ASTM D2845-00(2004)e1

(Test Method)Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constants of Rock

Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constants of Rock

SCOPE

1.1 This test method describes equipment and procedures for laboratory measurements of the pulse velocities of compression waves and shear waves in rock (1) (Note 2) and the determination of ultrasonic elastic constants (Note 1) of an isotropic rock or one exhibiting slight anisotropy.

Note 2--The elastic constants determined by this test method are termed ultrasonic since the pulse frequencies used are above the audible range. The terms sonic and dynamic are sometimes applied to these constants but do not describe them precisely (2). It is possible that the ultrasonic elastic constants may differ from those determined by other dynamic methods.

1.2 This test method is valid for wave velocity measurements in both anisotropic and isotropic rocks although the velocities obtained in grossly anisotropic rocks may be influenced by such factors as direction, travel distance, and diameter of transducers.

1.3 The ultrasonic elastic constants are calculated from the measured wave velocities and the bulk density. The limiting degree of anisotropy for which calculations of elastic constants are allowed and procedures for determining the degree of anisotrophy are specified.

1.4 The values stated in U.S. customary units are to be regarded as the standard. The metric equivalents of U.S. customary units are rationalized.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 2845 – 00 (Reapproved 2004)

Standard Test Method for

Laboratory Determination of Pulse Velocities and Ultrasonic

Elastic Constants of Rock

This standard is issued under the fixed designation D 2845; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made in the last sentence in Section 8.3.1.

1. Scope* 2. Referenced Documents

1.1 This test method describes equipment and procedures 2.1 ASTM Standards:

for laboratory measurements of the pulse velocities of com- D 653 Terminology Relating to Rock, Soil, and Contained

pression waves and shear waves in rock (1) (Note 2) and the Fluids

determination of ultrasonic elastic constants (Note 1)ofan D 3740 Practice for Minimum Requirements for Agencies

isotropic rock or one exhibiting slight anisotropy. Engaged in the Testing and/or Inspection of Soil and Rock

as Used in Engineering Design and Construction

NOTE 1—The elastic constants determined by this test method are

E 691 Practice for Conducting an Interlaboratory Study to

termed ultrasonic since the pulse frequencies used are above the audible

Determine the Precision of a Test Method

range. The terms sonic and dynamic are sometimes applied to these

constants but do not describe them precisely (2). It is possible that the

3. Terminology

ultrasonic elastic constants may differ from those determined by other

dynamic methods.

3.1 For common definitions of terms in this standard, refer

to Terminology D 653.

1.2 This test method is valid for wave velocity measure-

3.2 Definitions of Terms Specific to This Standard:

ments in both anisotropic and isotropic rocks although the

3.2.1 compression wave velocity—the dilational wave ve-

velocities obtained in grossly anisotropic rocks may be influ-

locity which is the propagation velocity of a longitudinal wave

enced by such factors as direction, travel distance, and diam-

in a medium that is effectively infinite in lateral extent. It is not

eter of transducers.

to be confused with bar or rod velocity.

1.3 The ultrasonic elastic constants are calculated from the

measured wave velocities and the bulk density. The limiting

NOTE 2—The compression wave velocity as defined here is the dilata-

degree of anisotropy for which calculations of elastic constants

tional wave velocity. It is the propagation velocity of a longitudinal wave

are allowed and procedures for determining the degree of

in a medium which is effectively infinite in lateral extent. It should not be

confused with the bar or rod velocity.

anisotrophy are specified.

1.4 The values stated in U.S. customary units are to be

4. Summary of Test Method

regarded as the standard. The metric equivalents of U.S.

4.1 Details of essential procedures for the determination of

customary units are rationalized.

the ultrasonic velocity, measured in terms of travel time and

1.5 This standard does not purport to address all of the

distance, of compression and shear waves in rock specimens

safety concerns, if any, associated with its use. It is the

include requirements of instrumentation, suggested types of

responsibility of the user of this standard to establish appro-

transducers, methods of preparation, and effects of specimen

priate safety and health practices and determine the applica-

geometry and grain size. Elastic constants may be calculated

bility of regulatory limitations prior to use.

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

Current edition approved June 10, 2000. Published August 2000. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1969. Last previous edition approved in 2000 as D 2845 – 00. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this test method. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 2845 – 00 (2004)

for isotropic or slightly anisotropic rocks, while anisotropy is 6.2 Pulse Generator Unit—This unit shall consist of an

reported in terms of the variation of wave velocity with electronic pulse generator and external voltage or power

direction in the rock. amplifiers if needed. A voltage output in the form of either

rectangular pulse or a gated sine wave is satisfactory. The

5. Significance and Use

generator shall have a voltage output with a maximum value

5.1 The primary advantages of ultrasonic testing are that it

afteramplificationofatleast50Vintoa50-Vimpedanceload.

yields compression and shear wave velocities, and ultrasonic

Avariable pulse width, with a range of 1 to 10µ s is desirable.

valuesfortheelasticconstantsofintacthomogeneousisotropic

The pulse repetition rate may be fixed at 60 repetitions per

rock specimens (3). Elastic constants are not to be calculated

second or less although a range of 20 to 100 repetitions per

for rocks having pronounced anisotropy by procedures de-

second is recommended. The pulse generator shall also have a

scribedinthistestmethod.Thevaluesofelasticconstantsoften

trigger-pulse output to trigger the oscilloscope. There shall be

do not agree with those determined by static laboratory

a variable delay of the main-pulse output with respect to the

methods or the in situ methods. Measured wave velocities

trigger-pulse output, with a minimum range of 0 to 20 µs.

likewise may not agree with seismic velocities, but offer good

6.3 Transducers—The transducers shall consist of a trans-

approximations. The ultrasonic evaluation of rock properties is

mitter that converts electrical pulses into mechanical pulses

useful for preliminary prediction of static properties. The test

and a receiver that converts mechanical pulses into electrical

methodisusefulforevaluatingtheeffectsofuniaxialstressand

pulses.Environmentalconditionssuchasambienttemperature,

water saturation on pulse velocity. These properties are in turn

moisture, humidity, and impact should be considered in select-

useful in engineering design.

ing the transducer element. Piezoelectric elements are usually

5.2 The test method as described herein is not adequate for

recommended, but magnetostrictive elements may be suitable.

measurement of stress-wave attenuation. Also, while pulse

Thickness-expander piezoelectric elements generate and sense

velocitiescanbeemployedtodeterminetheelasticconstantsof

predominately compression-wave energy; thickness-shear pi-

materials having a high degree of anisotropy, these procedures

ezoelectric elements are preferred for shear-wave measure-

are not treated herein.

ments. Commonly used piezoelectric materials include ceram-

ics such as lead-zirconate-titanate for either compression or

NOTE 3—The quality of the result produced by this standard is

shear, and crystals such as a-c cut quartz for shear. To reduce

dependent on the competence of the personnel performing it, and the

suitability of the equipment and facilities used. Agencies that meet the scattering and poorly defined first arrivals at the receiver, the

criteria of Practice D 3740 are generally considered capable of competent

transmitter shall be designed to generate wavelengths at least

and objective testing and sampling. Users of this standard are cautioned

3 3 the average grain size of the rock.

that compliance with Practice D 3740 does not in itself assure reliable

NOTE 4—Wavelengthisthewavevelocityintherockspecimendivided

results.Reliableresultsdependonmanyfactors;PracticeD 3740provides

bytheresonancefrequencyofthetransducer.Commonlyusedfrequencies

a means of evaluating some of those factors.

range from 75 kHz to 3 MHz.

6. Apparatus

6.3.1 In laboratory testing, it may be convenient to use

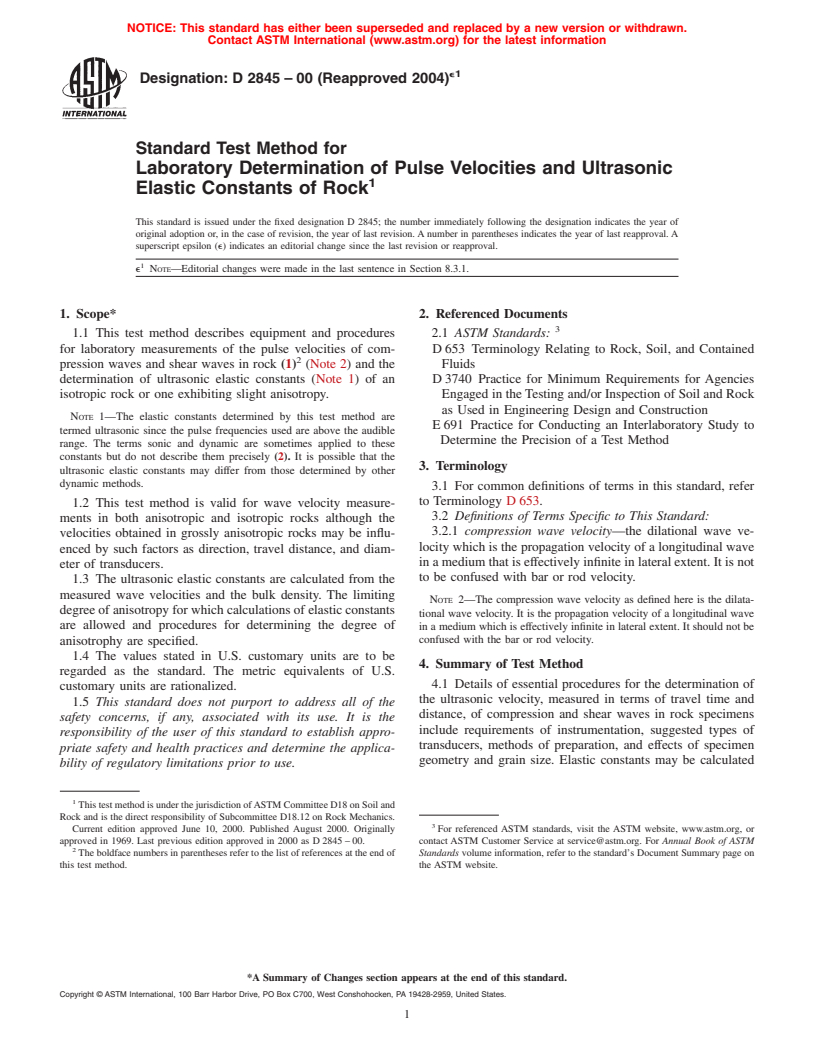

6.1 General—The testing apparatus (Fig. 1) should have unhoused transducer elements. But if the output voltage of the

impedance matched electronic components and shielded leads receiver is low, the element should be housed in metal

to ensure efficient energy transfer. To prevent damage to the (grounded) to reduce stray electromagnetic pickup. If protec-

apparatus allowable voltage inputs should not be exceeded. tion from mechanical damage is necessary, the transmitter as

NOTE 1—Components shown by dashed lines are optional, depending on method of travel-time measurement and voltage sensitivity of oscilloscope.

FIG. 1 Schematic Diagram of Typical Apparatus

e1

D 2845 – 00 (2004)

well as the receiver may be housed in metal. This also allows linearity over the range of the instrument. The calibration shall

special backings for the transducer element to alter its sensi- be checked against signals transmitted by the National Institute

tivity or reduce ringing (4). The basic features of a housed of Standards and Technology radio station WWV, or against a

element are illustrated in Fig. 2. Energy transmission between crystalcontrolledtime-markorfrequencygeneratorthatcanbe

the transducer element and test specimen can be improved by referenced back to the signals from WWV periodically. It is

( 1) machining or lapping the surfaces of the face plates to recommended that the calibration of the time measuring circuit

make them smooth, flat, and parallel, (2) making the face plate be checked at least once a month and after any severe impact

from a metal such as magnesium whose characteristic imped- that the instrument may receive.

anceisclosetothatofcommonrocktypes,(3)makingtheface

7. Test Specimens

plate as thin as practicable, and (4) coupling the transducer

element to the face plate by a thin layer of an electrically

7.1 Preparation—Exercise care in core drilling, handling,

conductive adhesive, an epoxy type being suggested.

sawing, grinding, and lapping the test specimen to minimize

6.3.2 Pulsevelocitiesmayalsobedeterminedforspecimens

the mechanical damage caused by stress and heat. It is

subjected to uniaxial states of stress. The transducer housings

recommended that liquids other than water be prevented from

in this case will also serve as loading platens and should be

contacting the specimen, except when necessary as a coupling

designed with thick face plates to assure uniform loading over

medium between specimen and transducer during the test. The

the ends of the specimen (5).

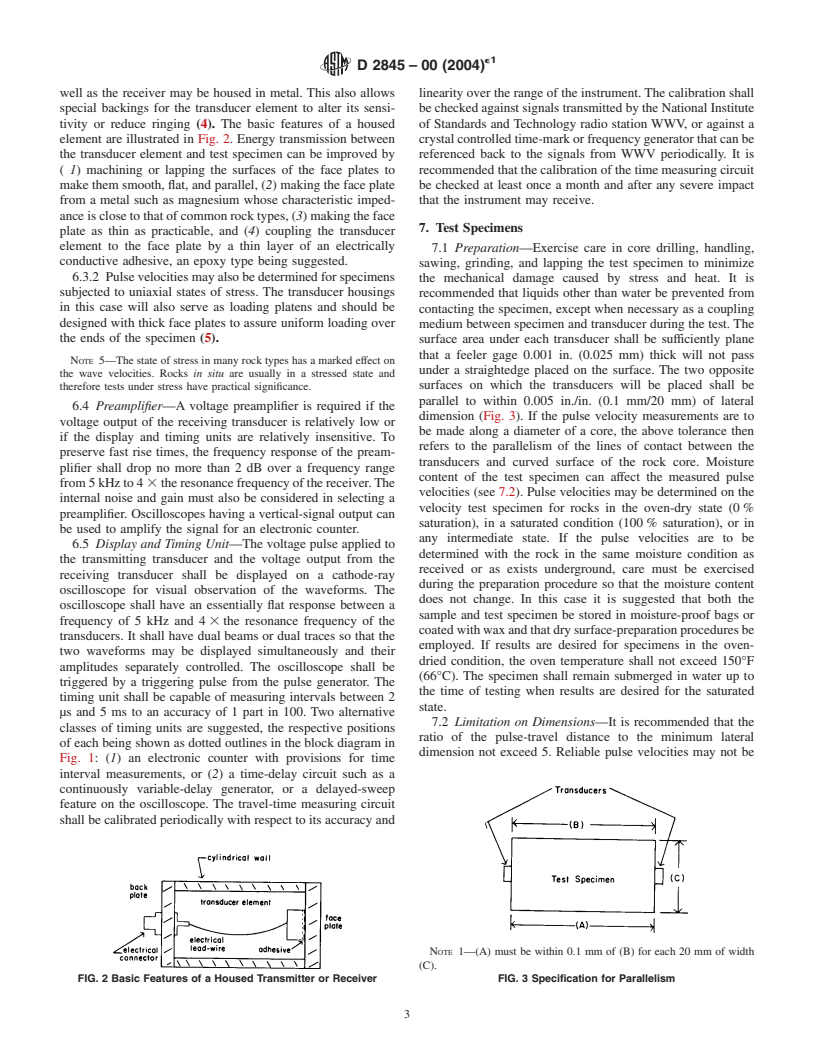

surface area under each transducer shall be sufficiently plane

that a feeler gage 0.001 in. (0.025 mm) thick will not pass

NOTE 5—The state of stress in many rock types has a marked effect on

under a straightedge placed on the surface. The two opposite

the wave velocities. Rocks in situ are usually in a stressed state and

surfaces on which the transducers will be placed shall be

therefore tests under stress have practical significance.

parallel to within 0.005 in./in. (0.1 mm/20 mm) of lateral

6.4 Preamplifier—A voltage preamplifier is required if the

dimension (Fig. 3). If the pulse velocity measurements are to

voltage output of the receiving transducer is relatively low or

be made along a diameter of a core, the above tolerance then

if the display and timing units are relatively insensitive. To

refers to the parallelism of the lines of contact between the

preserve fast rise times, the frequency response of the pream-

transducers and curved surface of the rock core. Moisture

plifier shall drop no more than 2 dB over a frequency range

content of the test specimen can affect the measured pulse

from5kHzto4 3 theresonancefrequencyofthereceiver.The

velocities (see 7.2). Pulse velocities may be determined on the

internal noise and gain must also be considered in selecting a

velocity test specimen for rocks in the oven-dry state (0 %

preamplifier. Oscilloscopes having a vertical-signal output can

saturation), in a saturated condition (100 % saturation), or in

be used to amplify the signal for an electronic counter.

any intermediate state. If the pulse velocities are to be

6.5 Display and Timing Unit—The voltage pulse applied to

determined with the rock in the same moisture condition as

the transmitting transducer and the voltage output from the

received or as exists underground, care must be exercised

receiving transducer shall be displayed on a cathode-ray

during the preparation procedure so that the moisture content

oscilloscope for visual observation of the waveforms. The

does not change. In this case it is suggested that both the

oscilloscope shall have an essentially flat response between a

sample and test specimen be stored in moisture-proof bags or

frequency of 5 kHz and 4 3 the resonance frequency of the

coatedwithwaxandthatdrysurface-preparationproceduresbe

transducers. It shall have dual beams or dual traces so that the

employed. If results are desired for specimens in the oven-

two waveforms may be displayed simultaneously and their

dried condition, the oven temperature shall not exceed 150°F

amplitudes separately controlled. The oscilloscope shall be

(66°C). The specimen shall remain submerged in water up to

triggered by a triggering pulse from the pulse generator. The

the time of testing when results are desired for the saturated

timing unit shall be capable of measuring intervals between 2

state.

µs and 5 ms to an accuracy of 1 part in 100. Two alternative

7.2 Limitation on Dimensions—It is recommended that the

classes of timing units are suggested, the respective positions

ratio of the pulse-travel distance to the minimum lateral

of each being shown as dotted outlines in the block diagram in

dimension not exceed 5. Reliable pulse velocities may not be

Fig. 1:(1) an electronic counter with provisions for time

interval measurements, or (2) a time-delay circuit such as a

continuously variable-delay generator, or a delayed-sweep

feature on the oscilloscope. The travel-time measuring circuit

shall be calibrated periodically with respect to its accuracy and

NOTE 1—(A) must be within 0.1 mm of (B) for each 20 mm of width

(C).

FIG. 2 Basic Features of a Housed Transmitter or Receiver FIG. 3 Specification for Parallelism

e1

D 2845 – 00 (2004)

measurable for high values of this ratio. The travel distance of

the pulse through the rock shall be at least 10 3 the average

grainsizesothatanaccurateaveragepropagationvelocitymay

be determined. The grain size of the rock sample, the natural

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.