ASTM A786/A786M-00

(Specification)Standard Specification for Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor Plates

Standard Specification for Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor Plates

SCOPE

1.1 This specification covers carbon, low-alloy, high-strength low-alloy, and alloy steel hot-rolled floor plates for flooring, stairways, transportation equipment, and general structural purposes. While it is generally provided in the as-rolled condition, floor plate also may be provided in the heat-treated condition, depending on the material specification. Rolled floor plates have raised figures at regular intervals on one surface of the plate.

1.2 Floor plate is available in dimensions that meet the classification size limits for sheet, heavy thickness sheet coil, or plate. Maximum thickness for product delivered under this specification is 1 in. [25 mm].

1.3 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other, without combining values.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 786/A 786M – 00

Standard Specification for

Rolled Steel Floor Plates

This standard is issued under the fixed designation A 786/A 786M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Tensile Strength Carbon Steel Plates

A 284/A 284M Specification for Low and Intermediate

1.1 This specification covers carbon, high-strength low-

Tensile Strength Carbon-Silicon Steel Plates for Machine

alloy, and alloy steel rolled floor plates for flooring, stairways,

Parts and General Construction

transportation equipment, and for general structural purposes.

A 370 Test Methods and Definitions for Mechanical Testing

While it is generally provided in the as-rolled condition, it may

of Steel Products

also be provided in the heat-treated condition (see Appendix

A 514/A 514M Specification for High-Yield-Strength,

Table X1.1). Rolled floor plates have raised figures at regular

Quenched and Tempered Alloy Steel Plate, Suitable for

intervals on one surface of the plate.

Welding

1.1.1 Carbon steel may be specified to chemical composi-

A 572/A 572M Specification for High-Strength Low-Alloy

tion limits, the maximum carbon of which should not exceed

Columbium-Vanadium Structural Steel

0.33 % or, an ASTM material specification with yield point or

A 573/A 573M Specification for Structural Carbon Steel

yield strength and tensile strength may be specified (see

Plates of Improved Toughness

Appendix Table X1.1).

A 588/A 588M Specification for High-Strength Low-Alloy

1.2 Rolled floor plate is customarily available in a limited

Structural Steel with 50 ksi (345 MPa) Minimum Yield

number of gage numbers or thicknesses. Standard gage num-

Point to 4 in. (100 mm) Thick

bers and thicknesses are shown in Table 1. The maximum

A 656/A 656M Specification for Hot-Rolled Structural

thickness to be delivered under this specification is 1 in. [25

Steel, High-Strength Low-Alloy Plate with Improved

mm].

Formability

1.3 When the steel is to be welded, it is presupposed that a

A 700 Practices for Packaging, Marking, and Loading

welding procedure suitable for the grade of steel and intended

Methods for Steel Products for Domestic Shipment

use or service will be utilized. See Appendix X3 of Specifica-

A 709/A 709M Specification for Carbon and High-

tion A 6/A 6M for information on weldability.

Strength Low-Alloy Structural Steel Shapes, Plates, and

1.4 The values stated in either inch-pound units or SI units

Bars and Quenched and Tempered Alloy Structural Steel

are to be regarded as standard. Within the text, the SI units are

Plates for Bridges

shown in brackets. The values stated in each system are not

E 30 Test Methods for Chemical Analysis of Steel, Cast

exact equivalents; therefore, each system must be used inde-

Iron, Open-Hearth Iron, and Wrought Iron

pendently of the other. Combining values from the two systems

E 59 Practice for Sampling Steel and Iron for Determination

may result in noncomformance with the specification.

of Chemical Composition

2. Referenced Documents

E 350 Test Method for Chemical Analysis of Carbon Steel,

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

2.1 ASTM Standards:

Wrought Iron

A 6/A 6M Specification for General Requirements for

2.2 American Welding Society Standards:

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

A5.1 Mild Steel Covered Arc-Welding Electrodes

Piling

A5.5 Low-Alloy Steel Covered Arc-Welding Electrodes

A 36/A 36M Specification for Carbon Structural Steel

2.3 Military Standards:

A 131/A 131M Specification for Structural Steel for Ships

MIL-STD-129 Marking for Shipment and Storage

A 242/A 242M Specification for High-Strength Low-Alloy

Structural Steel

A 283/A 283M Specification for Low and Intermediate

Discontinued. See 1994 Annual Book of ASTM Standards, Vol 01.04.

Annual Book of ASTM Standards, Vol 01.03.

1 5

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, Annual Book of ASTM Standards, Vol 01.05.

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 03.05.

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships. Available from American Welding Society, 550 N. W. LaJeune Rd., Miami, Fl

Current edition approved March 10, 2000. Published May 2000. Originally 33135.

published as A 786 – 81. Last previous edition A 786 – 93. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 01.04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 786/A 786M

MIL-STD-163 Steel Mill Products Preparation for Ship- 16, 17, 18, and 19, and Table B of the current edition of

ment and Storage Specification A 6/A 6M.

2.4 Federal Standard:

5. Ordering Information

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

5.1 Orders for material under this specification should

3. Classification

include the following information, as necessary, to describe

adequately the desired material:

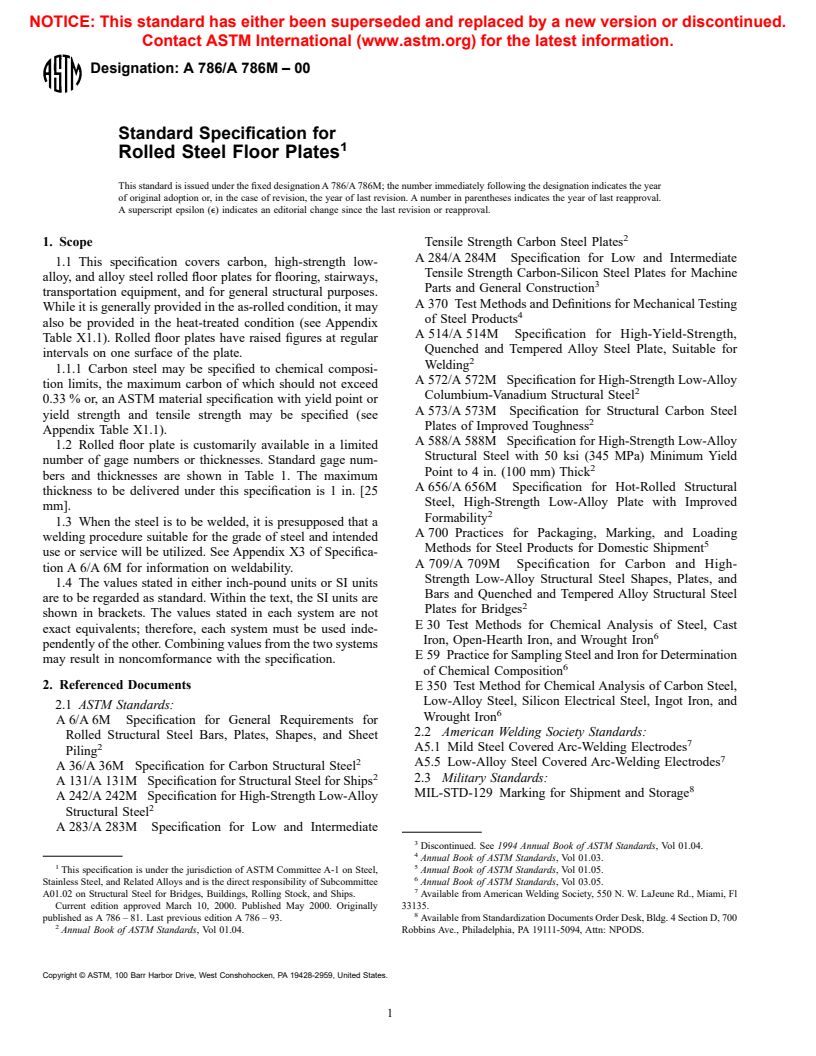

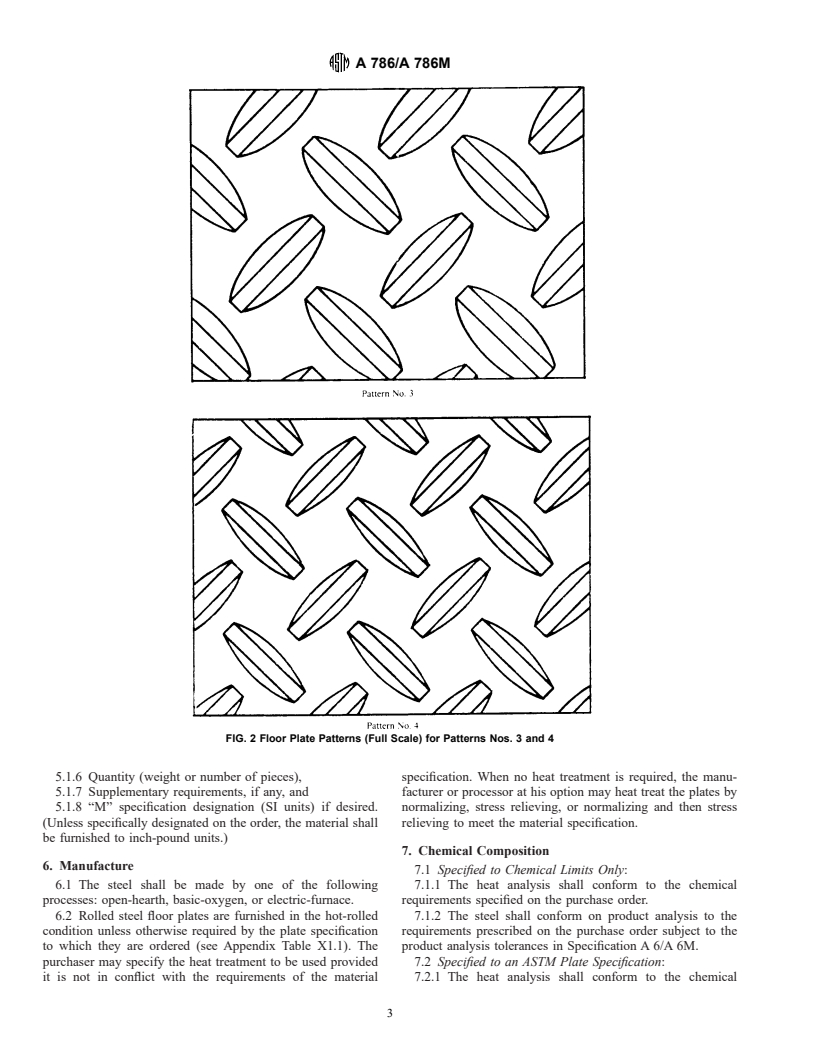

3.1 Individual floor plate patterns are manufactured exclu-

5.1.1 ASTM designation and year of issue,

sively by each producer and are not identical in dimension or

5.1.2 Chemical composition limits or ASTM material des-

appearance to patterns manufactured by other producers, al-

ignation and grade (if applicable) and year of issue (if neither

though there may be a close resemblance. Standard patterns are

is specified, the product will be supplied 0.33 % maximum

shown in Figs. 1-3.

carbon and without specified mechanical properties),

4. General Requirements for Delivery

5.1.3 Product (rolled floor plate),

4.1 Material furnished under this specification shall con- 5.1.4 Pattern designation (see Figs. 1-3),

form to the requirements of Sections 6, 7, 10, 11, 12, 14, 15, 5.1.5 Dimensions,

FIG. 1 Floor Plate Patterns (Full Scale) for Patterns Nos. 1 and 2

A 786/A 786M

FIG. 2 Floor Plate Patterns (Full Scale) for Patterns Nos. 3 and 4

5.1.6 Quantity (weight or number of pieces), specification. When no heat treatment is required, the manu-

5.1.7 Supplementary requirements, if any, and facturer or processor at his option may heat treat the plates by

5.1.8 “M” specification designation (SI units) if desired. normalizing, stress relieving, or normalizing and then stress

(Unless specifically designated on the order, the material shall relieving to meet the material specification.

be furnished to inch-pound units.)

7. Chemical Composition

6. Manufacture

7.1 Specified to Chemical Limits Only:

6.1 The steel shall be made by one of the following 7.1.1 The heat analysis shall conform to the chemical

processes: open-hearth, basic-oxygen, or electric-furnace. requirements specified on the purchase order.

6.2 Rolled steel floor plates are furnished in the hot-rolled 7.1.2 The steel shall conform on product analysis to the

condition unless otherwise required by the plate specification requirements prescribed on the purchase order subject to the

to which they are ordered (see Appendix Table X1.1). The product analysis tolerances in Specification A 6/A 6M.

purchaser may specify the heat treatment to be used provided 7.2 Specified to an ASTM Plate Specification:

it is not in conflict with the requirements of the material 7.2.1 The heat analysis shall conform to the chemical

A 786/A 786M

FIG. 3 Floor Plate Patterns (Full Scale) for Pattern No. 1

requirements table listed in the plate specification which is in Specification A 6/A 6M.

ordered (see Appendix Table X1.1).

7.3 Floor plate may be specified copper bearing with not

7.2.2 The steel shall conform on product analysis to the

less than 0.20 % copper in heat analysis or not less than 0.18 %

requirements prescribed in the heat analysis table for the

copper on product analysis.

ordered specification subject to the product analysis tolerances

TABLE 1 Standard Thicknesses and Theoretical Weight [Mass] for Rolled Floor Plates

A,B A,B A,B

Thickness Theoretical Thickness Theoretical Thickness Theoretical

Gage [mm] Weight, [Mass, in. [mm] Weight, [Mass, in. [mm] Weight, [Mass,

2 2 2 2 2 2

No. lb/ft kg/m ] lb/ft kg/m ] lb/ft kg/m ]

C

18 [1.4] 2.40 [11.72] 1 8 [3.5] 6.16 [30.08] 1 2 [13] 21.47 [104.8]

/ /

C

16 [1.6] 3.00 [14.65] 3 16 [5] 8.71 [42.53] 9 16 [14] 24.02 [117.3]

/ /

14 [2.0] 3.75 [18.31] 1 4 [6] 11.26 [54.98] 5 8 [16] 26.58 [129.8]

/ /

13 [2.5] 4.50 [21.97] 5 16 [8] 13.81 [67.43] 3 4 [20] 31.68 [154.7]

/ /

12 [3.0] 5.25 [25.63] 3 8 [10] 16.37 [79.93] 7 8 [22] 36.78 [179.6]

/ /

10 [4.0] 6.81 [33.25] 7 16 [11] 18.92 [92.38] 1 [25] 41.89 [204.5]

/

A

One cubic foot of rolled steel is assumed to weigh 490 lb. [One cubic metre is assumed to weigh 7850 kg.]

B

Theoretical weights are shown for estimating convenience.

C

The reverse side of the plate is flat except for the portion below the raised figures which may be hollow.

8. Tensile Properties Percent elongation is not required for rolled floor plate. ASTM

plate specifications that may be ordered are listed in Table

8.1 The material as represented by the test specimen shall

X1.1.

conform to the requirements for yield point or yield strength,

and tensile strength in the plate specification that is ordered.

9. Permissible Variations

The tension test shall be conducted on specimens with the

raised figures present. Thickness is measured at a position 9.1 The permissible variation for dimensions shall not

between the raised figures in an area unaffected by the pattern. exceed the limits in Tables 2-7 or Tables A1.1-A1.6, inclusive.

A 786/A 786M

SUPPLEMENTARY REQUIREMENTS

Standardized supplementary requirements for use at the option of the purchaser are listed in

Specification A 6/A 6M. Those that are considered suitable for use with this specification are listed by

title:

S2. Product Analysis

A 786/A 786M

PERMISSIBLE VARIATIONS IN DIMENSIONS AND WEIGHTS IN INCH-POUND UNITS

TABLE 2 Permissible Variations for Weight for Rolled Floor Plates Carbon, High-Strength Low-Alloy and Alloy Steel

A

NOTE 1— Tolerances for overweight for lots of circular and sketch plates are 1 ⁄4 times the amounts in the table below.

NOTE 2—Tolerances for overweight for single plates are 1 ⁄3 times the amounts in the table below.

NOTE 3—Tolerances for overweight for single circular and sketch plates are 1 ⁄3 times the amounts in the table below.

B

Tolerances for Average Weight of Lots Expressed in

Gage No. or Equivalent Theoretical

Percentage of the Specified Weights per Square Foot

Thickness, in. Weight, lb/ft

Over Under

18 to 3.00 excl 10 5

16, 14, 13, and 12 3.00 to 6.16, excl 8 5

10 and 1 8 6.16 to 8.71, excl 6 5

/

3 16 8.71 to 11.26, excl 5.5 3

/

1 4 11.26 to 13.81, excl 5 3

/

5 16 13.81 to 16.37, excl 4.5 3

/

3 8 16.37 to 18.92, excl 4 3

/

7 16 18.92 to 21.47, excl 3.5 2.5

/

1 2 and 9 16 21.47 to 26.58, excl 3 2.5

/ /

5 8,3 4,7 8, 26.58 to 41.89, incl 2.5 2.5

/ / /

and 1

A

Sketch plates are plates having three or more sides, and forms other than circles, squares, and rectangles.

B

The term lot means all the plates of each tabular weight group represented in each shipment.

TABLE 3 Permissible Variations for Width and Length for Rolled Floor Plates Carbon, High-Strength

Low-Alloy and Alloy Steel

A

Specified Dimensions, in. Tolerances, in., Over Specified Width and Length for Thicknesses

and Equivalent Weights Given

Under 3 8 in. 3 8to5 8 in., excl 5 8 to 1 in., incl

/ / / /

Under 16.37 16.37 to 26.58, 26.58 to 41.89

Width Length

2 2 2

lb/ft lb/ft , excl lb/ft , incl

Width Length Width Length Width Length

To 96, incl under 120 38127 16 58121

/ / / / /

120 to 240, excl 383412785811 8

/ / / / / /

240 to 360, excl 381 121185811 2

/ / / / /

360 to 480, incl 7 16 1 14121385815 8

/ / / / / /

A

Tolerances under specified width and length:

(a) For thicknesses 3 16 in. (8.71 lb/ft ) and over: 1 4 in.

/ /

(b) For thicknesses under 3 16 in.: 1 8 in.

/ /

TABLE 4 Permissible Camber for Raised Figures for Rolled

Floor Plates Carbon, High-Strength Low-Alloy and Alloy Steel

(See Fig. 4)

Camber, as it relates to raised 3 8 in. 3 (number of feet of

/

figures, is the curvature of the raised length)/5

figures in the length direction,

measured over the entire length of

the plate.

A

TABLE 5 Permissible Camber for Rectangular Sheared-Rolled

Floor Plates and Gas-Cut Rolled Floor Plates Carbon,

High-Strength Low-Alloy and Alloy Steel (See Fig. 5)

Thick- Specified Widths, Camber Tolerances for

nesses, in. Weights, in. Thickness and Widths Given

lb/ft

To 1, incl to 41.89, incl all 1 8 in. 3 (number of feet of length)/5

/

A

Camber, as it relates to plates, is the horizontal edge curvature in the length, measured over the entire length of the plate in the flat position.

A 786/A 786M

FIG. 4 Camber for Raised Figures for Rolled Floor Plates (see Table 3 or Table A1.3)

TABLE 6 Permissible Variations from Flatness for Carbon Steel Rectangular, Circular, and Sketch Rolled Floor Plates

(Applies to Carbon Steel Only)

NOTE 1— When the longer dimension is under 36 in., the permissible variation should not exceed ⁄4 in. When the longer dimension is from 36 in. to

72 in., incl, the permissible variation should not exceed 75 % of the tabular amount for the specified width, but in no case less than ⁄4 in.

NOTE 2— These variations apply to plates which have a specified minimum tensile strength of not more than 60 000 psi (415 MPa) or compatible

chemistry or hardness. The limits in the table are increased 50 % for plates specified to a higher minimum tensile strength or compatible chemistry or

hardness.

NOTE 3—This table and these notes cover the permissible variations for flatness of circular and sketch plates, based on the maximum dimensions of

those plates.

A,B

Permissible Variations from a Flat Surface for Specified Widths, in.

Specified Weight,

Specified Thickness, in.

To 36, 36 to 48, 48 to 60, 60 to 72, 72 to 84, 84 to 96,

lb/ft

excl excl excl excl excl excl

To 1 4 , excl To 11.26, excl 9 16 3415 16 1 1413811215 8

/ / / / / / / /

1 4to3 8 , excl 11.26 to 16.37, excl 12583415 16 1 1811413 8

/ / / / / / / / /

3 8to1 2 , excl 16.37 to 21.47, excl 129 16 585834781

/ / / / / / / /

1 2to3 4 , excl 21.47 to 31.68, excl 7 16 129 16 5858341

/ / / / / / / /

3 4 to 1, excl 31.68 to 41.89, ex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.