for 14 days. Determine

pass combustion test criteria of Test Method E136.

the weight gain after 14 days of exposure.

9.1.4.3 Calculate the percent weight gain after 14 days of

7. Physical Requirements

exposure to the elevated humidity.

7.1 The physical requirements listed in this section are

9.1.4.4 Precision and Bias—This test establishes a typical

definedasInspectionRequirements(seePracticeC390,section

property of vermiculite. It is an inherent characteristic. It is

5.1.2). The insulation shall conform to the following require-

only intended to indicate absorption under high humidity

ments:

conditions which are known to be characteristic of its usual

Type I Type II

3 3

insulation end use.

Bulk density, lb/ft (kg/m ) See Table 1

Grading (particle size) See Table 2

9.1.5 Water Repellency (Type II Only)—Determine the wa-

Water properties, max g wicked in 5 min N.A. 3

ter repellency of Type II vermiculite insulation in accordance

with the following procedure:

7.2 The physical properties listed in this section of the

9.1.5.1 Apparatus—(a ) Rigid plastic tube 50 mm inside

specification are defined as Qualification Requirements (see

diameter by 300 mm long with a 150-µm (100-mesh) screen

Practice C390, section 5.1.1). The insulation shall conform to

covering firmly fastened or adhered to the bottom. The tube

the following requirements:

shall be marked

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.