ASTM D7611/D7611M-19

(Practice)Standard Practice for Coding Plastic Manufactured Articles for Resin Identification

Standard Practice for Coding Plastic Manufactured Articles for Resin Identification

SIGNIFICANCE AND USE

4.1 Resin Identification Codes are used solely to identify the plastic resin used in a manufactured article. The intended manufactured articles include, but are not limited to, packaging.

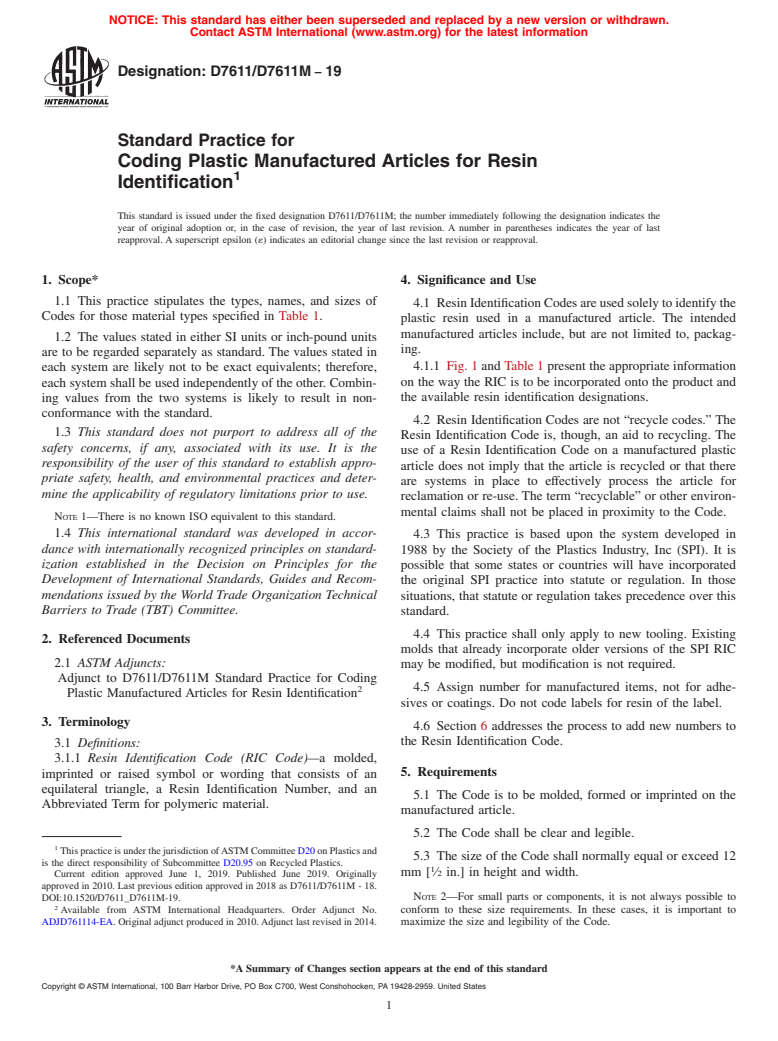

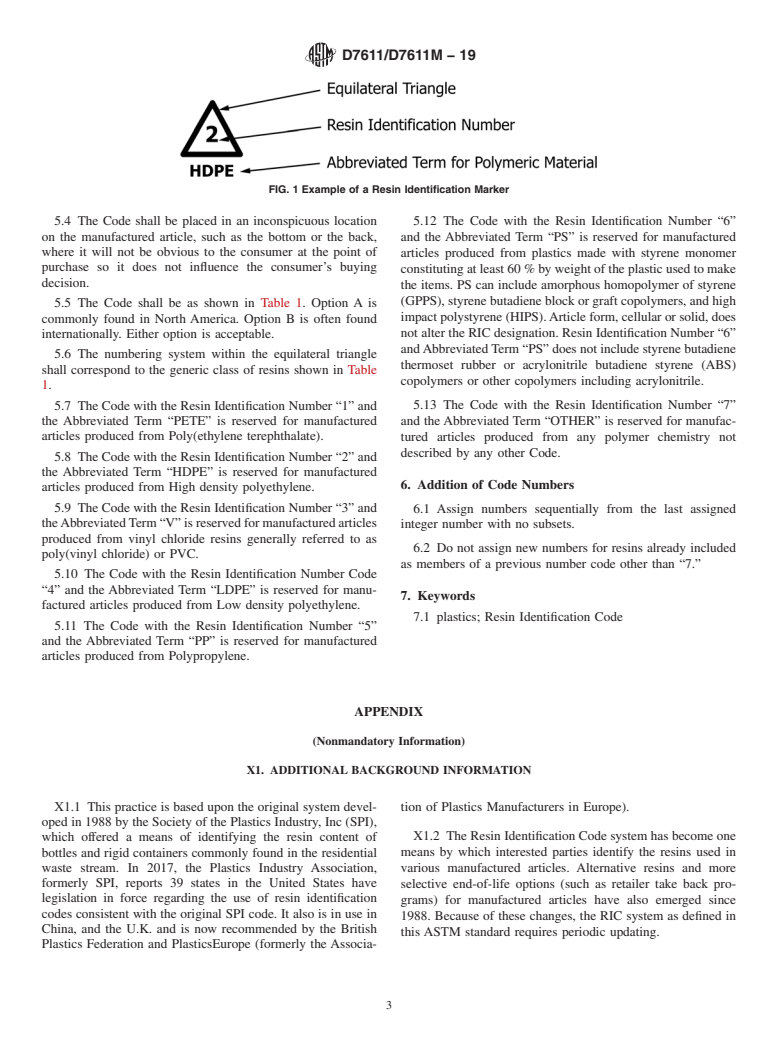

4.1.1 Fig. 1 and Table 1 present the appropriate information on the way the RIC is to be incorporated onto the product and the available resin identification designations.

FIG. 1 Example of a Resin Identification Marker

4.2 Resin Identification Codes are not “recycle codes.” The Resin Identification Code is, though, an aid to recycling. The use of a Resin Identification Code on a manufactured plastic article does not imply that the article is recycled or that there are systems in place to effectively process the article for reclamation or re-use. The term “recyclable” or other environmental claims shall not be placed in proximity to the Code.

4.3 This practice is based upon the system developed in 1988 by the Society of the Plastics Industry, Inc (SPI). It is possible that some states or countries will have incorporated the original SPI practice into statute or regulation. In those situations, that statute or regulation takes precedence over this standard.

4.4 This practice shall only apply to new tooling. Existing molds that already incorporate older versions of the SPI RIC may be modified, but modification is not required.

4.5 Assign number for manufactured items, not for adhesives or coatings. Do not code labels for resin of the label.

4.6 Section 6 addresses the process to add new numbers to the Resin Identification Code.

SCOPE

1.1 This practice stipulates the types, names, and sizes of Codes for those material types specified in Table 1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are likely not to be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems is likely to result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7611/D7611M −19

Standard Practice for

Coding Plastic Manufactured Articles for Resin

1

Identification

This standard is issued under the fixed designation D7611/D7611M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Significance and Use

1.1 This practice stipulates the types, names, and sizes of

4.1 ResinIdentificationCodesareusedsolelytoidentifythe

Codes for those material types specified in Table 1.

plastic resin used in a manufactured article. The intended

manufactured articles include, but are not limited to, packag-

1.2 The values stated in either SI units or inch-pound units

ing.

are to be regarded separately as standard. The values stated in

each system are likely not to be exact equivalents; therefore, 4.1.1 Fig. 1 and Table 1 present the appropriate information

on the way the RIC is to be incorporated onto the product and

each system shall be used independently of the other. Combin-

ing values from the two systems is likely to result in non- the available resin identification designations.

conformance with the standard.

4.2 Resin Identification Codes are not “recycle codes.” The

1.3 This standard does not purport to address all of the

Resin Identification Code is, though, an aid to recycling. The

safety concerns, if any, associated with its use. It is the

use of a Resin Identification Code on a manufactured plastic

responsibility of the user of this standard to establish appro-

article does not imply that the article is recycled or that there

priate safety, health, and environmental practices and deter-

are systems in place to effectively process the article for

mine the applicability of regulatory limitations prior to use.

reclamation or re-use. The term “recyclable” or other environ-

mental claims shall not be placed in proximity to the Code.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accor-

4.3 This practice is based upon the system developed in

dance with internationally recognized principles on standard- 1988 by the Society of the Plastics Industry, Inc (SPI). It is

ization established in the Decision on Principles for the

possible that some states or countries will have incorporated

Development of International Standards, Guides and Recom- the original SPI practice into statute or regulation. In those

mendations issued by the World Trade Organization Technical

situations, that statute or regulation takes precedence over this

Barriers to Trade (TBT) Committee.

standard.

4.4 This practice shall only apply to new tooling. Existing

2. Referenced Documents

molds that already incorporate older versions of the SPI RIC

2.1 ASTM Adjuncts:

may be modified, but modification is not required.

Adjunct to D7611/D7611M Standard Practice for Coding

2 4.5 Assign number for manufactured items, not for adhe-

Plastic Manufactured Articles for Resin Identification

sives or coatings. Do not code labels for resin of the label.

3. Terminology

4.6 Section 6 addresses the process to add new numbers to

the Resin Identification Code.

3.1 Definitions:

3.1.1 Resin Identification Code (RIC Code)—a molded,

5. Requirements

imprinted or raised symbol or wording that consists of an

equilateral triangle, a Resin Identification Number, and an

5.1 The Code is to be molded, formed or imprinted on the

Abbreviated Term for polymeric material.

manufactured article.

5.2 The Code shall be clear and legible.

1

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and

5.3 The size of the Code shall normally equal or exceed 12

is the direct responsibility of Subcommittee D20.95 on Recycled Plastics.

1

mm [ ⁄2 in.] in height and width.

Current edition approved June 1, 2019. Published June 2019. Originally

approved in 2010. Last previous edition approved in 2018 as D7611/D7611M - 18.

NOTE 2—For small parts or components, it is not always possible to

DOI:10.1520/D7611_D7611M-19.

2

Available from ASTM International Headquarters. Order Adjunct No. conform to these size requirements. In these cases, it is important to

ADJD761114-EA. Original adjunct produced in 2010.Adjunct last revised in 2014. maximize the size and legibility of the Code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7611/D7611M−19

TABLE 1 Resin Identification Codes

2

---------------------- Page: 2 ----------------------

D7611/D7611M−19

FIG. 1Example of a Resin Identification Mark

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7611/D7611M − 18 D7611/D7611M − 19

Standard Practice for

Coding Plastic Manufactured Articles for Resin

1

Identification

This standard is issued under the fixed designation D7611/D7611M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice stipulates the types, names, and sizes of Codes for those material types specified in Table 1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are likely not to be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems is likely to result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Adjuncts:

2

Adjunct to D7611/D7611M Standard Practice for Coding Plastic Manufactured Articles for Resin Identification

3. Terminology

3.1 Definitions:

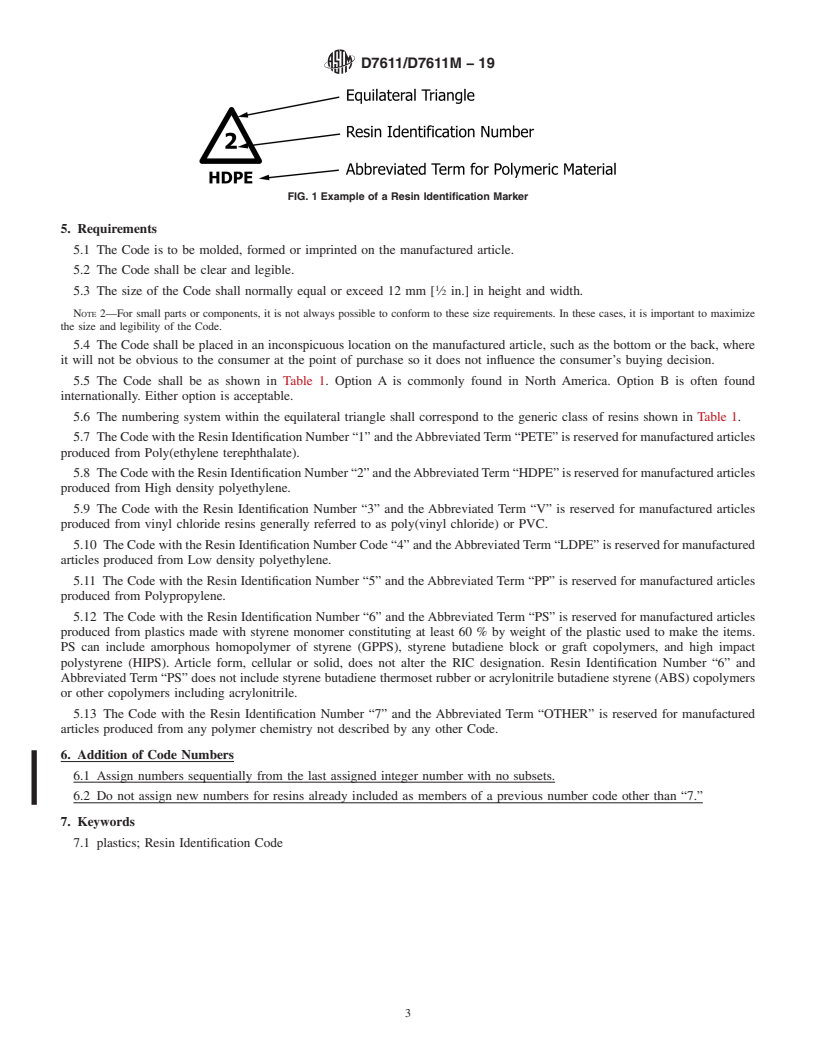

3.1.1 Resin Identification Code (RIC Code)—a molded, imprinted or raised symbol or wording that consists of an equilateral

triangle, a Resin Identification Number, and an Abbreviated Term for polymeric material.

4. Significance and Use

4.1 Resin Identification Codes are used solely to identify the plastic resin used in a manufactured article. The intended

manufactured articles include, but are not limited to, packaging.

4.1.1 Fig. 1 and Table 1 present the appropriate information on the way the RIC is to be incorporated onto the product and the

available resin identification designations.

4.2 Resin Identification Codes are not “recycle codes.” The Resin Identification Code is, though, an aid to recycling. The use

of a Resin Identification Code on a manufactured plastic article does not imply that the article is recycled or that there are systems

in place to effectively process the article for reclamation or re-use. The term “recyclable” or other environmental claims shall not

be placed in proximity to the Code.

4.3 This practice is based upon the system developed in 1988 by the Society of the Plastics Industry, Inc (SPI). It is possible

that some states or countries will have incorporated the original SPI practice into statute or regulation. In those situations, that

statute or regulation takes precedence over this standard.

4.4 This practice shall only apply to new tooling. Existing molds that already incorporate older versions of the SPI RIC may

be modified, but modification is not required.

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.95 on Recycled Plastics.

Current edition approved Nov. 15, 2018June 1, 2019. Published November 2018June 2019. Originally approved in 2010. Last previous edition approved in 20132018 as

ɛ1

D7611/D7611M - 1318. . DOI:10.1520/D7611_D7611M-18. DOI:10.1520/D7611_D7611M-19.

2

Available from ASTM International Headquarters. Order Adjunct No. ADJD761114-EA. Original adjunct produced in 2010. Adjunct last revised in 2014.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7611/D7611M − 19

TABLE 1 Resin Identification Codes

4.5 Assign number for manufactured items, not for adhesives or coatings. Do not code labels for resin of the label.

4.6 Section 6 addresses the process to add new numbers to the Resin Identification Code.

2

---------------------- Page: 2 ----------------------

D7611/D7611M − 19

FIG. 1 Example of a Resin Identification Marker

5. Requirements

5.1 The Code is to be molded,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.