ASTM E328-02(2008)

(Test Method)Standard Test Methods for Stress Relaxation Tests for Materials and Structures

Standard Test Methods for Stress Relaxation Tests for Materials and Structures

SIGNIFICANCE AND USE

Relaxation test data are necessary when designing most mechanically fastened joints to assure the permanent tightness of bolted or riveted assemblies, press or shrink-fit components, rolled-in tubes, etc. Other applications include predicting the decrease in the tightness of gaskets, in the hoop stress of solderless wrapped connections, in the constraining force of springs, and the stability of wire tendons in prestressed concrete.

The ability of a material to relax at high-stress concentrations such as are present at notches, inclusions, cracks, holes, fillets, etc., may be predicted from stress relaxation data. Such test data are also useful to judge the heat-treatment condition necessary for the thermal relief of residual internal stresses in forgings, castings, weldments, machined or cold-worked surfaces, etc. The tests outlined in these methods are limited to conditions of approximately constant constraint and environment.

The test results are highly sensitive to small changes in environmental conditions and thus require precise control of test conditions and methods.

The reproducibility of data will depend on the manner with which all test conditions are controlled. The effects of aging or residual stress may significantly affect results, as may variations in material composition.

SCOPE

Note 1—The method of testing for the stress relaxation of plastics has been withdrawn from this standard, and the responsibility has been transferred to Practice D 2991.

1.1 These test methods cover the determination of the time dependence of stress (stress relaxation) in materials and structures under conditions of approximately constant constraint, constant environment, and negligible vibration. In the procedures recommended, the material or structure is initially constrained by externally applied forces, and the change in the external force necessary to maintain this constraint is determined as a function of time.

1.2 Specific methods for conducting stress relaxation tests on materials subjected to tension, compression, bending and torsion stresses are described in Parts A, B, C, and D, respectively. These test methods also include recommendations for the necessary testing equipment and for the analysis of the test data.

1.3 It is recognized that the long time periods required for these types of tests are often unsuited for routine testing or for specification in the purchase of material. However, these tests are valuable tools in obtaining practical design information on the stress relaxation of materials subjected to the conditions enumerated, and in investigations of the fundamental behavior of materials.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

13.1 This test method covers the determination of the time-dependent decrease in stress in a specimen subjected to an uniaxial constant tension strain under conditions of uniform environment and negligible vibration. It also includes recommendations for the necessary testing equipment.

22.1 This test method covers the determination of the time-dependent decrease in stress in a specimen subjected to a long duration, uniaxial, constant compression strain in a uniform environment and negligible vibration. It also includes recommendations for the necessary testing equipment.

30.1 This test method covers the determination of the time-dependent decrease in stress in a specimen subject to long duration, constant bending strain, in a uniform environment, and negligible vibration...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E328 − 02(Reapproved 2008)

Standard Test Methods for

Stress Relaxation for Materials and Structures

This standard is issued under the fixed designation E328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

These test methods cover a broad range of testing activities. To aid in locating the subject matter

pertinent to a particular test, the standard is divided into a general section, which applies to all stress

relaxationtestsformaterialsandstructures.Thisgeneralsectionisfollowedbyletter-designatedparts

that apply to tests for material characteristics when subjected to specific, simple stresses, such as

uniform tension, uniform compression, bending or torsion. To choose from among these types of

stress, the following factors should be considered:

(1) When the material data are to be applied to the design of a particular class of component, the

stress during the relaxation test should be similar to that imposed on the component. For example,

tension tests are suitable for bolting applications and bending tests for leaf springs.

(2) Tension and compression relaxation tests have the advantage that the stress can be reported

simply and unequivocally. During bending relaxation tests, the state of stress is complex, but can be

accurately determined when the initial strains are elastic. If plastic strains occur on application of

force, stresses can usually be determined within a bounded range only.Tension relaxation tests, when

compared to compression tests, have the advantage that it is unnecessary to guard against buckling.

Therefore,whenthetestmethodisnotrestrictedbythetypeofstressinthecomponent,tensiontesting

is recommended.

(3) Bending tests for relaxation, when compared to tension and compression tests, have the

advantage of using lighter and simpler apparatus for specimens of the same cross-sectional area.

Strains are usually calculated from deflection or curvature measurements. Since the specimens can

usually be designed so that these quantities are much greater than the axial deformation in a direct

stress test, strain is more easily measured and more readily used for machine control in the bending

tests.Duetothesmallforcesnormallyrequiredandthesimplicityoftheapparatuswhenstaticfixtures

are sufficient, many specimens can be placed in a single oven or furnace when tests are made at

elevated temperatures.

1. Scope the procedures recommended, the material or structure is

NOTE 1—The method of testing for the stress relaxation of plastics has

initially constrained by externally applied forces, and the

been withdrawn from this standard, and the responsibility has been

change in the external force necessary to maintain this con-

transferred to Practice D2991.

straint is determined as a function of time.

1.1 These test methods cover the determination of the time

1.2 Specific methods for conducting stress relaxation tests

dependence of stress (stress relaxation) in materials and

on materials subjected to tension, compression, bending and

structures under conditions of approximately constant

torsion stresses are described in Parts A, B, C, and D,

constraint, constant environment, and negligible vibration. In

respectively.Thesetestmethodsalsoincluderecommendations

for the necessary testing equipment and for the analysis of the

These test methods are under the jurisdiction of ASTM Committee E28 on

test data.

Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on

Uniaxial Testing.

1.3 It is recognized that the long time periods required for

Current edition approved May 1, 2008. Published December 2008. Originally

these types of tests are often unsuited for routine testing or for

approved in 1967. Last previous approved in 2002 as E328–02. DOI: 10.1520/

E0328-02R08. specification in the purchase of material. However, these tests

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E328 − 02 (2008)

are valuable tools in obtaining practical design information on dure. However, the constraint is usually obtained initially by

the stress relaxation of materials subjected to the conditions the application of an external force at either a specific force

enumerated, and in investigations of the fundamental behavior application rate or a specific strain rate. The two methods will

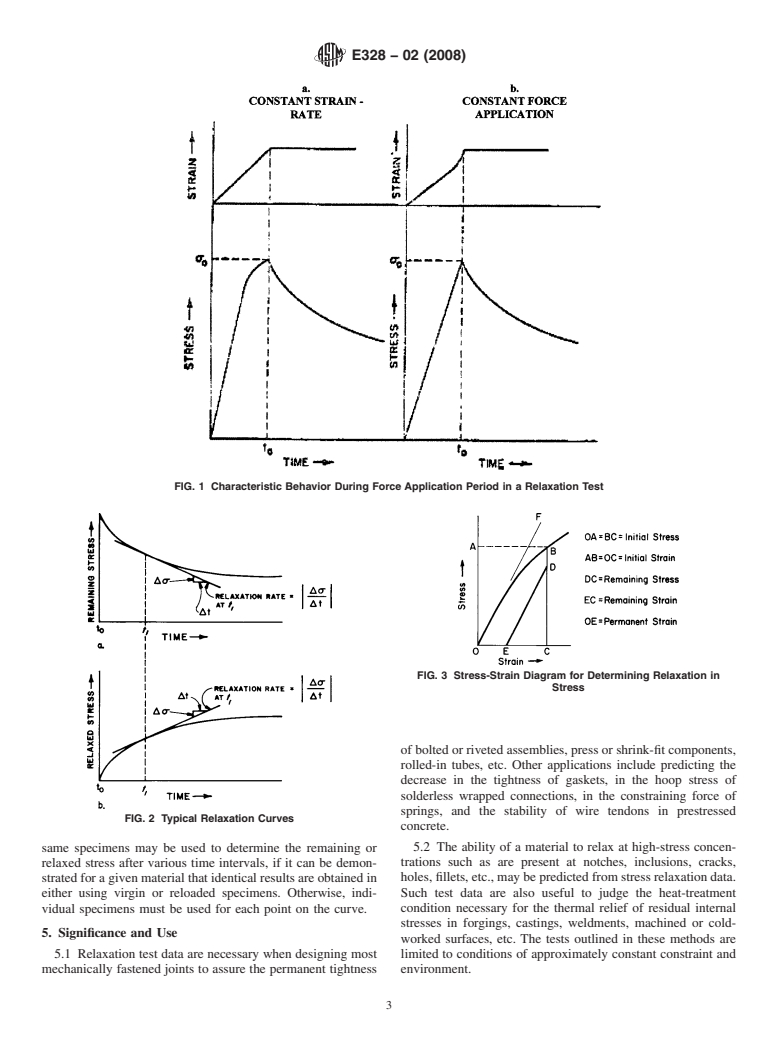

of materials. produce the characteristic behavior shown in Fig. 1 when the

initial stress, σ , exceeds the proportional limit. Some testing

1.4 Units—The values stated in inch-pound units are to be

machines, while reaching the constraint value, do not produce

regarded as standard. The values given in parentheses are

either a constant force application rate or constant strain rate,

mathematical conversions to SI units that are provided for

butsomethinginbetween.However,thegeneralcharacteristics

information only and are not considered standard.

of the data will be similar to those indicated. The stress

1.5 This standard does not purport to address all of the

application rate in either case should be reasonably rapid, but

safety concerns, if any, associated with its use. It is the

without impact or vibration, so that any relaxation during the

responsibility of the user of this standard to establish appro-

stress application period will be small.

priate safety and health practices and determine the applica-

3.1.3 zero time, t —the time when the given stress or

bility of regulatory limitations prior to use.

constraintconditionsareinitiallyobtainedinastressrelaxation

test.

2. Referenced Documents

3.1.3.1 Discussion—The stress relaxation test is considered

2.1 ASTM Standards:

to have started at zero time, t in Fig. 1. This is the reference

D2991Test Method for Stress-Relaxation of Plastics (With-

time from which the observed reduction in force to maintain

drawn 1990)

constant constraint is based. Selection of this time does not

E4Practices for Force Verification of Testing Machines

imply that the force application procedure or period, or both,

E8/E8MTest Methods for Tension Testing of Metallic Ma-

are not significant test parameters. These must always be

terials

considered in the application of the data.

E9Test Methods of Compression Testing of Metallic Mate-

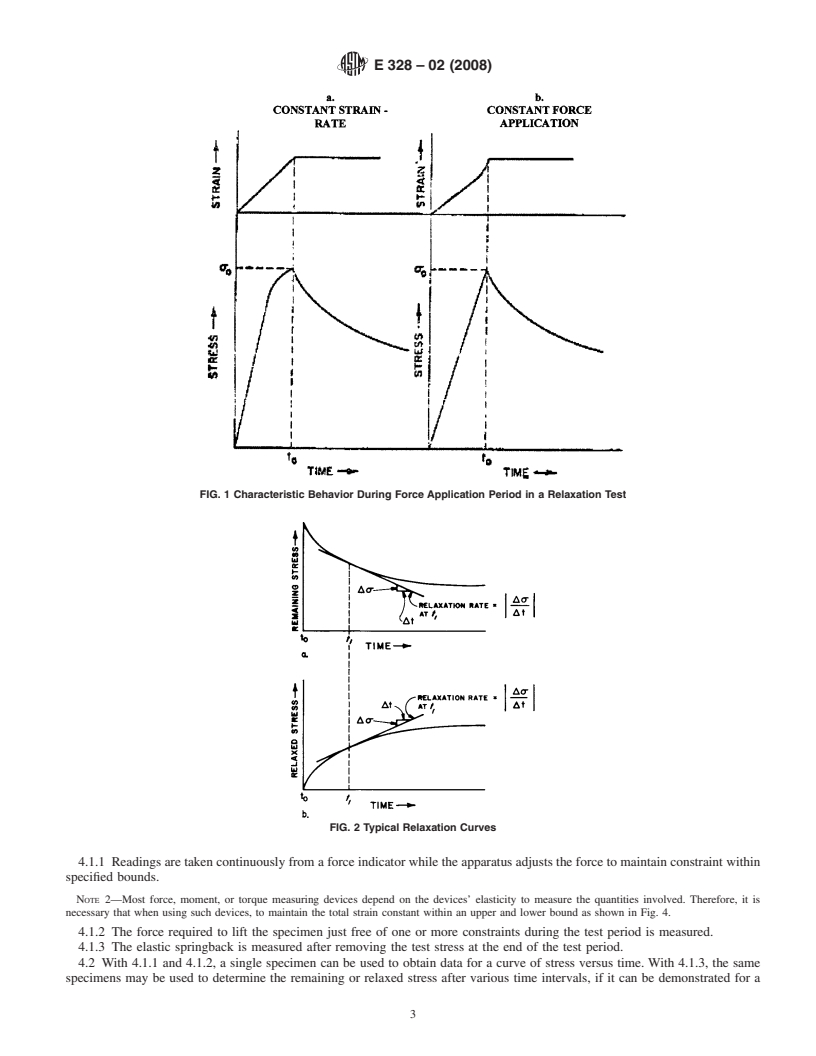

3.1.4 relaxation rate—the absolute value of the slope of the

rials at Room Temperature

relaxation curve at a given time.

E83Practice for Verification and Classification of Exten-

someter Systems 3.1.5 spherometer—an instrument used to measure circular

E139Test Methods for Conducting Creep, Creep-Rupture, or spherical curvature.

and Stress-Rupture Tests of Metallic Materials

3.1.6 indicated nominal temperature or indicated

E1012Practice for Verification of Testing Frame and Speci-

temperature—the temperature that is indicated by the

men Alignment Under Tensile and Compressive Axial

temperature-measuring device.

Force Application

4. Summary of Test Methods

3. Terminology

4.1 In each of the various methods of stress application

3.1 Definitions:

described in the applicable specific sections, the specimen is

3.1.1 stress relaxation—the time-dependent decrease in

subjected to an increasing force until the specified initial strain

stress in a solid under given constraint conditions.

is attained (see zero time in 3.1.3 and in Fig. 1). For the

3.1.1.1 Discussion—The general stress relaxation test is

duration of the test, the specimen constraint is maintained

performedbyisothermallyapplyingaforcetoaspecimenwith

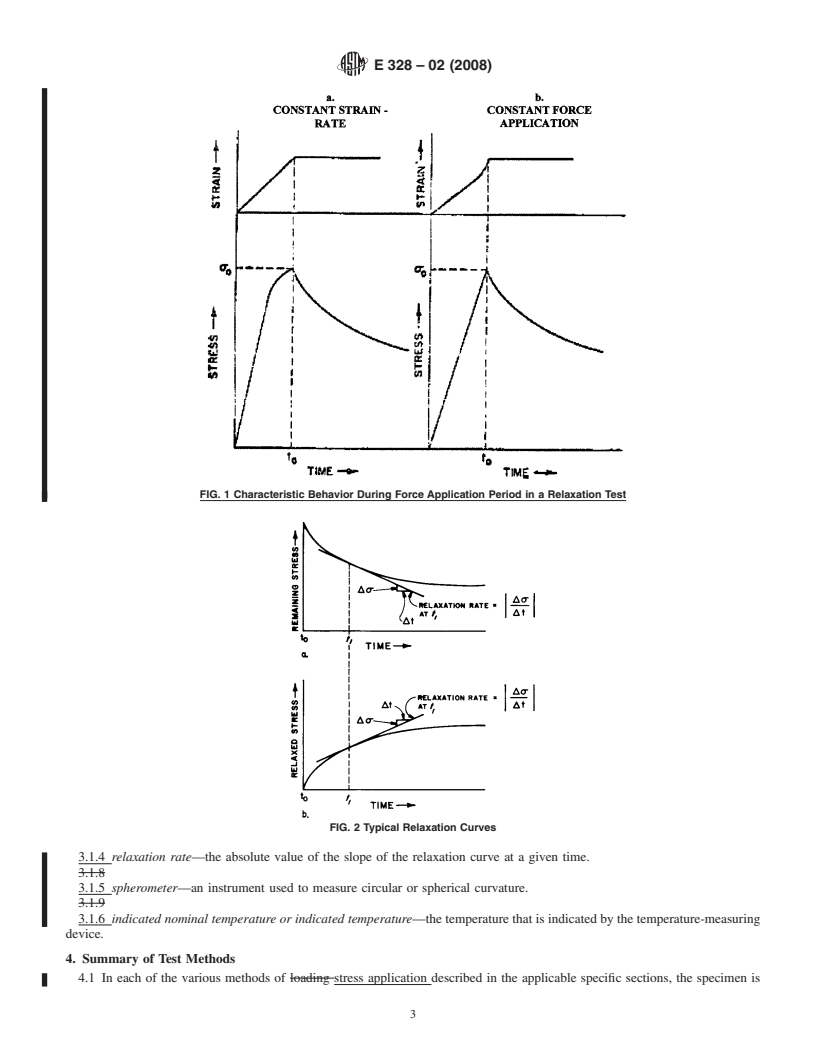

constant. The initial stress is calculated from the initial force

fixed value of constraint.The constraint is maintained constant

(moment, torque) as measured at zero time, the specimen

and the constraining force is determined as a function of time.

geometry, and the appropriate elastic constants, often using

The major problem in the stress relaxation test is that constant

simple elastic theory. The remaining stress may be calculated

constraint can be very difficult to maintain. The effects on test

fromtheforce(momentortorque)determinedunderconstraint

results are very significant and considerable attention must be

conditions either continuously (4.1.1), periodically (4.1.2), or

giventominimizetheconstraintvariation.Also,experimenters

by elastic springback at the end of the test period [4.1.3 (see

should determine and report the extent of variation in each

Fig. 3)].

stress relaxation test so that this factor can be taken into

4.1.1 Readings are taken continuously from a force indica-

consideration.

tor while the apparatus adjusts the force to maintain constraint

−2

3.1.2 initial stress [FL ]—the stress introduced into a

within specified bounds.

specimen by imposing the given constraint conditions before

NOTE 2—Most force, moment, or torque measuring devices depend on

stress relaxation begins.

the devices’ elasticity to measure the quantities involved. Therefore, it is

3.1.2.1 Discussion—Therearemanymethodsofperforming

necessary that when using such devices, to maintain the total strain

the stress relaxation test, each with a different starting proce- constant within an upper and lower bound as shown in Fig. 4.

4.1.2 Theforcerequiredtoliftthespecimenjustfreeofone

or more constraints during the test period is measured.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.3 The elastic springback is measured after removing the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on test stress at the end of the test period.

the ASTM website.

4.2 With 4.1.1 and 4.1.2, a single specimen can be used to

The last approved version of this historical standard is referenced on

www.astm.org. obtain data for a curve of stress versus time. With 4.1.3, the

E328 − 02 (2008)

FIG. 1 Characteristic Behavior During Force Application Period in a Relaxation Test

FIG. 3 Stress-Strain Diagram for Determining Relaxation in

Stress

ofboltedorrivetedassemblies,pressorshrink-fitcomponents,

rolled-in tubes, etc. Other applications include predicting the

decrease in the tightness of gaskets, in the hoop stress of

solderless wrapped connections, in the constraining force of

springs, and the stability of wire tendons in prestressed

FIG. 2 Typical Relaxation Curves

concrete.

5.2 The ability of a material to relax at high-stress concen-

same specimens may be used to determine the remaining or

relaxed stress after various time intervals, if it can be demon- trations such as are present at notches, inclusions, cracks,

holes,fillets,etc.,maybepredictedfromstressrelaxationdata.

stratedforagivenmaterialthatidenticalresultsareobtainedin

either using virgin or reloaded specimens. Otherwise, indi- Such test data are also useful to judge the heat-treatment

condition necessary for the thermal relief of residual internal

vidual specimens must be used for each point on the curve.

stresses in forgings, castings, weldments, machined or cold-

5. Significance and Use

worked surfaces, etc. The tests outlined in these methods are

5.1 Relaxation test data are necessary when designing most limited to conditions of approximately constant constraint and

mechanically fastened joints to assure the permanent tightness environment.

E328 − 02 (2008)

7.2 Thetemperatureshouldberecorded,preferablycontinu-

ously or at least periodically. Temperature variations of the

specimens from the indicated nominal test temperature due to

all causes, including cycling of the controller or position along

the specimen gage length, should not exceed 6 5°F (3°C) or

61/2%, whichever is greater. These limits should apply

initially and for the duration of the test.

7.3 The combined strain resulting from differential thermal

expansion(associatedwithnormaltemperaturevariationofthe

environment)betweenthetestspecimenandtheconstraintand

other variations in the constraint (such as elastic follow up)

should not exceed 60.000025 in./in. (mm/mm).

7.4 Temperature measurement should be made in accor-

dance with Practice E139.

8. Vibration Control

8.1 Since stress relaxation tests are quite sensitive to shock

and vibration, the test equipment and mounting should be

located so that the specimen is isolated from vibration.

9. Test Specimens

9.1 The test specimens should be of a shape most appropri-

ate for the testing method and end use. Wire may be tested in

the “as-received” condition and in the case of metal plate,

sheet, strip, bar, or rod, they may be machined to the desired

shape.

9.2 Residualstressesmaysignificantlyalterthestressrelax-

ation characteristics of the material and care should be exer-

cisedinmachiningtopreventalterationoftheresidualstresses.

9.3 Specimensfortestingmusthaveauniformcross-section

throughout the gage length and meet the following tolerances:

FIG. 4 Derivation of Stress-Relaxation Curve from Continuous

Tolerance, % of Diameter

Relaxation Technique

Nominal Diameter or Width

or Width

0.100 in. (2.5 mm) ±0.5

0.250 in. (6.4 mm) ±0.4

5.3 The test results are highly sensitive to small changes in

0.375 in. (9.5 mm) ±0.3

environmental conditions and thus require precise control of

0.500 in. (12.7 mm) ±0.2

test conditions and methods.

10. Environment

5.4 The reproducibility of data will depend on the manner

with which all test conditions are controlled. The effects of

10.1 If the test temperature is different from ambient,

aging or residual stress may significantly affect results, as may

specimens previously fitted with strain gages or extensometers

variations in material composition.

should be exposed to the test temperature for a period of time

sufficient to obtain dimensional stability before starting the

6. Apparatus

tests.

6.1 See the appropriate paragraph under each section.

10.2 The stress relaxation test may be started immediately

6.2 It is recommended that the equipment be located in a

upon achieving thermal equilibrium.

draft-free, constant-temperature environment, 6 5°F (3°C).

11. Guide for Processing Test Data

7. Temperature Control and Measurement

11.1 The remaining stress, relaxed stress, or applied force

7.1 Thetestspace(controlledtemperatureroom,furnace,or

may be plotted against time or log time. Log stress versus log

cold box) should be capable of being maintained at a constant

time plots may also be employed.

temperature by a suitable automatic device. This is the most

importantsinglefactorinastressrelaxationtestsincethestress 11.2 For convenience in comparing the

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E328–02 Designation:E328–02 (Reapproved 2008)

Standard Test Methods for

Stress Relaxation for Materials and Structures

This standard is issued under the fixed designation E328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

These test methods cover a broad range of testing activities. To aid in locating the subject matter

pertinent to a particular test, the standard is divided into a general section, which applies to all stress

relaxationtestsformaterialsandstructures.Thisgeneralsectionisfollowedbyletter-designatedparts

that apply to tests for material characteristics when subjected to specific, simple stresses, such as

uniform tension, uniform compression, bending or torsion. To choose from among these types of

stress, the following factors should be considered:

(1) When the material data are to be applied to the design of a particular class of component, the

stress during the relaxation test should be similar to that imposed on the component. For example,

tension tests are suitable for bolting applications and bending tests for leaf springs.

(2) Tension and compression relaxation tests have the advantage that the stress can be reported

simply and unequivocally. During bending relaxation tests, the state of stress is complex, but can be

accurately determined when the initial strains are elastic. If plastic strains occur on application of

force, stresses can usually be determined within a bounded range only.Tension relaxation tests, when

compared to compression tests, have the advantage that it is unnecessary to guard against buckling.

Therefore,whenthetestmethodisnotrestrictedbythetypeofstressinthecomponent,tensiontesting

is recommended.

(3) Bending tests for relaxation, when compared to tension and compression tests, have the

advantage of using lighter and simpler apparatus for specimens of the same cross-sectional area.

Strains are usually calculated from deflection or curvature measurements. Since the specimens can

usually be designed so that these quantities are much greater than the axial deformation in a direct

stress test, strain is more easily measured and more readily used for machine control in the bending

tests.Duetothesmallforcesnormallyrequiredandthesimplicityoftheapparatuswhenstaticfixtures

are sufficient, many specimens can be placed in a single oven or furnace when tests are made at

elevated temperatures.

1. Scope

NOTE 1—The method of testing for the stress relaxation of plastics has been withdrawn from this standard, and the responsibility has been transferred

to Practice D2991.

1.1 These test methods cover the determination of the time dependence of stress (stress relaxation) in materials and structures

under conditions of approximately constant constraint, constant environment, and negligible vibration. In the procedures

recommended, the material or structure is initially constrained by externally applied forces, and the change in the external force

necessary to maintain this constraint is determined as a function of time.

1.2 Specific methods for conducting stress relaxation tests on materials subjected to tension, compression, bending and torsion

stresses are described in Parts A, B, C, and D, respectively. These test methods also include recommendations for the necessary

testing equipment and for the analysis of the test data.

1.3 It is recognized that the long time periods required for these types of tests are often unsuited for routine testing or for

specification in the purchase of material. However, these tests are valuable tools in obtaining practical design information on the

stress relaxation of materials subjected to the conditions enumerated, and in investigations of the fundamental behavior of

materials.

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on Uniaxial

Testing.

´1

Current edition approved Nov 10, 2002. Published April 2003. Originally approved in 1967. Last previous approved 1986 as E328–86(96) .

Current edition approved May 1, 2008. Published December 2008. Originally approved in 1967. Last previous approved in 2002 as E328–02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E328–02 (2008)

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Units—The values stated in inch-pound units are to be regarded as standard. The values given in

parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D2991 Recommended Practice for Testing Stress-Relaxation of Plastics

E4 Practices for Force Verification of Testing Machines

E8/E8M Test Methods for Tension Testing of Metallic Materials

E9 Test Methods offor Compression Testing of Metallic Materials at Room Temperature

E83 Practice for Verification and Classification of Extensometer Systems

E139 Practice Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

E1012 Practice for Verification of Specimen Alignment Under Tensile Loading Practice for Verification of Test Frame and

Specimen Alignment Under Tensile and Compressive Axial Force Application

3. Terminology

3.1 Definitions:

3.1.1 stress relaxation—the time-dependent decrease in stress in a solid under given constraint conditions.

3.1.1.1 Discussion—The general stress relaxation test is performed by isothermally applying a force to a specimen with fixed

valueofconstraint.Theconstraintismaintainedconstantandtheconstrainingforceisdeterminedasafunctionoftime.Themajor

problem in the stress relaxation test is that constant constraint can be very difficult to maintain.The effects on test results are very

significant and considerable attention must be given to minimize the constraint variation. Also, experimenters should determine

and report the extent of variation in each stress relaxation test so that this factor can be taken into consideration.

−2

3.1.2 initial stress [FL ]—the stress introduced into a specimen by imposing the given constraint conditions before stress

relaxation begins.

3.1.2.1 Discussion—There are many methods of performing the stress relaxation test, each with a different starting procedure.

However,theconstraintisusuallyobtainedinitiallybytheapplicationofanexternalforceateitheraspecificforceapplicationrate

or a specific strain rate. The two methods will produce the characteristic behavior shown in Fig. 1 when the initial stress, s ,

exceeds the proportional limit. Some testing machines, while reaching the constraint value, do not produce either a constant force

application rate or constant strain rate, but something in between. However, the general characteristics of the data will be similar

to those indicated. The stress application rate in either case should be reasonably rapid, but without impact or vibration, so that

any relaxation during the stress application period will be small.

3.1.3 zero time, t —the time when the given stress or constraint conditions are initially obtained in a stress relaxation test.

3.1.3.1 Discussion—The stress relaxation test is considered to have started at zero time, t in Fig. 1. This is the reference time

from which the observed reduction in force to maintain constant constraint is based. Selection of this time does not imply that the

force application procedure or period, or both, are not significant test parameters. These must always be considered in the

application of the data.

3.1.4 relaxation rate—the absolute value of the slope of the relaxation curve at a given time.

3.1.5 spherometer—an instrument used to measure circular or spherical curvature.

3.1.6 indicated nominal temperature or indicated temperature—thetemperaturethatisindicatedbythetemperature-measuring

device.

4. Summary of Test Methods

4.1 In each of the various methods of stress application described in the applicable specific sections, the specimen is subjected

to an increasing force until the specified initial strain is attained (see zero time in 3.1.3 and in Fig. 1). For the duration of the test,

the specimen constraint is maintained constant.The initial stress is calculated from the initial force (moment, torque) as measured

at zero time, the specimen geometry, and the appropriate elastic constants, often using simple elastic theory. The remaining stress

may be calculated from the force (moment or torque) determined under constraint conditions either continuously (4.1.1),

periodically (4.1.2), or by elastic springback at the end of the test period [4.1.3 (see Fig. 3)].

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 08.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 03.01.

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

E328–02 (2008)

FIG. 1 Characteristic Behavior During Force Application Period in a Relaxation Test

FIG. 2 Typical Relaxation Curves

4.1.1 Readingsaretakencontinuouslyfromaforceindicatorwhiletheapparatusadjuststheforcetomaintainconstraintwithin

specified bounds.

NOTE 2—Most force, moment, or torque measuring devices depend on the devices’ elasticity to measure the quantities involved. Therefore, it is

necessary that when using such devices, to maintain the total strain constant within an upper and lower bound as shown in Fig. 4.

4.1.2 The force required to lift the specimen just free of one or more constraints during the test period is measured.

4.1.3 The elastic springback is measured after removing the test stress at the end of the test period.

4.2 With 4.1.1 and 4.1.2, a single specimen can be used to obtain data for a curve of stress versus time. With 4.1.3, the same

specimens may be used to determine the remaining or relaxed stress after various time intervals, if it can be demonstrated for a

E328–02 (2008)

FIG. 3 Stress-Strain Diagram for Determining Relaxation in

Stress

FIG. 4 Derivation of Stress-Relaxation Curve from Continuous

Relaxation Technique

given material that identical results are obtained in either using virgin or reloaded specimens. Otherwise, individual specimens

must be used for each point on the curve.

5. Significance and Use

5.1 Relaxation test data are necessary when designing most mechanically fastened joints to assure the permanent tightness of

boltedorrivetedassemblies,pressorshrink-fitcomponents,rolled-intubes,etc.Otherapplicationsincludepredictingthedecrease

in the tightness of gaskets, in the hoop stress of solderless wrapped connections, in the constraining force of springs, and the

stability of wire tendons in prestressed concrete.

5.2 Theabilityofamaterialtorelaxathigh-stressconcentrationssuchasarepresentatnotches,inclusions,cracks,holes,fillets,

etc., may be predicted from stress relaxation data. Such test data are also useful to judge the heat-treatment condition necessary

E328–02 (2008)

forthethermalreliefofresidualinternalstressesinforgings,castings,weldments,machinedorcold-workedsurfaces,etc.Thetests

outlined in these methods are limited to conditions of approximately constant constraint and environment.

5.3 The test results are highly sensitive to small changes in environmental conditions and thus require precise control of test

conditions and methods.

5.4 The reproducibility of data will depend on the manner with which all test conditions are controlled.The effects of aging or

residual stress may significantly affect results, as may variations in material composition.

6. Apparatus

6.1 See the appropriate paragraph under each section.

6.2 It is recommended that the equipment be located in a draft-free, constant-temperature environment, 63°C (65°F). 6 5°F

(3°C).

7. Temperature Control and Measurement

7.1 The test space (controlled temperature room, furnace, or cold box) should be capable of being maintained at a constant

temperature by a suitable automatic device. This is the most important single factor in a stress relaxation test since the stress

relaxationrate,dimensions,andconstraintconditionsofthespecimenaredependentuponthetesttemperature.Anytypeofheating

or cooling which permits close temperature control of the test space environment is satisfactory.

7.2 The temperature should be recorded, preferably continuously or at least periodically. Temperature variations of the

specimens from the indicated nominal test temperature due to all causes, including cycling of the controller or position along the

specimen gage length, should not exceed 6 3°C (5°F)5°F (3°C) or 61/2%, whichever is greater. These limits should apply

initially and for the duration of the test.

7.3 The combined strain resulting from differential thermal expansion (associated with normal temperature variation of the

environment) between the test specimen and the constraint and other variations in the constraint (such as elastic follow up) should

not exceed 60.000025 in./in. (mm/mm).

7.4 Temperature measurement should be made in accordance with Practice E139.

8. Vibration Control

8.1 Since stress relaxation tests are quite sensitive to shock and vibration, the test equipment and mounting should be located

so that the specimen is isolated from vibration.

9. Test Specimens

9.1 The test specimens should be of a shape most appropriate for the testing method and end use. Wire may be tested in the

“as-received” condition and in the case of metal plate, sheet,

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:E328–86 (Reapproved 1996) Designation:E328–02 (Reapproved 2008)

Standard Test Methods for

Stress Relaxation for Materials and Structures

This standard is issued under the fixed designation E328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The title was changed editorially in January 1996.

INTRODUCTION

These test methods cover a broad range of testing activities. To aid in locating the subject matter

pertinent to a particular test, the standard is divided into a general section, which applies to all stress

relaxationtestsformaterialsandstructures.Thisgeneralsectionisfollowedbyletter-designatedparts

that apply to tests for material characteristics when subjected to specific, simple stresses, such as

uniform tension, uniform compression, bending or torsion. To choose from among these types of

loading,stress, the following factors should be considered:

(1) When the material data are to be applied to the design of a particular class of component, the

stress during the relaxation test should be similar to that imposed on the component. For example,

tension tests are suitable for bolting applications and bending tests for leaf springs.

(2) Tension and compression relaxation tests have the advantage that the stress can be reported

simply and unequivocally. During bending relaxation tests, the state of stress is complex, but can be

accuratelydeterminedwhentheinitialstrainsareelastic.Ifplasticstrainsoccuronloading,application

of force, stresses can usually be determined within a bounded range only. Tension relaxation tests,

when compared to compression tests, have the advantage that it is unnecessary to guard against

buckling. Therefore, when the test method is not restricted by the type of stress in the component,

tension testing is recommended.

(3) Bending tests for relaxation, when compared to tension and compression tests, have the

advantage of using lighter and simpler apparatus for specimens of the same cross-sectional area.

Strains are usually calculated from deflection or curvature measurements. Since the specimens can

usually be designed so that these quantities are much greater than the axial deformation in a direct

stress test, strain is more easily measured and more readily used for machine control in the bending

tests.Duetothesmallforcesnormallyrequiredandthesimplicityoftheapparatuswhenstaticfixtures

are sufficient, many specimens can be placed in a single oven or furnace when tests are made at

elevated temperatures.

1. Scope

NOTE 1—The method of testing for the stress relaxation of plastics has been withdrawn from this standard, and the responsibility has been transferred

to Practice D2991.

1.1 These test methods cover the determination of the time dependence of stress (stress relaxation) in materials and structures

under conditions of approximately constant constraint, constant environment, and negligible vibration. In the procedures

recommended, the material or structure is initially constrained by externally applied forces, and the change in the external force

necessary to maintain this constraint is determined as a function of time.

1.2 Specific methods for conducting stress relaxation tests on materials subjected to tension, compression, bending and torsion

loadsstresses are described in Parts A, B, C, and D, respectively. These test methods also include recommendations for the

necessary testing equipment and for the analysis of the test data.

1.3 It is recognized that the long time periods required for these types of tests are often unsuited for routine testing or for

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.10 on Effect of

Elevated Temperature on Properties.

Current edition approved Feb. 28, 1986. Published May 1986. Originally published as E328–67T. Last previous edition E328–78.

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on Uniaxial

Testing.

Current edition approved May 1, 2008. Published December 2008. Originally approved in 1967. Last previous approved in 2002 as E328–02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E328–02 (2008)

specification in the purchase of material. However, these tests are valuable tools in obtaining practical design information on the

stress relaxation of materials subjected to the conditions enumerated, and in investigations of the fundamental behavior of

materials.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D2991 Recommended Practice for Testing Stress-Relaxation of Plastics

E4 Practices for Force Verification of Testing Machines

E8/E8M Test Methods for Tension Testing of Metallic Materials

E9 Test Methods of Compression Testing of Metallic Materials at Room Temperature

E83 Practice for Verification and Classification of Extensometer Systems

E139 Practice for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials Test Methods for

Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

E1012 Practice for Verification of Test Frame and Specimen Alignment Under Tensile and Compressive Axial Force

Application

3. Terminology

3.1 Definitions:

3.1.1 stress relaxation—the time-dependent decrease in stress in a solid under given constraint conditions.

3.1.1.1 Discussion—The general stress relaxation test is performed by isothermally loadingapplying a specimenforce to a

specimen with fixed value of constraint. The constraint is maintained constant and the constraining force is determined as a

function of time. The major problem in the stress relaxation test is that constant constraint is virtually impossiblecan be very

difficult to maintain. The effects on test results are very significant and considerable attention must be given to minimize the

constraint variation.Also, experimenters should determine and report the extent of variation in each stress relaxation test so that

this factor can be taken into consideration.

−2

3.1.2 initial stress [FL ]—the stress introduced into a specimen by imposing the given constraint conditions before stress

relaxation begins.

3.1.2.1 Discussion—There are many methods of performing the stress relaxation test, each with a different starting procedure.

However, the constraint is usually obtained initially by the application of thean external loadforce at either a specific loadforce

application rate or a specific strain rate.The two methods will produce the characteristic behavior shown in Fig. 1 when the initial

stress, s , exceeds the proportional limit. MostSome testing machines, while reaching the constraint value, do not produce either

a constant load force application rate or constant strain rate, but something in between. However, the general characteristics of the

data will be similar to those indicated. The rate of loadingstress application rate in either case should be reasonably rapid, but

without impact or vibration, so that any relaxation during the loadingstress application period will be small.

3.1.3 zero time, t —the time when the given loadingstress or constraint conditions are initially obtained in a stress relaxation

test.

3.1.3.1 Discussion—The stress relaxation test is considered to have started at zero time, t in Fig. 1. This is the reference time

from which the observed reduction in load to maintain constant constraint is based. Selection of this time does not imply that the

loadingprocedureorperiod,orboth,arenotsignificanttestparameters.Thesemustalwaysbeconsideredintheapplicationofthe

data.

−2

3.1.4remaining stress [FL ]—the stress remaining at a given time during a stress relaxation test.

3.1.5relaxed stress—the initial stress minus the remaining stress at a given time during a stress relaxation test.

3.1.6stress relaxation curve—a plot of the remaining or relaxed stress as a function of time.

3.1.6.1Discussion—Acurve to demonstrate that the stress relaxation behavior can be obtained by plotting either the remaining

stress or the relaxed stress as a function of time (see Fig. 2). The remaining stress will, of course, decrease with time, and the

relaxed stress will start at zero and increase with time as seen in Fig. 2(b).

3.1.7. This is the reference time from which the observed reduction in force to maintain constant constraint is based. Selection

of this time does not imply that the force application procedure or period, or both, are not significant test parameters. These must

always be considered in the application of the data.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 08.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 03.01.

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

E328–02 (2008)

FIG. 1 Characteristic Behavior During Force Application Period in a Relaxation Test

FIG. 2 Typical Relaxation Curves

3.1.4 relaxation rate—the absolute value of the slope of the relaxation curve at a given time.

3.1.8

3.1.5 spherometer—an instrument used to measure circular or spherical curvature.

3.1.9

3.1.6 indicated nominal temperature or indicated temperature—thetemperaturethatisindicatedbythetemperature-measuring

device.

4. Summary of Test Methods

4.1 In each of the various methods of loading stress application described in the applicable specific sections, the specimen is

E328–02 (2008)

subjectedtoanincreasingloadforceuntilthespecifiedinitialstrainisattained(see zero timein3.1.3andinFig.1).Fortheduration

of the test, the specimen constraint is maintained constant. The initial stress is calculated from the initial loadforce (moment,

torque) as measured at zero time, the specimen geometry, and the appropriate elastic constants, often using simple elastic theory.

The remaining stress may be calculated from the loadforce (moment or torque) determined under constraint conditions either

continuously (4.1.1), periodically (4.1.2), or by elastic springback at the end of the test period [4.1.3 (see Fig. 3)].

4.1.1 Readingsaretakencontinuouslyfromaforceindicatorwhiletheapparatusadjuststheforcetomaintainconstraintwithin

specified bounds.

NOTE 2—Most load,force, moment, or torque measuring devices depend on the devices’ elasticity to measure the quantities involved. Therefore, it is

necessary that when using such devices, to maintain the total strain constant within an upper and lower bound as shown in Fig. 4(a). .

4.1.2 The force required to lift the specimen just free of one or more constraints during the test period is measured.

4.1.3 The elastic springback is measured after unloadingremoving the test stress at the end of the test period.

4.2 With 4.1.1 and 4.1.2, a single specimen can be used to obtain data for a curve of stress versus time. With 4.1.3, the same

specimens may be used to determine the remaining or relaxed stress after various time intervals, if it can be demonstrated for a

given material that identical results are obtained in either using virgin or reloaded specimens. Otherwise, individual specimens

must be used for each point on the curve.

5. Significance and Use

5.1 Relaxation test data are necessary when designing most mechanically fastened joints to assure the permanent tightness of

boltedorrivetedassemblies,pressorshrink-fitcomponents,rolled-intubes,etc.Otherapplicationsincludepredictingthedecrease

in the tightness of gaskets, in the hoop stress of solderless wrapped connections, in the constraining force of springs, and the

stability of wire tendons in prestressed concrete.

5.2 Theabilityofamaterialtorelaxathigh-stressconcentrationssuchasarepresentatnotches,inclusions,cracks,holes,fillets,

etc., may be predicted from stress relaxation data. Such test data are also useful to judge the heat-treatment condition necessary

forthethermalreliefofresidualinternalstressesinforgings,castings,weldments,machinedorcold-workedsurfaces,etc.Thetests

outlined in these methods are limited to conditions of approximately constant constraint and environment.

5.3 The test results are highly sensitive to small changes in environmental conditions and thus require precise control of test

conditions and methods.

5.4 The reproducibility of data will depend on the manner with which all test conditions are controlled.The effects of aging or

residual stress may significantly affect results, as may variations in material composition.

6. Apparatus

6.1 See the appropriate paragraph under each section.

6.2 It is recommended that the equipment be located in a draft-free, constant-temperature environment, 6 5°F (63°C).

7. Temperature Control and Measurement

7.1 The test space (controlled temperature room, furnace, or cold box) should be capable of being maintained at a constant

temperature by a suitable automatic device. This is the most important single factor in a stress relaxation test since the stress

relaxationrate,dimensions,andconstraintconditionsofthespecimenaredependentuponthetesttemperature.Anytypeofheating

or cooling which permits close temperature control of the test space environment is satisfactory.

7.2 The temperature should be recorded, preferably continuously or at least periodically. Temperature variations of the

specimens from the indicated nominal test temperature due to all causes, including cycling of the controller or position along the

specimen gage length, should not exceed 6 5°F (3°C) or 61/2%, wh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.