ASTM D4634-99

(Specification)Standard Specification for Styrene-Maleic Anhydride Materials (S/MA)

Standard Specification for Styrene-Maleic Anhydride Materials (S/MA)

SCOPE

1.1 This specification covers styrene-maleic anhydride materials suitable for molding or extrusion.

1.2 This specification is intended to be a means of calling out properties of plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Materials should be selected by those having expertise in the plastics field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material other than those covered by this specification, and the economics.

1.3 The properties included in this standard are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These will be agreed upon between the user and the supplier, by using the suffixes as given in Section 5.

1.4 The values stated in SI units are to be regarded as the standard. The values in parentheses are given for information only.

1.5 The following precautionary caveat pertains only to the test method portion, Section 12, of this specification: This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4634 – 99

Standard Specification for

Styrene-Maleic Anhydride Materials (S/MA)

This standard is issued under the fixed designation D 4634; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 1—There is no equivalent or similar ISO standard for S/MA.

1. Scope*

1.1 This specification covers styrene-maleic anhydride ma-

2. Referenced Documents

terials suitable for molding or extrusion. Styrene-maleic anhy-

2.1 ASTM Standards:

dride materials, being thermoplastic, are reprocessable and

D 256 Test Methods for Impact Resistance of Plastics and

recyclable. This specification allows for the use of those

Electrical Insulating Materials

materials provided that all the specific requirements of this

D 618 Practice for Conditioning Plastics for Testing

specification are met.

D 638 Test Method for Tensile Properties of Plastics

1.2 The properties included in this standard are those

D 648 Test Method for Deflection Temperature of Plastics

required to identify the compositions covered. There may be

Under Flexural Load

other requirements necessary to identify particular character-

D 790 Test Methods for Flexural Properties of Unreinforced

istics important to specialized applications. These will be

and Reinforced Plastics and Electrical Insulating Materials

agreed upon between the user and the supplier, by using the

D 883 Terminology Relating to Plastics

suffixes as given in Section 5.

D 1525 Test Method for Vicat Softening Temperature of

1.3 This classification system and subsequent line call out

Plastics

(specification) are intended to provide means of calling out

D 1600 Terminology for Abbreviated Terms Relating to

properties of plastic materials used in the fabrication of end

Plastics

items or parts. It is not intended for the selection of materials.

D 1898 Practice for Sampling of Plastics

Materials should be selected by those having expertise in the

D 3641 Practice for Injection Molding Test Specimens of

plastics field after careful consideration of the design and the

Thermoplastic Molding and Extrusion Materials

performance required of the part, the environment to which it

D 3892 Practice for Packaging/Packing of Plastics

will be exposed, the fabrication process to be employed, costs

D 4000 Classification System for Specifying Plastic Mate-

involved, and the inherent properties of the material other than

rials

those covered by this classification system.

E 29 Practice for Using Significant Digits in Test Data to

1.4 The values stated in SI units are to be regarded as the

Determine Conformance with Specifications

standard.

2.2 Military Standard:

1.5 The following precautionary caveat pertains only to the

MIL-STD-105 Sampling Procedures and Tables for Inspec-

test methods portion, Section 11, of this specification. This

tion by Attributes

standard does not purport to address all of the safety concerns,

2.3 Underwriters Laboratories Standard:

if any, associated with its use. It is the responsibility of the user

UL 94 Standard for Tests for Flammability for Parts in

of this standard to establish appropriate safety and health

Devices and Appliances

practices and determine the applicability of regulatory limita-

tions prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction of ASTM Committee D-20 on the ASTM website.

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Materials. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Current edition approved July 10, 1999. Published September 1999. Originally Available from Underwriters Laboratories, Inc., Publications Stock, 333

published as D 4634 – 86. Last previous edition D 4634 – 86(1993). Pfingsten Road, Northbrook, IL 60062.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4634–99

NOTE 2—An example of this classification system is as follows: The

3. Terminology

designation S/MA 211 would indicate:

3.1 General—For definitions of technical terms pertaining

S/MA = Styrene-maleic anhydride,

to plastics used in this specification see Terminology D 883.

2 = injection-molding resin (group),

1 = general purpose (class),

1 = requirements given in Table S/MA (grade).

4. Classification

4.1.1 To facilitate the incorporation of future or special

4.1 Styrene-maleic anhydride materials are classified into

materials, the “other/unspecified” category (0) for group, class,

groups according to their use either for injection molding, or

and grade is shown in Table S/MA. The basic properties can be

for extrusion. These groups are subdivided into classes and

obtained from Tables A and B as they apply (see 4.3).

grades, as shown in Table S/MA.

TABLE S/MA Requirements for Natural Color Only

Flexural Izod Vicat

Tensile

B

Modulus Impact Softening

A

Strength

C D

Group Description Class Description Grade Description (D 790) Strength Point

(D 638) min,

min, (D 256) (D 1525)

MPa

MPa min, J/m min, °C

1 Crystal 1 general purpose 1 45 3000 20 120

0 other . . . .

2 high-heat resistant 1 45 2900 20 130

0 other . . . .

0 other 0 other . . . .

2 Impact-modified, 1 general purpose 1 40 2200 140 115

molding 2 33 2100 170 115

3 30 2000 200 115

0 other . . . .

2 high-impact 1 45 2200 500 115

2 34 2200 300 120

0 other . . . .

3 high-heat resistant 1 35 2500 120 135

2 33 2200 210 125

3 30 2200 80 125

0 other . . . .

4 plating 1 30 2000 150 120

0 other . . . .

5FR 1 28 1900 130 115

2 22 1800 70 115

0 other . . . .

0 other 0 other . . . .

3 Impact modified, 1 general purpose 1 40 2500 140 115

extrusion 2 35 2300 170 115

3 30 2200 200 115

0 other . . . .

2 high-heat resistant 1 33 2200 210 125

2 30 2200 80 125

0 other . . . .

3FR 1 28 1900 130 115

2 22 1800 70 115

0 other 0 other . . . .

0 Other 0 other 0 other . . . .

A

Tensile strength determined on 3.2-mm thick injection-molded Type I specimen, tested at 5 mm/min.

B

Flexural modulus determined on 12.5 by 3.2-mm injection molded specimen, 2-in. span, tangent, Method I, 1.3 mm/s.

C

Izod impact strength determined on 12.5 by 3.2-mm injection molded specimen. The specimen shall be cut from a bar of 125 mm in length (such as that used in the

Vicat test). All specimens shall be taken from the dead end (opposite to gate).

D

Vicat softening point shall be 1-kg load, 12.5 by 3.2-mm injection molded specimen, Rate B.

D4634–99

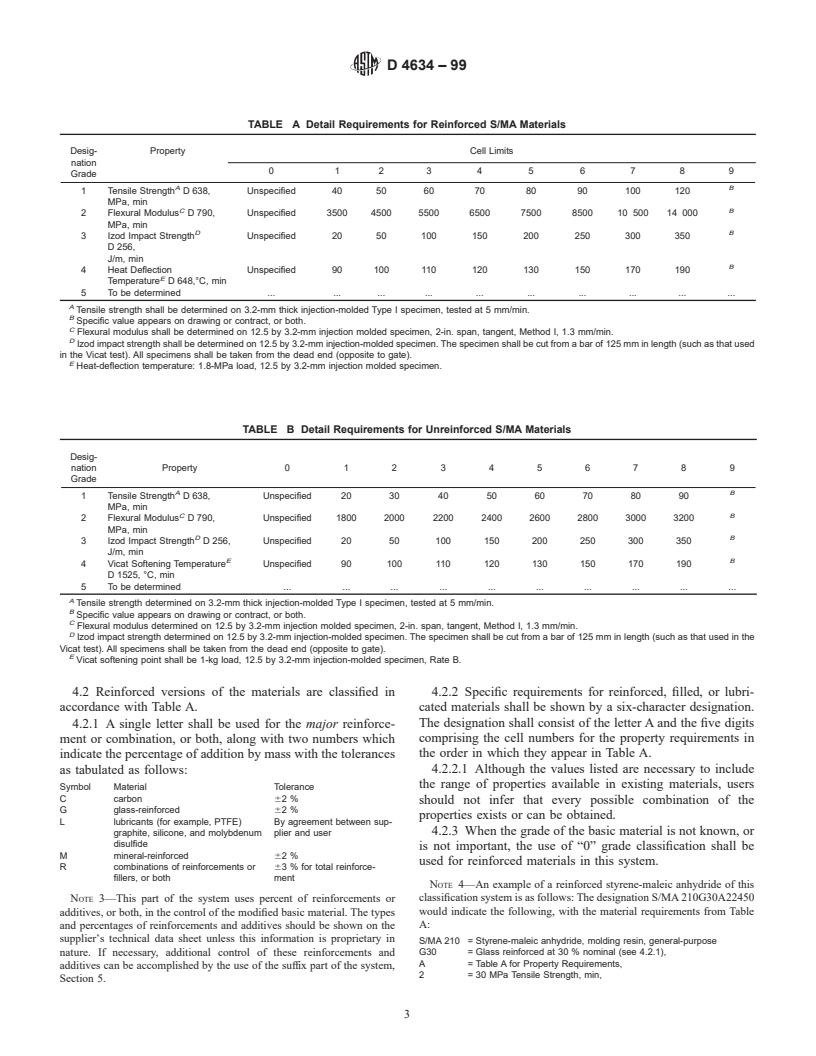

TABLE A Detail Requirements for Reinforced S/MA Materials

Desig- Property Cell Limits

nation

0 1 2 3 456 7 8 9

Grade

A B

1 Tensile Strength D 638, Unspecified 40 50 60 70 80 90 100 120

MPa, min

C B

2 Flexural Modulus D 790, Unspecified 3500 4500 5500 6500 7500 8500 10 500 14 000

MPa, min

D B

3 Izod Impact Strength Unspecified 20 50 100 150 200 250 300 350

D 256,

J/m, min

B

4 Heat Deflection Unspecified 90 100 110 120 130 150 170 190

E

Temperature D 648,°C, min

5 To be determined . . . . . . . . . .

A

Tensile strength shall be determined on 3.2-mm thick injection-molded Type I specimen, tested at 5 mm/min.

B

Specific value appears on drawing or contract, or both.

C

Flexural modulus shall be determined on 12.5 by 3.2-mm injection molded specimen, 2-in. span, tangent, Method I, 1.3 mm/min.

D

Izod impact strength shall be determined on 12.5 by 3.2-mm injection-molded specimen. The specimen shall be cut from a bar of 125 mm in length (such as that used

in the Vicat test). All specimens shall be taken from the dead end (opposite to gate).

E

Heat-deflection temperature: 1.8-MPa load, 12.5 by 3.2-mm injection molded specimen.

TABLE B Detail Requirements for Unreinforced S/MA Materials

Desig-

nation Property 0 1 2 3 45678 9

Grade

A B

1 Tensile Strength D 638, Unspecified 20 30 40 50 60 70 80 90

MPa, min

C B

2 Flexural Modulus D 790, Unspecified 1800 2000 2200 2400 2600 2800 3000 3200

MPa, min

D B

3 Izod Impact Strength D 256, Unspecified 20 50 100 150 200 250 300 350

J/m, min

E B

4 Vicat Softening Temperature Unspecified 90 100 110 120 130 150 170 190

D 1525, °C, min

5 To be determined . . . . . . . . . .

A

Tensile strength determined on 3.2-mm thick injection-molded Type I specimen, tested at 5 mm/min.

B

Specific value appears on drawing or contract, or both.

C

Flexural modulus determined on 12.5 by 3.2-mm injection molded specimen, 2-in. span, tangent, Method I, 1.3 mm/min.

D

Izod impact strength determined on 12.5 by 3.2-mm injection-molded specimen. The specimen shall be cut from a bar of 125 mm in length (such as that used in the

Vicat test). All specimens shall be taken from the dead end (opposite to gate).

E

Vicat softening point shall be 1-kg load, 12.5 by 3.2-mm injection-molded specimen, Rate B.

4.2 Reinforced versions of the materials are classified in 4.2.2 Specific requirements for reinforced, filled, or lubri-

accordance with Table A. cated materials shall be shown by a six-character designation.

The designation shall consist of the letter A and the five digits

4.2.1 A single letter shall be used for the major reinforce-

comprising the cell numbers for the property requirements in

ment or combination, or both, along with two numbers which

the order in which they appear in Table A.

indicate the percentage of addition by mass with the tolerances

4.2.2.1 Although the values listed are necessary to include

as tabulated as follows:

the range of properties available in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.