ASTM D5060-95(2000)e1

(Test Method)Standard Test Method for Determining Impurities in High-Purity Ethylbenzene by Gas Chromatography

Standard Test Method for Determining Impurities in High-Purity Ethylbenzene by Gas Chromatography

SCOPE

1.1 This test method describes the analysis of normally occurring impurities in, and the purity of, ethylbenzene by gas chromatography. Impurities determined include nonaromatic hydrocarbons, benzene, toluene, xylenes, cumene, and diethylbenzene isomers.

1.2 This test method is applicable for impurities at concentrations from 0.001 to 1.000 % and for ethylbenzene purities of 99 % or higher. At this level, p-xylene may not be detected.

1.3 The following applies to all specified limits in this standard: for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D5060–95(Reapproved2000)

Standard Test Method for

Determining Impurities in High-Purity Ethylbenzene by Gas

Chromatography

This standard is issued under the fixed designation D 5060; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Research report was added editorially in September 2004.

1. Scope E 1510 Practice for Installing Fused Silica Open Tubular

Capillary Columns in Gas Chromatographs

1.1 This test method describes the analysis of normally

2.2 Other Documents:

occurring impurities in, and the purity of, ethylbenzene by gas

OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

chromatography. Impurities determined include nonaromatic

1910.1200

hydrocarbons, benzene, toluene, xylenes, cumene, and dieth-

ylbenzene isomers.

3. Summary of Test Method

1.2 This test method is applicable for impurities at concen-

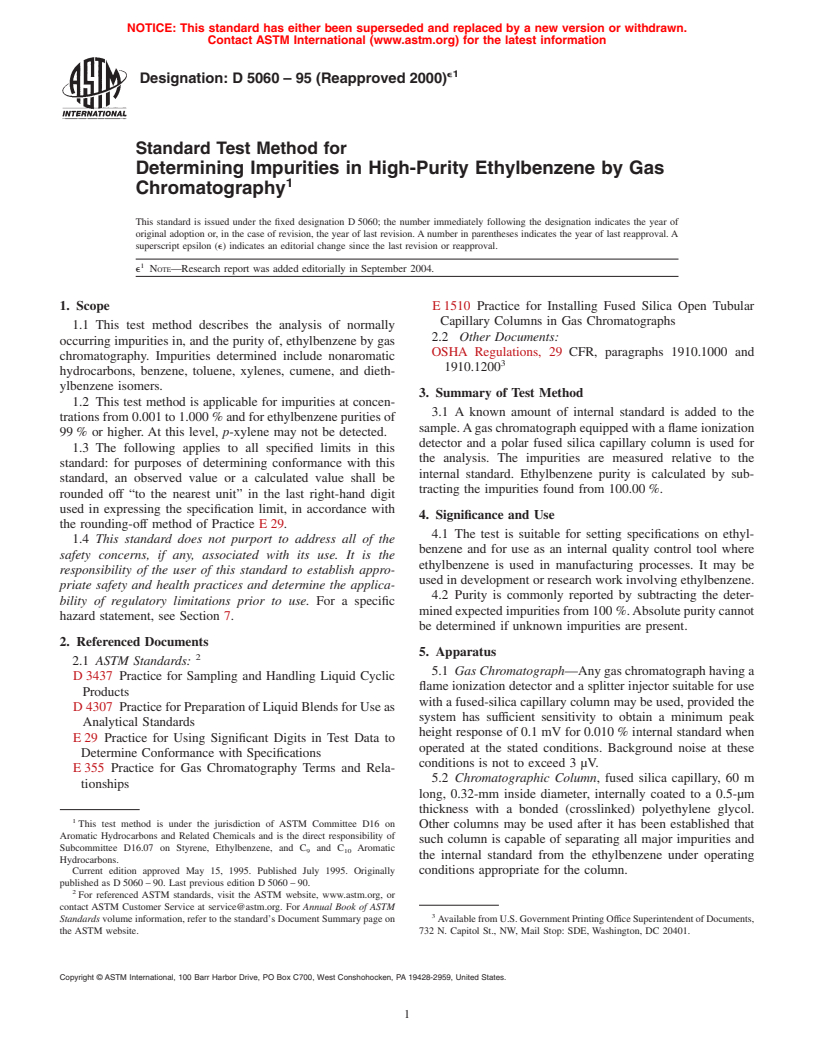

3.1 A known amount of internal standard is added to the

trations from 0.001 to 1.000 % and for ethylbenzene purities of

sample.Agas chromatograph equipped with a flame ionization

99 % or higher. At this level, p-xylene may not be detected.

detector and a polar fused silica capillary column is used for

1.3 The following applies to all specified limits in this

the analysis. The impurities are measured relative to the

standard: for purposes of determining conformance with this

internal standard. Ethylbenzene purity is calculated by sub-

standard, an observed value or a calculated value shall be

tracting the impurities found from 100.00 %.

rounded off “to the nearest unit” in the last right-hand digit

used in expressing the specification limit, in accordance with

4. Significance and Use

the rounding-off method of PracticeE29.

4.1 The test is suitable for setting specifications on ethyl-

1.4 This standard does not purport to address all of the

benzene and for use as an internal quality control tool where

safety concerns, if any, associated with its use. It is the

ethylbenzene is used in manufacturing processes. It may be

responsibility of the user of this standard to establish appro-

used in development or research work involving ethylbenzene.

priate safety and health practices and determine the applica-

4.2 Purity is commonly reported by subtracting the deter-

bility of regulatory limitations prior to use. For a specific

mined expected impurities from 100 %.Absolute purity cannot

hazard statement, see Section 7.

be determined if unknown impurities are present.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

5.1 GasChromatograph—Any gas chromatograph having a

D 3437 Practice for Sampling and Handling Liquid Cyclic

flame ionization detector and a splitter injector suitable for use

Products

with a fused-silica capillary column may be used, provided the

D 4307 PracticeforPreparationofLiquidBlendsforUseas

system has sufficient sensitivity to obtain a minimum peak

Analytical Standards

height response of 0.1 mV for 0.010 % internal standard when

E29 Practice for Using Significant Digits in Test Data to

operated at the stated conditions. Background noise at these

Determine Conformance with Specifications

conditions is not to exceed 3 µV.

E 355 Practice for Gas Chromatography Terms and Rela-

5.2 Chromatographic Column, fused silica capillary, 60 m

tionships

long, 0.32-mm inside diameter, internally coated to a 0.5-µm

thickness with a bonded (crosslinked) polyethylene glycol.

This test method is under the jurisdiction of ASTM Committee D16 on

Other columns may be used after it has been established that

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

such column is capable of separating all major impurities and

Subcommittee D16.07 on Styrene, Ethylbenzene, and C and C Aromatic

9 10

the internal standard from the ethylbenzene under operating

Hydrocarbons.

Current edition approved May 15, 1995. Published July 1995. Originally conditions appropriate for the column.

published as D 5060 – 90. Last previous edition D 5060 – 90.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

the ASTM website. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

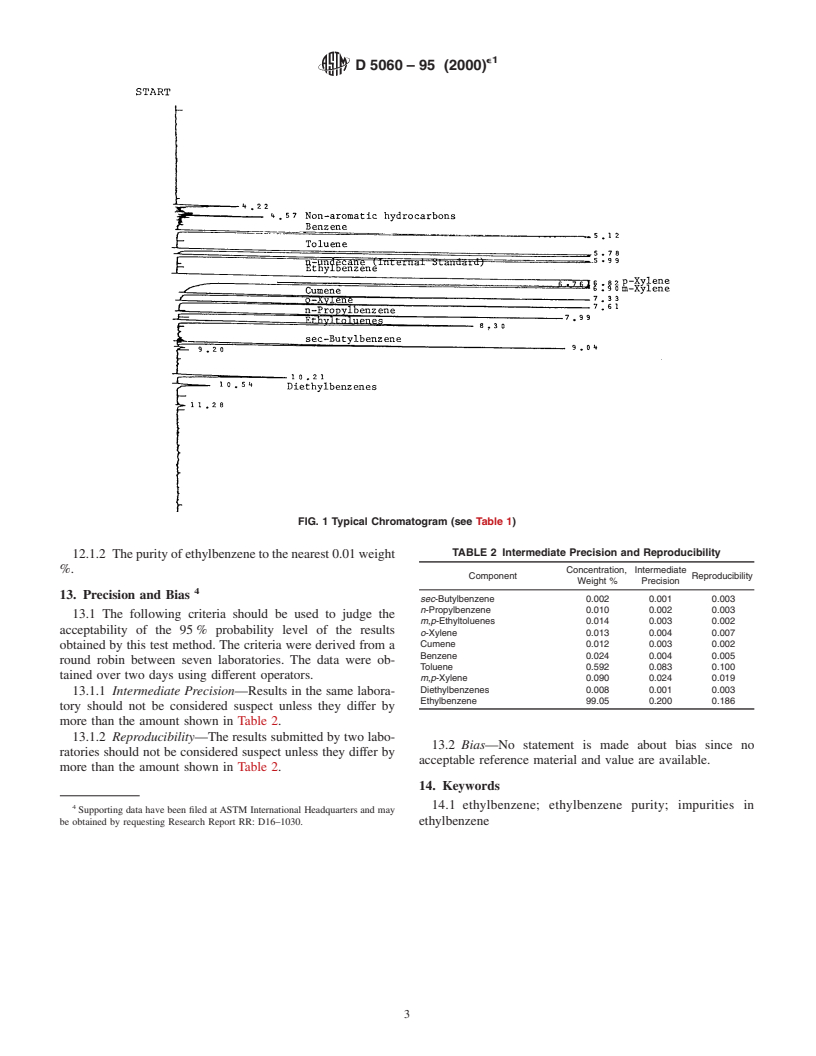

D5060–95 (2000)

5.3 Recorder, 1-mV,1sor less full scale response or

A = area of internal standard peak in stock ethylben-

s,b

electronic integration with tangent capabilities (recom-

zene, and

mended).

C = concentration of impurity, weight %.

i

5.4 Microsyringe, 10-µL.

9.5 Calculate response factor to the nearest 0.001.

5.5 Microsyringe, 50-µL.

5.6 Volumetric Flask, 50-mL. 10. Procedure

10.1 Install the chromatographic column and establish

6. Reagents and Materials

stable instrument operation at the operating conditions shown

6.1 Carrier Gas, hydrogen or helium, chromatographic

in Table 1. Refer to instructions provided by the manufacturer

grade.

of the gas chromatograph and Practices E 355 and E 1510.

6.2 Compressed Air, oil-free.

10.2 Fill a 50-mL volumetric flask to the mark with test

6.3 Hydrogen, chromatographic grade.

specimen.Withamicrosyringe,add30µLofthestandard.Mix

6.4 Nitrogen, chromatographic grade.

well. Using a density of 0.740 for n-undecane and 0.867 for

6.5 Pure Compounds for Calibration—n-Nonane, benzene,

ethylbenzene, this solution will contain 0.0512 weight %

toluene, ethylbenzene, and o-xylene. The purity of the ethyl- internal standard.

benzene should be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.