ASTM D1113-90a(2008)

(Test Method)Standard Test Method for Vegetable Matter and Other Alkali-Insoluble Impurities in Scoured Wool

Standard Test Method for Vegetable Matter and Other Alkali-Insoluble Impurities in Scoured Wool

SIGNIFICANCE AND USE

Test Method D 1113 is considered satisfactory for acceptance testing of commercial shipments, and the procedure has been used extensively in the trade for this purpose, particularly in connection with the determination of clean wool fiber present by Test Method D 584. The procedure in Test Method D 1113 is used by the U.S. Customs Service for the determination of the vegetable matter in importations of raw wool on which the allowance for loss of wool during commercial cleaning is based in part.

In case of a dispute arising from differences in reported test results when using Test Method D 1113 for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Students t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

SCOPE

1.1 This test method covers the determination of the content of oven-dried, ash-free, alcohol extractive-free vegetable matter and other alkali-insoluble impurities present in scoured wool. It is also applicable to “related fibers” such as the hair from the goat, camel, alpaca, and other animals.

Note 1—The determination of clean wool fiber present on a laboratory scale is covered in Test Method D 584, the determination of clean wool fiber present on a commercial scale is covered in Test Method D 1334, and the calculation of commercial weight and yield of various commercial compositions (formerly covered in Appendix to Test Method D 584) is covered in Practice D 2720.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety hazard statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1113 − 90a (Reapproved2008)

Standard Test Method for

Vegetable Matter and Other Alkali-Insoluble Impurities in

Scoured Wool

This standard is issued under the fixed designation D1113; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 other alkali-insoluble impurities, n— in scoured wool,

the oven-dried, ash-free, alcohol-extractives-free, alkali-

1.1 This test method covers the determination of the content

insoluble substances other than vegetable matter base, such as

of oven-dried, ash-free, alcohol extractive-free vegetable mat-

skin, cotton or other fibers, paper string, tag (dung) pieces, and

ter and other alkali-insoluble impurities present in scoured

paint pieces, etc.

wool. It is also applicable to “related fibers” such as the hair

3.1.2 oven-dried, adj—the condition of a material that has

from the goat, camel, alpaca, and other animals.

been heated under prescribed conditions of temperature and

NOTE 1—The determination of clean wool fiber present on a laboratory

humidity until there is no further significant change in its mass.

scale is covered in Test Method D584, the determination of clean wool

3.1.2.1 Discussion—An oven-dried material will retain a

fiber present on a commercial scale is covered inTest Method D1334, and

the calculation of commercial weight and yield of various commercial small amount of moisture that is dependent on the temperature

compositions (formerly covered in Appendix to Test Method D584)is

and relative humidity of the atmosphere in contact with the

covered in Practice D2720.

materialduringthedryingprocess.Anoven-driedmaterialwill

1.2 This standard does not purport to address all of the

only be moisture-free when the air supplied to the drying oven

safety concerns, if any, associated with its use. It is the

has been previously desiccated.

responsibility of the user of this standard to establish appro-

3.1.2.2 Discussion—The term “mass” in the above defini-

priate safety and health practices and determine the applica-

tionisthecorrectdesignationforwhatiscommonlydesignated

bility of regulatory limitations prior to use. For specific safety

“weight”.

hazard statements, see Section 8.

3.1.3 vegetable matter base, n— in raw wool, oven-dried

scoured burrs, seeds, twigs, leaves, and grasses, free of mineral

2. Referenced Documents

matter and alcohol-extractable matter.

2.1 ASTM Standards:

3.1.4 For the definition of wool and other textile terms used

D123 Terminology Relating to Textiles

in this method, refer to Terminology D123.

D584 Test Method for Wool Content of Raw Wool—

Laboratory Scale

4. Summary of Test Method

D1334 Test Method for Wool Content of Raw Wool—

4.1 The wool, or other animal fiber, is dissolved in a boiling

Commercial Scale

3% sodium hydroxide solution or a hot 10% sodium hydroxide

D2720 Practice for Calculation of Commercial Weight and

solution under specified controlled conditions. The weights of

Yield of Scoured Wool, Top, and Noil for Various Com-

theash-free,oven-driedcomponentsoftheundissolvedresidue

mercial Compositions

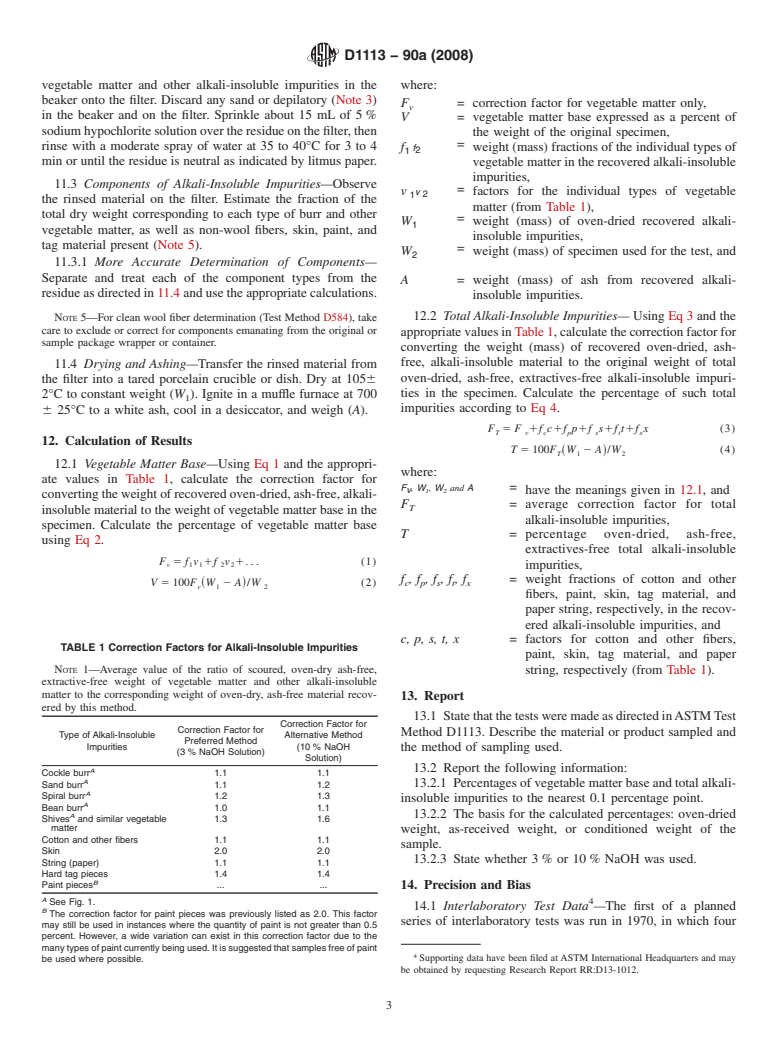

are converted by means of tabulated factors to the correspond-

3. Terminology ing weights of vegetable matter base and other alkali-insoluble

impurities.

3.1 Definitions:

5. Significance and Use

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

5.1 Test Method D1113 is considered satisfactory for accep-

and is the direct responsibility of Subcommittee D13.13 on Wool and Felt.

tance testing of commercial shipments, and the procedure has

Current edition approved Aug. 1, 2008. Published October 2008. Originally

been used extensively in the trade for this purpose, particularly

approved in 1950. Last previous edition approved in 2001 as D1113–90a (2001).

DOI: 10.1520/D1113-90AR08.

in connection with the determination of clean wool fiber

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

present by Test Method D584. The procedure in Test Method

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D1113 is used by the U.S. Customs Service for the determi-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. nation of the vegetable matter in importations of raw wool on

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1113 − 90a (2008)

shipping container, and between test specimens within a laboratory

which the allowance for loss of wool during commercial

sampling unit to produce a sampling plan with a meaningful producer’s

cleaning is based in part.

risk, consumer’s risk, acceptable quality level, and limiting quality level.

5.1.1 In case of a dispute arising from differences in

9.2 Laboratory Sample—As a laboratory sample for accep-

reported test results when using Test Method D1113 for

tance testing, proceed as follows:

acceptance testing of commercial shipments, the purchaser and

9.2.1 For tests to be made in connection with Test Methods

the supplier should conduct comparative tests to determine if

D584 and D1334, prepare a portion of scoured and dried wool

there is a statistical bias between their laboratories. Competent

from each lot sampling unit of the lot sample described in 9.1.

statistical assistance is recommended for the investigation of

Makesurethateachportionisapproximately100g,whichwill

bias.As a minimum, the two parties should take a group of test

becomealaboratorysamplingunit.Notethattheseportionsare

specimens that are as homogeneous as possible and that are

to be obtained from random locations in the wool mass. If the

from a lot of material of the type in question. The test

scoured wool is judged to contain over 5 % of vegetable matter

specimens should then be randomly assigned in equal numbers

and sufficient scoured wool is available, prepare another

to each laboratory for testing.The average results from the two

replicate, that is, a second laboratory sample unit.

laboratories should be compared using Students t-test for

9.2.2 For tests on samples of scoured wool not obtained in

unpaireddataandanacceptableprobabilitylevelchosenbythe

connection with Test Methods D584 and D1334 take replicate

two parties before the testing is begun. If a bias is found, either

sample units as directed in 9.2.1.

its cause must be found and corrected or the purchaser and the

supplier must agree to interpret future test results in light of the

9.3 Test Specimens—As test specimens, prepare two test

known bias.

specimens from each laboratory sampling unit by combining

ten or more pinches of fiber into a bundle having a mass of 40

6. Apparatus

61g.

6.1 Filter, 40-mesh sieve (U. S. Sieve Series, opening

10. Conditioning

0.0165 in. (0.42 mm)) or metal screen, or cheese cloth having

10.1 Dry specimens taken as directed in 9.1 under the

comparable openings.

conditions for oven drying prescribed in Test Method D584.

6.2 Oven—Aforced-draft oven designed to supply clean air

10.2 Weigh specimens taken as directed in 9.2 in the

at a desired temperature with a tolerance of 62°C.

condition as received, in the oven-dry condition, or after

6.3 Muffle Furnace, thermostatically controlled in the range

exposure in the standard atmosphere for testing textiles,

of 700 6 25°C.

dependinguponthedirectionsorrequirementsoftheinterested

6.4 Beakers—Heatresistantglassorstainlesssteel,of2-litre

parties.

capacity.

10.3 Weigh specimens (10.1 or 10.2) to the nearest 0.01 g.

(W ).

7. Reagents and Materials

11. Procedure

7.1 Sodium Hydroxide Solution (NaOH), 3 % by weight.

11.1 Preferred Method—In a 2-L heat-resistant glass or

7.2 Sodium Hydroxide Solution, 10 % by weight.

stainlesssteelbeaker,bring1Lof3 %NaOHsolutiontoaboil.

7.3 Sodium Hypochlorite Solution (NaOCl), 5 % by weight.

With the solution at a boil, carefully add the entire weighed

specimen. Quickly immerse the wool in the NaOH solution

8. Hazards

with the aid of a stirring rod, and adjust the heat to resume

8.1 Sodiumhydroxideisextremelycorrosive,andcaremust boilingofthesolution.Boilthesolutiongentlywithcontinuous

be exercised to avoid contact with the eyes, skin, or clothing. stirring for 90 6 2 s. Remove the beaker from the heat and add

500 ml of tap water, stir, then allow to settle.

8.2 Operators should wear eye protection while handling

caustic solutions.

NOTE 3—The preferred method uses 3 % sodium hydroxide solution, in

which most wools are soluble when treated as directed. However, certain

coarse, dry carpet wools do not dissolve completely in the 3 % solution.

9. Sampling

For such wools the alternative method (11.1.1), in which 10 % sodium

9.1 LotSample—Asalotsampleforacceptancetesting,take hydroxide solution is used, is necessary.

NOTE 4—Keep depilatory in pulled wool specimens to a minimum by

at random the number of shipping containers directed in an

treating the sample as directed in 10.3 of Test Method D584.

applicable material specification or other agreement between

11.1.1 Alternative Method (Note 2)—In a 2-L heat-resistant

the purchaser and the supplier. Consider shipping containers to

glass or stainless steel beaker, bring 600 cm (mL) of 10 %

be the lot sampling unit.

NaOH solution to a boil. Remove the beaker from the heat,

NOTE 2—An adequate specification or other agreement between the

place on a dry wooden or asbestos mat, and immediatel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.