ASTM D4154-01(2008)

(Specification)Standard Performance Specification for Men's and Boys' Knitted and Woven Beachwear and Sports Shirt Fabrics

Standard Performance Specification for Men's and Boys' Knitted and Woven Beachwear and Sports Shirt Fabrics

SIGNIFICANCE AND USE

Upon mutual agreement between the purchaser and the supplier, fabrics intended for this end use should meet all of the requirements listed in Table 1 of this performance specification.

It is recognized that for purposes of fashion or aesthetics, the ultimate consumer of articles made from these fabrics may find acceptable fabrics that do not conform to all of the requirements in Table 1. Therefore, one or more of the requirements listed in Table 1 may be modified by mutual agreement between the purchaser and the supplier.

In such cases, any references to the specification shall specify that: This fabric meets ASTM Specification D 4154 except for the following characteristic(s).”

Where no prepurchase agreement has been reached between the purchaser and the supplier, and in case of controversy, the requirements listed in Table 1 are intended to be used as a guide only. As noted in 5.2, ultimate consumer demands dictate varying performance parameters for any particular style of fabric.

The uses and significance of particular properties and test methods are discussed in the appropriate sections of the specified test methods.

SCOPE

1.1 This performance specification covers knitted and woven fabrics comprised of any textile fiber or mixture of fibers used in men's and boy's beachwear and sports shirts.

1.2 This performance specification is not applicable to knitted and woven fabrics used for interlining and swimwear.

1.3 These requirements apply to both the length and width directions for those properties where fabric direction is pertinent.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4154 −01(Reapproved 2008)

Standard Performance Specification for

Men’s and Boys’ Knitted and Woven Beachwear and Sports

Shirt Fabrics

This standard is issued under the fixed designation D4154; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2594 Test Method for Stretch Properties of Knitted Fabrics

Having Low Power

1.1 This performance specification covers knitted and wo-

D2724 Test Methods for Bonded, Fused, and Laminated

ven fabrics comprised of any textile fiber or mixture of fibers

Apparel Fabrics

used in men’s and boy’s beachwear and sports shirts.

D2905 Practice for Statements on Number of Specimens for

1.2 This performance specification is not applicable to

Textiles (Withdrawn 2008)

knitted and woven fabrics used for interlining and swimwear.

D3786 Test Method for Bursting Strength of Textile

Fabrics—Diaphragm Bursting Strength Tester Method

1.3 These requirements apply to both the length and width

directions for those properties where fabric direction is perti- D3787 Test Method for Bursting Strength of Textiles—

Constant-Rate-of-Traverse (CRT) Ball Burst Test

nent.

D5034 TestMethodforBreakingStrengthandElongationof

1.4 This standard does not purport to address all of the

Textile Fabrics (Grab Test)

safety concerns, if any, associated with its use. It is the

2.2 AATCC Test Methods:

responsibility of the user of this standard to establish appro-

8 Colorfastness to Crocking: AATCC Crockmeter Method

priate safety and health practices and determine the applica-

15 Colorfastness to Perspiration

bility of regulatory limitations prior to use.

16 Colorfastness to Light

2. Referenced Documents 23 Colorfastness to Burnt Gas Fumes

61 Colorfastness to Washing, Domestic, and Laundering,

2.1 ASTM Standards:

Commercial: Accelerated

D123 Terminology Relating to Textiles

96 Dimensional Changes in Laundering of Woven and

D434 Test Method for Resistance to Slippage of Yarns in

Knitted Textiles Except Wool

Woven Fabrics Using a Standard Seam (Withdrawn

3 116 Colorfastness to Crocking: Rotary Vertical Crockmeter

2003)

Method

D1424 Test Method for Tearing Strength of Fabrics by

124 Appearance of Durable Press Fabrics After Repeated

Falling-Pendulum (Elmendorf-Type) Apparatus

Home Launderings

D2262 Test Method for Tearing Strength of Woven Fabrics

132 Colorfastness to Drycleaning

by the Tongue (Single Rip) Method (Constant-Rate-of-

135 Dimensional Changes in Automatic Home Launderings

Traverse Tensile Testing Machine) (Withdrawn 1995)

of Durable Press Woven of Knit Fabrics

172 Colorfastness to Non-chlorine Bleach in Home Laun-

This performance specification is under the jurisdiction of ASTM Committee dering

D13 on Textiles and is the direct responsibility of Subcommittee D13.61 on

188 Colorfastness to Chlorine Bleach in Home Laundering

Apparel.

Evaluation Procedure 1 Gray Scale for Color Change

Current edition approved Aug. 1, 2008. Published October 2008. Originally

Evaluation Procedure 2 Gray Scale for Staining

approved in 1982. Last previous edition approved in 2001 as D4154 – 01. DOI:

10.1520/D4154-01R08.

Evaluation Procedure 3 AATCC Chromatic Transference

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Scale

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. AATCC Technical Manual, available from American Association of Textile

The last approved version of this historical standard is referenced on Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC

www.astm.org. 27709, http://www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4154−01 (2008)

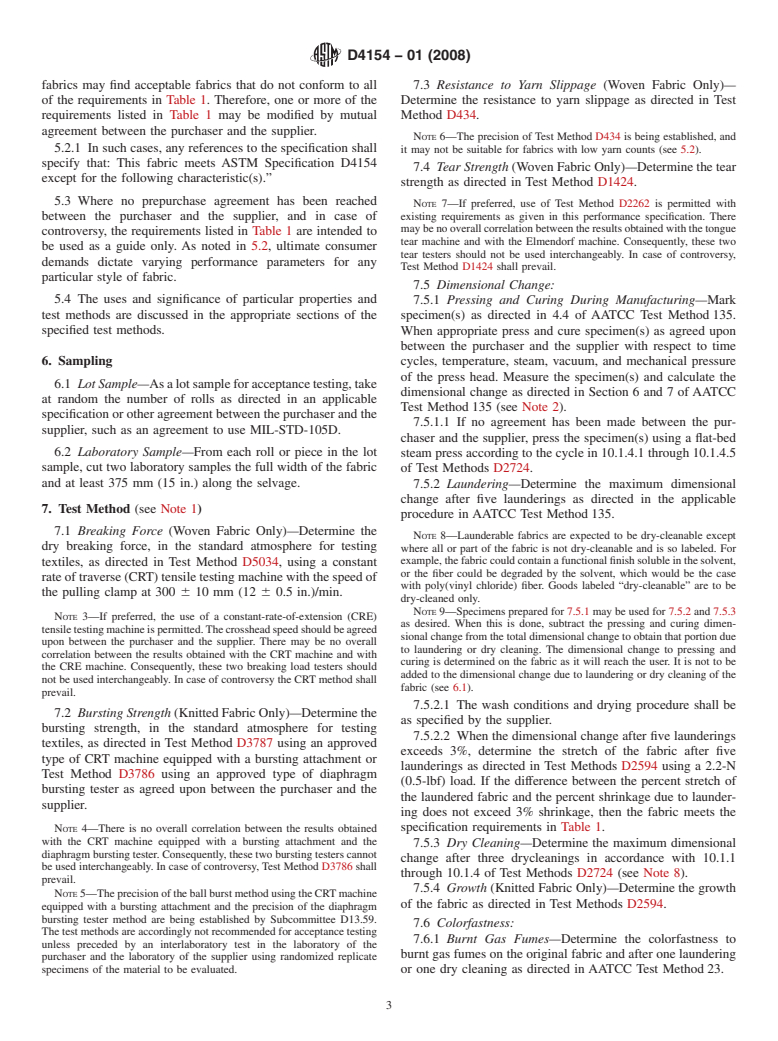

TABLE 1 Specification Requirements

NOTE 1—Class for colorfastness and DP rating is based on a numerical scale of 5 for negligible or no color change, color transfer, or wrinkle to 1 for

very severe color change, color transfer, or wrinkle. The numerical rating in Table 1 or a higher numerical rating is acceptable.

Requirements

Characteristic Section

Knitted Woven

Breaking strength (load) (CRT) . 111 N (25 lbf), min 7.1

Bursting strength (load) (ball burst) 222 N (50 lbf) . 7.2

Yarn slippage, 6-mm ( ⁄4-in.) separation . 89 N (20 lbf), min 7.3

Tongue tear strength . 6.7 N (1.5 lbf), min 7.4

Dimensional Change:

Pressing and finishing 2 % max 1 % max, pre-finished fabrics 7.5.1

After five launderings (see 7.5.2.2 if shrinkage exceeds 3 %) 3 % max 2 % max, post-finished fabrics 7.5.2

After three dry cleanings 3 % max 3 % max 7.5.3

Growth 3 % max 3 % max 7.5.4

Colorfastness:

Burnt Gas Fumes—2 Cycles:

A A

Shade change, original fabric Class 4 min Class 4 min 7.6.1

A A

Shade change after 1 laundering or 1 dry cleaning Class 4 min Class 4 min

Laundering:

A A

Shade change Class 4 min Class 4 min 7.6.2

B B

Class 3 min Class 3 min

Staining

Dry cleaning:

A A

Shade change Class 4 min Class 4 min 7.6.3

Crocking:

C C

Dry Class 4 min Class 4 min 7.6.4

C C

Class 3 min Class 3 min

Wet

Perspiration:

A A

Shade Change Class 4 min Class 4 min 7.6.5

B B

Class 3 min Class 3 min

Staining

A A

Light (40 AATCC FU) (xenon-arc) Step 4 min Step 4 min 7.6.6

A A

Chlorine Bleach Class 4 , min Class 4 ,min 7.6.7

A A

Non-chlorine Bleach Class 4 , min Class 4 ,min 7.6.8

D D

Fabric appearance (see 7.7.1.1)DP3.5 min DP 3.5 min 7.7

Flammability pass pass 7.8

A

AATCC Gray Scale for Color Change.

B

AATCC Gray Scale for Staining.

C

AATCC Chromatic Transference Scale.

D

For durable-press fabrics only.

2.3 Federal Standard: 3.3.1 pressing and finishing—This term takes into account

16 CFR, Chapter II—Consumer Product Safety Commission all of the industrial pressing and finishing treatments used in

Subchapter D—Flammable Fabrics Act Regulations. garment production.

2.4 Military Standard:

NOTE 2—No standard method is available for reproducing on a

MIL-STD-105D Sampling Procedures and Tables for In-

laboratory level the results of industrial pressing or finishing treatments

used in the manufacture of garments.

spection by Attributes

3.4 Definitions of terms used in a dictionary of common

NOTE 1—Reference to test methods in this performance specification

terms are suitable for terms used in this performance specifi-

give only the permanent part of the designation of ASTM, AATCC, or

other test methods. The current editions of each test method cited shall

cation.

prevail.

4. Specification Requirements

3. Terminology

4.1 The properties of fabrics of woven and knitted fabrics

3.1 Definitions:

for mens’s and boy’s beachwear and sport shirts shall conform

3.1.1 dimensional change, n— in pressing and finishing of

to the specification requirements in Table 1.

textiles, the change in dimensions of a fabric caused by

pressing and finishing during garment manufacture. 5. Significance and Use

5.1 Upon mutual agreement between the purchaser and the

3.2 For definitions of other textile terms used in this

specification, refer to the individual ASTM and AATCC test supplier,fabricsintendedforthisenduseshouldmeetallofthe

requirements listed in Table 1 of this performance specifica-

methods and to Terminology D123.

tion.

3.3 Definitions of Terms Specific to This Standard:

5.2 It is recognized that for purposes of fashion or

aesthetics, the ultimate consumer of articles made from these

Available from Superintendent of Documents, Government Printing Office,

Washington, DC 20402.

6 7

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 The development of a standard method has been referred to Subcommittee

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. D13.59 on Fabric Test Methods, General.

D4154−01 (2008)

fabrics may find acceptable fabrics that do not conform to all 7.3 Resistance to Yarn Slippage (Woven Fabric Only)—

of the requirements in Table 1. Therefore, one or more of the Determine the resistance to yarn slippage as directed in Test

requirements listed in Table 1 may be modified by mutual Method D434.

agreement between the purchaser and the supplier.

NOTE 6—The precision of Test Method D434 is being established, and

5.2.1 In such cases, any references to the specification shall it may not be suitable for fabrics with low yarn counts (see 5.2).

specify that: This fabric meets ASTM Specification D4154

7.4 Tear Strength (Woven Fabric Only)—Determine the tear

except for the following characteristic(s).”

strength as directed in Test Method D1424.

5.3 Where no prepurchase agreement has been reached

NOTE 7—If preferred, use of Test Method D2262 is permitted with

between the purchaser and the supplier, and in case of existing requirements as given in this performance specification. There

maybenooverallcorrelationbetweentheresultsobtainedwiththet

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4154–01 Designation: D 4154 – 01 (Reapproved 2008)

Standard Performance Specification for

Men’s and Boys’ Knitted and Woven Beachwear and Sports

Shirt Fabrics

This standard is issued under the fixed designation D 4154; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This performance specification covers knitted and woven fabrics comprised of any textile fiber or mixture of fibers used in

men’s and boy’s beachwear and sports shirts.

1.2 This performance specification is not applicable to knitted and woven fabrics used for interlining and swimwear.

1.3 These requirements apply to both the length and width directions for those properties where fabric direction is pertinent.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 434 Test Method for Resistance to Slippage of Yarns in Woven Fabrics Using a Standard Seam

D 1424 Test Method for Tear ResistanceTearing Strength of Fabrics by Falling–-Pendulum Type (Elmendorf) Apparatus

D 2262 Test Method for Tearing Strength of Woven Fabrics by the Tongue (Single Rip) Method (Constant-Rate-of-Traverse

Tensile Testing Machine)

D 2594 Test MethodsMethod for Stretch Properties of Knitted Fabrics Having Low Power

D 2724 Test Methods for Bonded, Fused, and Laminated Apparel Fabrics

D 2905 Practice for Statements on Number of Specimens for Textiles

D 3786Test Method for Hydraulic Bursting Strength of Knitted Goods and Nonwoven Fabrics: Diaphragm Bursting Strength

Tester Method Test Method for Bursting Strength of Textile FabricsDiaphragm Bursting Strength Tester Method

D 3787 Test Method for Bursting Strength of Knitted Goods: TextilesConstant-Rate-of-Traverse (CRT) Ball Burst Test

D 5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

2.2 AATCC Test Methods:

8 Colorfastness to Crocking: AATCC Crockmeter Method

15 Colorfastness to Perspiration

16 Colorfastness to Light

23 Colorfastness to Burnt Gas Fumes

61 Colorfastness to Washing, Domestic, and Laundering, Commercial: Accelerated

96 Dimensional Changes in Laundering of Woven and Knitted Textiles Except Wool

116 Colorfastness to Crocking: Rotary Vertical Crockmeter Method

124 Appearance of Durable Press Fabrics After Repeated Home Launderings

132 Colorfastness to Drycleaning

135 Dimensional Changes in Automatic Home Launderings of Durable Press Woven of Knit Fabrics

172 Colorfastness to Non-chlorine Bleach in Home Laundering

188 Colorfastness to Chlorine Bleach in Home Laundering

This specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.61 on Apparel.

Current edition approved May 10, 2001. Published July 2001. Originally published as D4154–82. Last previous edition D4154–95a.

This performance specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.61 on Apparel.

Current edition approved Aug. 1, 2008. Published October 2008. Originally approved in 1982. Last previous edition approved in 2001 as D 4154 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Discontinued; see 1994 Annual Book of ASTM Standards , Vol 07.01.

AATCC Technical Manual, available from American Association of Textile Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709,

http://www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4154 – 01 (2008)

Evaluation Procedure 1 Gray Scale for Color Change

Evaluation Procedure 2 Gray Scale for Staining

Evaluation Procedure 3 AATCC Chromatic Transference Scale

2.3 Federal Standard:

16 CFR, Chapter II—Consumer Product Safety Commission Subchapter D—Flammable Fabrics Act Regulations.

2.4 Military Standard:

MIL-STD-105D Sampling Procedures and Tables for Inspection by Attributes

NOTE 1—Reference to test methods in this performance specification give only the permanent part of the designation ofASTM,AATCC, or other test

methods. The current editions of each test method cited shall prevail.

3. Terminology

3.1 Definitions:

3.1.1 dimensional change, n— in pressing and finishing of textiles, the change in dimensions of a fabric caused by pressing and

finishing during garment manufacture.

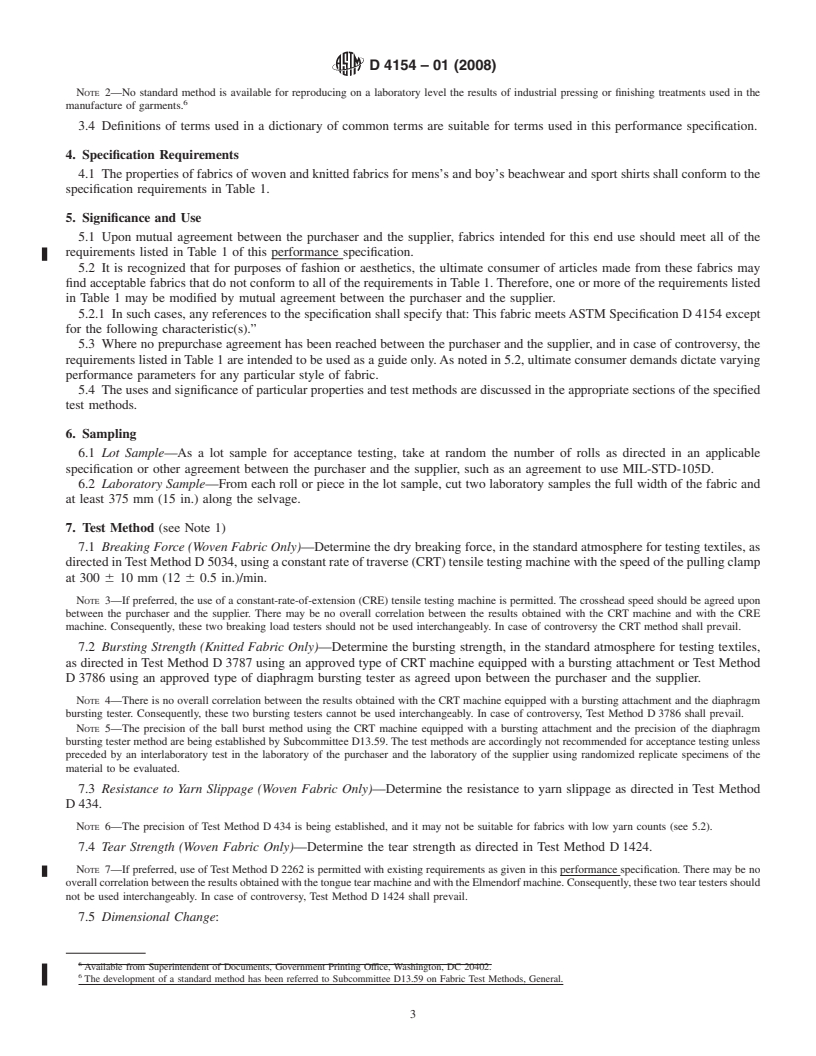

TABLE 1 Specification Requirements

NOTE 1—Class for colorfastness and DP rating is based on a numerical scale of 5 for negligible or no color change, color transfer, or wrinkle to 1 for

very severe color change, color transfer, or wrinkle. The numerical rating in Table 1 or a higher numerical rating is acceptable.

Requirements

Characteristic Section

Knitted Woven

Breaking strength (load) (CRT) . 111 N (25 lbf), min 7.1

Bursting strength (load) (ball burst) 222 N (50 lbf) . 7.2

Yarn slippage, 6-mm ( ⁄4-in.) separation . 89 N (20 lbf), min 7.3

Tongue tear strength . 6.7 N (1.5 lbf), min 7.4

Dimensional Change:

Pressing and finishing 2 % max 1 % max, pre-finished fabrics 7.5.1

After five launderings (see 7.5.2.2 if shrinkage exceeds 3 %) 3 % max 2 % max, post-finished fabrics 7.5.2

After three dry cleanings 3 % max 3 % max 7.5.3

Growth 3 % max 3 % max 7.5.4

Colorfastness:

Burnt Gas Fumes—2 Cycles:

A A

Shade change, original fabric Class 4 min Class 4 min 7.6.1

A A

Shade change after 1 laundering or 1 dry cleaning Class 4 min Class 4 min

Laundering:

A A

Shade change Class 4 min Class 4 min 7.6.2

B B

Staining Class 3 min Class 3 min

Dry cleaning:

A A

Shade change Class 4 min Class 4 min 7.6.3

Crocking:

C C

Dry Class 4 min Class 4 min 7.6.4

C C

Wet Class 3 min Class 3 min

Perspiration:

A A

Shade Change Class 4 min Class 4 min 7.6.5

B B

Staining Class 3 min Class 3 min

A A

Light (40 AATCC FU) (xenon-arc) Step 4 min Step 4 min 7.6.6

A A

Chlorine Bleach Class 4 , min Class 4 , min 7.6.7

A A

Non-chlorine Bleach Class 4 , min Class 4 , min 7.6.8

D D

Fabric appearance (see 7.7.1.1) DP 3.5 min DP 3.5 min 7.7

Flammability pass pass 7.8

A

AATCC Gray Scale for Color Change.

B

AATCC Gray Scale for Staining.

C

AATCC Chromatic Transference Scale.

D

For durable-press fabrics only.

3.2 For definitions of other textile terms used in this specification, refer to the individualASTM andAATCC test methods and

to Terminology D 123.

3.3 Definitions of Terms Specific to This Standard:

3.3.1 pressing and finishing—Thistermtakesintoaccountalloftheindustrialpressingandfinishingtreatmentsusedingarment

production.

Discontinued; see 1997 Annual Book of ASTM Standards , Vol 07.02.

Available from Superintendent of Documents, Government Printing Office, Washington, DC 20402.

AATCC Technical Manual, available from the American Association of Textile Chemists and Colorists, P.O. Box 12215, Research Triangle Park, NC 27709.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

D 4154 – 01 (2008)

NOTE 2—No standard method is available for reproducing on a laboratory level the results of industrial pressing or finishing treatments used in the

manufacture of garments.

3.4 Definitions of terms used in a dictionary of common terms are suitable for terms used in this performance specification.

4. Specification Requirements

4.1 The properties of fabrics of woven and knitted fabrics for mens’s and boy’s beachwear and sport shirts shall conform to the

specification requirements in Table 1.

5. Significance and Use

5.1 Upon mutual agreement between the purchaser and the supplier, fabrics intended for this end use should meet all of the

requirements listed in Table 1 of this performance specification.

5.2 It is recognized that for purposes of fashion or aesthetics, the ultimate consumer of articles made from these fabrics may

find acceptable fabrics that do not conform to all of the requirements in Table 1. Therefore, one or more of the requirements listed

in Table 1 may be modified by mutual agreement between the purchaser and the supplier.

5.2.1 In such cases, any references to the specification shall specify that: This fabric meetsASTM Specification D 4154 except

for the following characteristic(s).”

5.3 Where no prepurchase agreement has been reached between the purchaser and the supplier, and in case of controversy, the

requirements listed in Table 1 are intended to be used as a guide only.As noted in 5.2, ultimate consumer demands dictate varying

performance parameters for any particular style of fabric.

5.4 The uses and significance of particular properties an

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4154–01 Designation: D 4154 – 01 (Reapproved 2008)

Standard Performance Specification for

Men’s and Boys’ Knitted and Woven Beachwear and Sports

Shirt Fabrics

This standard is issued under the fixed designation D 4154; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This performance specification covers knitted and woven fabrics comprised of any textile fiber or mixture of fibers used in

men’s and boy’s beachwear and sports shirts.

1.2 This performance specification is not applicable to knitted and woven fabrics used for interlining and swimwear.

1.3 These requirements apply to both the length and width directions for those properties where fabric direction is pertinent.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 434 Test Method for Resistance to Slippage of Yarns in Woven Fabrics Using a Standard Seam

D 1424 Test Method for Tear ResistanceTearing Strength of Fabrics by Falling–-Pendulum Type (Elmendorf) Apparatus

D 2262 Test Method for Tearing Strength of Woven Fabrics by the Tongue (Single Rip) Method (Constant-Rate-of-Traverse

Tensile Testing Machine)

D 2594 Test MethodsMethod for Stretch Properties of Knitted Fabrics Having Low Power

D 2724 Test Methods for Bonded, Fused, and Laminated Apparel Fabrics

D 2905 Practice for Statements on Number of Specimens for Textiles

D 3786 Test Method for Hydraulic Bursting Strength of Knitted Goods and Nonwoven Fabrics: Diaphragm Bursting Strength

Tester Method Test Method for Bursting Strength of Textile FabricsDiaphragm Bursting Strength Tester Method

D 3787 Test Method for Bursting Strength of Knitted Goods: TextilesConstant-Rate-of-Traverse (CRT) Ball Burst Test

D 5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

2.2 AATCC Test Methods:

8 Colorfastness to Crocking: AATCC Crockmeter Method

15 Colorfastness to Perspiration

16 Colorfastness to Light

23 Colorfastness to Burnt Gas Fumes

61 Colorfastness to Washing, Domestic, and Laundering, Commercial: Accelerated

96 Dimensional Changes in Laundering of Woven and Knitted Textiles Except Wool

116 Colorfastness to Crocking: Rotary Vertical Crockmeter Method

124 Appearance of Durable Press Fabrics After Repeated Home Launderings

132 Colorfastness to Drycleaning

135 Dimensional Changes in Automatic Home Launderings of Durable Press Woven of Knit Fabrics

172 Colorfastness to Non-chlorine Bleach in Home Laundering

188 Colorfastness to Chlorine Bleach in Home Laundering

This specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.61 on Apparel.

Current edition approved May 10, 2001. Published July 2001. Originally published as D4154–82. Last previous edition D4154–95a.

This performance specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.61 on Apparel.

Current edition approved Aug. 1, 2008. Published October 2008. Originally approved in 1982. Last previous edition approved in 2001 as D 4154 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Discontinued; see 1994 Annual Book of ASTM Standards, Vol 07.01.

AATCC Technical Manual, available from American Association of Textile Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709,

http://www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4154 – 01 (2008)

Evaluation Procedure 1 Gray Scale for Color Change

Evaluation Procedure 2 Gray Scale for Staining

Evaluation Procedure 3 AATCC Chromatic Transference Scale

2.3 Federal Standard:

16 CFR, Chapter II—Consumer Product Safety Commission Subchapter D—Flammable Fabrics Act Regulations.

2.4 Military Standard:

MIL-STD-105D Sampling Procedures and Tables for Inspection by Attributes

NOTE 1—Reference to test methods in this performance specification give only the permanent part of the designation ofASTM,AATCC, or other test

methods. The current editions of each test method cited shall prevail.

3. Terminology

3.1 Definitions:

3.1.1 dimensional change, n— in pressing and finishing of textiles, the change in dimensions of a fabric caused by pressing and

finishing during garment manufacture.

TABLE 1 Specification Requirements

NOTE 1—Class for colorfastness and DP rating is based on a numerical scale of 5 for negligible or no color change, color transfer, or wrinkle to 1 for

very severe color change, color transfer, or wrinkle. The numerical rating in Table 1 or a higher numerical rating is acceptable.

Requirements

Characteristic Section

Knitted Woven

Breaking strength (load) (CRT) . 111 N (25 lbf), min 7.1

Bursting strength (load) (ball burst) 222 N (50 lbf) . 7.2

Yarn slippage, 6-mm ( ⁄4-in.) separation . 89 N (20 lbf), min 7.3

Tongue tear strength . 6.7 N (1.5 lbf), min 7.4

Dimensional Change:

Pressing and finishing 2 % max 1 % max, pre-finished fabrics 7.5.1

After five launderings (see 7.5.2.2 if shrinkage exceeds 3 %) 3 % max 2 % max, post-finished fabrics 7.5.2

After three dry cleanings 3 % max 3 % max 7.5.3

Growth 3 % max 3 % max 7.5.4

Colorfastness:

Burnt Gas Fumes—2 Cycles:

A A

Shade change, original fabric Class 4 min Class 4 min 7.6.1

A A

Shade change after 1 laundering or 1 dry cleaning Class 4 min Class 4 min

Laundering:

A A

Shade change Class 4 min Class 4 min 7.6.2

B B

Staining Class 3 min Class 3 min

Dry cleaning:

A A

Shade change Class 4 min Class 4 min 7.6.3

Crocking:

C C

Dry Class 4 min Class 4 min 7.6.4

C C

Wet Class 3 min Class 3 min

Perspiration:

A A

Shade Change Class 4 min Class 4 min 7.6.5

B B

Staining Class 3 min Class 3 min

A A

Light (40 AATCC FU) (xenon-arc) Step 4 min Step 4 min 7.6.6

A A

Chlorine Bleach Class 4 , min Class 4 , min 7.6.7

A A

Non-chlorine Bleach Class 4 , min Class 4 , min 7.6.8

D D

Fabric appearance (see 7.7.1.1) DP 3.5 min DP 3.5 min 7.7

Flammability pass pass 7.8

A

AATCC Gray Scale for Color Change.

B

AATCC Gray Scale for Staining.

C

AATCC Chromatic Transference Scale.

D

For durable-press fabrics only.

3.2 For definitions of other textile terms used in this specification, refer to the individualASTM andAATCC test methods and

to Terminology D 123.

3.3 Definitions of Terms Specific to This Standard:

3.3.1 pressing and finishing—Thistermtakesintoaccountalloftheindustrialpressingandfinishingtreatmentsusedingarment

production.

Discontinued; see 1997 Annual Book of ASTM Standards, Vol 07.02.

Available from Superintendent of Documents, Government Printing Office, Washington, DC 20402.

AATCC Technical Manual, available from the American Association of Textile Chemists and Colorists, P.O. Box 12215, Research Triangle Park, NC 27709.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

D 4154 – 01 (2008)

NOTE 2—No standard method is available for reproducing on a laboratory level the results of industrial pressing or finishing treatments used in the

manufacture of garments.

3.4 Definitions of terms used in a dictionary of common terms are suitable for terms used in this performance specification.

4. Specification Requirements

4.1 The properties of fabrics of woven and knitted fabrics for mens’s and boy’s beachwear and sport shirts shall conform to the

specification requirements in Table 1.

5. Significance and Use

5.1 Upon mutual agreement between the purchaser and the supplier, fabrics intended for this end use should meet all of the

requirements listed in Table 1 of this performance specification.

5.2 It is recognized that for purposes of fashion or aesthetics, the ultimate consumer of articles made from these fabrics may

find acceptable fabrics that do not conform to all of the requirements in Table 1. Therefore, one or more of the requirements listed

in Table 1 may be modified by mutual agreement between the purchaser and the supplier.

5.2.1 In such cases, any references to the specification shall specify that: This fabric meetsASTM Specification D 4154 except

for the following characteristic(s).”

5.3 Where no prepurchase agreement has been reached between the purchaser and the supplier, and in case of controversy, the

requirements listed in Table 1 are intended to be used as a guide only.As noted in 5.2, ultimate consumer demands dictate varying

performance parameters for any particular style of fabric.

5.4 The uses and significance of particular properties a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.