ASTM F2789-10(2020)

(Guide)Standard Guide for Mechanical and Functional Characterization of Nucleus Devices

Standard Guide for Mechanical and Functional Characterization of Nucleus Devices

SIGNIFICANCE AND USE

5.1 Nucleus devices are generally designed to augment the mechanical function of native degenerated nucleus material or to replace tissue that has been removed during a surgical procedure. This guide outlines methods for evaluating many different types of devices. Comparisons between devices must be made cautiously and with careful analysis, taking into account the effects that design and functional differences can have on the testing configurations and overall performance, and the possibility that mechanical failure may not be related to clinical failure and inversely, that mechanical success may not be related to clinical success.

5.2 These tests are conducted in vitro to allow for analysis of the mechanical performance of the nucleus device under specific testing modalities. The loads applied may differ from the complex loading seen in vivo, and therefore the results from these tests may not directly predict in vivo performance.

5.3 These tests are used to quantify the static and dynamic properties and performance of different implant designs. The mechanical tests are conducted in vitro using simplified loads and moments. Fatigue testing in a simulated body fluid or saline may have fretting, aging, corroding, or lubricating effects on the device and thereby affect the relative performance of tested devices. Hence, the test environment and the effect of that environment, whether a simulated body fluid, normal saline bath (9 g NaCl per 1000 mL H2O), or dry, is an important characteristic of the test and must be reported accurately.

5.4 Dynamic testing methods should be designed to answer the following questions, including but not limited to: Does the device still function as intended after cycling? Does it retain adequate performance characteristics (for example, mechanical and kinematic properties such as ROM)? Did the device wear or degrade? If there is evidence of wear or degradation of the device, it should be identified and quantified with reasonable ...

SCOPE

1.1 This guide describes various forms of nucleus replacement and nucleus augmentation devices. It further outlines the types of testing that are recommended in evaluating the performance of these devices.

1.2 Biocompatibility of the materials used in a nucleus replacement device is not addressed in this guide. However, users should investigate the biocompatibility of their device separately (see X1.1).

1.3 While it is understood that expulsion and endplate fractures represent documented clinical failures, this guide does not specifically address them, although some of the factors that relate to expulsion have been included (see X1.3).

1.4 Multiple tests are described in this guide; however, the user need not use them all. It is the responsibility of the user of this guide to determine which tests are appropriate for the devices being tested and their potential application. Some tests may not be applicable for all types of devices. Moreover, some nucleus devices may not be stable in all test configurations. However, this does not necessarily mean that the test methods described are unsuitable.

1.5 The science of nucleus device design is still very young and includes technology that is changing more quickly than this guide can be modified. Therefore, the user must carefully consider the applicability of this guide to the user’s particular device; the guide may not be appropriate for every device. For example, at the time of publication, this guide does not address the nucleus replacement and nucleus augmentation devices that are designed to be partially or completely resorbable in the body. However, some of the test recommended in this guide may be applicable to evaluate such devices. It has not been demonstrated that mechanical failure of nucleus devices is related to adverse clinical results. Therefore this standard should be used with care in evaluating proposed nucleus devices.

1.6 This guide is not int...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2789 − 10 (Reapproved 2020)

Standard Guide for

Mechanical and Functional Characterization of Nucleus

Devices

This standard is issued under the fixed designation F2789; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 Thisguideisnotintendedtobeaperformancestandard.

It is the responsibility of the user of this guide to characterize

1.1 This guide describes various forms of nucleus replace-

the safety and effectiveness of the nucleus device under

ment and nucleus augmentation devices. It further outlines the

evaluation.

types of testing that are recommended in evaluating the

performance of these devices. 1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.2 Biocompatibility of the materials used in a nucleus

standard. Angular measurements may be reported in either

replacement device is not addressed in this guide. However,

degrees or radians.

users should investigate the biocompatibility of their device

1.8 This standard does not purport to address all of the

separately (see X1.1).

safety concerns, if any, associated with its use. It is the

1.3 While it is understood that expulsion and endplate

responsibility of the user of this standard to establish appro-

fractures represent documented clinical failures, this guide

priate safety, health, and environmental practices and deter-

does not specifically address them, although some of the

mine the applicability of regulatory limitations prior to use.

factors that relate to expulsion have been included (see X1.3).

1.9 This international standard was developed in accor-

1.4 Multiple tests are described in this guide; however, the

dance with internationally recognized principles on standard-

userneednotusethemall.Itistheresponsibilityoftheuserof

ization established in the Decision on Principles for the

this guide to determine which tests are appropriate for the

Development of International Standards, Guides and Recom-

devices being tested and their potential application. Some tests

mendations issued by the World Trade Organization Technical

maynotbeapplicableforalltypesofdevices.Moreover,some

Barriers to Trade (TBT) Committee.

nucleus devices may not be stable in all test configurations.

However, this does not necessarily mean that the test methods

2. Referenced Documents

described are unsuitable.

2.1 ASTM Standards:

1.5 The science of nucleus device design is still very young

D2990Test Methods forTensile, Compressive, and Flexural

and includes technology that is changing more quickly than

Creep and Creep-Rupture of Plastics

this guide can be modified. Therefore, the user must carefully D6204Test Method for Rubber—Measurement of Unvulca-

consider the applicability of this guide to the user’s particular

nized Rheological Properties Using Rotorless Shear Rhe-

device; the guide may not be appropriate for every device. For ometers

example,atthetimeofpublication,thisguidedoesnotaddress

E6Terminology Relating to Methods of MechanicalTesting

thenucleusreplacementandnucleusaugmentationdevicesthat E111Test Method for Young’s Modulus, Tangent Modulus,

are designed to be partially or completely resorbable in the

and Chord Modulus

body. However, some of the test recommended in this guide E132TestMethodforPoisson’sRatioatRoomTemperature

may be applicable to evaluate such devices. It has not been

E328Test Methods for Stress Relaxation for Materials and

demonstrated that mechanical failure of nucleus devices is Structures

related to adverse clinical results. Therefore this standard

E1823TerminologyRelatingtoFatigueandFractureTesting

should be used with care in evaluating proposed nucleus F561 Practice for Retrieval and Analysis of Medical

devices.

Devices, and Associated Tissues and Fluids

F1582Terminology Relating to Spinal Implants

ThistestmethodisunderthejurisdictionofASTMCommitteeF04onMedical

andSurgicalMaterialsandDevicesandisthedirectresponsibilityofSubcommittee

F04.25 on Spinal Devices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2020. Published April 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2010. Last previous edition approved in 2010 as F2789 – 10 (2015). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F2789-10R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2789 − 10 (2020)

F1714GuideforGravimetricWearAssessmentofProsthetic 3.2.4 extrusion, n—a condition during testing when a por-

Hip Designs in Simulator Devices tion of a device displaces through a surrounding membrane or

F1877Practice for Characterization of Particles enclosure but does not separate from the rest of the device.

F1980Guide for Accelerated Aging of Sterile Barrier Sys- Extrusion may be considered a specific type of migration and

tems for Medical Devices

forthepurposesofthisstandardisonlyusefulwhenthetesting

F2267TestMethodforMeasuringLoadInducedSubsidence is being conducted within a surrogate annulus or enclosure.

of Intervertebral Body Fusion Device Under Static Axial

3.2.5 fatigue life, n—The number of cycles, N, that the

Compression

nucleus device can sustain at a particular load or moment

F2346Test Methods for Static and Dynamic Characteriza-

before functional or mechanical failure occurs.

tion of Spinal Artificial Discs

3.2.6 functional failure, n—A failure that renders the

F2423Guide for Functional, Kinematic, and Wear Assess-

nucleusdeviceineffectiveorunabletoresistloadorfunctionas

ment of Total Disc Prostheses

predetermined within desired parameters (for example, perma-

2.2 Other Standards:

nent deformation, dissociation, dehydration, expulsion, extru-

ISO 10993Biological Evaluation of Medical Devices: Parts

sion or fracture), or both.

1–20

ISO 18192–1Implants for Surgery—Wear ofTotal Interver- 3.2.6.1 Discussion—Functional failure may or may not be

tebral Spinal Disc Prostheses correlated with clinical failure.

3.2.7 hysteresis, n—The resultant loop on a force displace-

3. Terminology

ment plot that is created from a mechanical test performed on

3.1 For definition of terms, refer to Terminologies E6,

a viscoelastic material.The area inside the loop can be used to

E1823, and F1582.

determine the energy absorption.

3.2 Definitions:

3.2.8 mechanical failure, n—A failure associated with the

3.2.1 coordinate system/axes, n—Three orthogonal axes are

onset of a defect in the material (for example, a fatigue

defined by Terminology F1582. The center of the coordinate

fracture, a static fracture, or surface wear).

system is located at the geometric center of the native disc.

3.2.8.1 Discussion—Amechanicalfailurecanoccurwithout

Because of design intent, or procedural limitations, the device

there being a functional failure.

might not be implanted at the center of the native disc;

therefore, the geometric center of the disc might not be the 3.2.9 migration, n—A condition during testing when a

device displaces from its original position during testing.

geometric center of the device. For uniformity in comparison

between devices, it is important that the origin be placed with Migration may or may not be considered a specific type of

functional failure. The user is expected to define their criteria

respect to the disc, not the device. This is done so that all

loading is consistently applied and measurement made with for acceptable levels of migration and provide rationale for

thosecriteria.Seealsodefinitionsforexpulsion,extrusion,and

respect to the anatomy of the spine, and not with respect to the

device. The XY plane bisects the sagittal plane between subsidence.

superior and inferior surfaces that are intended to simulate the

3.2.10 nucleus device, n—A generic term that refers to all

adjacent vertebral endplates. The positive X axis is to be

types of devices intended to replace or augment the nucleus

directed anteriorly. The positive Z axis is to be directed

pulposus in the intervertebral disc.Adjectives can be added to

superiorly. Shear components of loading are defined to be the

the term “nucleus device” to more thoroughly describe the

components parallel to the XY plane. The compressive axial

device’s intended function. Terms 3.2.10.1 through 3.2.10.9

force is defined to be the component in either the positive or

will be used to address specific types of nucleus devices

negative Z direction depending on the test frame set-up.

throughouttherestofthisguide.Thesetermsmaynotapplyto

Torsional load is defined as the component of moment about

all nucleus devices and some combinations of terms may be

the Z axis.

applicabletocertaindevices.However,thistermshouldnotbe

3.2.2 energy absorption, n—The work or energy (in joules)

used interchangeably with annular repair device.

that a material can store, temporarily or permanently, after a

3.2.10.1 complete nucleus replacement device, n—A

given stress is applied and then released.

nucleus device that is designed to replace most or all (≥50%

3.2.3 expulsion, n—a condition during testing when the

by volume) of the nucleus pulposus of the intervertebral disc.

deviceoracomponentofthedevicebecomesfullydisplacedor

3.2.10.2 partial nucleus replacement device, n—A nucleus

dislodged from its implanted position (that is, in the direction

device that is designed to replace some (<50% by volume) of

of shear) through a surrogate annulus, or enclosure used to

the nucleus pulposus of the intervertebral disc.

simulate an annular boundary. Expulsion may be considered a

specific type of migration and for the purposes of this standard

3.2.10.3 nucleus augmentation device, n—Anucleus device

is only useful when the testing is being conducted within a

that is designed to supplement or augment, but not replace, the

surrogate annulus or enclosure.

existing nucleus pulposus in the intervertebral disc.

3.2.10.4 encapsulated nucleus device, n—A nucleus device

that includes an outer jacket, bag, or a similar casing, which in

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. turn interfaces directly with the in vivo environment.

F2789 − 10 (2020)

3.2.10.5 open nucleus device, n—A nucleus device that is 4. Summary of Test Method

not encased. The material interfaces directly with the in vivo

4.1 The tests for characterizing the performance of nucleus

environment.

devices can include one or more of the following: static and

3.2.10.6 in situ formed nucleus device, n—Anucleus device

dynamic axial compression, axial torsion, and shear tests,

that is introduced into the disc space without a predetermined

functional range of motion, subsidence, mechanical behavior

geometry. This may include injectable, in situ curing or

change due to aging, swelling pressure, and viscoelastic

polymerizing nucleus devices.

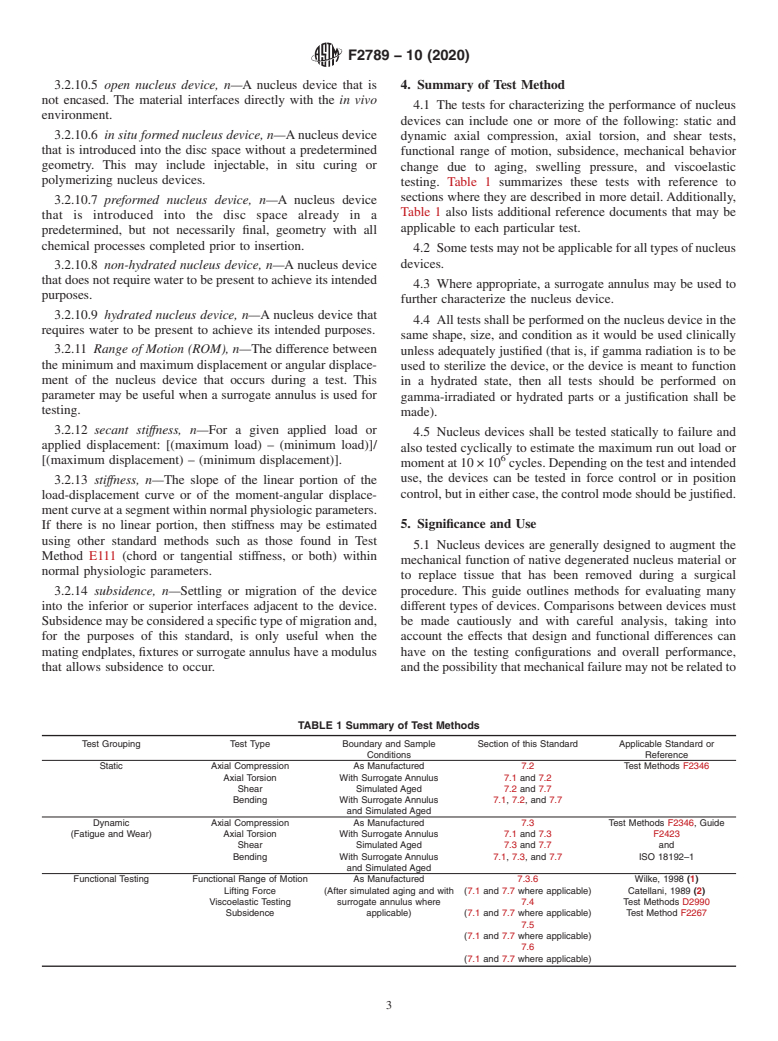

testing. Table 1 summarizes these tests with reference to

sections where they are described in more detail.Additionally,

3.2.10.7 preformed nucleus device, n—A nucleus device

Table 1 also lists additional reference documents that may be

that is introduced into the disc space already in a

applicable to each particular test.

predetermined, but not necessarily final, geometry with all

chemical processes completed prior to insertion.

4.2 Sometestsmaynotbeapplicableforalltypesofnucleus

devices.

3.2.10.8 non-hydrated nucleus device, n—Anucleus device

thatdoesnotrequirewatertobepresenttoachieveitsintended

4.3 Where appropriate, a surrogate annulus may be used to

purposes.

further characterize the nucleus device.

3.2.10.9 hydrated nucleus device, n—Anucleus device that

4.4 Alltestsshallbeperformedonthenucleusdeviceinthe

requires water to be present to achieve its intended purposes.

same shape, size, and condition as it would be used clinically

3.2.11 Range of Motion (ROM), n—The difference between

unless adequately justified (that is, if gamma radiation is to be

the minimum and maximum displacement or angular displace-

used to sterilize the device, or the device is meant to function

ment of the nucleus device that occurs during a test. This

in a hydrated state, then all tests should be performed on

parameter may be useful when a surrogate annulus is used for

gamma-irradiated or hydrated parts or a justification shall be

testing.

made).

3.2.12 secant stiffness, n—For a given applied load or

4.5 Nucleus devices shall be tested statically to failure and

applied displacement: [(maximum load) – (minimum load)]/

also tested cyclically to estimate the maximum run out load or

[(maximum displacement) – (minimum displacement)].

momentat10×10 cycles.Dependingonthetestandintended

use, the devices can be tested in force control or in position

3.2.13 stiffness, n—The slope of the linear portion of the

control,butineithercase,thecontrolmodeshouldbejustified.

load-displacement curve or of the moment-angular displace-

mentcurveatasegmentwithinnormalphysiologicparameters.

5. Significance and Use

If there is no linear portion, then stiffness may be estimated

using other standard methods such as those found in Test

5.1 Nucleus devices are generally designed to augment the

Method E111 (chord or tangential stiffness, or both) within

mechanical function of native degenerated nucleus material or

normal physiologic parameters.

to replace tissue that has been removed during a surgical

3.2.14 subsidence, n—Settling or migration of the device procedure. This guide outlines methods for evaluating many

into the inferior or superior interfaces adjacent to the device. different types of devices. Comparisons between devices must

Subsidencemaybeconsideredaspecifictypeofmigrationand, be made cautiously and with careful analysis, taking into

for the purposes of this standard, is only useful when the account the effects that design and functional differences can

matingendplates,fixturesorsurrogateannulushaveamodulus have on the testing configurations and overall performance,

that allows subsidence to occur. andthepossibilitythatmechanicalfailuremaynotberelatedto

TABLE 1 Summary of Test Methods

Test Grouping Test Type Boundary and Sample Section of this Standard Applicable Standard or

Conditions Reference

Static Axial Compression As Manufactured 7.2 Test Methods F234

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.