ASTM A499-15(2020)

(Specification)Standard Specification for Steel Bars and Shapes, Carbon Rolled from “T” Rails

Standard Specification for Steel Bars and Shapes, Carbon Rolled from “T” Rails

ABSTRACT

This specification covers the standard for carbon steel bars and shapes rolled from standard rail steel. The material shall be hot wrought from section “T” rails and shall be produced by hot forming slit railroad rail parts to yield straight lengths. One tension test and one hardness test shall be performed from each lot to determine the mechanical properties and shall conform to the requirement in tensile strength, elongation, Brinell hardness, and Rockwell B hardness.

SCOPE

1.1 This specification covers carbon steel bars and shapes produced from standard rail steel. These bars are furnished in the as-wrought condition intended for structural use, or bar and shape uses, where high tensile properties are applicable. These materials are available in four strength levels as Grade 50, Grade 60, Grade 70, and Grade 80.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A499 −15 (Reapproved 2020)

Standard Specification for

Steel Bars and Shapes, Carbon Rolled from “T” Rails

This standard is issued under the fixed designation A499; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.1.2 Square and Round Edge Flats, ⁄8 in. to 5 in.

(15.9mm to 127 mm), inclusive, in width and thickness from

1.1 This specification covers carbon steel bars and shapes

⁄64in. to 1 in. (2.8 mm to 25 mm), inclusive, within 6 lb/ft

produced from standard rail steel. These bars are furnished in

(8.8kg⁄m) limit.

theas-wroughtconditionintendedforstructuraluse,orbarand

3.1.1.3 Hexagons and Octagons, in sizes ⁄2 in. to 1 in.

shape uses, where high tensile properties are applicable.These

(12.7 mm to 25 mm) in ⁄16 in. (1.6 mm) increments.

materials are available in four strength levels as Grade 50,

3.1.1.4 Bar Size Shapes:

Grade 60, Grade 70, and Grade 80.

(1) Equal and Unequal Angles, ⁄4 in. to 3 in. (19.0 mm to

1.2 The values stated in inch-pound units are to be regarded

76 mm) length of legs and thickness ranging from ⁄64in. to

as standard. The values given in parentheses are mathematical

⁄8in. (2.8 mm to 9.5 mm), inclusive.

conversions to SI units that are provided for information only

1 3 1 1 3

(2) Tees, 1 ⁄4 in., 1 ⁄8 in., 1 ⁄2in. by ⁄8in., and ⁄16in.

and are not considered standard.

thickness (32 mm, 35 mm, 38 mm by 3.2 mm and 4.8 mm

1.3 This international standard was developed in accor-

thickness).

dance with internationally recognized principles on standard- (3) Channels, 1 in. to 2 ⁄2in. (25 mm to 64 mm), inclusive,

ization established in the Decision on Principles for the

in depth and ⁄8in. to 1 in. (9.5 mm to 25 mm), inclusive, in

Development of International Standards, Guides and Recom- width of flange.

mendations issued by the World Trade Organization Technical

3.1.1.5 Special Bar Sections:

5 7

Barriers to Trade (TBT) Committee. (1) Ovals, from ⁄8in. to ⁄8in. (15.9 mm to 22.2 mm) in

5 7

longest dimension by ⁄16in. to ⁄16in. (7.9 mm to 11.1 mm),

2. Referenced Documents

inclusive, in the small dimension.

7 13

(2) Diamonds, ⁄8in. and ⁄16 in. (22.2 mm and 20.6 mm)

2.1 ASTM Standards:

5 3

in the longest dimension by ⁄8in. to ⁄4in. (15.9 mm to

A1Specification for Carbon Steel Tee Rails

19.0mm), inclusive, in the smallest dimension.

A29/A29MSpecificationforGeneralRequirementsforSteel

1 1

(3) I-Beams,1 ⁄2in. and 2 ⁄8in. (35 mm and 54 mm) in

Bars, Carbon and Alloy, Hot-Wrought

1 1

width and ⁄8in. to ⁄4 in. (3.2 mm to 6.4 mm), inclusive, in

A370Test Methods and Definitions for Mechanical Testing

thickness.

of Steel Products

1 5

(4) U-Bars,1 ⁄4in. and 1 ⁄16in. (32 mm and 33 mm) in

5 5

width and ⁄32in. to ⁄16in. (4.0 mm to 7.9 mm) in thickness.

3. Terminology

(5) Channeled Flats,1 ⁄4 in. to 2 in. (32 mm to 51 mm),

3.1 Definitions of Terms Specific to This Standard:

3 3

inclusive, in depth, and ⁄16in. to ⁄8in. (4.8 mm to 9.5 mm),

3.1.1 Rail steel bars and bar size shapes are available in the

inclusive, in thickness.

following sections and nominal sizes:

3.1.1.1 Rounds, Squares, and Round Corner Squares in

4. Ordering Information

3 1

sizes ranging from ⁄8in. to 1 ⁄4 in. (9.5 mm to 32 mm).

4.1 Orders for material under this specification should

include the following information:

4.1.1 Quantity (weight or number of pieces),

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

4.1.2 Name of material (rail steel carbon bars),

StainlessSteelandRelatedAlloysandisthedirectresponsibilityofA01.15onBars.

4.1.3 Grade of steel (Grade 50, Grade 60, Grade 70, and

Current edition approved Sept. 1, 2020. Published September 2020. Originally

Grade 80),

approved in 1964. Last previous edition approved in 2015 as A499–15. DOI:

10.1520/A0499-15R20.

4.1.4 Dimensions (diameter, thickness, width, etc. and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

length),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.5 Cross section (rounds, square, hexagon, etc.) (3.1),

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1.6 ASTM designation and date of issue,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

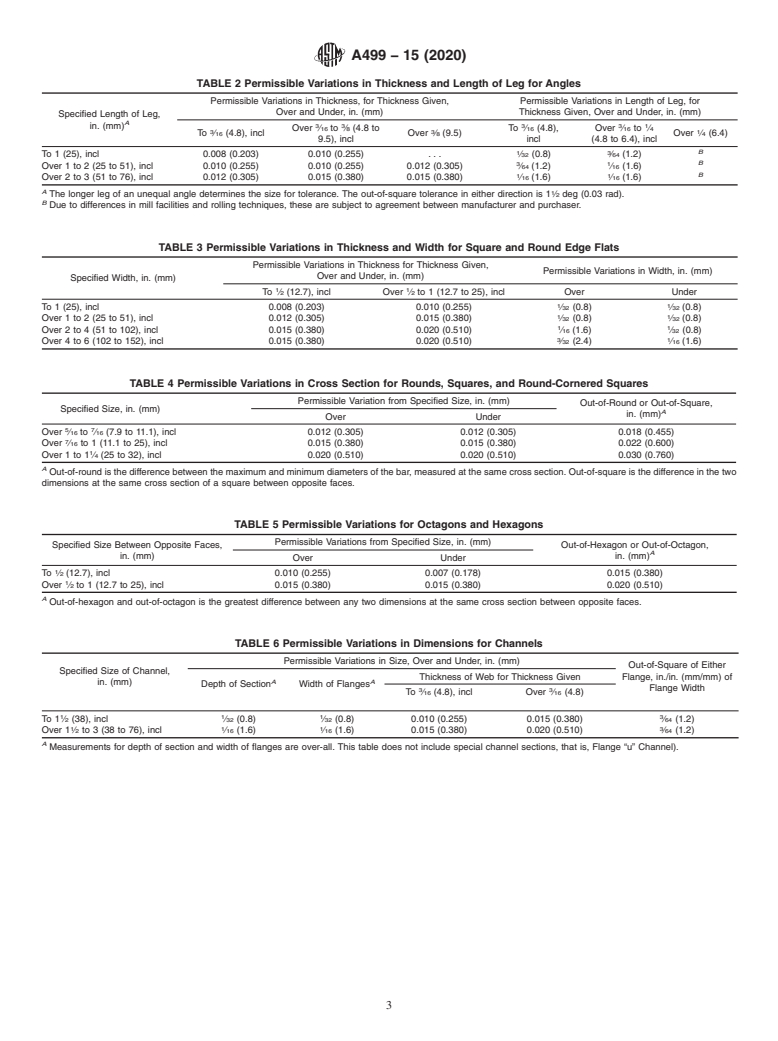

A499−15 (2020)

TABLE 1 Mechanical Requirements

4.1.7 Certification, if required (Section 11), and

4.1.8 End use. Grade 50 Grade 60 Grade 70 Grade 80

Tensile strength, min, ksi (MPa) 80 (550) 90 (620) 95 (655) 110 (760)

NOTE 1—A typical ordering description is as follows: 10 000 lb, rail

Yield point, min, ksi (MPa) 50 (345) 60 (415) 70 (485) 80 (550)

steel carbon bars, 1.000 in. diameter by 10 ft, round, ASTM A499 dated

Elongation in 8 in. or 200 mm,55 5 5

_______.

min, %

Elongation in 2 in. or 50 mm,77 7 7

min, %

5. General Requirements

A

Brinell hardness, min 159 190 197 229

A

5.1 Material furnished under this specification shall con- Rockwell B hardness, min 83 91 93 98

A

form to the applicable requirements of the current edition of

Hardness tests are an acceptable alternative for tension tests where the bar size

precludes a tension test specimen in accordance with Test Methods and Defini-

Specification A29/A29M, unless otherwise provided herein.

tions A370.

6. Materials and Manufacture

6.1 Material—The material shall be hot wrought from

8.3 Number of Tests—One tension test or one hardness test,

standard section “T” rails. No other materials, such as those

atthemanufacturer’soption,shallbemadefromeachlot.Alot

known by the terms “rerolled,” “rail steel equivalent,” or “rail

shall consist of one section of the same size produced in one

steel quality,” shall be substituted.

continuous shift (turn) of operation (normally an 8 h period).

6.2 Hot Forming—The material shall be produced by hot

9. Dimensions and Permissible Variations

forming slit railroad rail parts to yield straight lengths in the

9.1 Dimensions—The permissible variations in dimensions

sections and nominal sizes specified in 3.1.1.

shall be in accordance with the requirements specified in

6.3 Condition:

Tables 2-7. Due to differences in mill facilities, tolerances of

6.3.1 The material shall be furnished hot wrought, as

special bar sections vary among the manufacturers and such

wrought.

tolerances are subject to agreement between manufacturer and

6.3.2 Thematerialshallbefurnishedincutlengthsorranges

purchaser.

of random lengths, as specified by the purchaser.

9.2 Length—The permissible variations for length shall be

7. Chemical Composition in accordance with the requirements specified in Table 8.

7.1 The chemical composition of rails does not change 9.3 Straightness—Variationsinstraightnessshallnotexceed

1 1

during use in track, reheating, slitting or rolling; consequently, ⁄4in. (6.4 mm) in any 5 ft (1.52 m); or ⁄4in.× number of feet

the composition of rail steel products will fall within the limits of length divided by 5 (6.4 mm × number of metres of length

specified in Specification A1 for standard section “T” rails of divided by 1.52).

basic-oxygen or el

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.