ASTM C480/C480M-08(2015)

(Test Method)Standard Test Method for Flexure Creep of Sandwich Constructions

Standard Test Method for Flexure Creep of Sandwich Constructions

SIGNIFICANCE AND USE

5.1 The determination of the creep rate provides information on the behavior of sandwich constructions under constant applied force. Creep is defined as deflection under constant force over a period of time beyond the initial deformation as a result of the application of the force. Deflection data obtained from this test method can be plotted against time, and a creep rate determined. By using standard specimen constructions and constant loading, the test method may also be used to evaluate creep behavior of sandwich panel core-to-facing adhesives.

5.2 This test method provides a standard method of obtaining flexure creep of sandwich constructions for quality control, acceptance specification testing, and research and development.

5.3 Factors that influence the sandwich construction creep response and shall therefore be reported include the following: facing material, core material, adhesive material, methods of material fabrication, facing stacking sequence and overall thickness, core geometry (cell size), core density, core thickness, adhesive thickness, specimen geometry, specimen preparation, specimen conditioning, environment of testing, specimen alignment, loading procedure, speed of testing, facing void content, adhesive void content, and facing volume percent reinforcement. Further, facing and core-to-facing strength and creep response may be different between precured/bonded and co-cured facesheets of the same material.

SCOPE

1.1 This test method covers the determination of the creep characteristics and creep rate of flat sandwich constructions loaded in flexure, at any desired temperature. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C480/C480M − 08(Reapproved 2015)

Standard Test Method for

Flexure Creep of Sandwich Constructions

This standard is issued under the fixed designation C480/C480M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E6Terminology Relating to Methods of MechanicalTesting

E122PracticeforCalculatingSampleSizetoEstimate,With

1.1 This test method covers the determination of the creep

Specified Precision, the Average for a Characteristic of a

characteristics and creep rate of flat sandwich constructions

Lot or Process

loaded in flexure, at any desired temperature. Permissible core

E177Practice for Use of the Terms Precision and Bias in

material forms include those with continuous bonding surfaces

ASTM Test Methods

(such as balsa wood and foams) as well as those with

E456Terminology Relating to Quality and Statistics

discontinuous bonding surfaces (such as honeycomb).

E1309 Guide for Identification of Fiber-Reinforced

1.2 The values stated in either SI units or inch-pound units

Polymer-Matrix Composite Materials in Databases

are to be regarded separately as standard. Within the text the

E1434Guide for Recording Mechanical Test Data of Fiber-

inch-pound units are shown in brackets. The values stated in

Reinforced Composite Materials in Databases

eitherSIunitsorinch-poundunitsaretoberegardedseparately

as standard.The values stated in each system may not be exact

3. Terminology

equivalents;therefore,eachsystemshallbeusedindependently

3.1 Definitions—Terminology D3878 defines terms relating

of the other. Combining values from the two systems may

to high-modulus fibers and their composites. Terminology

result in non-conformance with the standard.

C274 defines terms relating to structural sandwich construc-

1.3 This standard does not purport to address all of the

tions. Terminology D883 defines terms relating to plastics.

safety concerns, if any, associated with its use. It is the

Terminology E6 defines terms relating to mechanical testing.

responsibility of the user of this standard to establish appro-

Terminology E456 and Practice E177 define terms relating to

priate safety and health practices and determine the applica-

statistics.Intheeventofaconflictbetweenterms,Terminology

bility of regulatory limitations prior to use.

D3878 shall have precedence over the other terminology

documents.

2. Referenced Documents

3.2 Symbols:

2.1 ASTM Standards:

3.2.1 A—distance between pivot point and point of applied

C274Terminology of Structural Sandwich Constructions

force on the specimen

C393/C393MTest Method for Core Shear Properties of

3.2.2 b—specimen width

Sandwich Constructions by Beam Flexure

D883Terminology Relating to Plastics 3.2.3 B—distancefrompivotpointtocenterofgravityofthe

D3878Terminology for Composite Materials

loading arm

D5229/D5229MTestMethodforMoistureAbsorptionProp-

3.2.4 c—core thickness

erties and Equilibrium Conditioning of Polymer Matrix

3.2.5 CR —creep rate at time, i

I i

Composite Materials

3.2.6 d—sandwich total thickness

D7249/D7249MTestMethodforFacingPropertiesofSand-

wich Constructions by Long Beam Flexure

3.2.7 d—initial static deflection under the same load and at

the same temperature

3.2.8 D—total deflection at time, t

This specification is under the jurisdiction of ASTM Committee D30 on

3.2.9 F—applied facing stress

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

f

Sandwich Construction.

3.2.10 F —applied core shear stress

s

Current edition approved July 1, 2015. Published August 2015. Originally

approved in 1961. Last previous edition approved in 2008 as C480/C480M–08.

3.2.11 M—distance between point and weight point

DOI: 10.1520/C0480_C0480M-08R15.

2 3.2.12 n—number of specimens

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.13 p—mass of loading plate and rod

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.2.14 P—applied force

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C480/C480M − 08 (2015)

3.2.15 S—length of support span 7. Apparatus

3.2.16 w—mass of lever arm

7.1 Micrometers and Calipers—Amicrometer having a flat

anvil interface, or a caliper of suitable size, shall be used. The

3.2.17 W—mass of weight (including tray mass)

instruments(s) shall have an accuracy of 625 µm [60.001 in.]

for thickness measurement, and an accuracy of 6250 µm

4. Summary of Test Method

[60.010 in.] for length and width measurements.

4.1 This test method consists of subjecting a beam of

NOTE 1—The accuracies given above are based on achieving measure-

sandwich construction to a sustained force normal to the plane

ments that are within1%ofthe sample length, width and thickness.

of the sandwich, using either a 3-point or a 4-point loading

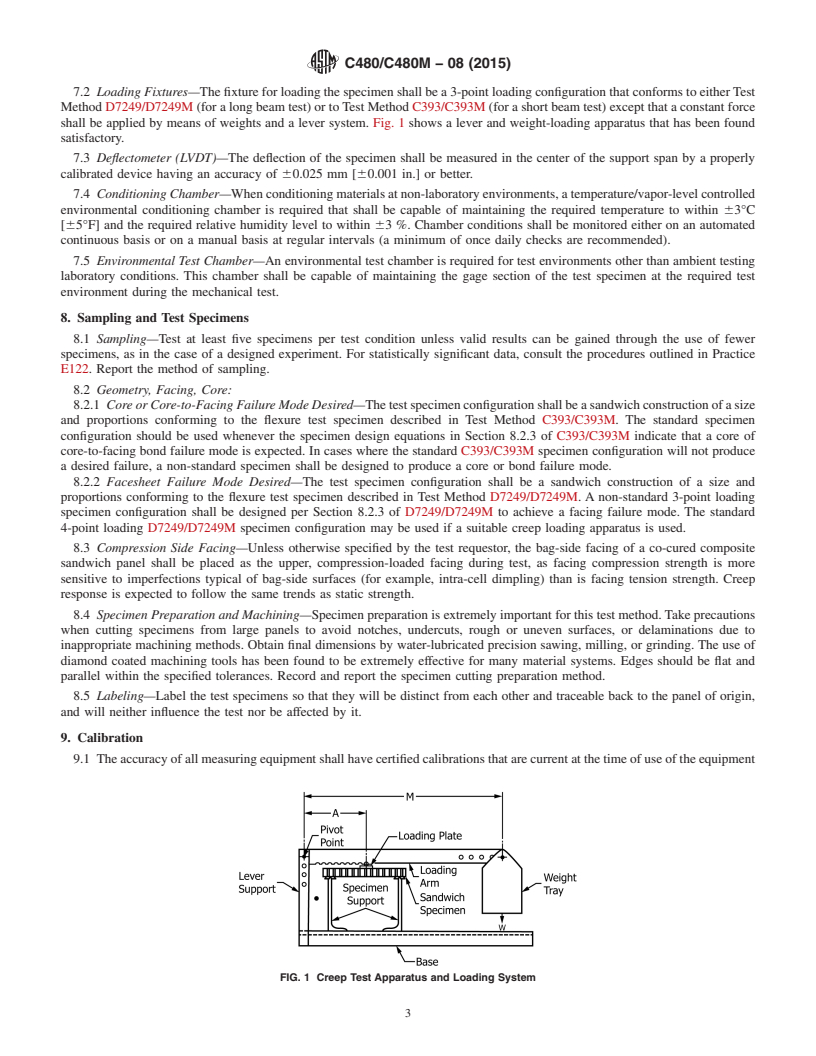

7.2 Loading Fixtures—The fixture for loading the specimen

fixture. Deflection versus time measurements are recorded.

shall be a 3-point loading configuration that conforms to either

Test Method D7249/D7249M (for a long beam test) or to Test

4.2 For long beam specimens conforming to Test Method

D7249/D7249M, the only acceptable failure modes for sand- Method C393/C393M (for a short beam test) except that a

constantforceshallbeappliedbymeansofweightsandalever

wich facesheet strength are those which are internal to one of

the facesheets. Failure of the sandwich core or the core-to- system.Fig.1showsaleverandweight-loadingapparatusthat

has been found satisfactory.

facesheetbondprecedingfailureofoneofthefacesheetsisnot

an acceptable failure mode for this specimen configuration.

7.3 Deflectometer (LVDT)—The deflection of the specimen

shall be measured in the center of the support span by a

4.3 For short-beam specimens conforming to Test Method

properly calibrated device having an accuracy of 60.025 mm

C393/C393M,theonlyacceptablefailuremodesarecoreshear

[60.001 in.] or better.

or core-to-facing bond. Failure of the sandwich facing preced-

ing failure of the core or core-to-facing bond is not an

7.4 Conditioning Chamber—When conditioning materials

acceptable failure mode for this specimen configuration.

at non-laboratory environments, a temperature/vapor-level

controlledenvironmentalconditioningchamberisrequiredthat

4.4 Careful post-test inspection of the specimen is required

shall be capable of maintaining the required temperature to

as facing failure occurring in proximity to the loading points

within 63°C [65°F] and the required relative humidity level

canbecausedbylocalthrough-thicknesscompressionorshear

to within 63 %. Chamber conditions shall be monitored either

failure of the core that precedes failure of the facing.

on an automated continuous basis or on a manual basis at

regular intervals (a minimum of once daily checks are recom-

5. Significance and Use

mended).

5.1 The determination of the creep rate provides informa-

7.5 Environmental Test Chamber—An environmental test

tion on the behavior of sandwich constructions under constant

chamber is required for test environments other than ambient

applied force. Creep is defined as deflection under constant

testing laboratory conditions.This chamber shall be capable of

force over a period of time beyond the initial deformation as a

maintaining the gage section of the test specimen at the

result of the application of the force. Deflection data obtained

required test environment during the mechanical test.

from this test method can be plotted against time, and a creep

ratedetermined.Byusingstandardspecimenconstructionsand

8. Sampling and Test Specimens

constant loading, the test method may also be used to evaluate

creep behavior of sandwich panel core-to-facing adhesives.

8.1 Sampling—Test at least five specimens per test condi-

tionunlessvalidresultscanbegainedthroughtheuseoffewer

5.2 This test method provides a standard method of obtain-

specimens, as in the case of a designed experiment. For

ingflexurecreepofsandwichconstructionsforqualitycontrol,

statistically significant data, consult the procedures outlined in

acceptance specification testing, and research and develop-

Practice E122. Report the method of sampling.

ment.

8.2 Geometry, Facing, Core:

5.3 Factors that influence the sandwich construction creep

response and shall therefore be reported include the following:

facing material, core material, adhesive material, methods of

material fabrication, facing stacking sequence and overall

thickness, core geometry (cell size), core density, core

thickness, adhesive thickness, specimen geometry, specimen

preparation, specimen conditioning, environment of testing,

specimen alignment, loading procedure, speed of testing,

facing void content, adhesive void content, and facing volume

percent reinforcement. Further, facing and core-to-facing

strength and creep response may be different between

precured/bondedandco-curedfacesheetsofthesamematerial.

6. Interferences

6.1 The interferences listed in Test Methods C393/C393M

and D7249/D7249M are also applicable to this test method. FIG. 1 Creep Test Apparatus and Loading System

C480/C480M − 08 (2015)

includes not only the vapor of a liquid and its condensate, but the liquid

8.2.1 Core or Core-to-Facing Failure Mode Desired—The

itself in large quantities, as for immersion.

testspecimenconfigurationshallbeasandwichconstructionof

a size and proportions conforming to the flexure test specimen 10.3 If no explicit conditioning process is performed, the

described in Test Method C393/C393M. The standard speci- specimen conditioning process shall be reported as “uncondi-

men configuration should be used whenever the specimen tioned” and the moisture content as “unknown”.

designequationsinSection8.2.3ofC393/C393Mindicatethat

11. Procedure

acoreofcore-to-facingbondfailuremodeisexpected.Incases

where the standard C393/C393M specimen configuration will

11.1 Parameters to Be Specified Before Test:

notproduceadesiredfailure,anon-standardspecimenshallbe

11.1.1 The specimen sampling method, specimen geometry,

designed to produce a core or bond failure mode.

and conditioning travelers (if required).

8.2.2 Facesheet Failure Mode Desired—The test specimen

11.1.2 Theloadingfixturesupportspan(andloadingspanif

configuration shall be a sandwich construction of a size and

a 4-point loading configuration is used).

proportions conforming to the flexure test specimen described

11.1.3 The force, P, to be applied to the specimen and the

in Test Method D7249/D7249M.Anon-standard 3-point load-

maximum time for the test.

ing specimen configuration shall be designed per Section 8.2.3

11.1.4 The properties and data reporting format desired.

of D7249/D7249M to achieve a facing failure mode. The

11.1.5 The environmental conditioning test parameters.

standard 4-point loading D7249/D7249M specimen configura-

11.1.6 The nominal thicknesses of the facing materials.

tion may be used if a suitable creep loading apparatus is used.

NOTE 3—Determine specific material property, accuracy, and data

8.3 Compression Side Facing—Unless otherwise specified

reportingrequirementspriortotestforproperselectionofinstrumentation

and data recording equipment. Estimate the maximum specimen deflec-

by the test requestor, the bag-side facing of a co-cured

tion to aid in transducer selection, calibration of equipment, and determi-

composite sandwich panel shall be placed as the upper,

nation of equipment settings.

compression-loaded facing during test, as facing compression

11.2 General Instructions:

strength is more sensitive to imperfections typical of bag-side

11.2.1 Reportanydeviationsfromthistestmethod,whether

surfaces (for example, intra-cell dimpling) than is facing

intentional or inadvertent.

tensionstrength.Creepresponseisexpectedtofollowthesame

11.2.2 Conditionthespecimensasrequired.Storethespeci-

trends as static strength.

mens in the conditioned environment until test time, if the test

8.4 Specimen Preparation and Machining—Specimen

environment is different than the conditioning environment.

preparation is extremely important for this test method. Take

11.2.3 Before testing, measure and record the specimen

precautionswhencuttingspecimensfromlargepanelstoavoid

length, width and thickness at three places in the test section.

notches,undercuts,roughorunevensurfaces,ordelaminations

Measure the specimen length and width with an accuracy of

due to inappropriate machining methods. Obtain final dimen-

6250 µm [60.010 in.]. Measure the specimen thickness with

sions by water-lubricated precision sawing, milling, or grind-

anaccuracyof 625µm[60.001in.].Recordthedimensionsto

ing. The use of diamond coated machining tools has been

three significant figures in units of millimeters [inches].

found to be extremely effective for many material systems.

11.3 Measure and record the length of the support and

Edges should be flat and parallel within the specified toler-

loading spans.

ances. Record and report the specimen cutting preparation

method.

11.4 The weight required to apply the specified force to the

specimen by the 3-point loading lever system shown in Fig. 1

8.5 Labeling—Label the test specimens so that they will be

may be calculated as follows:

distinct from each other and traceable back to the panel of

origin, and will neither influence the test nor be affected by it.

~P 2 p! A 2 wB

W 5 (1)

M

9. Calibration

where:

9.1 The accuracy of all measuring equipment shall have

W = mass of weight (including tray mass), N [lb],

certified calibrations that are current at the time of use of the

P = force applied to specimen, N [lb],

equipment

p = mass of loading plate and rod, N [lb],

w = mass of lever arm, N [lb],

10. Conditioning

A = distance between pivot point and point of applied force

10.1 The recommended pre-test specimen condition is ef- on the specimen, mm [in.].

fective moisture equilibrium at a specific relative humidity per B = distance from pivot point to center of gravity of the

loading arm, mm [in.], and

D5229/D5229M; however, if the test requestor does not

M = distance between pivot point and weight point, mm,

explicitly specify a pre-test conditioning environment, condi-

tioning is not required and the test specimens may be tested as

11.5 Test Environment—If possible, test the specimen under

prepared.

the same fluid exposure level used for conditioning. However,

cases such as elevated temperature testing of a moist specimen

10.2 The pre-test specimen conditioning process, to include

place unrealistic requirements

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C480/C480M − 08 C480/C480M − 08 (Reapproved 2015)

Standard Test Method for

Flexure Creep of Sandwich Constructions

This standard is issued under the fixed designation C480/C480M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the creep characteristics and creep rate of flat sandwich constructions loaded

in flexure, at any desired temperature. Permissible core material forms include those with continuous bonding surfaces (such as

balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the

inch-pound units are shown in brackets. The values stated in either SI units or inch-pound units are to be regarded separately as

standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of

the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C274 Terminology of Structural Sandwich Constructions

C393/C393M Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

D7249/D7249M Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure

E6 Terminology Relating to Methods of Mechanical Testing

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E1309 Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials in Databases

E1434 Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to high-modulus fibers and their composites. Terminology C274

defines terms relating to structural sandwich constructions. Terminology D883 defines terms relating to plastics. Terminology E6

defines terms relating to mechanical testing. Terminology E456 and Practice E177 define terms relating to statistics. In the event

of a conflict between terms, Terminology D3878 shall have precedence over the other terminology documents.

3.2 Symbols:

3.2.1 A—distance between pivot point and point of applied force on the specimen

3.2.2 b—specimen width

This specification is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.09 on Sandwich

Construction.

Current edition approved Sept. 1, 2008July 1, 2015. Published October 2008 August 2015. Originally approved in 1961. Last previous edition approved in 20052008 as

C480 – 99C480/C480M – 08.(2005). DOI: 10.1520/C0480_C0480M-08.10.1520/C0480_C0480M-08R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C480/C480M − 08 (2015)

3.2.3 B—distance from pivot point to center of gravity of the loading arm

3.2.4 c—core thickness

3.2.5 CR —creep rate at time, i

I i

3.2.6 d—sandwich total thickness

3.2.7 d—initial static deflection under the same load and at the same temperature

3.2.8 D—total deflection at time, t

3.2.9 F —applied facing stress

f

3.2.10 F —applied core shear stress

s

3.2.11 M—distance between point and weight point

3.2.12 n—number of specimens

3.2.13 p—mass of loading plate and rod

3.2.14 P—applied force

3.2.15 S—length of support span

3.2.16 w—mass of lever arm

3.2.17 W—mass of weight (including tray mass)

4. Summary of Test Method

4.1 This test method consists of subjecting a beam of sandwich construction to a sustained force normal to the plane of the

sandwich, using either a 3-point or a 4-point loading fixture. Deflection versus time measurements are recorded.

4.2 For long beam specimens conforming to Test Method D7249/D7249M, the only acceptable failure modes for sandwich

facesheet strength are those which are internal to one of the facesheets. Failure of the sandwich core or the core-to-facesheet bond

preceding failure of one of the facesheets is not an acceptable failure mode for this specimen configuration.

4.3 For short-beam specimens conforming to Test Method C393/C393M, the only acceptable failure modes are core shear or

core-to-facing bond. Failure of the sandwich facing preceding failure of the core or core-to-facing bond is not an acceptable failure

mode for this specimen configuration.

4.4 Careful post-test inspection of the specimen is required as facing failure occurring in proximity to the loading points can

be caused by local through-thickness compression or shear failure of the core that precedes failure of the facing.

5. Significance and Use

5.1 The determination of the creep rate provides information on the behavior of sandwich constructions under constant applied

force. Creep is defined as deflection under constant force over a period of time beyond the initial deformation as a result of the

application of the force. Deflection data obtained from this test method can be plotted against time, and a creep rate determined.

By using standard specimen constructions and constant loading, the test method may also be used to evaluate creep behavior of

sandwich panel core-to-facing adhesives.

5.2 This test method provides a standard method of obtaining flexure creep of sandwich constructions for quality control,

acceptance specification testing, and research and development.

5.3 Factors that influence the sandwich construction creep response and shall therefore be reported include the following: facing

material, core material, adhesive material, methods of material fabrication, facing stacking sequence and overall thickness, core

geometry (cell size), core density, core thickness, adhesive thickness, specimen geometry, specimen preparation, specimen

conditioning, environment of testing, specimen alignment, loading procedure, speed of testing, facing void content, adhesive void

content, and facing volume percent reinforcement. Further, facing and core-to-facing strength and creep response may be different

between precured/bonded and co-cured facesheets of the same material.

6. Interferences

6.1 The interferences listed in Test Methods C393/C393M and D7249/D7249M are also applicable to this test method.

7. Apparatus

7.1 Micrometers and Calipers—A micrometer having a flat anvil interface, or a caliper of suitable size, shall be used. The

instruments(s) shall have an accuracy of 625 μm [60.001 in.] for thickness measurement, and an accuracy of 6250 μm [60.010

in.] for length and width measurements.

NOTE 1—The accuracies given above are based on achieving measurements that are within 1 % of the sample length, width and thickness.

C480/C480M − 08 (2015)

7.2 Loading Fixtures—The fixture for loading the specimen shall be a 3-point loading configuration that conforms to either Test

Method D7249/D7249M (for a long beam test) or to Test Method C393/C393M (for a short beam test) except that a constant force

shall be applied by means of weights and a lever system. Fig. 1 shows a lever and weight-loading apparatus that has been found

satisfactory.

7.3 Deflectometer (LVDT)—The deflection of the specimen shall be measured in the center of the support span by a properly

calibrated device having an accuracy of 60.025 mm [60.001 in.] or better.

7.4 Conditioning Chamber—When conditioning materials at non-laboratory environments, a temperature/vapor-level controlled

environmental conditioning chamber is required that shall be capable of maintaining the required temperature to within 63°C

[65°F] and the required relative humidity level to within 63 %. Chamber conditions shall be monitored either on an automated

continuous basis or on a manual basis at regular intervals (a minimum of once daily checks are recommended).

7.5 Environmental Test Chamber—An environmental test chamber is required for test environments other than ambient testing

laboratory conditions. This chamber shall be capable of maintaining the gage section of the test specimen at the required test

environment during the mechanical test.

8. Sampling and Test Specimens

8.1 Sampling—Test at least five specimens per test condition unless valid results can be gained through the use of fewer

specimens, as in the case of a designed experiment. For statistically significant data, consult the procedures outlined in Practice

E122. Report the method of sampling.

8.2 Geometry, Facing, Core:

8.2.1 Core or Core-to-Facing Failure Mode Desired—The test specimen configuration shall be a sandwich construction of a size

and proportions conforming to the flexure test specimen described in Test Method C393/C393M. The standard specimen

configuration should be used whenever the specimen design equations in Section 8.2.3 of C393/C393M indicate that a core of

core-to-facing bond failure mode is expected. In cases where the standard C393/C393M specimen configuration will not produce

a desired failure, a non-standard specimen shall be designed to produce a core or bond failure mode.

8.2.2 Facesheet Failure Mode Desired—The test specimen configuration shall be a sandwich construction of a size and

proportions conforming to the flexure test specimen described in Test Method D7249/D7249M. A non-standard 3-point loading

specimen configuration shall be designed per Section 8.2.3 of D7249/D7249M to achieve a facing failure mode. The standard

4-point loading D7249/D7249M specimen configuration may be used if a suitable creep loading apparatus is used.

8.3 Compression Side Facing—Unless otherwise specified by the test requestor, the bag-side facing of a co-cured composite

sandwich panel shall be placed as the upper, compression-loaded facing during test, as facing compression strength is more

sensitive to imperfections typical of bag-side surfaces (for example, intra-cell dimpling) than is facing tension strength. Creep

response is expected to follow the same trends as static strength.

8.4 Specimen Preparation and Machining—Specimen preparation is extremely important for this test method. Take precautions

when cutting specimens from large panels to avoid notches, undercuts, rough or uneven surfaces, or delaminations due to

inappropriate machining methods. Obtain final dimensions by water-lubricated precision sawing, milling, or grinding. The use of

diamond coated machining tools has been found to be extremely effective for many material systems. Edges should be flat and

parallel within the specified tolerances. Record and report the specimen cutting preparation method.

8.5 Labeling—Label the test specimens so that they will be distinct from each other and traceable back to the panel of origin,

and will neither influence the test nor be affected by it.

9. Calibration

9.1 The accuracy of all measuring equipment shall have certified calibrations that are current at the time of use of the equipment

FIG. 1 Creep Test Apparatus and Loading System

C480/C480M − 08 (2015)

10. Conditioning

10.1 The recommended pre-test specimen condition is effective moisture equilibrium at a specific relative humidity per

D5229/D5229M; however, if the test requestor does not explicitly specify a pre-test conditioning environment, conditioning is not

required and the test specimens may be tested as prepared.

10.2 The pre-test specimen conditioning process, to include specified environmental exposure levels and resulting moisture

content, shall be reported with the test data.

NOTE 2—The term moisture, as used in Test Method D5229/D5229M, includes not only the vapor of a liquid and its condensate, but the liquid itself

in large quantities, as for immersion.

10.3 If no explicit conditioning process is performed, the specimen conditioning process shall be reported as “unconditioned”

and the moisture content as “unknown”.

11. Procedure

11.1 Parameters to Be Specified Before Test:

11.1.1 The specimen sampling method, specimen geometry, and conditioning travelers (if required).

11.1.2 The loading fixture support span (and loading span if a 4-point loading configuration is used).

11.1.3 The force, P, to be applied to the specimen and the maximum time for the test.

11.1.4 The properties and data reporting format desired.

11.1.5 The environmental conditioning test parameters.

11.1.6 The nominal thicknesses of the facing materials.

NOTE 3—Determine specific material property, accuracy, and data reporting requirements prior to test for proper selection of instrumentation and data

recording equipment. Estimate the maximum specimen deflection to aid in transducer selection, calibration of equipment, and determination of equipment

settings.

11.2 General Instructions:

11.2.1 Report any deviations from this test method, whether intentional or inadvertent.

11.2.2 Condition the specimens as required. Store the specimens in the conditioned environment until test time, if the test

environment is different than the conditioning environment.

11.2.3 Before testing, measure and record the specimen length, width and thickness at three places in the test section. Measure

the specimen length and width with an accuracy of 6250 μm [60.010 in.]. Measure the specimen thickness with an accuracy of

625 μm [60.001 in.]. Record the dimensions to three significant figures in units of millimeters [inches].

11.3 Measure and record

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.