ASTM A249/A249M-04

(Specification)Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

SCOPE

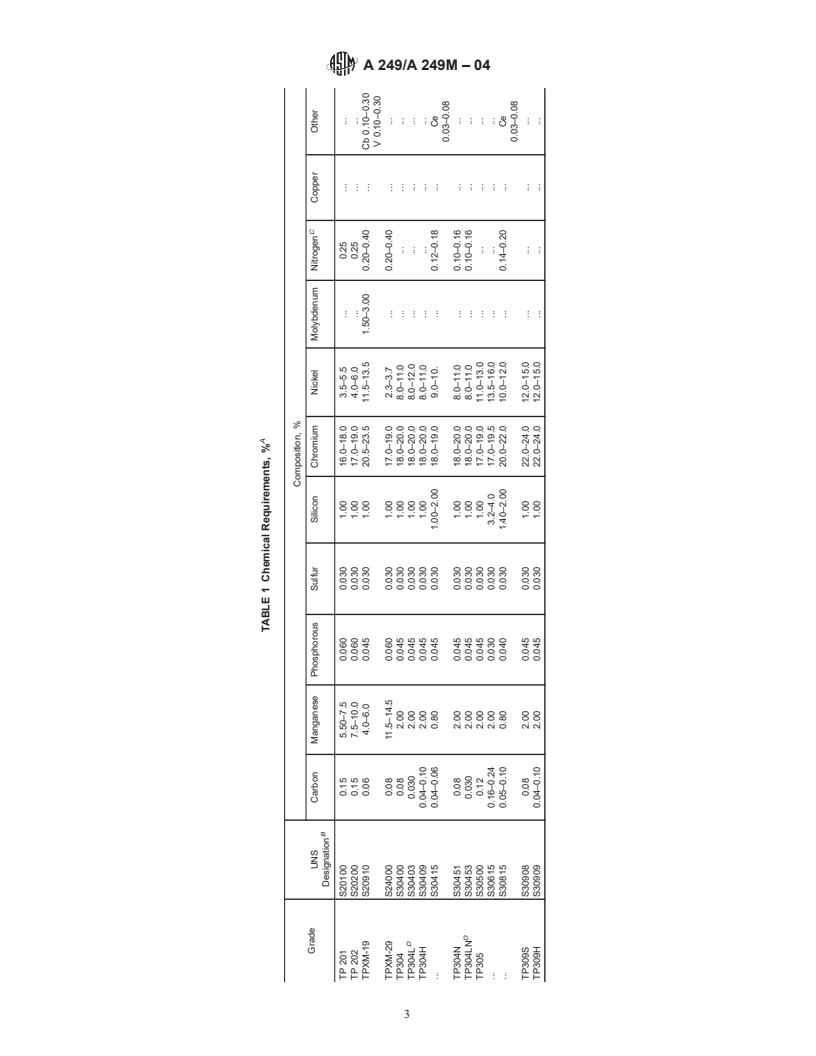

1.1 This specification covers nominal-wall-thickness welded tubes and heavily cold worked welded tubes made from the austenitic steels listed in Table 1, with various grades intended for such use as boiler, superheater, heat exchanger, or condenser tubes.

1.2 Grades TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP316H, TP321H, TP347H, and TP348H are modifications of Grades TP304, TP309S, TP309Cb, TP310S, TP310Cb, TP316, TP321, TP347, and TP348, and are intended for high-temperature service such as for superheaters and reheaters.

1.3 The tubing sizes and thicknesses usually furnished to this specification are 1/8 in. [3.2 mm] in inside diameter to 12 in. [304.8 mm] in outside diameter and 0.015 to 0.320 in. [0.4 to 8.1 mm], inclusive, in wall thickness. Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

1.4 Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] in inside diameter or 0.015 in. [0.4 mm] in thickness.

1.5 Optional supplementary requirements are provided and, when one or more of these are desired, each shall be so stated in the order.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

1.7 The following safety hazards caveat pertains only to the test method described in the Supplementary Requirements of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific warning statement is given in Supplementary Requirement S7, Note S7.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Used in USDOE-NE Standards

Designation: A 249/A 249M – 04

Standard Specification for

Welded Austenitic Steel Boiler, Superheater, Heat-

1

Exchanger, and Condenser Tubes

This standard is issued under the fixed designation A 249/A 249M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* cation. The inch-pound units shall apply unless the “M”

2 designation of this specification is specified in the order.

1.1 This specification covers nominal-wall-thickness

1.7 The following safety hazards caveat pertains only to the

welded tubes and heavily cold worked welded tubes made from

test method described in the Supplementary Requirements of

the austenitic steels listed in Table 1, with various grades

this specification. This standard does not purport to address all

intended for such use as boiler, superheater, heat exchanger, or

of the safety concerns, if any, associated with its use. It is the

condenser tubes.

responsibility of the user of this standard to establish appro-

1.2 Grades TP304H, TP309H, TP309HCb, TP310H,

priate safety and health practices and determine the applica-

TP310HCb, TP316H, TP321H, TP347H, and TP348H are

bility of regulatory limitations prior to use. A specific warning

modifications of Grades TP304, TP309S, TP309Cb, TP310S,

statement is given in Supplementary Requirement S7, Note

TP310Cb, TP316, TP321, TP347, and TP348, and are intended

S7.1.

for high-temperature service such as for superheaters and

reheaters.

2. Referenced Documents

1.3 The tubing sizes and thicknesses usually furnished to

3

1 2.1 ASTM Standards:

this specification are ⁄8 in. [3.2 mm] in inside diameter to 12 in.

A 262 Practices for Detecting Susceptibility to Intergranu-

[304.8 mm] in outside diameter and 0.015 to 0.320 in. [0.4 to

lar Attack in Austenitic Stainless Steels

8.1 mm], inclusive, in wall thickness. Tubing having other

A 480/A 480M Specification for General Requirements for

dimensions may be furnished, provided such tubes comply

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

with all other requirements of this specification.

Sheet, and Strip

1.4 Mechanical property requirements do not apply to

1 A 1016/A 1016M Specification for General Requirements

tubing smaller than ⁄8 in. [3.2 mm] in inside diameter or 0.015

for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain-

in. [0.4 mm] in thickness.

less Steel Tubes

1.5 Optional supplementary requirements are provided and,

E 112 Test Methods for Determining Average Grain Size

when one or more of these are desired, each shall be so stated

E 213 Practice for Ultrasonic Examination of Metal Pipe

in the order.

and Tubing

1.6 The values stated in either inch-pound units or SI units

E 273 Practice for Ultrasonic Examination of the Weld

are to be regarded separately as standard. Within the text, the

Zone of Welded Pipe and Tubing

SI units are shown in brackets. The values stated in each

E 527 Practice for Numbering Metals and Alloys (UNS)

system are not exact equivalents; therefore, each system must

2.2 ASME Boiler and Pressure Vessel Code:

be used independently of the other. Combining values from the

4

Section VIII

two systems may result in nonconformance with the specifi-

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

3

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A01.10 on Stainless and Alloy Steel Tubular Products. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2004. Published June 2004. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1941. Last previous edition approved in 2003 as A 249/A 249M – 03a. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Available from American Society of Mechanical Engineers (ASME), ASME

cation SA-249 in Section II of that Code. International Headquarters, Three Park Ave., New York, NY 10016-5990.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 249/A 249M – 04

3. Ordering Information 3.1.4 Size (outside diameter and nominal wall thickness),

3.1.5 Length (specific or random),

3.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for material ordered under this

3.1.6 Optional requirements (13.6),

speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.