ASTM C1172-96e1

(Specification)Standard Specification for Laminated Architectural Flat Glass

Standard Specification for Laminated Architectural Flat Glass

SCOPE

1.1 This specification covers the quality requirements for cut sizes of flat laminated glass consisting of two or more lites of glass bonded with an interlayer material for use in building glazing.

1.2 Depending on the number, thickness and treatment of plies, and the number and thickness of interlayers, the glass shall be laminated safety glass, laminated security glass or laminated bullet resistant glass.

1.3 The dimensional values, except thickness designations, stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 1172 – 96

Standard Specification for

Laminated Architectural Flat Glass

This standard is issued under the fixed designation C 1172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made in Section 4 in August 1996.

1. Scope Performance Specifications and Methods of Tests

2.4 Federal Document:

1.1 This specification covers the quality requirements for

CPSC 16CFR1201 Consumer Product Safety Commission

cut sizes of flat laminated glass consisting of two or more lites

Safety Standard for Architectural Glazing Materials

of glass bonded with an interlayer material for use in building

glazing.

3. Terminology

1.2 Depending on the number, thickness and treatment of

3.1 Definitions—Refer to Terminology C 162, Specifica-

plies, and the number and thickness of interlayers, the glass

tions C 1036 or C 1048, as appropriate.

shall be laminated safety glass, laminated security glass or

3.1.1 blemishes in flat glass—Refer to Specifications

laminated bullet resistant glass.

C 1036 or C 1048, as appropriate.

1.3 The dimensional values, except thickness designations,

3.2 Definitions of Terms Specific to This Standard:

stated in inch-pound units are to be regarded as the standard.

3.2.1 adhesion chips—See fuse.

The values given in parenthesis are for information only.

3.2.2 blow-in—a separation of glass and interlayer at or

1.4 The following safety hazards caveat pertains only to the

close to the laminate edge caused by penetration of the

test method portion, Section 8, of this specification. This

autoclaving medium into the edge during manufacturing.

standard does not purport to address all of the safety concerns,

3.2.3 boil (bubble)—a gas pocket in the interlayer material

if any, associated with its use. It is the responsibility of the user

or between the glass and interlayer.

of this standard to establish appropriate safety and health

3.2.4 covered edge—the perimetric area of the laminate

practices and determine the applicability of regulatory limita-

covered by the channel or sash when installed.

tions prior to use.

3.2.5 decorative glass—glass with an ornamental appear-

2. Referenced Documents ance created by a textured glass surface (patterned glass),

design printed interlayer, application of decal(s) to the glass or

2.1 Reference to these documents shall be the latest revision

interlayer, or other embellishments performed on or to the glass

unless otherwise specified by the authority applying this

or interlayer material to give the glass an ornamental appear-

specification.

ance.

2.2 ASTM Standards:

3.2.6 delamination—a condition in which one or two of the

C 162 Terminology of Glass and Glass Products

2 lites of glass loses the bond between the glass lite and the

C 1036 Specification for Flat Glass

interlayer.

C 1048 Specification for Heat-Treated Flat Glass—Kind

2 3.2.7 discoloration—areas of the interlayer that are blushed

HS, Kind FT Coated and Uncoated Glass

or whitish in appearance indicating excessive moisture content

E 308 Practice for Computing the Colors of Objects by

3 in the interlayer and consequently poor or no adhesion.

Using the CIE System

3.2.8 edge boil—see boil.

2.3 ANSI Standard:

3.2.9 edge cover—See covered edge.

Z97.1 Safety Glazing Materials Used in Buildings—Safety

3.2.10 exposed edge—the perimetric area of the laminate

exposed to the environment after installation.

3.2.11 fuse—a glass particle or crystalline material that is

This specification is under the jurisdiction of ASTM Committee C–14 on Glass

permanently bonded to a surface of a lite.

and Glass Productsand is the direct responsibility of Subcommittee C14.08on Flat

3.2.12 glass edge bite—See covered edge.

Glass.

Current edition approved June 10, 1996. Published August 1996. Originally

published as C 1172 – 91. Last previous edition C 1172 – 91.

2 4

Annual Book of ASTM Standards, Vol 15.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 06.01. Floor, New York, NY 10036.

Available from Superintendent of Documents, U.S. Government Printing

Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1172

3.2.13 hair—a slender, pigmented filament from human or to laminate during the laminating process. This blemish is

animal epidermis or other thread-like filament. discernible due to the textured appearance of the interlayer

3.2.14 inside dirt—foreign material trapped inside the lami- material.

nate.

4. Classification

3.2.15 interlayer—a layer of material acting as an adhesive

4.1 Kinds—Laminated flat glass furnished under this speci-

between plies of glass which adds additional performance to

fication shall be of the following kinds, as specified:

the finished product, for example, impact resistance, solar

4.1.1 Kind LA—Two or more lites of flat annealed transpar-

control, acoustical insulation.

ent glass conforming to the applicable requirements of Speci-

3.2.16 interlayer scuff—See dirt streak.

fication C 1036 and bonded by an interlayer material.

3.2.17 laminate—See laminated glass.

4.1.2 Kind LC—Two or more lites of flat glass, one or more

3.2.18 laminated bullet resistant glass—multiple lites of flat

of which are chemically strengthened glass bonded by an

glass, bonded by interlayer material, that resist penetration

interlayer material.

from medium- to super-power arms and high-power rifles.

4.1.3 Kind LD—Two or more lites of flat glass, one or more

3.2.19 laminated glass—an assembly consisting of two or

of which are decorative glass, conforming to the applicable

more lites of glass, conforming to Specification C 1036 or

requirements of Specifications C 1036 and C 1048 (if one or

C 1048 that are bonded together by interlayer material.

more of the lites are tempered or heat-strengthened glass) and

3.2.20 laminated safety glass—two or more lites of flat

bonded by an interlayer material.

glass, bonded by interlayer material. In the case of breakage,

4.1.4 Kind LHS—Two or more lites of flat glass, all of

the interlayer serves to retain the glass fragments, limit the size

which are heat-strengthened glass conforming to the applicable

of the opening and reduce the risk of cutting or piercing

requirements of Specification C 1048 and bonded by an inter-

injuries.

layer material.

3.2.21 laminated security glass—two or more lites of flat

4.1.5 Kind LM—Two or more lites of flat glass, one or more

glass, bonded by interlayer material, that resist manual pen-

of which are mirror glass conforming to the applicable require-

etration, including physical attack from hand-held or hand-

ments of Specifications C 1036 and C 1048 (if one or more of

thrown objects.

the lites are tempered or heat-strengthened glass) and bonded

3.2.22 lint—short fibers of yarn or fabric trapped within the

by an interlayer material.

laminate.

4.1.6 Kind LP—Two or more lites of flat glass, one or more

3.2.23 lite or light—a panel or sheet of glass or a panel or

of which are pattern glass conforming to the applicable

sheet of laminated glass.

requirements of Specifications C 1036 and C 1048 (if one or

3.2.24 mismatch—misalignment of the edges of two lites of

more of the lites are tempered or heat-strengthened glass) and

glass, when laminated.

bonded by an interlayer material.

3.2.25 nonsymmetrical—a term used to describe the con-

4.1.7 Kind LR—Two or more lites of flat glass, one or more

struction of a laminate comprised of different glass types or

of which are reflective glass, conforming to the applicable

thickness, or both.

requirements of Specifications C 1036 and C 1048 (if one or

3.2.26 offset—intentional mismatch (see mismatch).

more of the lites are tempered or heat-strengthened glass) and

3.2.27 ply—one sheet or panel of glass in a laminate.

bonded by an interlayer material.

3.2.28 separation—an area of the laminate that has become

4.1.8 Kind LSP—Two or more lites of flat glass, one or

delaminated (see delamination).

more of which are spandrel glass, conforming to the applicable

3.2.29 shiner—an area on a glass edge that has not been

requirements of Specifications C 1036 and C 1048 (if one or

ground or polished.

more of the lites are tempered or heat-strengthened glass) and

3.2.30 short interlayer—a condition of the laminate in

bonded by an interlayer material.

which the interlayer does not extend to the edge.

4.1.9 Kind LT—Two or more lites of flat glass, all of which

3.2.31 slippage—See mismatch.

are fully tempered glass conforming to the applicable require-

3.2.32 streak—a defect in interlayer caused by interlayer

ments of Specification C 1048 and bonded by an interlayer

inhomogeneity or a smudging effect on the interlayer of the

material.

laminate.

4.1.10 Kind LW—Two or more lites of flat glass, one or

3.2.33 surfaces—surfaces of glass faces are counted as Nos.

more of which are wired glass, conforming to the applicable

1, 2, 3, and 4, respectively. The No. 1 surface is the surface that

requirements of Specification C 1036 and bonded by an inter-

is to the exterior; the Nos. 2 and 3 surfaces are those separated

layer material.

by and bonded to the interlayer material; the No. 4 surface is

4.1.11 Kind LX—Laminated glass with combinations not

the surface that is to the interior.

previously defined.

3.2.34 symmetrical—a term used to describe the construc-

5. Ordering Information

tion of a laminate comprised of only one glass type and

thickness.

5.1 Purchasers should select the preferred options permitted

3.2.35 template—a pattern used as a guide to define the

in this specification and include the following information in

overall size and shape of a cut lite.

procurement documents:

3.2.36 two-ply flat glass (laminates)—See laminated glass. 5.1.1 Title, number, and date of this specification.

3.2.37 unlaminated area—an area of the laminate that failed 5.1.2 Kind of laminated flat glass as referred to in this

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1172

specification (see Section 4). 6.5 Luminous transmittance shall be as specified (see 7.5).

5.1.3 Edgework requirements (see 8.2). 6.6 Laminates specified for safety glazing shall meet the

5.1.4 Thickness requirements: requirements of the specified safety glazing standards (see 7.1).

5.1.4.1 Thickness designation of each individual ply of

7. Test Methods

glass to be used in the laminate,

7.1 Impact Test for Safety Glazing—Test and interpret in

5.1.4.2 Interlayer type and thickness designation, and

accordance with ANSI Z97.1 or CPSC 16CFR1201, or both, as

5.1.4.3 Overall nominal thickness of the laminate.

applicable.

5.1.5 Nominal length and width of the laminate.

7.2 Overall Bow and Warp—Place sample glass in a free-

5.1.5.1 Blueprint, drawing, template, configuration specifi-

standing vertical position, with the longest edge resting on

cation, or other forms of information which detail overall size,

blocks at the quarter points. With the laminate in this position,

configuration, and orientation.

place a straightedge across the concave surface, parallel to and

5.1.6 Classification of each individual lite of raw glass to be

within 1 in. (25.4 mm) of the edge, and measure the maximum

used in the laminate, in accordance with the Classification and

deviation with a taper or feeler gage. A dial indicator may also

Intended Use section of Specification C 1036.

be used.

5.1.6.1 Color or tint of each individual lite of raw glass.

7.3 Size—Measure length and width from edge to edge,

5.1.7 Color or tint of the interlayer.

including flares, mismatch, or offset (see 8.5).

5.1.7.1 A combination of different tints of interlayer is

7.4 Visual Inspection—Place the specimen in a vertical

possible, however, certain visual blemishes may result. (Con-

position. The viewer shall look through the specimen, using

sult the supplier(s) before specifying.)

daylight without direct sunlight, or using a background light

5.1.8 The luminous transmittance of the laminate (see 6.5).

suitable for observing the blemishes. View at 36 in. (914 mm)

5.1.9 Safety standards or regulations to which the laminate

except where otherwise specified in Table 1.

must conform (see 6.6).

7.5 Transmittance—Using Practice E 308, measure trans-

5.1.10 All other standards to which the laminate must

mittance by illuminating each laminated specimen at normal

conform.

incidence with light having the spectral composition of Inter-

5.2 Packaging Requirements—Glass packaging and protec-

national Commission on Illumination (CIE) illuminate C.

tion will be standard manufacturer practice unless otherwise

Measure the ratio of transmittance to incident luminous flux by

specified. Consult manufacturer before specifying.

calculating from the spectral distribution of illuminate C as

6. Other Requirements

defined by Practice E 308.

6.1 Heat strengthened or fully tempered glass plies shall

8. Fabrication Requirements

conform to the requirements of Specification C 1048 for the

incorporated glass type. 8.1 All dimensional fabrication, such as cutting to overall

6.2 Annealed glass plies shall conform to the requirements dimensions, edgework, drilling, notching, grinding, sandblast-

of Specification C 1036 for the incorporated glass type. ing and etching, on laminates incorporating heat-strengthened,

6.3 Consult laminator for specifications for chemically chemically strengthened, or fully tempered glass shall be

strengthened glass plies. performed prior to strengthening or tempering. After the glass

6.4 Spandrel glass plies shall conform to the requirements has been strengthened or tempered, it shall not be modified

of Specification C 1048 for the incorporated glass type. except as recommended by the fabricator.

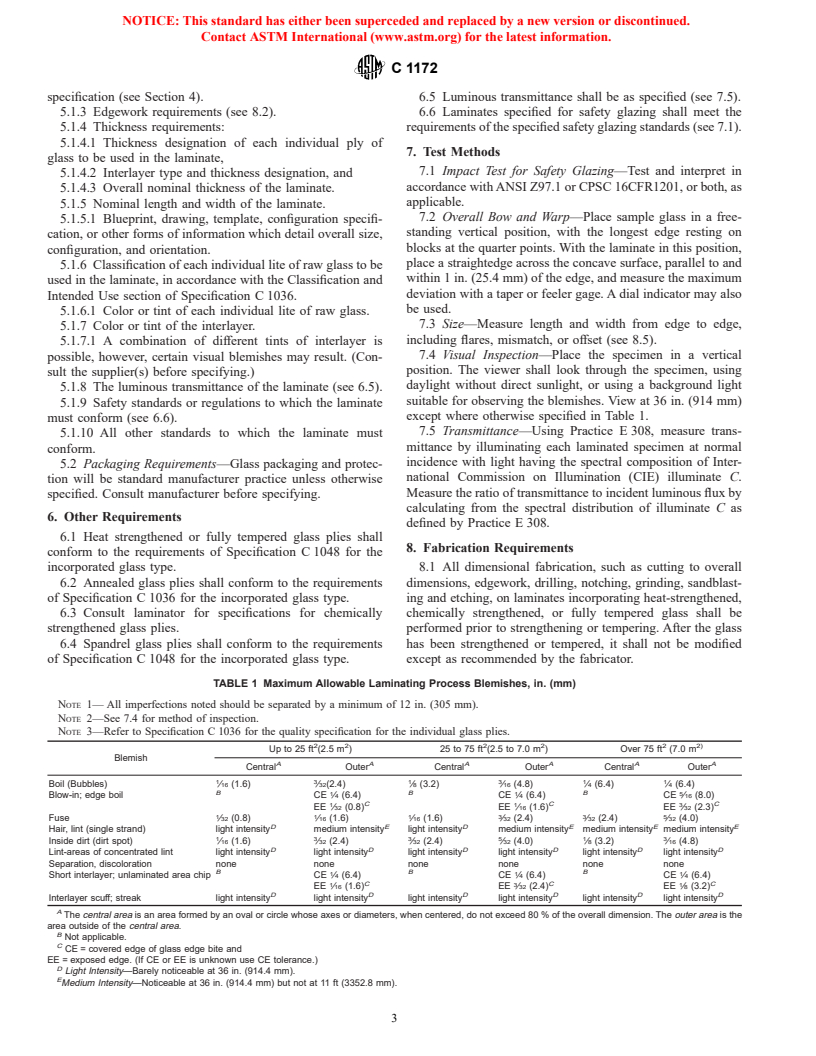

TABLE 1 Maximum Allowable Laminating Process Blemishes, in. (mm)

NOTE 1— All imperfections noted should be separated by a minimum of 12 in. (305 mm).

NOTE 2—See 7.4 for method of inspection.

NOTE 3—Refer to Specification C 1036 for the quality specification for the individual glass plies.

2 2 2 2 2 2)

Up to 25 ft (2.5 m ) 25to75ft (2.5 to 7.0 m ) Over 75 ft (7.0 m

Blemish

A A A A A A

Central Outer Central Outer Central Outer

1 3 1 3 1 1

Boil (Bubbles) ⁄16 (1.6) ⁄32(2.4) ⁄8 (3.2) ⁄16 (4.8) ⁄4 (6.4) ⁄4 (6.4)

B 1 B 1 B 5

Blow-in; edge boil C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.