ASTM D6991-17e1

(Test Method)Standard Test Method for Measurements of Internal Stresses in Organic Coatings by Cantilever (Beam) Method

Standard Test Method for Measurements of Internal Stresses in Organic Coatings by Cantilever (Beam) Method

SIGNIFICANCE AND USE

5.1 Stresses in coatings arise as a result of their shrinkage or expansion if expected movements are prevented by coating adhesion to its substrate.

5.2 There are several causes leading to arrival of stresses in the coatings: film formation (cross-linking, solvent evaporation, etc.); differences in thermal expansion coefficients between coating and substrate; humidity and water absorption; environmental effects (ultraviolet radiation, temperature and humidity), and others.

5.3 Knowledge of the internal stresses in coatings is very important because they may effect coating performance and service life. If the internal stress exceeds the tensile strength of the film, cracks are formed. If stress exceeds adhesion between coating and substrate, it will reduce adhesion and can lead to delamination of coatings. Quantitative information about stresses in coatings can be useful in coating formulation and recommendations for their application and use.

5.4 This method has been found useful for air-dry industrial organic coatings but the applicability has not yet been assessed for thin coatings (thickness

SCOPE

1.1 This test method covers the procedure for measurements of internal stresses in organic coatings by using the cantilever (beam) method.

1.2 This method is appropriate for the coatings for which the modulus of elasticity of substrate (Es) is significantly greater than the modulus of elasticity of coating (Ec) and for which the thickness of substrate is significantly greater than thickness of coating (see Note 7 and Note 8).

1.3 The stress values are limited by the adhesion values of coating to the substrate and by the tensile strength of the coating, or both.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6991 − 17

Standard Test Method for

Measurements of Internal Stresses in Organic Coatings by

1

Cantilever (Beam) Method

This standard is issued under the fixed designation D6991; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made in Note 2 and Note 3 in October 2017.

1. Scope D823 Practices for Producing Films of Uniform Thickness

of Paint, Varnish, and Related Products on Test Panels

1.1 Thistestmethodcoverstheprocedureformeasurements

D7091 Practice for Nondestructive Measurement of Dry

of internal stresses in organic coatings by using the cantilever

Film Thickness of Nonmagnetic Coatings Applied to

(beam) method.

Ferrous Metals and Nonmagnetic, Nonconductive Coat-

1.2 This method is appropriate for the coatings for which

ings Applied to Non-Ferrous Metals

the modulus of elasticity of substrate (Es) is significantly

greater than the modulus of elasticity of coating (Ec) and for 3. Terminology

which the thickness of substrate is significantly greater than

3.1 Definitions of Terms Specific to This Standard:

thickness of coating (see Note 7 and Note 8).

3.1.1 cantilever, n—a beam or member securely fixed at one

1.3 The stress values are limited by the adhesion values of

end and hanging free at the other end.

coating to the substrate and by the tensile strength of the

3.1.2 deflection, n—the displacement of a beam from its

coating, or both.

original position by an applied force.

3.1.2.1 Discussion—The deflection of the beam is used to

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information measure that force acting on the tip.

only.

3.1.3 internal stress, n—astresssystemwithinasolidthatis

1.5 This standard does not purport to address all of the not dependent on external forces.

safety concerns, if any, associated with its use. It is the

4. Test Method

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and to

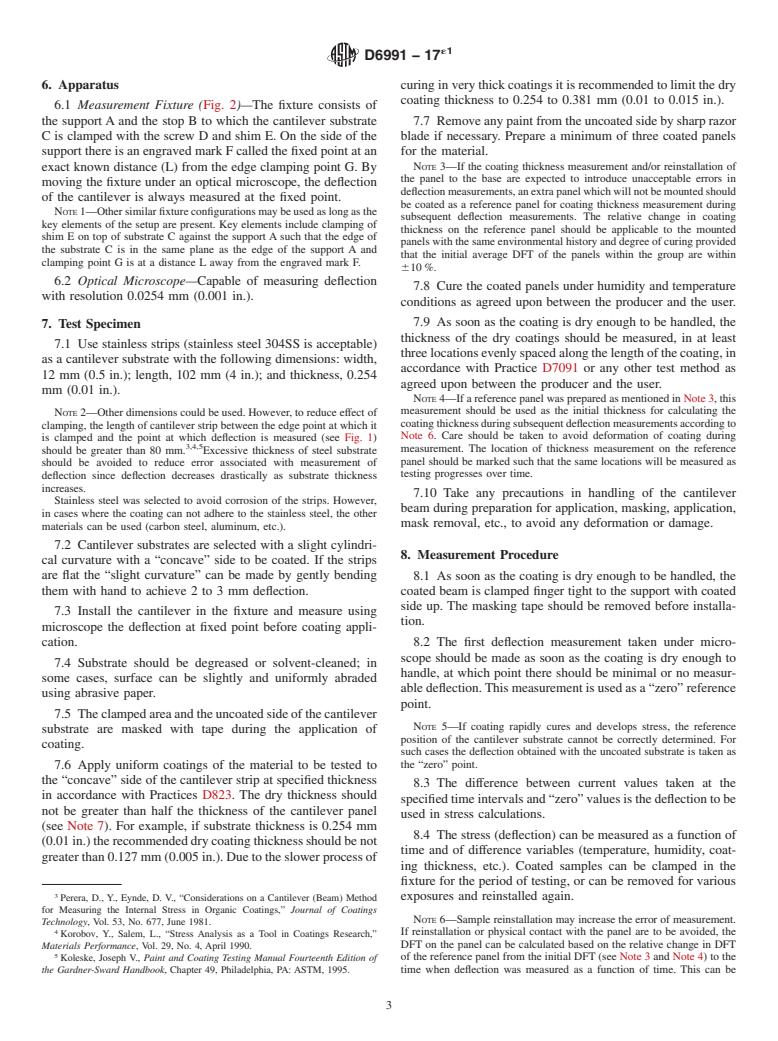

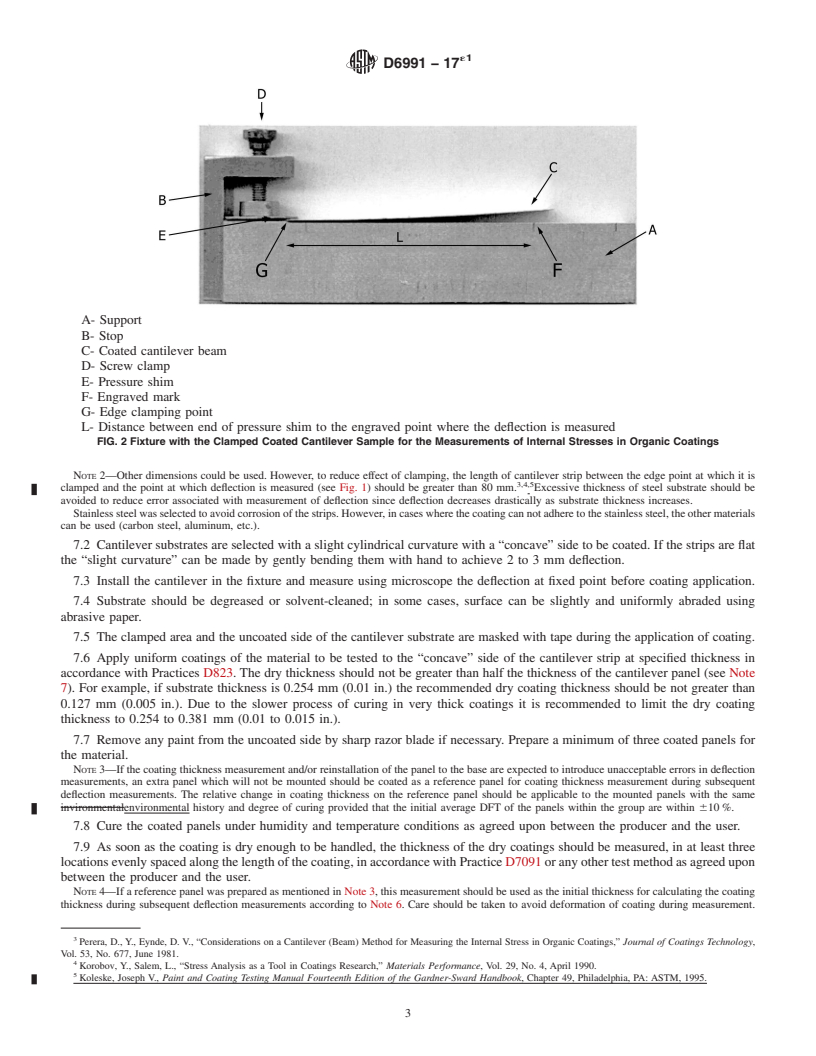

4.1 Internal stresses in coatings are determined by the

determine the applicability of regulatory limitations prior to

cantilever method (Fig. 1). Substrate A in the shape of a

use.

rectangularcantileverbeamisclampedbyitsendBinaspecial

1.6 This international standard was developed in accor-

fixture E. Coating (F) is applied to one side of the beam.

dance with internationally recognized principles on standard-

Internal stresses occur in the film when it is being cured

ization established in the Decision on Principles for the

(drying, cross-linking, etc.). When there is sufficient adhesion

Development of International Standards, Guides and Recom-

between the coating and the substrate, the stresses bend the

mendations issued by the World Trade Organization Technical

cantilever beam, forcing its free end D to be deflected from its

Barriers to Trade (TBT) Committee.

original position by a distance of h. The deflection of the beam

is measured under an optical microscope and internal stress is

2. Referenced Documents

calculated using the equation for the cantilever method. See Eq

2

2.1 ASTM Standards:

1 in Section 9, (Formula 1).

5. Significance and Use

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

5.1 Stressesincoatingsariseasaresultoftheirshrinkageor

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

expansion if expected movements are prevented by coating

Current edition approved May 1, 2017. Published August 2017. Originally

adhesion to its substrate.

approved in 2005. Last previous edition approved in 2010 as D6991 – 05 (2100).

DOI: 10.1520/D6991-17E01.

5.2 There are several causes leading to arrival of stresses in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the coatings: film formation (cross-linking, solvent

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

evaporation,etc.);differencesinthermalexpansioncoefficients

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. between coating and substrate; humidity and water absorption;

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D6991 − 17

A- Cantilever beam (substrate)

B- Beam end clamped in Fixture E

c- Coating thickness

D- Free end deflected under stress

E- Fixture

F- Coating

G- Width of beam

h- Deflection

L- Distance between t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6991 − 17 D6991 − 17

Standard Test Method for

Measurements of Internal Stresses in Organic Coatings by

1

Cantilever (Beam) Method

This standard is issued under the fixed designation D6991; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made in Note 2 and Note 3 in October 2017.

1. Scope

1.1 This test method covers the procedure for measurements of internal stresses in organic coatings by using the cantilever

(beam) method.

1.2 This method is appropriate for the coatings for which the modulus of elasticity of substrate (Es) is significantly greater than

the modulus of elasticity of coating (Ec) and for which the thickness of substrate is significantly greater than thickness of coating

(see Note 7 and Note 8).

1.3 The stress values are limited by the adhesion values of coating to the substrate and by the tensile strength of the coating,

or both.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability

of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D823 Practices for Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels

D7091 Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals

and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 cantilever, n—a beam or member securely fixed at one end and hanging free at the other end.

3.1.2 deflection, n—the displacement of a beam from its original position by an applied force.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved May 1, 2017. Published August 2017. Originally approved in 2005. Last previous edition approved in 2010 as D6991 – 05 (2100). DOI:

10.1520/D6991-17.10.1520/D6991-17E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.2.1 Discussion—

The deflection of the beam is used to measure that force acting on the tip.

3.1.3 internal stress, n—a stress system within a solid that is not dependent on external forces.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D6991 − 17

4. Test Method

4.1 Internal stresses in coatings are determined by the cantilever method (Fig. 1). Substrate A in the shape of a rectangular

cantilever beam is clamped by its end B in a special fixture E. Coating (F) is applied to one side of the beam. Internal stresses occur

in the film when it is being cured (drying, cross-linking, etc.). When there is sufficient adhesion between the coating and the

substrate, the stresses bend the cantilever beam, forcing its free end D to be deflected from its original position by a distance of

h. The deflection of the beam is measured under an optical microscope and internal stress is calculated using the equation for the

cantilever method. See Eq 1 in Section 9, (Formula 1).

5. Significance and Use

5.1 Stresses in coatings arise as a result of their shrinkage or expansion if expected movements are prevented by coating

adhesion to its substrate.

5.2 There are several causes leading to arrival of stresses in the coatings: film formation (cro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.