ASTM A769/A769M-17(2023)

(Specification)Standard Specification for Carbon and High-Strength Electric Resistance Forge-Welded Steel Structural Shapes

Standard Specification for Carbon and High-Strength Electric Resistance Forge-Welded Steel Structural Shapes

ABSTRACT

This specification covers carbon and high-strength steel shapes of structural quality manufactured by the electric resistance forge-welding process from coils. The specimens shall be established by the steel supplier, shape manufacturer, and shape purchaser of the materials. Specimens shall conform to the required chemical compositions of carbon, manganese, phosphorus, sulfur and silicon. Specimens shall undergo tension tests, peel tests and tee tension tests and shall conform to the required values of tensile strength, yield point, and elongation.

SCOPE

1.1 This specification covers carbon and high-strength steel shapes of structural quality manufactured by the electric-resistance forge-welding process from coils.

1.2 The size range covered is described in nominal dimensions for columns, beams, and tees.

Size Range, in. (mm)

Web thickness

0.060 to 0.500 [1.5 to 12.7]

Flange thickness

0.060 to 0.500 [1.5 to 12.7]

Overall depth

2.00 to 24.00 [50 to 600]

Flange width

0.50 to 12.00 [12.7 to 300]

1.3 These shapes are intended for two classes of application:

1.3.1 Class 1—General structural use where static loading predominates.

1.3.2 Class 2—Structural use where fatigue loading occurs and is a principal design consideration.

Note 1: Caution—Because of the absence of smooth, integral, large radius fillets at the junctions of the webs and the flanges (see Fig. 1), fatigue limits of resistance forge-welded shapes in torsion, lateral loading, and flexure are usually lower than those for hot-rolled shapes of similar size and material. Users should consult shape manufacturers for recommended values of fatigue limits for each specific use, material, and size in cases where dynamic loading is a principal design consideration.

FIG. 1 Appearance of Peel Test Criteria

1.4 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A769/A769M − 17 (Reapproved 2023)

Standard Specification for

Carbon and High-Strength Electric Resistance Forge-

Welded Steel Structural Shapes

This standard is issued under the fixed designation A769/A769M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

1.1 This specification covers carbon and high-strength steel

of this standard to establish appropriate safety, health, and

shapes of structural quality manufactured by the electric-

environmental practices and determine the applicability of

resistance forge-welding process from coils.

regulatory limitations prior to use.

1.2 The size range covered is described in nominal dimen-

1.7 This international standard was developed in accor-

sions for columns, beams, and tees.

dance with internationally recognized principles on standard-

Size Range, in. (mm)

ization established in the Decision on Principles for the

Web thickness 0.060 to 0.500 [1.5 to 12.7]

Development of International Standards, Guides and Recom-

Flange thickness 0.060 to 0.500 [1.5 to 12.7]

mendations issued by the World Trade Organization Technical

Overall depth 2.00 to 24.00 [50 to 600]

Flange width 0.50 to 12.00 [12.7 to 300]

Barriers to Trade (TBT) Committee.

1.3 These shapes are intended for two classes of application:

2. Referenced Documents

1.3.1 Class 1—General structural use where static loading

predominates.

2.1 ASTM Standards:

1.3.2 Class 2—Structural use where fatigue loading occurs

A6/A6M Specification for General Requirements for Rolled

and is a principal design consideration.

Structural Steel Bars, Plates, Shapes, and Sheet Piling

A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

NOTE 1—Caution—Because of the absence of smooth, integral, large

A568/A568M Specification for Steel, Sheet, Carbon,

radius fillets at the junctions of the webs and the flanges (see Fig. 1),

fatigue limits of resistance forge-welded shapes in torsion, lateral loading, Structural, and High-Strength, Low-Alloy, Hot-Rolled and

and flexure are usually lower than those for hot-rolled shapes of similar

Cold-Rolled, General Requirements for

size and material. Users should consult shape manufacturers for recom-

A635/A635M Specification for Steel, Sheet and Strip,

mended values of fatigue limits for each specific use, material, and size in

Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon,

cases where dynamic loading is a principal design consideration.

Structural, High-Strength Low-Alloy, and High-Strength

1.4 When the steel is to be welded, it is presupposed that a

Low-Alloy with Improved Formability, General Require-

welding procedure suitable for the grade of steel and intended

ments for

use or service will be utilized. See Appendix X3 of Specifica-

A700 Guide for Packaging, Marking, and Loading Methods

tion A6/A6M for information on weldability.

for Steel Products for Shipment

1.5 The values stated in either SI units or inch-pound units

2.2 American Welding Society Standard:

are to be regarded separately as standard. The values stated in

AWS Specification D 1.1 Structural Welding Code

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining 3. Ordering Information

values from the two systems may result in non-conformance

3.1 Orders for material under this specification should

with the standard.

include the following, as required, to describe the desired

1.6 The following safety hazards caveat pertains only to the material adequately:

test methods portion, Section 10, of this specification: This

3.1.1 Quantity (total number of feet (metres) or lengths),

1 2

This specification is under the jurisdiction of ASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock and Ships. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2023. Published June 2023. Originally the ASTM website.

approved in 1979. Last previous edition approved in 2017 as A769/A769M – 17. Available from American Welding Society (AWS), 8669 NW 36 St., #130,

DOI: 10.1520/A0769_A0769M-17R23. Miami, FL 33166-6672, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A769/A769M − 17 (2023)

FIG. 1 Appearance of Peel Test Criteria

A

TABLE 1 Chemical Requirements

3.2 ASTM designation and year of issue, grade, and class,

General Limitations, %

3.3 Shape and size,

Carbon 0.26 max

Manganese 0.30 min to 1.65 max

3.4 Length of each piece,

Phosphorus 0.03 max

Sulfur 0.035 max

3.5 Information on intended application,

Silicon 0.60 max

A

3.6 Other special requirements, and

The choice and use of alloying elements (combined with carbon, manganese,

phosphorus, and sulfur within the limits prescribed) to provide the specified

3.7 Required certification and test reports.

mechanical properties, or to enhance the atmospheric corrosion resistance, or

both, may vary with manufacturer and thickness of material. The heat analysis,

4. Materials and Manufacture

including the alloying elements intentionally added, shall be reported to the

purchaser. Permitted variations in product analysis shall be within the limits

4.1 The shapes shall be manufactured from coils by the

established in Table A of Specification A6/A6M for plate steel coils or Specification

A568/A568M for sheet steel coils.

electric-resistance forge-welding process. All components of a

shape shall be furnished to the same grade unless otherwise

specified.

4.2 For Class 1 shapes the average width of weld at the joint

to the flange shall be more than 110 % of the nominal web

steel manufacturer shall provide a test report of the heat

thickness (see Fig. 1(b)). The acceptability of coil-splice welds

analysis to the shape manufacturer. Heat analysis reports shall

in webs and flanges shall be subject to negotiation between the

be furnished by the shape manufacturer to the shape purchaser.

purchaser and the manufacturer.

5.2 The steel manufacturer, shape manufacturer, and the

4.3 For Class 2 shapes the average width of weld at the joint

shape purchaser shall establish a chemical composition, which

to the flange shall be more than 130 % of the nominal web

will assure the purchaser of the desired properties while

thickness (see Fig. 1(b)). Coil-splice welds shall not be

providing the shape manufacturer with material that is weld-

permitted.

able by the electric-resistance welding process.

4.4 Flash caused by welding will not be removed unless

6. Tension Test

indicated on the purchase order.

6.1 The material as represented by the test specimen shall

NOTE 2—Flash is considered to be non-structural.

conform to the requirements of tensile properties prescribed in

5. Chemical Composition Table 2.

5.1 A chemical analysis of each heat of steel shall be made 6.2 The shape manufacturer shall furnish test reports of

by the steel manufacturer. The chemical composition thus tensile properties determined in accordance with Sections 8, 9,

determined shall conform to the requirements of Table 1. The and 10.

A769/A769M − 17 (2023)

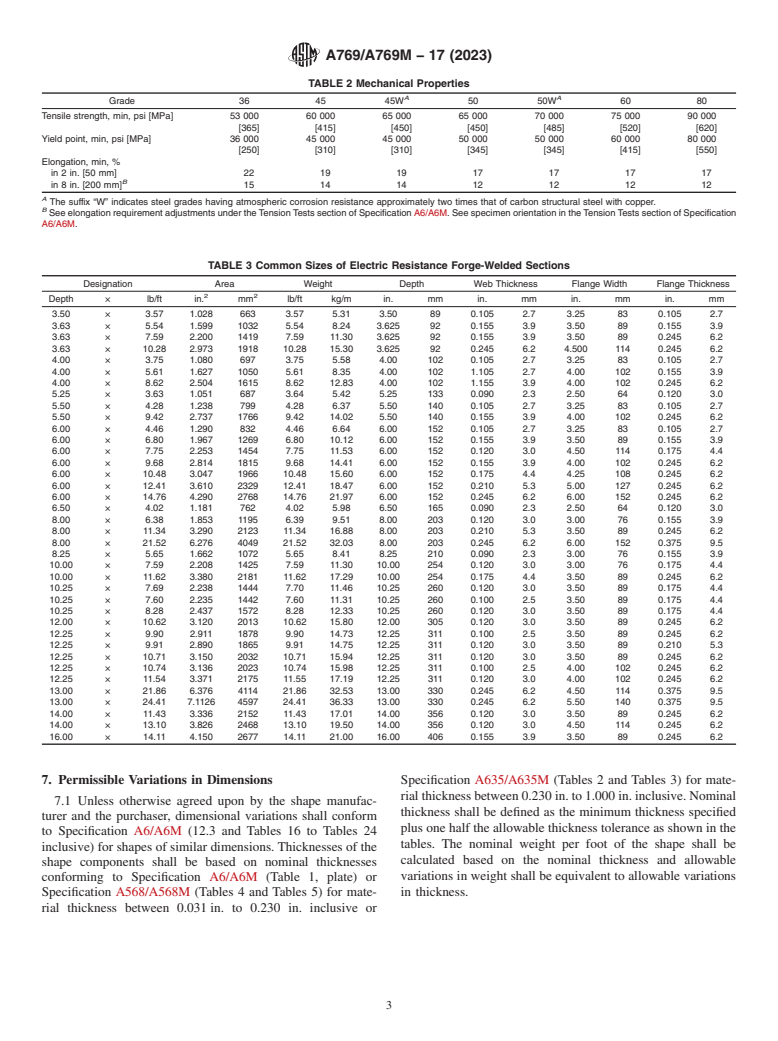

TABLE 2 Mechanical Properties

A A

Grade 36 45 45W 50 50W 60 80

Tensile strength, min, psi [MPa] 53 000 60 000 65 000 65 000 70 000 75 000 90 000

[365] [415] [450] [450] [485] [520] [620]

Yield point, min, psi [MPa] 36 000 45 000 45 000 50 000 50 000 60 000 80 000

[250] [310] [310] [345] [345] [415] [550]

Elongation, min, %

in 2 in. [50 mm] 22 19 19 17 17 17 17

B

in 8 in. [200 mm] 15 14 14 12 12 12 12

A

The suffix “W” indicates steel grades having atmospheric corrosion resistance approximately two times that of carbon structural steel with copper.

B

See elongation requirement adjustments under the Tension Tests section of Specification A6/A6M. See specimen orientation in the Tension Tests section of Specification

A6/A6M.

TABLE 3 Common Sizes of Electric Resistance Forge-Welded Sections

Designation Area Weight Depth Web Thickness Flange Width Flange Thickness

2 2

Depth × lb/ft in. mm lb/ft kg/m in. mm in. mm in. mm in. mm

3.50 × 3.57 1.028 663 3.57 5.31 3.50 89 0.105 2.7 3.25 83 0.105 2.7

3.63 × 5.54 1.599 1032 5.54 8.24 3.625 92 0.155 3.9 3.50 89 0.155 3.9

3.63 × 7.59 2.200 1419 7.59 11.30 3.625 92 0.155 3.9 3.50 89 0.245 6.2

3.63 × 10.28 2.973 1918 10.28 15.30 3.625 92 0.245 6.2 4.500 114 0.245 6.2

4.00 × 3.75 1.080 697 3.75 5.58 4.00 102 0.105 2.7 3.25 83 0.105 2.7

4.00 × 5.61 1.627 1050 5.61 8.35 4.00 102 1.105 2.7 4.00 102 0.155 3.9

4.00 × 8.62 2.504 1615 8.62 12.83 4.00 102 1.155 3.9 4.00 102 0.245 6.2

5.25 × 3.63 1.051 687 3.64 5.42 5.25 133 0.090 2.3 2.50 64 0.120 3.0

5.50 × 4.28 1.238 799 4.28 6.37 5.50 140 0.105 2.7 3.25 83 0.105 2.7

5.50 × 9.42 2.737 1766 9.42 14.02 5.50 140 0.155 3.9 4.00 102 0.245 6.2

6.00 × 4.46 1.290 832 4.46 6.64 6.00 152 0.105 2.7 3.25 83 0.105 2.7

6.00 × 6.80 1.967 1269 6.80 10.12 6.00 152 0.155 3.9 3.50 89 0.155 3.9

6.00 × 7.75 2.253 1454 7.75 11.53 6.00 152 0.120 3.0 4.50 114 0.175 4.4

6.00 × 9.68 2.814 1815 9.68 14.41 6.00 152 0.155 3.9 4.00 102 0.245 6.2

6.00 × 10.48 3.047 1966 10.48 15.60 6.00 152 0.175 4.4 4.25 108 0.245 6.2

6.00 × 12.41 3.610 2329 12.41 18.47 6.00 152 0.210 5.3 5.00 127 0.245 6.2

6.00 × 14.76 4.290 2768 14.76 21.97 6.00 152 0.245 6.2 6.00 152 0.245 6.2

6.50 × 4.02 1.181 762 4.02 5.98 6.50 165 0.090 2.3 2.50 64 0.120 3.0

8.00 × 6.38 1.853 1195 6.39 9.51 8.00 203 0.120 3.0 3.00 76 0.155 3.9

8.00 × 11.34 3.290 2123 11.34 16.88 8.00 203 0.210 5.3 3.50 89 0.245 6.2

8.00 × 21.52 6.276 4049 21.52 32.03 8.00 203 0.245 6.2 6.00 152 0.375 9.5

8.25 × 5.65 1.662 1072 5.65 8.41 8.25 210 0.090 2.3 3.00 76 0.155 3.9

10.00 × 7.59 2.208 1425 7.59 11.30 10.00 254 0.120 3.0 3.00 76 0.175 4.4

10.00 × 11.62 3.380 2181 11.62 17.29 10.00 254 0.175 4.4 3.50 89 0.245 6.2

10.25 × 7.69 2.238 1444 7.70 11.46 10.25 260 0.120 3.0 3.50 89 0.175 4.4

10.25 × 7.60 2.235 1442 7.60 11.31 10.25 260 0.100 2.5 3.50 89 0.175 4.4

10.25 × 8.28 2.437 1572 8.28 12.33 10.25 260 0.120 3.0 3.50 89 0.175 4.4

12.00 × 10.62 3.120 2013 10.62 15.80 12.00 305 0.120 3.0 3.50 89 0.245 6.2

12.25 × 9.90 2.911 1878 9.90 14.73 12.25 311 0.100 2.5 3.50 89 0.245 6.2

12.25 × 9.91 2.890 1865 9.91 14.75 12.25 311 0.120 3.0 3.50 89 0.210 5.3

12.25 × 10.71 3.150 2032 10.71 15.94 12.25 311 0.120 3.0 3.50 89 0.245 6.2

12.25 × 10.74 3.136 2023 10.74 15.98 12.25 311 0.100 2.5 4.00 102 0.245 6.2

12.25 × 11.54 3.371 2175 11.55 17.19 12.25 311 0.120 3.0 4.00 102 0.245 6.2

13.00 × 21.86 6.376 4114 21.86 32.53 13.00 330 0.245 6.2 4.50 114 0.375 9.5

13.00 × 24.41 7.1126 4597 24.41 36.33 13.00 330 0.245 6.2 5.50 140 0.375 9.5

14.00 × 11.43 3.336 2152 11.43 17.01 14.00 356 0.120 3.0 3.50 89 0.245 6.2

14.00 × 13.10 3.826 2468 13.10 19.50 14.00 356 0.120 3.0 4.50 114 0.245 6.2

16.00 × 14.11 4.150 2677 14.11 21.00 16.00 406 0.155 3.9 3.50 89 0.245 6.2

7. Permissible Variations in Dimensions Specification A635/A635M (Tables 2 and Tables 3) for mate-

rial thickness between 0.230 in. to 1.000 in. inclusive. Nominal

7.1 Unless otherwise agreed upon by the shape manufac-

thickness shall be defined as the minimum thickness specified

turer and the purchaser, dimensional variations shall conform

plus one half the allowable thickness tolerance as shown in the

to Specification A6/A6M (12.3 and Tables 16 to Tables 24

tables. The nominal weight per foot of the shape shall be

inclusive) for shapes of similar dimensions. Thicknesses of the

calculated based on the nominal thickness and allowable

shape components shall be based on nominal thicknesses

variations in weight shall be equivalent to allowable variations

conforming to Specification A6/A6M (Table 1, plate) or

Specification A568/A568M (Tables 4 and Tables 5) for mate- in thickness.

rial thickness between 0.031 in. to 0.230 in. inclusive or

A769/A769M − 17 (2023)

8. Number of Tests the flange from the web and the flange from the stem of tee

sections mechanically for a length of approximately 2 in.

8.1 Tension Tests:

(50 mm) by any method that places the weld bond plane in

8.1.1 For steel ordered from the steel manufacturer as coiled

progressive, peeling tension. A slotted bending hook, Fig. 2(a),

sheet or plate to minimum mechanical properties (ASTM or

is preferred. Fracture may be initiated on the bond plane by a

equivalent), the shape manufacturer may certify his product

notch pressed or sawed into the end of the specimen along the

based on the steel manufacturer’s test reports of mechanical

weld bond plane (Fig. 2(c)). Striking of the inner surface of the

properties.

flange on alternate sides of the weld with a hammer may be

8.1.1.1 In addition, the shape manufacturer shall make one

used to perform the peel test, if necessary, in cases where a

tension test using a specimen which is representative of the

bending hook is not appropriate. Appearance and width of the

approximate middle of the original coil length.

fracture are the bases for evaluating weld quality.

8.1.2 For all steel not made to minimum mechanical

10.2.1 Flange Pullout—The usual mode of fracture causes a

properties, regardless of thickness, the shape manufacturer

pullout of the surface of the flange under the weld. This is

shall make the tests for each coil per the requirements of

evidence of an acceptable metallurgical bond. The average

Specification A6/A6M, sections 11.4.2, 11.4.3, or 11.4.4

width of the pullout material (Fig. 1(b)) expressed as a

(Tables B and C shall be followed) as applicable. Specimens

percentage of the nominal web thickness shall be: for Class 1

taken for testing from the middle of the original coil length

shapes, more than 110 %; and for Class 2 shapes, more than

shall, in addition, be taken from the approximate quarter point

130 %. Typically, the appearance of pulled out material is

of the original coil width.

rough, often having a woody texture. A general nonoriented

8.2 Peel Tests:

roughness or granular appearance is acceptable. Measure the

8.2.1 One peel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.