ASTM D7151-05

(Test Method)Standard Test Method for Determination of Elements in Insulating Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

Standard Test Method for Determination of Elements in Insulating Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

SIGNIFICANCE AND USE

This test method covers the rapid determination of 12 elements in insulating oils, and it provides rapid screening of used oils for indications of wear. Test times approximate several minutes per test specimen, and detectability is in the 10-100 μg/kg range.

This test method can be used to monitor equipment condition and help to define when corrective action is needed. It can also be used to detect contamination such as from silicone fluids (via Silicon) or from dirt (via Silicon and Aluminum).

This test method can be used to indicate the efficiency of reclaiming used insulating oil.

SCOPE

1.1 This test method describes the determination of metals and contaminants in insulating oils by inductively coupled plasma atomic emission spectrometry (ICP-AES). The specific elements are listed in Table 1. This test method is similar to Test Method D 5185, but differs in methodology, which results in the greater sensitivity required for insulating oil applications.

1.2 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine insoluble particulates. Analytical results are particle size dependent, and low results are obtained for particles larger than several micrometers.

1.3 This test method determines the dissolved metals (which may originate from overheating) and a portion of the particulate metals (which generally originate from a wear mechanism). While this ICP method detects nearly all particles less than several micrometers, the response of larger particles decreases with increasing particle size because larger particles are less likely to make it through the nebulizer and into the sample excitation zone.

1.4 This test method includes an option for filtering the oil sample for those users who wish to separately determine dissolved metals and particulate metals (and hence, total metals).

1.5 Elements present at concentrations above the upper limit of the calibration curves can be determined with additional, appropriate dilutions and with no degradation of precision.

1.6 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7151 − 05

StandardTest Method for

Determination of Elements in Insulating Oils by Inductively

Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

This standard is issued under the fixed designation D7151; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and to determine the

1.1 This test method describes the determination of metals

applicability of regulatory limitations prior to use.

and contaminants in insulating oils by inductively coupled

plasma atomic emission spectrometry (ICP-AES). The specific

2. Referenced Documents

elements are listed in Table 1. This test method is similar to

2.1 ASTM Standards:

Test Method D5185, but differs in methodology, which results

C1109 Practice for Analysis of Aqueous Leachates from

in the greater sensitivity required for insulating oil applica-

Nuclear Waste Materials Using Inductively Coupled

tions.

Plasma-Atomic Emission Spectroscopy

1.2 This test method uses oil-soluble metals for calibration

D923 Practices for Sampling Electrical Insulating Liquids

and does not purport to quantitatively determine insoluble

D1744 Test Method for Water in Liquid Petroleum Products

particulates.Analytical results are particle size dependent, and

by Karl Fischer Reagent

low results are obtained for particles larger than several

D2864 Terminology Relating to Electrical Insulating Liq-

micrometers.

uids and Gases

D4307 Practice for Preparation of Liquid Blends for Use as

1.3 Thistestmethoddeterminesthedissolvedmetals(which

Analytical Standards

may originate from overheating) and a portion of the particu-

D5185 TestMethodforDeterminationofAdditiveElements,

late metals (which generally originate from a wear mecha-

Wear Metals, and Contaminants in Used Lubricating Oils

nism). While this ICP method detects nearly all particles less

and Determination of Selected Elements in Base Oils by

than several micrometers, the response of larger particles

Inductively Coupled Plasma Atomic Emission Spectrom-

decreases with increasing particle size because larger particles

etry (ICP-AES)

are less likely to make it through the nebulizer and into the

sample excitation zone.

3. Terminology

1.4 This test method includes an option for filtering the oil

3.1 Definitions for general terms may be found in Termi-

sample for those users who wish to separately determine

nology D2864.

dissolved metals and particulate metals (and hence, total

3.2 Definitions of Terms Specific to This Standard:

metals).

3.2.1 Babington-type nebulizer—a device that generates an

1.5 Elementspresentatconcentrationsabovetheupperlimit

aerosol by flowing a liquid over a surface that contains an

of the calibration curves can be determined with additional,

orifice from which gas flows at a high velocity.

appropriate dilutions and with no degradation of precision.

3.2.2 inductively-coupled plasma (ICP)—a high-

1.6 The values stated in SI (metric) units are to be regarded

temperature discharge generated by flowing an ionizable gas

as the standard. The inch-pound units given in parentheses are

through a magnetic field induced by a load coil that surrounds

for information only.

the tubes carrying the gas.

1.7 This standard does not purport to address all of the

3.2.3 linear response range—the elemental concentration

safety concerns, if any, associated with its use. It is the

range over which the calibration curve is a straight line, within

the precision of the test method.

This test method is under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mitteeD27.03 on Analytical Tests. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2005. Published June 2005. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7151-05. the ASTM website.

Eisentraut, K. J., Newman, R. W., Saba, C. S., Kauffman, R. E., and Rhine, W. Withdrawn. The last approved version of this historical standard is referenced

E., Analytical Chemistry, Vol 56, 1984. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7151 − 05

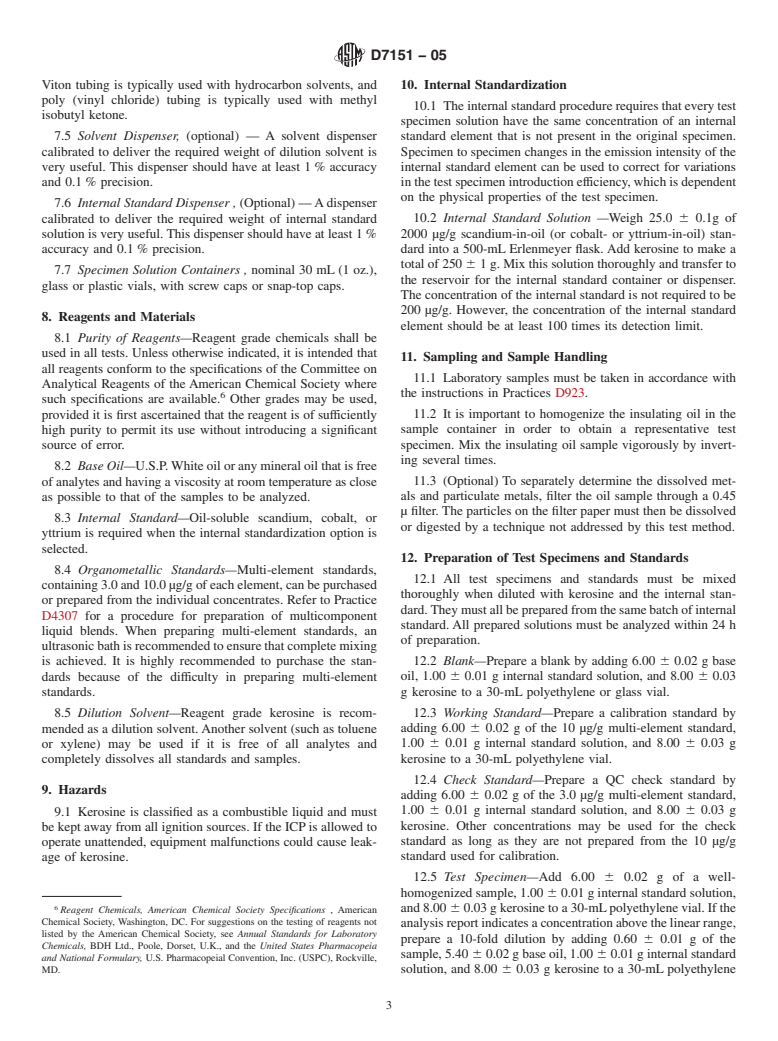

A

TABLE 1 Elements Determined and Suggested Wavelengths

corrections, all concentrations must be within the previously

Element Wavelength, nm

established linear response range of each element listed in

Aluminum 308.22, 396.15, 309.27

Table 1.

Cadmium 226.50. 214.44

6.1.1 Spectral interferences can usually be avoided by

Cobalt 228.62 231.16

judicious choice of analytical wavelengths. When spectral

Copper 324.75

Iron 259.94, 238.20

interferences cannot be avoided, the necessary corrections

Lead 220.35

should be made using the computer software supplied by the

Nickel 231.60, 227.02, 221.65

ICP manufacturer or the empirical method given in Test

Scandium 361.38

Silicon 288.16, 251.61

Method C1109 or by Boumans.

Silver 328.07

6.1.2 Interference correction factors can be negative if

Sodium 589.59

off-peak background correction is employed for an element.A

Tin 189.99, 242.95

Tungsten 239.71

negative correction factor can result when an interfering line is

Yttrium 371.03

encountered at the background correction wavelength rather

Zinc 206.20, 202.55, 213.86, 334.58, 481.05

than at the peak wavelength.

A

These wavelengths are only suggested and do not represent all possible

choices.

6.2 Viscosity Effects—Differences in the viscosities of the

test specimen solutions and standard solutions can cause

differences in the uptake rates.These differences can adversely

affect the accuracy of the analysis. The effects can be reduced

3.2.4 profiling—a technique that determines the wavelength

for which the signal intensity measured for a particular analyte by using a peristaltic pump to deliver solutions to the nebulizer

or by the use of internal standardization, or both.

is a maximum.

3.2.5 wear metal—an element introduced into the oil by

6.3 Particulates—Theuseofaninternalstandardwillreveal

wear of oil-wetted parts.

when particulates cause flow problems. Use of a Babington-

type high-solids nebulizer helps to minimize plugging of the

3.2.6 dissolved metal—a metallic element in the oil which

nebulizer.Also, the specimen introduction system can limit the

will pass a 0.45 µ filter.

transport of particulates, and the plasma can incompletely

4. Summary of Test Method

atomize larger particulates, thereby causing low results.

4.1 A weighed portion of a thoroughly homogenized insu-

6.4 Solvent Moisture—Excessive moisture (>30 mg/kg) in

lating oil is diluted 2.5:1 by weight with kerosine or other

the kerosine used for dilution can cause poor recovery of some

suitable solvent. Standards are prepared in the same manner.

elements. This can be minimized by checking each lot of

Aninternalstandardisaddedtothesolutionstocompensatefor

kerosineformoisturecontentusingTestMethodD1744andby

variations in test specimen introduction efficiency. The solu-

analyzing all diluted standards and test specimens within 24 h

tions are introduced to the ICP instrument by a peristaltic

of preparation.

pump. If free aspiration is used, an internal standard must be

used. By comparing emission intensities of elements in the test 7. Apparatus

specimen with emission intensities measured with the stan-

7.1 Balance, top loading, with automatic tare, capable of

dards, the concentrations of elements in the test specimen are

weighing to 0.001g, capacity of at least 150 g. A balance with

calculated.

a capacity of at least 250 g is required if preparing the Internal

Standard according to 10.2.

5. Significance and Use

7.2 Inductively Coupled Plasma Atomic Emission

5.1 This test method covers the rapid determination of 12

Spectrometer—Either a sequential or simultaneous spectrom-

elements in insulating oils, and it provides rapid screening of

eter is suitable, if equipped with a quartz ICP torch and RF

used oils for indications of wear. Test times approximate

generator to form and maintain the plasma. Suggested wave-

several minutes per test specimen, and detectability is in the

lengths for the determination of the elements in insulating oil

10-100 µg/kg range.

are given in Table 1.

5.2 This test method can be used to monitor equipment

7.3 Nebulizer—Use the nebulizer recommended by the ICP

condition and help to define when corrective action is needed.

manufacturer.ABabington-type high-solids nebulizer may be

It can also be used to detect contamination such as from

useful if samples contain high solids. This type of nebulizer

silicone fluids (via Silicon) or from dirt (via Silicon and

reduces the possibility of clogging and minimizes aerosol

Aluminum).

particle effects.

5.3 Thistestmethodcanbeusedtoindicatetheefficiencyof

7.4 Peristaltic Pump—A peristaltic pump is required to

reclaiming used insulating oil.

provide a constant flow of solution. The pump tubing must be

able to withstand at least 6 h exposure to the dilution solvent.

6. Interferences

6.1 Spectral—Check all spectral interferences expected

from the elements listed in Table 1. Follow the ICP manufac-

Boumans, P. W .J. M., “Corrections for Spectral Interferences in Optical

turer’s operating guide to develop and apply correction factors

Emission Spectroscopy with Special Reference to the RF Inductively Coupled

to compensate for the interferences. To apply interference Plasma,” Spectrochimica Acta, 1976, Vol 318, pp. 147-152.

D7151 − 05

Viton tubing is typically used with hydrocarbon solvents, and 10. Internal Standardization

poly (vinyl chloride) tubing is typically used with methyl

10.1 Theinternalstandardprocedurerequiresthateverytest

isobutyl ketone.

specimen solution have the same concentration of an internal

7.5 Solvent Dispenser, (optional) — A solvent dispenser standard element that is not present in the original specimen.

calibrated to deliver the required weight of dilution solvent is Specimen to specimen changes in the emission intensity of the

very useful. This dispenser should have at least 1 % accuracy internal standard element can be used to correct for variations

inthetestspecimenintroductionefficiency,whichisdependent

and 0.1 % precision.

on the physical properties of the test specimen.

7.6 Internal Standard Dispenser , (Optional) —Adispenser

calibrated to deliver the required weight of internal standard 10.2 Internal Standard Solution —Weigh 25.0 6 0.1g of

solution is very useful. This dispenser should have at least 1 % 2000 µg/g scandium-in-oil (or cobalt- or yttrium-in-oil) stan-

accuracy and 0.1 % precision. dard into a 500-mL Erlenmeyer flask. Add kerosine to make a

total of 250 6 1 g. Mix this solution thoroughly and transfer to

7.7 Specimen Solution Containers , nominal 30 mL (1 oz.),

the reservoir for the internal standard container or dispenser.

glass or plastic vials, with screw caps or snap-top caps.

The concentration of the internal standard is not required to be

200 µg/g. However, the concentration of the internal standard

8. Reagents and Materials

element should be at least 100 times its detection limit.

8.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

11. Sampling and Sample Handling

all reagents conform to the specifications of the Committee on

11.1 Laboratory samples must be taken in accordance with

Analytical Reagents of the American Chemical Society where

6 the instructions in Practices D923.

such specifications are available. Other grades may be used,

11.2 It is important to homogenize the insulating oil in the

provided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without introducing a significant sample container in order to obtain a representative test

specimen. Mix the insulating oil sample vigorously by invert-

source of error.

ing several times.

8.2 Base Oil—U.S.P.Whiteoiloranymineraloilthatisfree

of analytes and having a viscosity at room temperature as close 11.3 (Optional) To separately determine the dissolved met-

als and particulate metals, filter the oil sample through a 0.45

as possible to that of the samples to be analyzed.

µ filter. The particles on the filter paper must then be dissolved

8.3 Internal Standard—Oil-soluble scandium, cobalt, or

or digested by a technique not addressed by this test method.

yttrium is required when the internal standardization option is

selected.

12. Preparation of Test Specimens and Standards

8.4 Organometallic Standards—Multi-element standards,

12.1 All test specimens and standards must be mixed

containing3.0and10.0µg/gofeachelement,canbepurchased

thoroughly when diluted with kerosine and the internal stan-

or prepared from the individual concentrates. Refer to Practice

dard.Theymustallbepreparedfromthesamebatchofinternal

D4307 for a procedure for preparation of multicomponent

standard. All prepared solutions must be analyzed within 24 h

liquid blends. When preparing multi-element standards, an

of preparation.

ultrasonicbathisrecommendedtoensurethatcompletemixing

is achieved. It is highly recommended to purchase the stan- 12.2 Blank—Prepare a blank by adding 6.00 6 0.02 g base

oil, 1.00 6 0.01 g internal standard solution, and 8.00 6 0.03

dards because of the difficulty in preparing multi-element

standards. g kerosine to a 30-mL polyethylene or glass vial.

8.5 Dilution Solvent—Reagent grade kerosine is recom- 12.3 Working Standard—Prepare a calibration standard by

adding 6.00 6 0.02 g of the 10 µg/g multi-element standard,

mended as a dilution solvent.Another solvent (such as toluene

or xylene) may be used if it is free of all analytes and 1.00 6 0.01 g internal standard solution, and 8.00 6 0.03 g

completely dissolves all standards and samples. kerosine to a 30-mL polyethylene vial.

12.4 Check Standard—Prepare a QC check standard by

9. Hazards

adding 6.00 6 0.02 g of the 3.0 µg/g multi-element standard,

1.00 6 0.01 g internal standard solution, and 8.00 6 0.03 g

9.1 Kerosine is classified as a combustible liquid and must

kerosine. Other concentrations may be used for the check

be kept away from all ignition sources. If the ICPis allowed to

standard as long as they are not prepared from the 10 µg/g

operate unattended, equipment malfunctions could cause leak-

standard used for calibration.

age of kerosine.

12.5 Test Spe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.