ASTM D2867-09(2014)

(Test Method)Standard Test Methods for Moisture in Activated Carbon

Standard Test Methods for Moisture in Activated Carbon

SIGNIFICANCE AND USE

4.1 The moisture content of activated carbon is often required to define and express its properties in relation to the net weight of the carbon.

4.2 The moisture content of activated carbon packed in typical shipping containers will usually increase during transportation and storage. Users of activated carbon in applications where low moisture content is important should be aware of this effect.

SCOPE

1.1 These test methods provide three procedures for the determination of the moisture content of activated carbon. The procedures may also be used to dry samples required for other tests. The oven-drying and moisture balance methods are used when water is the only volatile material present and is in significant quantities, and the activated carbon is not heat-sensitive (some activated carbons can ignite spontaneously at temperatures as low as 150°C). The xylene-extraction method is used when a carbon is known or suspected to be heat sensitive or to contain nonwater-miscible organic compounds instead of or in addition to water. The oven-drying method described in these test methods may be used as the reference for development of instrumental techniques for moisture determination in activated carbon.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2867 − 09 (Reapproved 2014)

Standard Test Methods for

1

Moisture in Activated Carbon

This standard is issued under the fixed designation D2867; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Summary of Test Methods

3.1 Oven-Drying Test Method—A sample of carbon is put

1.1 These test methods provide three procedures for the

into a dry, closed capsule (of known weight) and weighed

determination of the moisture content of activated carbon. The

accurately. The capsule is opened and placed with the lid in a

procedures may also be used to dry samples required for other

preheated oven. The sample is dried to constant weight then

tests. The oven-drying and moisture balance methods are used

removed from the oven and with the capsule closed, cooled to

when water is the only volatile material present and is in

ambient temperature. The closed capsule is weighed again

significant quantities, and the activated carbon is not heat-

accurately. The weight loss is expressed as a percentage of the

sensitive (some activated carbons can ignite spontaneously at

weight of the original sample.

temperatures as low as 150°C). The xylene-extraction method

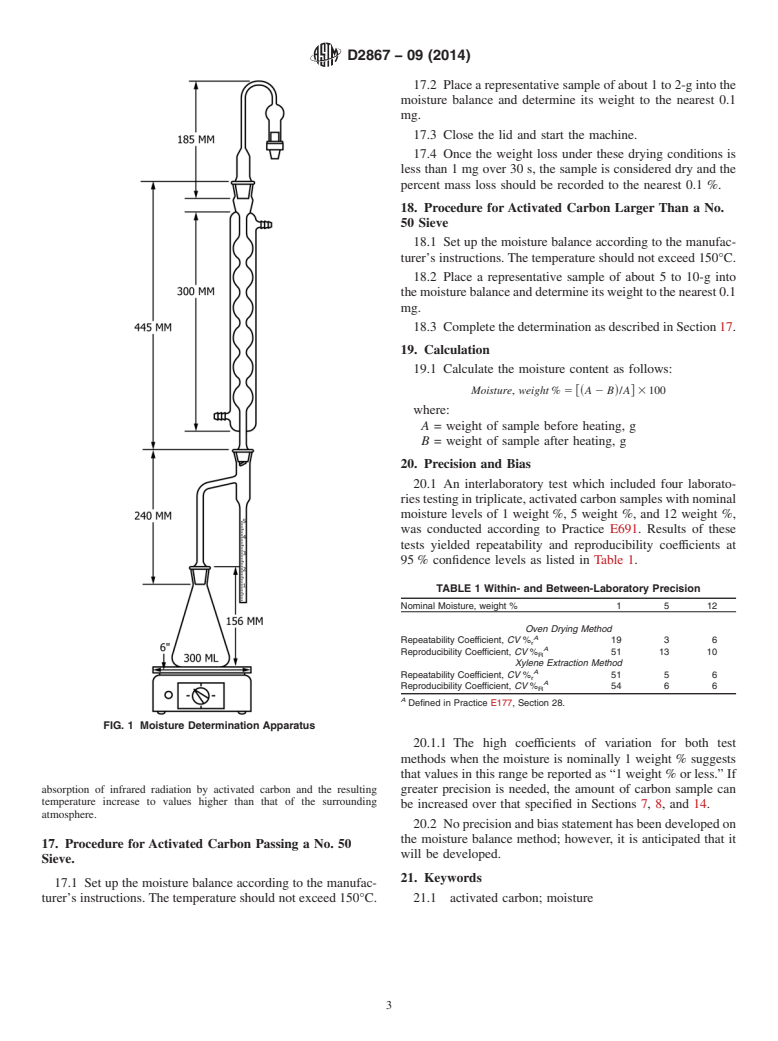

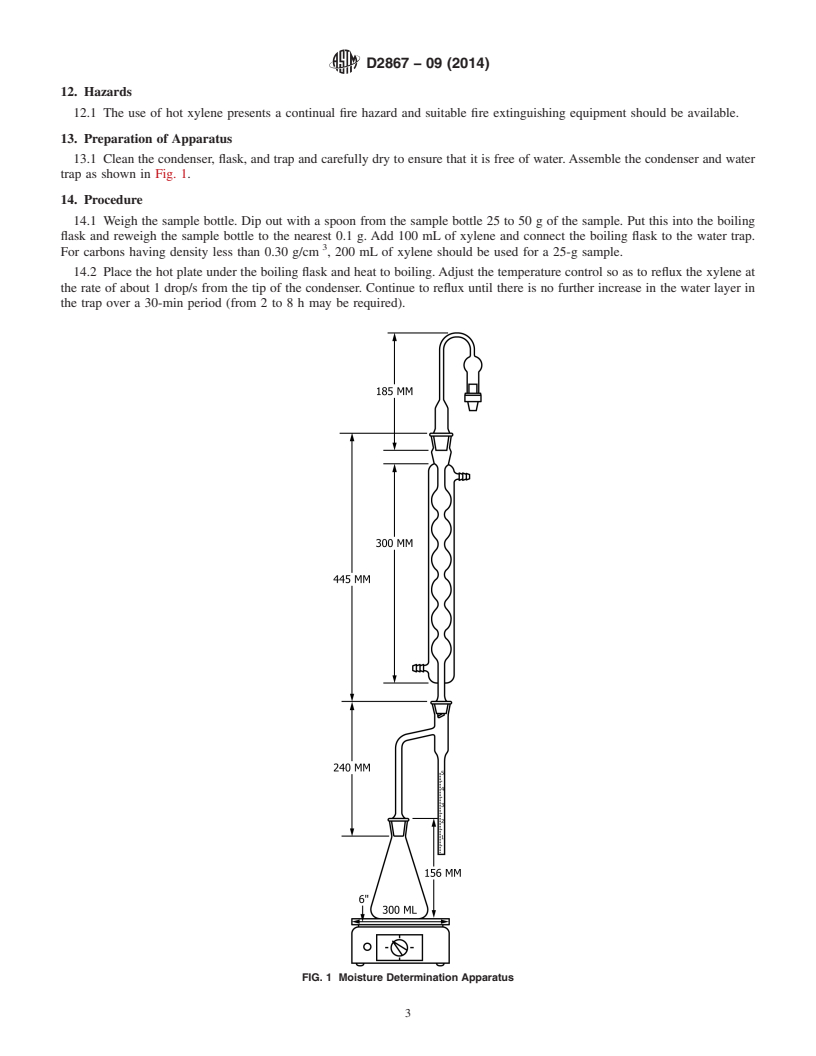

3.2 Xylene-Extraction Test Method— A known, accurate

is used when a carbon is known or suspected to be heat

weightofcarbonisputintoaboilingflask.Aknownvolumeof

sensitive or to contain nonwater-miscible organic compounds

xylene is added to the flask and the flask then connected to a

instead of or in addition to water. The oven-drying method

water trap. A hot plate is used to heat the xylene until boiling.

described in these test methods may be used as the reference

The temperature is controlled to allow steady reflux. Reflux

for development of instrumental techniques for moisture de-

continues until no further water can be collected in the trap.

termination in activated carbon.

The weight of water collected is expressed as a percentage of

1.2 The values stated in SI units are to be regarded as

the weight of the original sample.

standard. No other units of measurement are included in this

3.3 Moisture Balance Test Method—A sample of activated

standard.

carbonisplacedinamoisturebalanceandtheweightmeasured

1.3 This standard does not purport to address all of the

accurately. The sample is dried to constant weight. The weight

safety concerns, if any, associated with its use. It is the

loss is expressed as a percentage of the weight of the original

responsibility of the user of this standard to establish appro-

sample.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4. Significance and Use

4.1 The moisture content of activated carbon is often

2. Referenced Documents

required to define and express its properties in relation to the

2

net weight of the carbon.

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in

4.2 The moisture content of activated carbon packed in

ASTM Test Methods

typical shipping containers will usually increase during trans-

E691 Practice for Conducting an Interlaboratory Study to

portation and storage. Users of activated carbon in applications

Determine the Precision of a Test Method where low moisture content is important should be aware of

this effect.

OVEN-DRYING METHOD

1

These test methods are under the jurisdiction of ASTM Committee D28 on

Activated Carbon and are the direct responsibility of Subcommittee D28.04 on Gas

5. Apparatus

Phase Evaluation Tests.

Current edition approved July 1, 2014. Published September 2014. Originally

5.1 Moisture Oven—Most commercial, electrically heated,

approved in 1970. Last previous edition approved in 2009 as D2867 – 09. DOI:

forced-circulation drying ovens capable of temperature regu-

10.1520/D2867-09R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or lation between 145 and 155°C may be used.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 Capsules with Covers—Low-form glass weighing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bottles with ground-glass stoppers or seamless metal boxes

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2867 − 09 (2014)

with covers may be used. They should be as shallow as 11. Reagent

possible, consistent with convenient handling.

11.1 Xylene—Reagent grade in accordance

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2867 − 09 D2867 − 09 (Reapproved 2014)

Standard Test Methods for

1

Moisture in Activated Carbon

This standard is issued under the fixed designation D2867; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods provide three procedures for the determination of the moisture content of activated carbon. The

procedures may also be used to dry samples required for other tests. The oven-drying and moisture balance methods are used when

water is the only volatile material present and is in significant quantities, and the activated carbon is not heat-sensitive (some

activated carbons can ignite spontaneously at temperatures as low as 150°C). The xylene-extraction method is used when a carbon

is known or suspected to be heat sensitive or to contain nonwater-miscible organic compounds instead of or in addition to water.

The oven-drying method described in these test methods may be used as the reference for development of instrumental techniques

for moisture determination in activated carbon.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Methods

3.1 Oven-Drying Test Method—A sample of carbon is put into a dry, closed capsule (of known weight) and weighed accurately.

The capsule is opened and placed with the lid in a preheated oven. The sample is dried to constant weight then removed from the

oven and with the capsule closed, cooled to ambient temperature. The closed capsule is weighed again accurately. The weight loss

is expressed as a percentage of the weight of the original sample.

3.2 Xylene-Extraction Test Method— A known, accurate weight of carbon is put into a boiling flask. A known volume of xylene

is added to the flask and the flask then connected to a water trap. A hot plate is used to heat the xylene until boiling. The temperature

is controlled to allow steady reflux. Reflux continues until no further water can be collected in the trap. The weight of water

collected is expressed as a percentage of the weight of the original sample.

3.3 Moisture Balance Test Method—A sample of activated carbon is placed in a moisture balance and the weight measured

accurately. The sample is dried to constant weight. The weight loss is expressed as a percentage of the weight of the original

sample.

4. Significance and Use

4.1 The moisture content of activated carbon is often required to define and express its properties in relation to the net weight

of the carbon.

1

These test methods are under the jurisdiction of ASTM Committee D28 on Activated Carbon and are the direct responsibility of Subcommittee D28.04 on Gas Phase

Evaluation Tests.

Current edition approved Nov. 1, 2009July 1, 2014. Published December 2009September 2014. Originally approved in 1970. Last previous edition approved in 20042009

as D2867 – 04.D2867 – 09. DOI: 10.1520/D2867-09.10.1520/D2867-09R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2867 − 09 (2014)

4.2 The moisture content of activated carbon packed in typical shipping containers will usually increase during transportation

and storage. Users of activated carbon in applications where low moisture content is important should be aware of this effect.

OVEN-DRYING METHOD

5. Apparatus

5.1 Moisture Oven—Most commercial, electrically heated,

for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.