ASTM C273-00e1

(Test Method)Standard Test Method for Shear Properties of Sandwich Core Materials

Standard Test Method for Shear Properties of Sandwich Core Materials

SCOPE

1.1 This test method covers the determination of shear properties of sandwich construction core materials associated with shear distortion of planes parallel to the facings. It covers the determination of shear strength parallel to the plane of the sandwich, and the shear modulus associated with strains in a plane normal to the facings. The test may be conducted on core materials bonded directly to the loading plates or the sandwich facings bonded to the plates.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation:C273–00

Standard Test Method for

Shear Properties of Sandwich Core Materials

This standard is issued under the fixed designation C 273; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1 2 2

´ NOTE—In 5.3, the value 6 000 000 lb-in. /in. was editorially corrected to 600 000 lb-in. /in. in July 2000.

1. Scope shear stress at proportional limit, at yield, or at maximum load)

and to compute an effective core shear modulus.

1.1 This test method covers the determination of shear

3.2 The test does not produce pure shear, but the specimen

properties of sandwich construction core materials associated

length is prescribed so that secondary stresses have a minimum

with shear distortion of planes parallel to the facings. It covers

effect.Approximate shear properties can also be obtained from

the determination of shear strength parallel to the plane of the

a sandwich flexure test (see Test Method C 393).

sandwich, and the shear modulus associated with strains in a

3.3 This test method provides a standard method of obtain-

plane normal to the facings.The test may be conducted on core

ing sandwich core shear data for quality control, acceptance

materials bonded directly to the loading plates or the sandwich

specification testing, sandwich design, and research and devel-

facings bonded to the plates.

opment.

1.2 The values stated in SI units are to be regarded as the

standard. The inch-pound units given may be approximate.

4. Apparatus

1.3 This standard does not purport to address all of the

4.1 Test Machine, capable of maintaining a controlled load-

safety concerns, if any, associated with its use. It is the

ing rate and indicating the load with an accuracy of 61%of

responsibility of the user of this standard to establish appro-

the indicated value. The accuracy of the test machine shall be

priate safety and health practices and determine the applica-

verified in accordance with PracticesE4.

bility of regulatory limitations prior to use.

4.2 Deflectometer, compressometer, or extensometer, ca-

2. Referenced Documents pableofmeasuringthedisplacementwithaprecisionofatleast

61%.

2.1 ASTM Standards:

4.3 Micrometer, gage, or caliper, capable of measuring

C 393 Test Method for Flexural Properties of Flat Sandwich

accurately to 0.025 mm (0.001 in.).

Constructions

C 394 Test Method for Shear Fatigue of Sandwich Core

5. Test Specimens

Materials

3 5.1 The test specimen shall have a thickness equal to the

E4 Practices for Force Verification of Testing Machines

thickness of the sandwich, a width not less than 50 mm (2 in.),

3. Significance and Use and a length not less than twelve times the thickness, except as

agreed upon by the purchaser and the seller.

3.1 The core shear properties are fundamental properties

5.2 Measure the thickness to the nearest 0.025 mm (0.001

thatareusedinthedesignofsandwichpanels.Thistestmethod

in.) and the length and width to the nearest 0.25 mm (0.01 in.).

provides information on the load-deflection behavior of sand-

Weigh the specimen to the nearest 0.1 g and calculate the

wichconstructionsorcoreswhenloadedinshearparalleltothe

specimen density.

plane of the facings. From a complete load-deflection curve, it

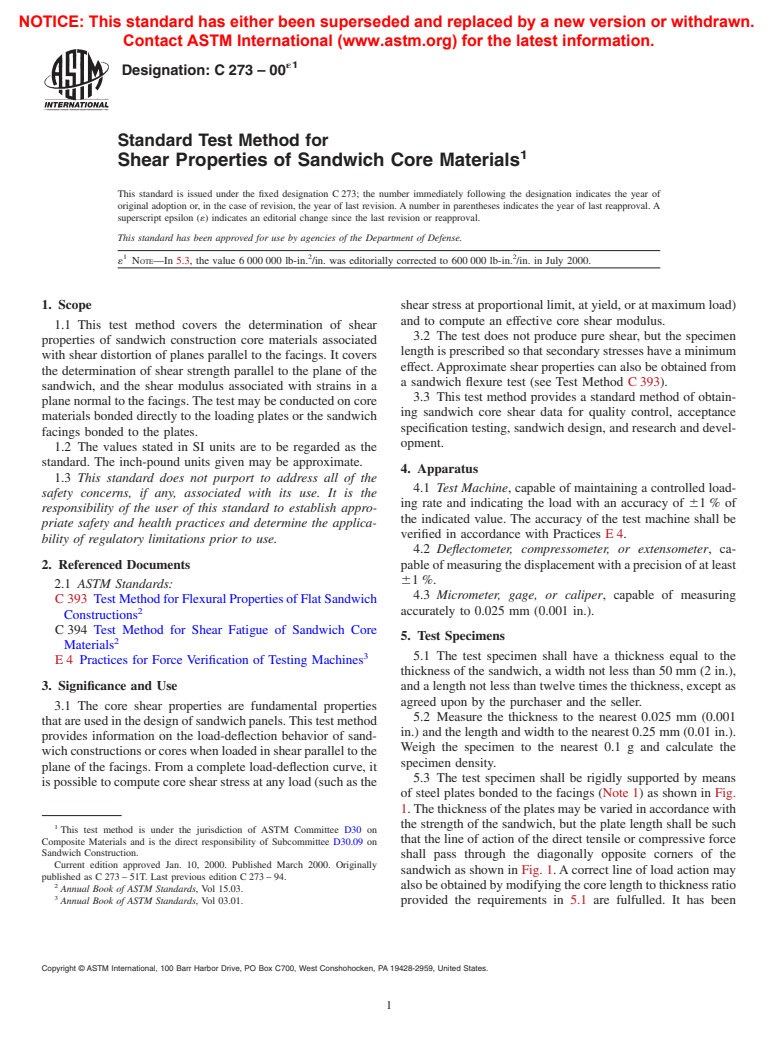

5.3 The test specimen shall be rigidly supported by means

is possible to compute core shear stress at any load (such as the

of steel plates bonded to the facings (Note 1) as shown in Fig.

1.The thickness of the plates may be varied in accordance with

the strength of the sandwich, but the plate length shall be such

This test method is under the jurisdiction of ASTM Committee D30 on

that the line of action of the direct tensile or compressive force

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

Sandwich Construction.

shall pass through the diagonally opposite corners of the

Current edition approved Jan. 10, 2000. Published March 2000. Originally

sandwich as shown in Fig. 1.Acorrect line of load action may

published as C 273 – 51T. Last previous edition C 273 – 94.

alsobeobtainedbymodifyingthecorelengthtothicknessratio

Annual Book of ASTM Standards, Vol 15.03.

Annual Book of ASTM Standards, Vol 03.01. provided the requirements in 5.1 are fulfulled. It has been

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

C273–00

NOTE 2—A suggested rate of cross-head movement is 0.50 mm/min

(0.020 in./min).

7.2 The failure mode desired is a 100 % shear failure of the

core. Specimens that exhibit cohesive failures of the core-to-

plate adhesive or adhesion failures to the core or plates should

be rejected. The thickness of the adhesive bond to honeycomb

core (adhesive-filled depth into the honeycomb core cells) may

affect the core shear strength and modulus values depending

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.