ASTM D6438-05(2010)

(Test Method)Standard Test Method for Acetone, Methyl Acetate, and Parachlorobenzotrifluoride Content of Paints, and Coatings by Solid Phase Microextraction-Gas Chromatography

Standard Test Method for Acetone, Methyl Acetate, and Parachlorobenzotrifluoride Content of Paints, and Coatings by Solid Phase Microextraction-Gas Chromatography

SIGNIFICANCE AND USE

In order to calculate the volatile organic content (VOC) of paints containing EPA exempt solvents, it is necessary to know the acetone, methyl acetate, or parachlorobenzotrifluoride content. This gas chromatographic test method provides a simple and direct way for measuring these solvents. Each analyte is measured with respect to a unique internal standard. For acetone, the internal standard used is acetone-d6, for methyl acetate it is methyl acetate-d3, and for PCBTF it is metachlorobenzotrifluoride (MCBTF). These unique analyte/internal standard pairs behave very nearly as single solvents with respect to evaporation rate and adsorption rate onto a coated silica fiber (SPME) but are separable on a gas chromatograph (GC) capillary column. The only critical analytical technique required for successfully performing this test method is the ability of an analyst to weigh a paint sample and internal standard, corresponding to the analyte of interest, into a septum capped vial. After weighing, solvent evaporation has no effect on the final value of the determination. Since whole paint is not injected into the gas chromatograph, the analytical system is never compromised.

SCOPE

1.1 This test method is for the determination of acetone, methyl acetate, or parachlorobenzotrifluoride (PCBTF), or combination of any of the three, in paints and coatings, by solid phase microextraction (SPME) headspace sampling, and subsequent injection into a gas chromatograph. It has been evaluated for cellulose nitrate, acrylic, and urethane solvent-borne systems. The established working range of this test method is: acetone, 28 to 90 %; methyl acetate, 12 to 22 %; parachlorobenzotrifluoride, 10 to 17 %. There is no reason to believe that it will not work outside these ranges. A minor modification of this test method would make it suitable for the analysis of the same analytes in water-borne coatings (see Note 1).

Note 1—Water-borne paints are internally standardized and diluted with water followed by addition of solid sodium chloride.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6438 −05(Reapproved2010)

Standard Test Method for

Acetone, Methyl Acetate, and Parachlorobenzotrifluoride

Content of Paints, and Coatings by Solid Phase

Microextraction-Gas Chromatography

This standard is issued under the fixed designation D6438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Methyl Acetate or t-Butyl Acetate Content of Solvent-

borne and Waterborne Paints, Coatings, Resins, and Raw

1.1 This test method is for the determination of acetone,

Materials by Direct Injection Into a Gas Chromatograph

methyl acetate, or parachlorobenzotrifluoride (PCBTF), or

E180 Practice for Determining the Precision of ASTM

combinationofanyofthethree,inpaintsandcoatings,bysolid

Methods for Analysis and Testing of Industrial and Spe-

phase microextraction (SPME) headspace sampling, and sub-

cialty Chemicals (Withdrawn 2009)

sequent injection into a gas chromatograph. It has been

evaluated for cellulose nitrate, acrylic, and urethane solvent-

3. Terminology

borne systems. The established working range of this test

method is: acetone, 28 to 90 %; methyl acetate, 12 to 22 %; 3.1 Abbreviations:

parachlorobenzotrifluoride, 10 to 17 %. There is no reason to

3.1.1 PCBTF—parachlorobenzotrifluoride,

believe that it will not work outside these ranges. A minor (4-chlorobenzotrifluoride)

modification of this test method would make it suitable for the

3.1.2 MCBTF—metachlorobenzotrifluoride

analysisofthesameanalytesinwater-bornecoatings(seeNote

(3-chlorobenzotrifluoride)

1).

3.1.3 SPME—solid phase microextraction

NOTE 1—Water-borne paints are internally standardized and diluted

3.1.4 VOC—volatile organic compound

with water followed by addition of solid sodium chloride.

3.1.5 PEG/DVB—polyethylene glycol/divinylbenzene

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3.1.6 FID—flame ionization detector

standard.

3.1.7 MS—mass selective or mass spectral

1.3 This standard does not purport to address all of the

3.1.8 SIM—selected ion monitoring

safety concerns, if any, associated with its use. It is the

3.1.9 GC—gas chromatograph

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.10 Sr—repeatability standard deviations

bility of regulatory limitations prior to use.

3.1.11 SR—reproducibility standard deviations

3.1.12 r—repeatability, 95 % confidence limit

2. Referenced Documents

3.1.13 R—reproducibility, 95 % confidence limit

2.1 ASTM Standards:

D3925 Practice for Sampling Liquid Paints and Related

4. Summary of Test Method

Pigmented Coatings

4.1 A suitable aliquot of whole solvent-borne paint is

D6133 Test Method for Acetone, p-Chlorobenzotrifluoride,

internally standardized and diluted with dioctyl phthalate. The

headspace of this solution is sampled with an SPME fiber,

which is then thermally desorbed in the injection port of a gas

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

chromatograph onto a suitable capillary column. Either a flame

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

ionization or mass specific detector may be used to measure

Current edition approved Dec. 1, 2010. Published December 2010. Originally

peak areas of analytes and internal standards.

approved in 1999. Last previous edition approved in 2005 as D6438 – 99 (2005).

DOI: 10.1520/D6438-05R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6438−05(2010)

TABLE 1 FID Instrument Conditions TABLE 2 MS Instrument Conditions

Detector: Flame ionization Detector: Electron ionization or mass selective

Column: 60m×0.25mm100%polyethylene glycol, 0.5-µm Detection Mode: Selected ion monitoring (SIM) of ions m/e 58, 64,

film thickness 74, 77, and 180

Carrier Gas: Helium Dwell Time: 100 milliseconds or less

Flow Rage: 1.0 mL per minute (20 cm per second) Solvent Delay: 0.0 min

Split Ratio: 200 to 1 Column: 25m×0.20mm5% phenyl/95 % methyl

A

Fiber desorption time: 5 to 6 s polydimethylsiloxane

Temperature, ° C Carrier Gas: Helium

Inlet 260° Flow Rate: 1.0 mL per minute (20 cm per second)

Detector 270° Split Ratio: 200 to 1

A

Initial 35° for 12 min Fiber desorption time: 5 to 6 s

Rate 1 30° per minute to 100°, hold 10 min Temperatures, ° C

Rate 2 30° per minute to 240°, hold 2 min Inlet 260°

Detector 280°

A

If the fiber desorption is carried out longer than 5 or 6 s, the acetone peaks

Initial 40° for 2 min

exhibit tailing. A 5 to 6–s desorption time transfers 98 to 99 % of the analytes to the

Rate 1 10° per minute to 90°, hold 1 min

capillary column. The fiber may be cleaned by inserting it into the GC inlet for 15

Rate 2 40° per minute to 240°, hold 1 min

s after analytes of interest have eluted.

A

If the fiber desorption is carried out longer than 5 or 6 s, the acetone peaks

exhibit tailing. A 5 to 6–s desorption time transfers 98 to 99 % of the analytes to the

capillary column. The fiber may be cleaned by inserting it into the GC inlet for 15

s after analytes of interest have eluted.

5. Significance and Use

5.1 In order to calculate the volatile organic content (VOC)

of paints containing EPA exempt solvents, it is necessary to

6.3 Gas Chromatograph, Mass Selective (MS) Detection—

know the acetone, methyl acetate, or parachlorobenzotrifluo-

Any capillary gas chromatograph equipped with a mass selec-

ride content. This gas chromatographic test method provides a

tive detector may be used. The detector must be capable of

simple and direct way for measuring these solvents. Each

measuring in the selected ion monitoring (SIM) mode at dwell

analyte is measured with respect to a unique internal standard.

times of 100 milliseconds or less.

For acetone, the internal standard used is acetone-d6, for

6.3.1 For MS instrument conditions, see Table 2.

methyl acetate it is methyl acetate-d3, and for PCBTF it is

6.3.2 Inlet liner, 0.75-mm, should be placed in the injection

metachlorobenzotrifluoride (MCBTF). These unique analyte/

port.

internal standard pairs behave very nearly as single solvents

6.3.3 The instrument should have a software data system to

with respect to evaporation rate and adsorption rate onto a

allow extraction and integration of the SIM ions.

coated silica fiber (SPME) but are separable on a gas chro-

matograph (GC) capillary column. The only critical analytical

7. Column and Fiber Conditioning

techniquerequiredforsuccessfullyperformingthistestmethod

7.1 Either or both capillary columns should be conditioned

is the ability of an analyst to weigh a paint sample and internal

according to the manufacturer’s recommendation. The col-

standard,correspondingtotheanalyteofinterest,intoaseptum

umns may then be used indefinitely without further condition-

capped vial. After weighing, solvent evaporation has no effect

ing.

onthefinalvalueofthedetermination.Sincewholepaintisnot

injected into the gas chromatograph, the analytical system is

7.2 TheSPMEfibershouldbeconditionedandusedaccord-

never compromised.

ing to the manufacturer’s recommendation.

7.3 The SPME fiber should be inserted into a 260° C

6. Apparatus

injection port for 30 s prior to daily use.

6.1 Manual SPME Holder, fitted with partially crosslinked

polyethylene glycol/divinylbenzene (PEG/DVB) fiber assem-

8. Reagents and Materials

bly, 65–µm film thickness.

8.1 Purity of Reagents—Reagent grade chemicals shall be

6.2 Gas Chromatograph, FID Detection—Any capillary gas

used in all tests. Unless otherwise indicated, it is intended that

chromatograph equipped with a flame ionization detector may all reagents shall conform to the specifications of the Commit-

be used. Temperature programming capability is desirable, but

tee onAnalytical Reagents of theAmerican Chemical Society,

isothermal operations may be utilized. where such specifications are available. Other grades may be

6.2.1 For FID instrument conditions, see Table 1.

used, provided it is first ascertained that the reagent is of

6.2.2 Inlet Liner, 0.75-mm should be placed in the injection

sufficiently high purity to permit its use without lessening the

port.

accuracy of the determination.

6.2.3 Integrator—Any electronic integrator that can accu-

8.2 Carrier Gas, Helium of 99.995 % or higher purity.

rately quantify a gas chromatographic peak area is acceptable.

8.3 Acetone -d6 , 99.9 % isotopic purity.

The sole source of supply of the manual holder and fibers known to the

committee at this time is Supelco Company, Supelco Park, Bellefonte, PA Reagent Chemicals, American Chemical Society Specifications, American

16823-0048. If you are aware of alternative suppliers, please provide this informa- Chemical Society, Washington, DC. For suggestions on the testing of reagents not

tion to ASTM International Headquarters. Your comments will receive careful listed by the American Chemical Society, see Analar Standards for Laboratory

consideration at a meeting of the responsible technical committee, which you may Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopia and

attend. National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D6438−05(2010)

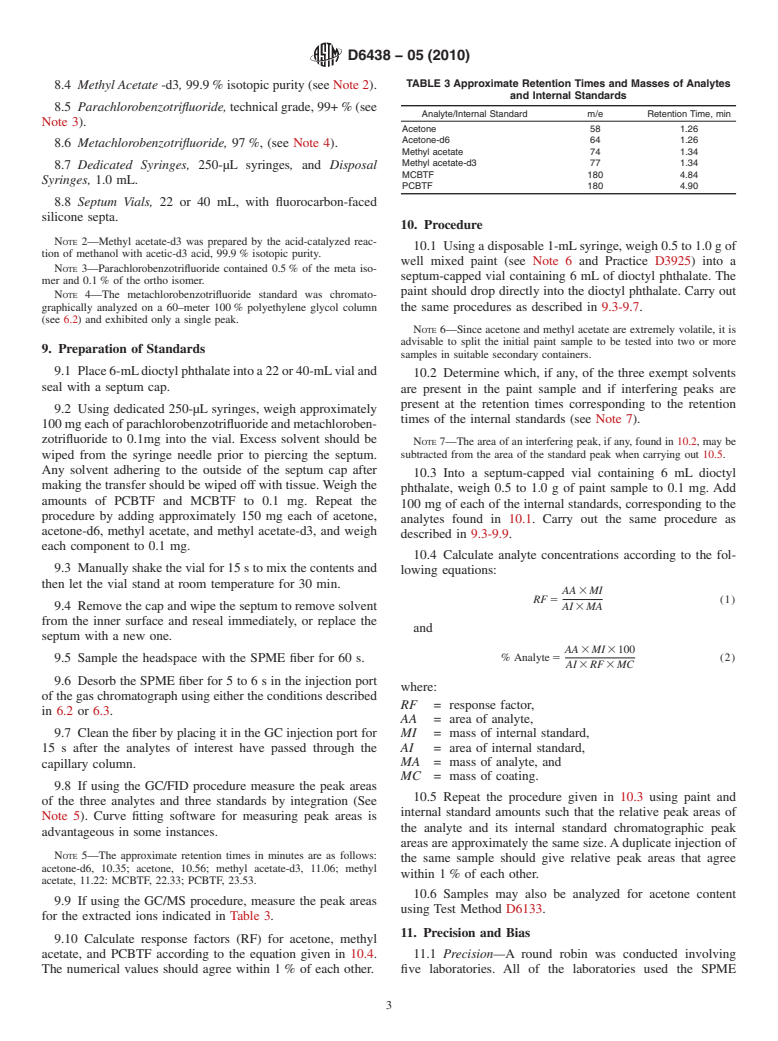

TABLE 3 Approximate Retention Times and Masses of Analytes

8.4 Methy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.