ASTM C234-91a

(Test Method)Standard Test Method for Comparing Concretes on the Basis of the Bond Developed with Reinforcing Steel (Withdrawn 2000)

Standard Test Method for Comparing Concretes on the Basis of the Bond Developed with Reinforcing Steel (Withdrawn 2000)

SCOPE

1.1 This test method covers comparison of concretes on the basis of the bond developed with reinforcing steel.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: C 234 - 91a

AMERICAN SOCIETY FOR TESTING AND MATERIALS

ISTb 1918 RaceSt Philadelphia, Pa 19103

Reprinfed from the Annual Book of ASTM Standards. Copyright ASTM

If not listed in the current comblned index, will appear In the nexi edaion.

Standard Test Method for

Comparing Concretes on the Basis of the Bond Developed

with Reinforcing Steel'

This standard is issued under the fixed designation C 234; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (t) indicates an editorial change since the last revision or reapproval.

reinforcing bar or for establishing bond values for structural

1. Scope

design purposes. This test method is adaptable to use for

1.1 This test method covers comparison of concretes on

research purposes by varying the conditions as desired but no

the basis of the bond developed with reinforcing steel.

attempt to do so has been included in the method.

1.2 The values stated in inch-pound units are to be

3.2 This test method may also be used to determine the

regarded as the standard.

conformance of a product or a treatment with a requirement

1.3 This standard does not purport to address all of the

relating to its effect on the bond developed between concrete

safety problems, if any, associated with its use. li is the

and reinforcing steel.

responsibility of the user of this standard to establish appro-

priate safity and health practices and determine the applica-

4. Apparatus

bility of regulatory limitations prior to use.

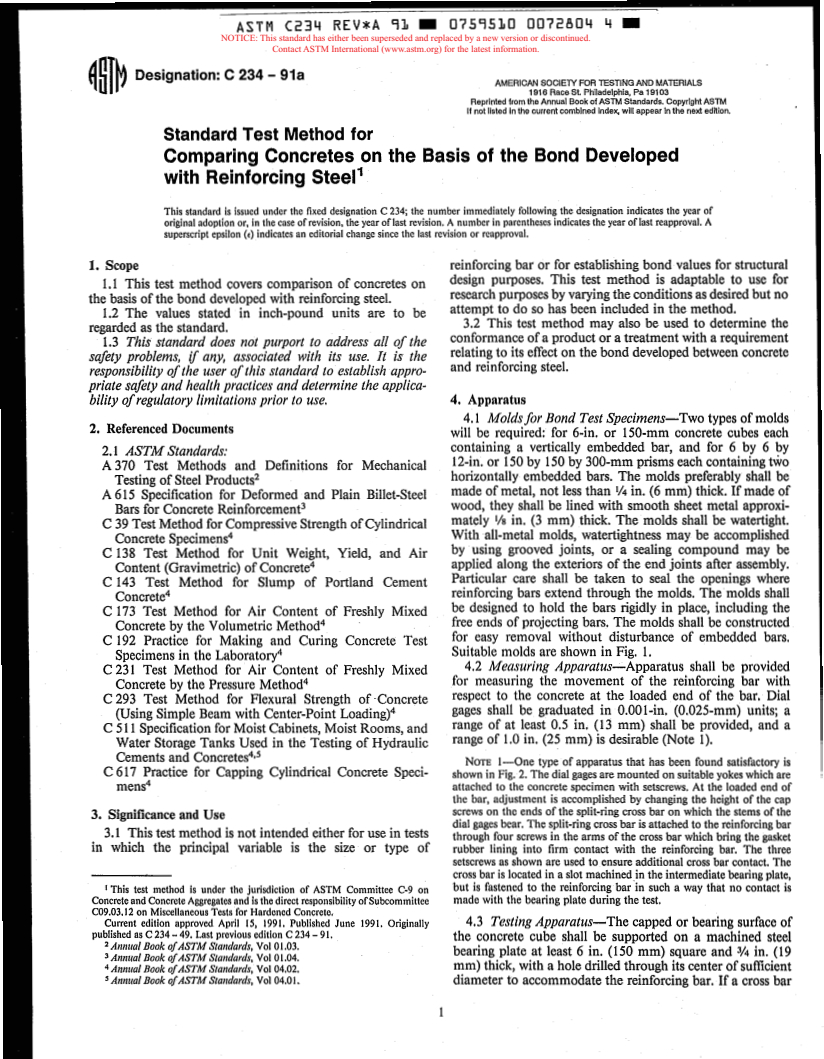

4.1 Molds for Bond Test Specimens-Two types of molds

2. Referenced Documents

will be required: for 6411. or 150-mm concrete cubes each

containing a vertically embedded bar, and for 6 by 6 by

2.1 ASTM Standards:

12411. or 150 by 150 by 300-mm prisms each containing two

A370 Test Methods and Definitions for Mechanical

horizonfally embedded bars. The molds preferably shall be

Testing of Steel Products2

made of metal, not less than 9'4 in. (6 mm) thick. If made of

A 6 15 Specification for Deformed and Plain Billet-Steel

wood, they shall be lined with smooth sheet metal approxi-

Bars for Concrete Reinforcement3

mately '/8 in, (3 mm) thick. The molds shall be watertight.

C 39 Test Method for Compressive Strength of Cylindrical

With all-metal molds, watertightness may be accomplished

Concrete Specimens4

by using grooved joints, or a sealing compound may be

C 138 Test Method for Unit Weight, Yield, and Air

applied along the exteriors of the end joints after assembly.

Content (Gravimetric) of Concrete4

Particular care shall be taken to seal the openings where

C 143 Test Method for Slump of Portland Cement

reinforcing bars extend through the molds. The molds shall

Concrete4

be designed to hold the bars rigidly in place, including the

C 173 Test Method for Air Content of Freshly Mixed

free ends of projecting bars. The molds shall be constructed

Concrete by the Volumetric Method4

for easy removal without disturbance of embedded bars.

C 192 Practice for Making and Curing Concrete Test

Suitable molds are shown in Fig. 1.

Specimens in the Laboratory4

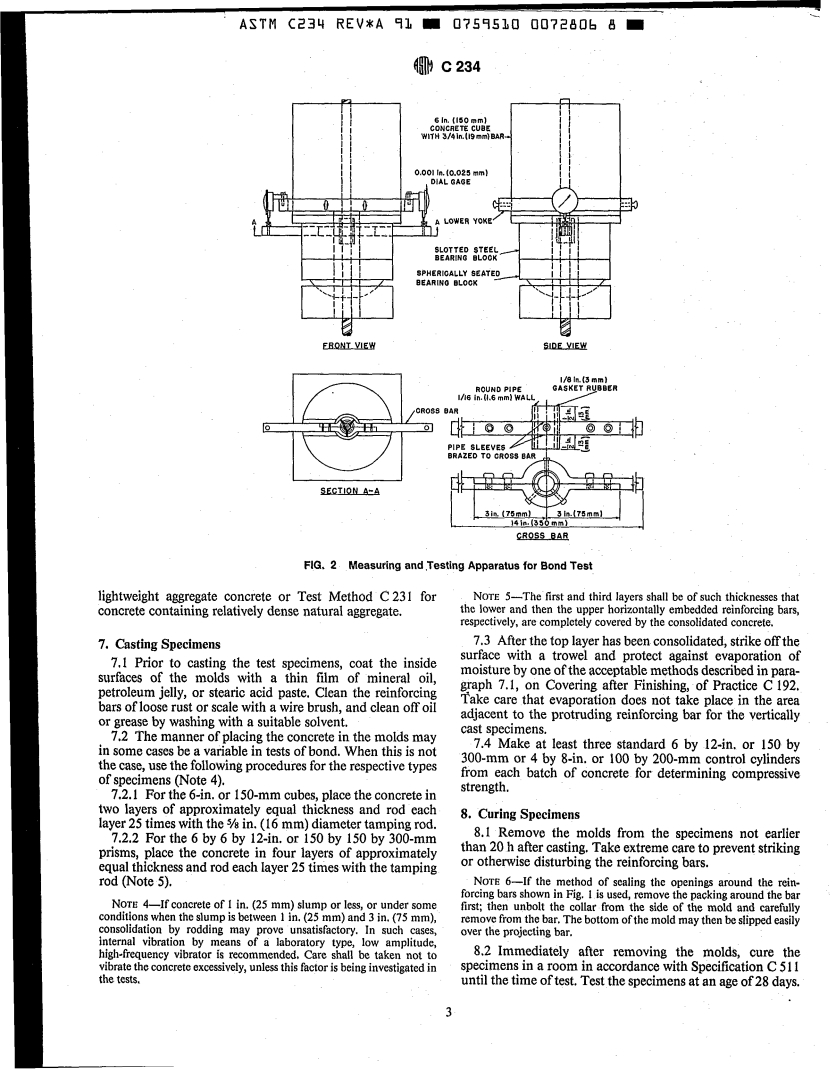

4.2 Measuring Apparatus-Apparatus shall be provided

C 231 Test Method for Air Content of Freshly Mixed

for measuring the movement of the reinforcing bar with

Concrete by the Pressure Method4

respect to the concrete at the loaded end of the bar. Dial

C 293 Test Method for Flexural Strength of -Concrete

gages shall be graduated in O.OOl-in, (0.025-mm) units; a

(Using Simple Beam with Center-Point L~ading)~

range of at least 0.5 in. (13 mm) shall be provided, and a

C 5 1 1 Specification for Moist Cabinets, Moist Rooms, and

range of 1.0 in. (25 mm) is desirable (Note i).

Water Storage Tanks Used in the Testing of Hydraulic

Cements and Concretes415

NOTE 1-One type of apparatus that has been found satisfactory is

C 6 17 Practice for Capping Cylindrical Concrete Speci- shown in Fig. 2. The dial gages are mounted on suitable yokes which are

attached to the concrete specimen with setscrews. At the loaded end of

mens4

the bar, adjusfment is accomplished by changing the height of the cap

screws on the ends of the split-ring cross bar on which the stems of the

3. Significance and Use

cross bar is attached to the reinforcing bar

dial gages bear. The split-ring

3.1 This test method is not intended either for use in tests

through four screws in the arms of the cross bar which bring the gasket

in which the principal variable is the size or type of rubber lining into firm contact with the reinforcing bar. The three

setscrews as shown are used to ensure additional cross bar contact. The

cross bar is located in a slot machined in the intermediate bearing plate,

but is fastened to the reinforcing bar in such a way that no contact is

'This lest method is under the jurisdiction of ASTM Comm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.