ASTM D6788-02(2012)

(Specification)Standard Specification for Repositionable Pressure-Sensitive Flags

Standard Specification for Repositionable Pressure-Sensitive Flags

ABSTRACT

This specification covers repositionable pressure-sensitive flags used to mark, flag, and index documents, books, periodicals, and so forth. Flags covered here consist of a single sheet of matte film partially covered by adhesive. A non-adhesive tab or section at one end of the flag serves for easy removal from most surfaces, including paper. The backing shall consist of polyester, polypropylene, or polyethylene film, and shall have a transparent matte surface on one side that is writable by pens and pencils. Flags are available in the following types: Type 1, which are of specified width, and have a colored tab at one end; Type 2, which are of the same width as Type 1, and have a printed message on the top side of the flag; Type 3, which twice the width of Type 1, and have a white tab at one end to highlight writing; Type 4, which are half the width of Type 1, and have a colored tab at one end; and Type 5, which are half the width of Type 1, and have an arrow or a message printed on the top side of the flag. Sampled specimens shall conform to physical requirements in terms of minimum and maximum adhesion, dispension force, and thickness.

SCOPE

1.1 This specification covers repositionable pressure-sensitive flags used to mark, flag, and index documents, books, periodicals, and so forth.

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently, without combining values in any way.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 14, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6788 −02 (Reapproved 2012)

Standard Specification for

Repositionable Pressure-Sensitive Flags

This standard is issued under the fixed designation D6788; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Federal Specifications:

CID A-A-2826Tabs, Signal (Repositionable), cancelled

1.1 This specification covers repositionable pressure-

November, 19, 1999

sensitiveflagsusedtomark,flag,andindexdocuments,books, 4

PPP-T-680Federal Packaging Standard

periodicals, and so forth.

2.3 ISO Standard:

ISO 9002Quality Systems Model for Quality Assurance in

1.2 The values stated in either inch-pound or SI units are to

Production and Installation

be regarded separately as standard. The values stated in each

2.4 ANSI/ASQC Standard:

system are not exact equivalents; therefore, each system must

ANSI/ASQC Z 1.9Sampling and Tables for Inspection by

be used independently, without combining values in any way.

Variables for Percent Defective

1.3 The following safety hazards caveat pertains only to the

test methods portion, Section 14, of this specification. This

3. Terminology

standard does not purport to address all of the safety concerns,

3.1 Definitions—General terms in this specification are de-

if any, associated with its use. It is the responsibility of the user

fined in Terminology D996.

of this standard to establish appropriate safety and health

3.2 pad of flags—a vertical stack of individual flags with

practices and determine the applicability of regulatory require-

one flag positioned on top of the other.

ments prior to use.

4. Significance and Use

2. Referenced Documents

4.1 The repositionable, pressure-sensitive flags covered by

2.1 ASTM Standards:

this specification are intended for marking, flagging, and

D996Terminology of Packaging and Distribution Environ-

indexing of documents, books, periodicals, and so forth. Flags

ments

consist of a single sheet of matte film partially covered by

D3330/D3330MTestMethodforPeelAdhesionofPressure- adhesive. There is a non-adhesive tab or section at one end of

Sensitive Tape the flag for easy removal from surfaces. The flag is removable

D3652/D3652MTest Method for Thickness of Pressure- from most surfaces including paper. Flags may have a printed

message on the top side of the flag.

Sensitive Tapes

D3715/D3715MPractice for QualityAssurance of Pressure-

4.2 This specification replaces U.S. Government CIDA-A-

Sensitive Tapes

2826.

D3811/D3811MTestMethodforUnwindForceofPressure-

Sensitive Tapes 5. Classification

D3951Practice for Commercial Packaging

5.1 Type 1 flags are 1 in. wide (25 mm) and have a colored

D4332Practice for Conditioning Containers, Packages, or

tab at one end.

Packaging Components for Testing

5.2 Type 2 flags are 1 in. wide (25 mm) and have a printed

message on the top side of the flag.

This specification is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Labels. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

Current edition approved April 1, 2012. Published May 2012. Originally www.access.gpo.gov.

approved in 2002. Last previous edition approved in 2007 as D6788–02 (2007). Available from www.dia.mil. For additional information or comments write to

DOI: 10.1520/D6788-02R12. General ServicesAdministration, Federal Supply Service, FSSAquisition Manage-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ment Center, Environmental Programs and Engineering Policy Division (FCOE),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Washington, DC 20406.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6788−02 (2012)

5.3 Type3flagsare2in.wide(50mm)andhaveawhitetab 8.2 Conduct tests in an atmosphere of 50 6 2% relative

at one end to highlight writing. humidity and 23.0 6 2.0°C as described in Practice D4332.

5.4 Type4flagsare ⁄2in.wide(12mm)andhaveacolored

9. Physical Properties

tab at one end.

9.1 The flags shall comply with the physical test require-

5.5 Type 5 flags are ⁄2 in. wide (12 mm) and have an arrow

ments listed in Table 1.

or a message printed on the top side of the flag.

10. Dimensions, Mass, and Permissible Variations

6. Ordering Information

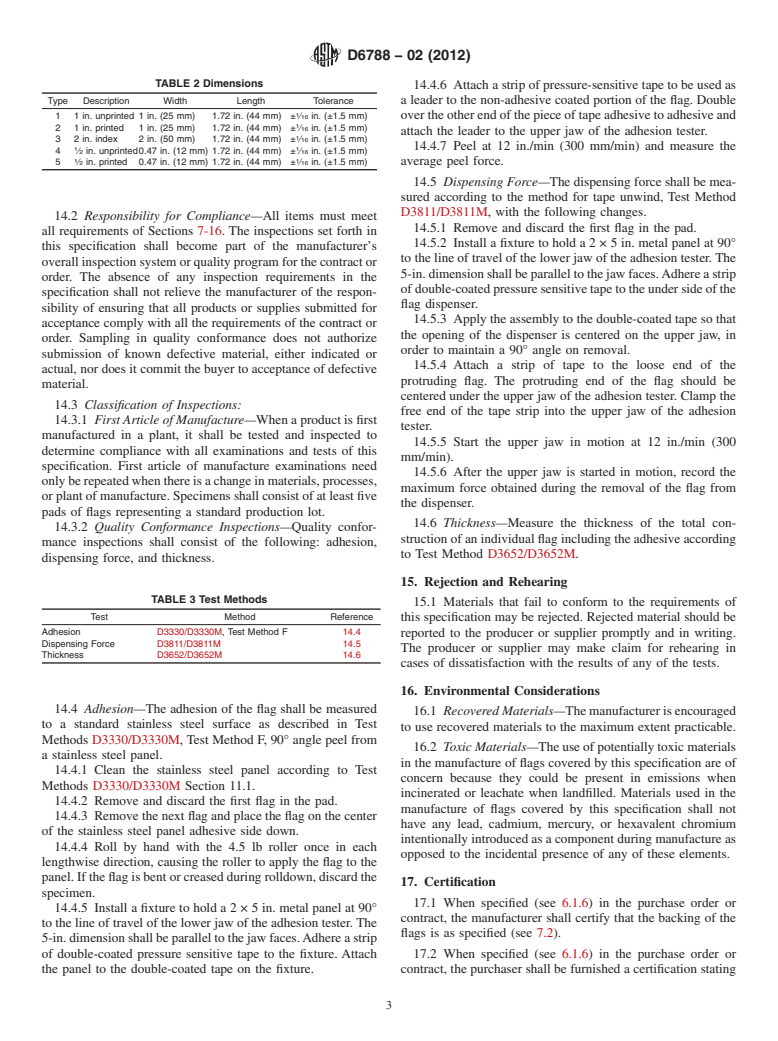

10.1 The dimensions of the flags shall be as specified in

6.1 The inquiry or order shall include the following:

Table 2.

6.1.1 ASTM designation and date of issue,

6.1.2 Type required (see Section 5),

10.2 Color Tab Width—Type 1, 3, and 4 flags have a color

6.1.3 Number of flags in each dispenser,

tab at the non-adhesive end of the flag. The length of the color

6.1.4 Color of tab on flag for unprinted flags,

tab shall be ⁄8 in. (16 mm). The tolerance on color tab length

6.1.5 Printed message, if any,

shall be 6 ⁄16 in. (61.5 mm). The colored tab shall extend the

6.1.6 When testing and inspection certification is required

full width of the flag.

(see Section 17), and

11. Workmanship

6.1.7 For government orders, conformance to federal pack-

aging standards.

11.1 Theflagsandthedispensershallbecleanandfreefrom

dirt, foreign matter, holes, tears, wrinkles, and other defects

7. Materials and Manufacture

that might affect appearance or serviceability. Flags shall be

7.1 The materials used in construction of the flags shall

uniform in color and formation. The finished product shall

conform to the requirements of this specification.

conform to the levels of quality established herein.

7.2 Backing—The film backing shall consist of polyester,

12. Sampling

polypropylene, or polyethylene film. The backing shall have

sufficient strength to resist tearing by hand. The backing shall

12.1 End Item Examination—The lot size for visual inspec-

have a transparent matte surface on one side that is writable by

tion shall be as specified in the end item inspection of 5.3 of

pens and pencils.

Practice D3715/D3715M. The sample unit shall be one pad of

7.2.1 Writing on the flags shall not exhibit feathering,

flags. The AQL shall be 2.5%.

spreading, skipping, beading, visible discontinuities or fading

12.2 End Item Testing—Lot size and sampling for end item

of ink when writing with any writing instrument including a

testing shall be as specified in end item testing of 5.4 of

metalrollerpen,felttippen,permanentmarker,ballpointpen,

Practice D3715/D3715M. The sample unit shall be one pad of

or fountain pen.

flags. The AQL shall be 4.0%.

7.2.2 Individual flags shall release easily from the pad

12.2.1 Adhesionhasadoublespecificationlimit(thereisan

without leaving any trace of adhesive on the underlying sheet.

upper and lower limit to the specification). For adhesion, use

7.3 Adhesive—The adhesive shall be pressure-sensitive, re-

Table C-3 and Example C-3 of ANSI/ASQC Z 1.9.

positionable, and water-insoluble. Each flag in the pad shall

have a coating of the adhesive on the back side of the flag. 13. Specimen Preparation and Number of Tests

7.3.1 The adhesive coating shall be applied flush to one

13.1 Specimen preparation shall be as specified in Section

horizontal edge of the flag and shall extend the entire width of

14.

the flag. The adhesive shall cover at least 60% of the surface

13.2 Number of tests per unit of product shall be four. The

areaoftheflagtoensuresecureholdingoftheflagtoasurface.

sample unit shall be one pad of flags.

7.3.2 The adhesive shall leave no visible residue on the

surfacetowhichitisappliedandremoved.Removaloftheflag

14. Test Methods

from paper shall not rip or damage the paper.

14.1 Responsibility for Inspection—Unless otherwise speci-

7.4 Pad and Dispenser—Single flags shall be stacked in a

fiedinthecontractororder,themanufacturerisresponsiblefor

pad.Thepadofflagsshallbecontainedinadispenserpackage

the performance of all inspection requirements as specified

that allo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.