ASTM F2418-05

(Specification)Standard Specification for Polypropylene (PP) Corrugated Wall Stormwater Collection Chambers

Standard Specification for Polypropylene (PP) Corrugated Wall Stormwater Collection Chambers

ABSTRACT

This specification covers requirements, test methods, materials, and marking for polypropylene (PP), open bottom, buried chambers of corrugated wall construction used for collection, detention, and retention of stormwater runoff. Applications include commercial, residential, agricultural, and highway drainage, including installation under parking lots and roadways. Chambers are produced in arch shapes with dimensions based on chamber rise, chamber span, and wall stiffness. They are manufactured with integral feet that provide base support. They may include perforations to enhance water flow and must meet test requirements for arch stiffness, flattening, and accelerated weathering. The successful performance of the product depends upon the type and depth of bedding and backfill, and care in installation. This specification includes requirements for the manufacturer to provide chamber installation instructions to the purchaser.

SCOPE

1.1 This specification covers requirements, test methods, materials, and marking for polypropylene (PP), open bottom, buried chambers of corrugated wall construction used for collection, detention, and retention of stormwater runoff. Applications include commercial, residential, agricultural, and highway drainage, including installation under parking lots and roadways.

1.2 Chambers are produced in arch shapes with dimensions based on chamber rise, chamber span, and wall stiffness. Chambers are manufactured with integral feet that provide base support. Chambers may include perforations to enhance water flow. Chambers must meet test requirements for arch stiffness, flattening, and accelerated weathering.

1.3 Analysis and experience have shown that the successful performance of this product depends upon the type and depth of bedding and backfill, and care in installation. This specification includes requirements for the manufacturer to provide chamber installation instructions to the purchaser.

1.4 The values stated in inch-pounds are to be regarded as the standard. The SI units in parentheses are given for information only.

1.5 This standard does not purport to address water quality issues or hydraulic performance requirements associated with its use. It is the responsibility of the user to ensure that appropriate engineering analysis is performed to evaluate the water quality issues and hydraulic performance requirements for each installation.

The following safety hazards caveat pertains only to the test method portion, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 2418 – 05

Standard Specification for

Polypropylene (PP) Corrugated Wall Stormwater Collection

1

Chambers

This standard is issued under the fixed designation F 2418; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers requirements, test methods, 2.1 ASTM Standards:

materials, and marking for polypropylene (PP), open bottom, D 256 Test Methods for Determining the Izod Pendulum

buried chambers of corrugated wall construction used for Impact Resistance of Plastics

collection, detention, and retention of stormwater runoff. Ap- D 618 Practice for Conditioning Plastics for Testing

plications include commercial, residential, agricultural, and D 638 Test Method for Tensile Properties of Plastics

highwaydrainage,includinginstallationunderparkinglotsand D 790 TestMethodsforFlexuralPropertiesofUnreinforced

roadways. and Reinforced Plastics and Electrical Insulating Materials

1.2 Chambers are produced in arch shapes with dimensions D 1600 Terminology for Abbreviated Terms Relating to

based on chamber rise, chamber span, and wall stiffness. Plastics

Chambersaremanufacturedwithintegralfeetthatprovidebase D 2122 Test Method for Determining Dimensions of Ther-

support. Chambers may include perforations to enhance water moplastic Pipe and Fittings

flow. Chambers must meet test requirements for arch stiffness, D 2412 Test Method for Determination of External Loading

flattening, and accelerated weathering. Characteristics of Plastic Pipe by Parallel-Plate Loading

1.3 Analysis and experience have shown that the successful D 2990 Test Methods for Tensile, Compressive, and Flex-

performance of this product depends upon the type and depth ural Creep and Creep-Rupture of Plastics

of bedding and backfill, and care in installation. This specifi- D 4101 Specification for Propylene Plastic Injection and

cation includes requirements for the manufacturer to provide Extrusion Materials

chamber installation instructions to the purchaser. D 4329 Practice for Fluorescent UV Exposure of Plastics

1.4 The values stated in inch-pounds are to be regarded as D 6992 Test Method for Accelerated Tensile Creep and

the standard. The SI units in parentheses are given for Creep-Rupture of Geosynthetic Materials Based on Time-

information only. Temperature Superposition Using the Stepped Isothermal

1.5 This standard does not purport to address water quality Method.

issues or hydraulic performance requirements associated with F 412 Terminology Relating to Plastic Piping Systems

its use. It is the responsibility of the user to ensure that 2.2 AASHTO Specification:

appropriate engineering analysis is performed to evaluate the Section 12 Buried Structures and Tunnel Liners, 12.12

3

water quality issues and hydraulic performance requirements Thermoplastic Pipes

for each installation.

3. Terminology

1.6 The following safety hazards caveat pertains only to the

3.1 Definitions: Definitions used in this specification are in

test method portion, Section 6, of this specification: This

standard does not purport to address all of the safety concerns, accordance with the definitions in Terminology F 412, and

abbreviations are in accordance with Terminology D 1600,

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health unless otherwise indicated.

practices and determine the applicability of regulatory limita-

tions prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic the ASTM website.

3

Piping and is the direct responsibility of Subcommittee F17.65 on Land Drainage. AASHTO LRFD Bridge Design Specifications-Dual Units, Third Edition,

Current edition approved Aug. 1, 2005. Published August 2005. Originally 2004. Available from American Association of State Highway and Transportation

approved in 2004. Last previous edition approved in 2004 as F2418-04. Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

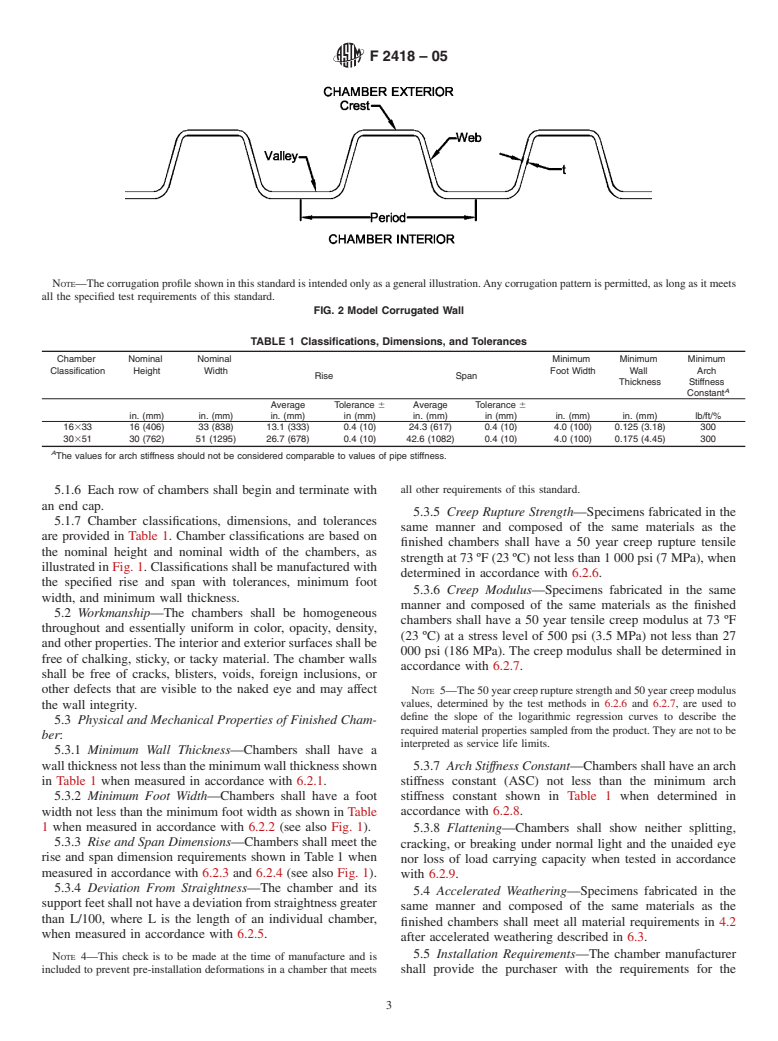

F2418–05

3.1.1 chamber—an arch-shaped structure manufactured of 3.1.14 web—the element of a corrugated wall that connects

thermoplastic wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.