ASTM C1002-20

(Specification)Standard Specification for Steel Self-Piercing Tapping Screws for Application of Gypsum Panel Products or Metal Plaster Bases to Wood Studs or Steel Studs

Standard Specification for Steel Self-Piercing Tapping Screws for Application of Gypsum Panel Products or Metal Plaster Bases to Wood Studs or Steel Studs

ABSTRACT

This specification covers steel self-piercing tapping screws for use in fastening gypsum panel products and metal plaster bases to cold-formed steel studs and wood members and for fastening gypsum panel products to gypsum board. Steel screws covered by this specification are of four types of thread configurations: (1) Type G, course-pitch high-thread self-piercing screws for fastening gypsum board to gypsum board; (2) Type S, fine-thread screw for fastening gypsum board to cold formed steel members; (3) Type W, course-thread screw for fastening gypsum board to wood members; and (4) Type A, course-pitch tapping screw thread for fastening metal plaster bases to wood or cold-formed steel. All these steel screw types shall be tested for the determination of performance requirements and physical properties (hardness and ductility) covered in this specification. For the appearance of screws, the form shall be straight and neatly formed, and the threads shall be clean and smooth. Screws shall also have a corrosion-resistant treatment which shall not inhibit adhesion to finishing compounds nor bleed through field-applied decoration.

SCOPE

1.1 This specification covers steel self-piercing tapping screws for use in fastening gypsum panel products and metal plaster bases to cold-formed steel studs less than 0.033 in. (0.84 mm) in thickness and wood members, and for fastening gypsum panel products to gypsum board.

1.2 This specification also covers test methods for determining performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification:

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1002 −20

Standard Specification for

Steel Self-Piercing Tapping Screws for Application of

Gypsum Panel Products or Metal Plaster Bases to Wood

1

Studs or Steel Studs

This standard is issued under the fixed designation C1002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Wire Rods and Coarse Round Wire, Carbon Steel, and

Alloy Steel

1.1 This specification covers steel self-piercing tapping

A1040 Guide for Specifying Harmonized Standard Grade

screws for use in fastening gypsum panel products and metal

Compositions for Wrought Carbon, Low-Alloy, andAlloy

plaster bases to cold-formed steel studs less than 0.033 in.

Steels

(0.84 mm) in thickness and wood members, and for fastening

C11 Terminology Relating to Gypsum and Related Building

gypsum panel products to gypsum board.

Materials and Systems

1.2 Thisspecificationalsocoverstestmethodsfordetermin-

C475/C475M Specification for Joint Compound and Joint

ing performance requirements and physical properties.

Tape for Finishing Gypsum Board

C645 Specification for Nonstructural Steel Framing Mem-

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical bers

C847 Specification for Metal Lath

conversions to SI units that are provided for information only

and are not considered standard. C1396/C1396M Specification for Gypsum Board

1.4 The following safety hazards caveat pertains only to the

3. Terminology

test methods described in this specification: This standard does

not purport to address all of the safety concerns, if any,

3.1 Definitions:

associated with its use. It is the responsibility of the user of this

3.1.1 Fordefinitionsrelatingtogypsumandrelatedbuilding

standard to establish appropriate safety, health, and environ-

materials and systems, see Terminology C11.

mental practices and determine the applicability of regulatory

3.2 Definitions:

limitations prior to use.

3.3 Definitions of Terms Specific to This Standard:

1.5 This international standard was developed in accor-

3.3.1 self-piercing, adj—the ability to penetrate without

dance with internationally recognized principles on standard-

benefitofapre-drilledholewithsharp-pointanglesofnotmore

ization established in the Decision on Principles for the

than 30°.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Classification

Barriers to Trade (TBT) Committee.

4.1 Steel screws covered by this specification are of four

2. Referenced Documents types of thread configurations:

2

4.1.1 Type G, coarse-pitch high-thread self-piercing screws

2.1 ASTM Standards:

for fastening gypsum board to gypsum board.

A510/A510M Specification for General Requirements for

4.1.2 Type S, fine-thread screw for fastening gypsum board

to cold formed steel members.

1

This specification is under the jurisdiction of ASTM Committee C11 on

4.1.3 Type W, coarse-thread screw for fastening gypsum

Gypsum and Related Building Materials and Systems and is the direct responsibility

board to wood members.

of Subcommittee C11.02 on Specifications and Test Methods for Accessories and

4.1.4 Type A, coarse-pitch tapping screw thread for fasten-

Related Products.

Current edition approved Oct. 1, 2020. Published November 2020. Originally

ing metal plaster bases to wood or cold-formed steel.

approved in 1983. Last previous edition approved in 2018 as C1002 – 18. DOI:

10.1520/C1002-20.

2 5. Materials

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Screws shall be made from steel wire manufactured in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. accordance with Specification A510/A510M.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

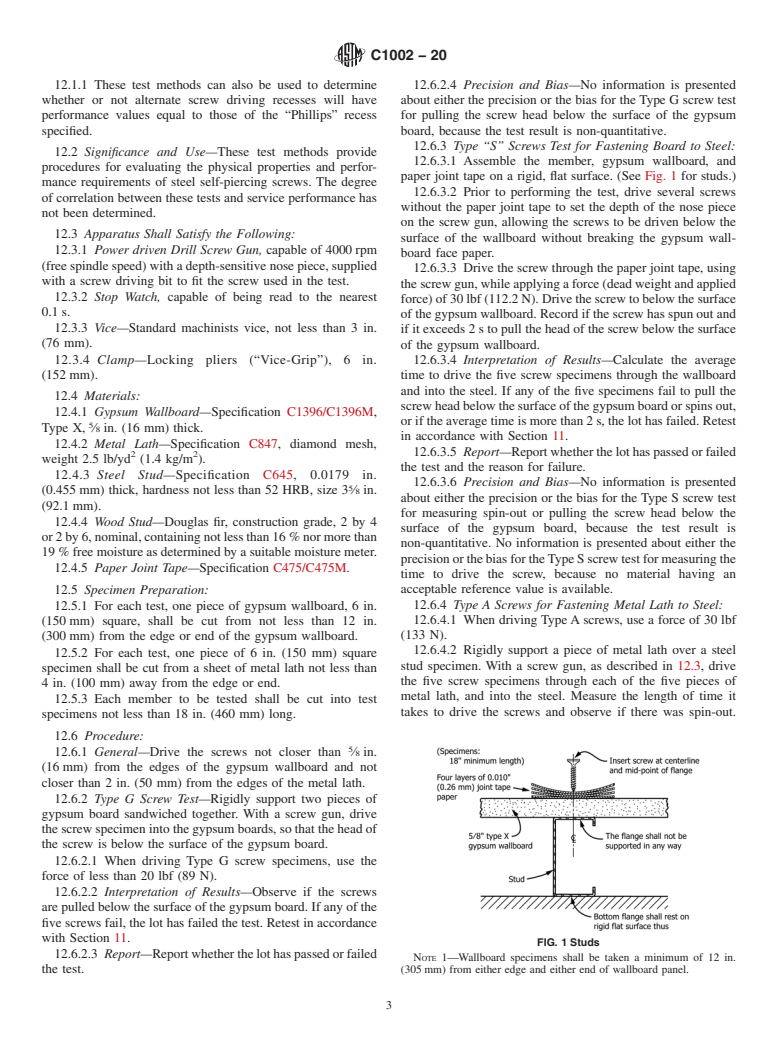

C1002−20

5.1.1 Chemical composition for Type G and Type W screws 8.1.3 Screws for Fastening Metal Plaster Bases—Not less

shall be in accordance with Specification A1040, Grade 1013 than 0.437 in. (11.1 mm).

to 1022.

8.2 Head Contour:

5.1.2 Chemical composition for Type S and Type A screws

8.2.1 Screws for Fastening Gypsum Panel Products—The

shall be in accordance with Specification A1040, Grade 1018

top of the head shall be flat.The outer flange thickness shall be

to 1022.

0.025 6 0.005 in. (0.64 6 0.13 mm). The contour beneath the

flange head shall be such that the screw head shall be able to

6. Physical Propertie

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1002 − 18 C1002 − 20

Standard Specification for

Steel Self-Piercing Tapping Screws for Application of

Gypsum Panel Products or Metal Plaster Bases to Wood

1

Studs or Steel Studs

This standard is issued under the fixed designation C1002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers steel self-piercing tapping screws for use in fastening gypsum panel products and metal plaster bases

to cold-formed steel studs less than 0.033 in. (0.84 mm) in thickness and wood members, and for fastening gypsum panel products

to gypsum board.

1.2 This specification also covers test methods for determining performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The SI (metric) values given in parentheses are

approximate and are for information only. mathematical conversions to SI units that are provided for information only and are not

considered standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification:This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior

to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A510/A510M Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel, and Alloy Steel

A1040 Guide for Specifying Harmonized Standard Grade Compositions for Wrought Carbon, Low-Alloy, and Alloy Steels

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

C475/C475M Specification for Joint Compound and Joint Tape for Finishing Gypsum Board

C645 Specification for Nonstructural Steel Framing Members

C847 Specification for Metal Lath

C1396/C1396M Specification for Gypsum Board

1

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.02 on Specifications and Test Methods for Accessories and Related Products.

Current edition approved April 1, 2018Oct. 1, 2020. Published April 2018November 2020. Originally approved in 1983. Last previous edition approved in 20162018 as

C1002 – 16.C1002 – 18. DOI: 10.1520/C1002-18.10.1520/C1002-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1002 − 20

3. Terminology

3.1 Definitions:

3.1.1 For definitions relating to gypsum and related building materials and systems, see Terminology C11. For definitions relating

to gypsum and related building materials and systems, see Terminology C11.

3.2 Definitions:

3.3 Definitions of Terms Specific to This Standard:

3.3.1 self-piercing, v—adj—the ability to penetrate without benefit of a pre-drilled hole with sharp-point angles of not more than

30°.

4. Classification

4.1 Steel screws covered by this specification are of four types of thread configurations:

4.1.1 Type G, course-pitchcoarse-pitch high-thread self-piercing screws for fastening gypsum board to gypsum board.

4.1.2 Type S, fine-thread screw for fastening gypsum board to cold formed steel members.

4.1.3 Type W, course-threadcoarse-thread screw for fastening gypsum board to wood members.

4.1.4 Type A, course-pitchcoarse-pitch tapping screw thread for fastening metal plaster bases to wood or cold-formed steel.

5. Materials

5.1 Screws shall be made from steel wire manufactured in accordance with Specificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.