ASTM D2427-92(2001)

(Test Method)Standard Test Method for Determination of C2 through C5 Hydrocarbons in Gasolines by Gas Chromatography

Standard Test Method for Determination of C<sub>2</sub> through C<sub>5</sub> Hydrocarbons in Gasolines by Gas Chromatography

SCOPE

1.1 This test method provides for the determination of the two (Cs) through five- (C5) carbon paraffins and mono-olefins in gasolines. The concentrations by volume or mass (weight) of the following components are generally reported:

1.1.1 Ethylene plus ethane

1.1.2 Propane

1.1.3 Propylene

1.1.4 Isobutane

1.1.5 n-Butane

1.1.6 Butene-1 plus isobutylene

1.1.7 trans-Butene-2

1.1.8 cis-Butene-2

1.1.9 Isopentane 3-Methylbutene-1

1.1.10 n-Pentane

1.1.11 Pentene-1

1.1.12 2-Methylbutene-1

1.1.13 trans-Pentene-2

1.1.14 cis-Pentene-2

1.1.15 2-Methylbutene-2

1.2 This test method does not provide for the determination of cyclic olefins, diolefins, or acetylenes. These are usually minor components in finished gasolines.

1.3 Samples to be analyzed should not contain significant amounts of material boiling lower than ethylene.

1.4 SI (metric) units of measurement are preferred and used throughout this standard. Alternative units, in common usage, are also provided to improve the clarity and aid the user of this test method.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation:D2427–92 (Reapproved 2001)

Standard Test Method for

Determination of C through C Hydrocarbons in Gasolines

2 5

by Gas Chromatography

This standard is issued under the fixed designation D 2427; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method provides for the determination of the 2.1 ASTM Standards:

two (C ) through five(C -) carbon paraffins and mono-olefins D 1319 Test Method for Hydrocarbon Types In Liquid

2 5

ingasolines.Theconcentrationsbyvolumeormass(weight)of Petroleum Products by Fluorescent Indicator Adsorption

the following components are generally reported: D 2001 Test Method for Depentanization of Gasoline and

1.1.1 Ethylene plus ethane Naphthas

1.1.2 Propane

3. Summary of Test Method

1.1.3 Propylene

3.1 The sample is injected into a gas - liquid partition

1.1.4 Isobutane

1.1.5 n-Butane column. The components are separated as they pass through

the column with an inert carrier gas and their presence in the

1.1.6 Butene-1 plus isobutylene

1.1.7 trans-Butene-2 effluent is detected and recorded as a chromatogram. Materials

containing components having more than five carbon atoms

1.1.8 cis-Butene-2

1.1.9 Isopentane can either be backflushed from the system without measure-

ment, or recorded as a broad peak by reversing the direction of

3-Methylbutene-1

1.1.10 n-Pentane the carrier gas through the column at such time as to regroup

the higher-boiling portion (C and heavier) of the sample. If

1.1.11 Pentene-1

1.1.12 2-Methylbutene-1 backflushing is used, the concentration of C through C

2 5

hydrocarbons may be related to the whole sample by adding a

1.1.13 trans-Pentene-2

known quantity of low-boiling internal standard to the sample

1.1.14 cis-Pentene-2

1.1.15 2-Methylbutene-2 prior to analysis.Alternatively, a known amount of sample can

be charged and compared to a standard sample run under the

1.2 This test method does not provide for the determination

of cyclic olefins, diolefins, or acetylenes. These are usually same conditions. Sample composition is determined from the

chromatogram by comparing peak areas with those obtained

minor components in finished gasolines.

1.3 Samples to be analyzed should not contain significant using known amounts of calibration standards or a synthetic

blend.

amounts of material boiling lower than ethylene.

1.4 SI (metric) units of measurement are preferred and used

4. Significance and Use

throughout this standard. Alternative units, in common usage,

4.1 In hydrocarbon type analyses of gasolines, such as Test

are also provided to improve the clarity and aid the user of this

Method D 1319, highly volatile fuels can need to be stabilized

test method.

by depentanization (Test Method D 2001) prior to analysis. A

1.5 This standard does not purport to address all of the

knowledge of the composition of light hydrocarbons in the

safety concerns, if any, associated with its use. It is the

overhead from depentanization is useful in converting analyses

responsibility of the user of this standard to establish appro-

of the depentanized fraction to total sample.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Apparatus

5.1 Chromatograph—Any chromatograph having a thermo-

This test method is under the jurisdiction of ASTM Committee D02 on

stated oven and a detection system of adequate sensitivity may

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.04 on Hydrocarbon Analysis.

Current edition approved Nov. 10, 2001. Published December 1992. Originally

published as D 2427 – 65 T. Last previous edition D 2427 – 87. Annual Book of ASTM Standards, Vol 05.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D2427–92 (2001)

be used. The detection system must have sufficient sensitivity 7. Preparation of Apparatus

to produce a recorder deflection of at least 5 mm for 0.1 liquid

7.1 Column Preparation—The method used to prepare the

volume percent of pentene-1 in the sample or synthetic blend

column is not critical as long as the finished column produces

being analyzed.

the desired separation. Preparation of the packing is not

difficult once the support, partitioning liquid, and loading level

NOTE 1—If the sensitivity of a given system is inadequate, it can be

increased by using a more sensitive recorder or detector, or by using more have been determined. Some stationary phases are susceptible

sample if the resolution is substantially unaffected.

to oxidation and must be protected from excessive exposure to

air during the evaporation and drying steps. The following

5.2 Recorder—A 1 to 10-mV recorder with a full-scale

general directions have been found to produce columns of

response time of 2 s or less and a noise level no greater than

acceptable characteristics:

60.3 % of full scale.

7.1.1 Weigh out the desired quantity of support, usually

5.3 Columns:

twice that required to fill the column.

5.3.1 A description of columns and valving arrangements

7.1.2 Calculate and weigh out the required quantity of

that meet the requirements of this method are described in

partitioning agent. Dissolve the partitioning agent in a volume

Annex A1. Persons using other column materials must estab-

ofchemicallyinert,low-boilingsolventequaltoapproximately

lish that the column gives results that meet the precision

twice the volume of support.

requirements of Section 10.

7.1.3 Graduallyaddthesupportmaterialtothesolutionwith

5.3.2 Analyzer Column—The column system used must be

gentle stirring.

capable of resolving the individual C to C paraffins and

2 5

7.1.4 Slowly evaporate the solvent while gently agitating

olefins well enough so that the individual hydrocarbons listed

the mixture until the packing is nearly dry and no free liquid is

in Section 1 may be reported. The resolution should be such

apparent.

that at the operating conditions selected, the distance from the

7.1.5 Spread the packing in thin layers on a nonabsorbent

base line in the valley between two peaks representing com-

surface and air or oven dry as required to remove all traces of

pounds reported is not greater than 50 % of the height of the

solvent.

smaller peak. If an internal standard is used, it must be

7.1.6 Resieve the packing to remove fines and agglomerates

completely resolved from the other components.

produced in the impregnation step.

5.3.3 Precut Column—This column must be capable of

7.1.7 Fill the column tubing with packing by plugging one

separating the C and lighter olefins and paraffins from the C

5 6

end with a wad of glass wool and pouring the packing into the

andheavierolefinsandparaffins.Theresolutionshouldbesuch

other end through a small funnel. Vibrate the tubing continu-

that at the operating conditions selected, the distance from the

ously over its entire length while filling. When the packing

base line to the valley between 2-methylbutene-2 and 2,2-

ceases to flow, tap the column gently on the floor or bench top

dimethylbutane is not greater than 50% of the height of the

whilevibratingiscontinued.Addpackingasnecessaryuntilno

smaller peak. If an internal standard is used, it must be eluted

further settling occurs during a 2-min period. Remove a small

with the C and lighter materials.

amount of packing from the open end, plug with a wad of glass

wool, and shape the column to fit the chromatograph.

6. Reagents and Materials

7.1.8 If multiple columns are joined by tubing unions, the

6.1 Compounds for calibration shall be of a purity of not

dead volume in the union should be filled with column

less than 99 mole %. Calibrants should include compounds

packing.

1.1.5-1.1.15 as listed in Section 1. The concentration of

7.2 Chromatograph—Mount the column in the chromato-

ethylene, ethane, propylene, and propane is generally so low in

graph and establish the operating conditions required to give

most samples that calibration with these materials is unneces-

the desired separation (see Annex A1). Allow sufficient time

sary (Warning—Extremely flammable gas under pressure.

for the instrument to reach equilibrium as indicated by a stable

Extremely flammable liquids.) Commercially available certi-

recorder base line. Control the oven temperature so that it is

fied blends of light hydrocarbons may be used to establish

constant to within 0.5°C without thermostat cycling which

calibration data where their compositions are applicable. If an

causes an uneven base line. Set the carrier gas flow rate,

internal standard is used to relate the concentration of light

measured with a soap film meter, so that it is constant to within

hydrocarbons to the whole sample it must be included as a

1 mL/min of the selected value.

calibrant.

6.2 Carrier Gas—A carrier gas appropriate to the type of

8. Procedure

detector used should be employed. Helium or hydrogen can be

used with thermal conductivity detector (Warning— 8.1 Calibration—Determine the relative area response of

Compressed gas under high pressure.) (Warning—Hydrogen the compounds to be reported by injecting known quantities of

is extremely flammable under pressure.) Nitrogen or argon can the pure compounds or by using synthetic blends of known

be used with ionization or gas density detectors (Warning— composition. For those compounds that are normally gases at

Compressed gas under high pressure). room temperature it is advantageous to use commercially

6.3 Liquid Phase—See Annex A1. available certified light hydrocarbon blends. Sample light

6.4 Solid Support, for use in packed column; usually hydrocarbon blends contained in pressure containers from the

crushed firebrick or diatomaceous earth. Mesh size should be liquid phase (Warning—Extremely flammable gas under pres-

appropriate to the system selected from the supplement. sure.) Blends of those hydrocarbons that are normally liquid at

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D2427–92 (2001)

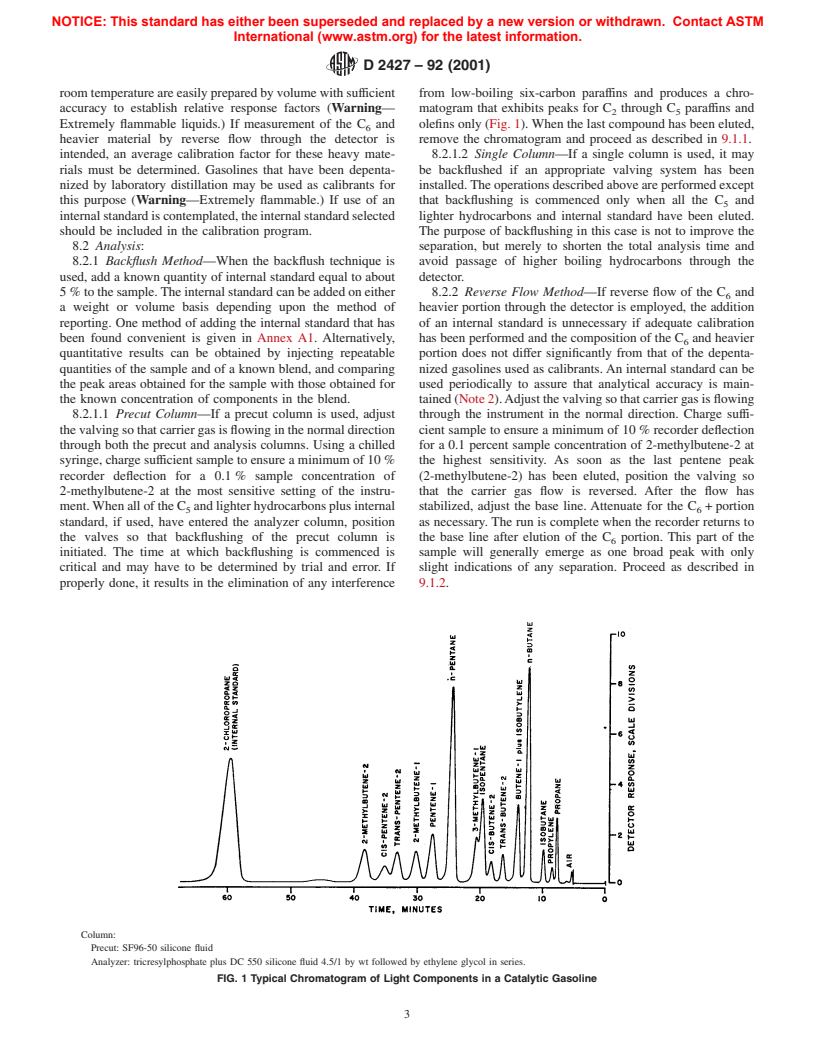

roomtemperatureareeasilypreparedbyvolumewithsufficient from low-boiling six-carbon paraffins and produces a chro-

accuracy to establish relative response factors (Warning— matogram that exhibits peaks for C through C paraffins and

2 5

Extremely flammable liquids.) If measurement of the C and olefins only (Fig. 1). When the last compound has been eluted,

heavier material by reverse flow through the detector is remove the chromatogram and proceed as described in 9.1.1.

intended, an average calibration factor for these heavy mate- 8.2.1.2 Single Column—If a single column is used, it may

rials must be determined. Gasolines that have been depenta- be backflushed if an appropriate valving system has been

nized by laboratory distillation may be used as calibrants for installed.Theoperationsdescribedaboveareperformedexcept

this purpose (Warning—Extremely flammable.) If use of an that backflushing is commenced only when all the C and

internalstandardiscontemplated,theinternalstandardselected lighter hydrocarbons and internal standard have been eluted.

should be included in the calibration program. The purpose of backflushing in this case is not to improve the

8.2 Analysis: separation, but merely to shorten the total analysis time and

8.2.1 Backflush Method—When the backflush technique is avoid passage of higher boiling hydrocarbons through the

used, add a known quantity of internal standard equal to about detector.

5 %tothesample.Theinternalstandardcanbeaddedoneither 8.2.2 Reverse Flow Method—If reverse flow of the C and

a weight or volume basis depending upon the method of heavier portion through the detector is employed, the addition

reporting. One method of adding the internal standard that has of an internal standard is unnecessary if adequate calibration

been found convenient is given in Annex A1. Alternatively, has been performed and the composition of the C and heavier

quantitative results can be obtained by injecting repeatable portion does not differ significantly from that of the depenta-

quantities of the sample and of a known blend, and comparing nized gasolines used as calibrants.An internal standard can be

the peak areas obtained for the sample with those obtained for used periodically to assure that analytical accuracy is main-

the known concentration of components in the blend. tained(Note2).Adjustthevalvingsothatcarriergasisflowing

8.2.1.1 Precut Column—If a precut column is used, adjust through the instrument in the normal direction. Charge suffi-

thevalvingsothatcarriergasisflowinginthenormaldirection cient sample to ensure a minimum of 10 % recorder deflection

through both the precut and analysis columns. Using a chilled for a 0.1 percent sample concentration of 2-methylbutene-2 at

syringe, charge sufficient sample to ensure a minimum of 10 % the highest sensitivity. As soon as the last pentene peak

recorder deflection for a 0.1 % sample concentration of (2-methylbutene-2) has been eluted, position the valving so

2-methylbutene-2 at the most sensitive setting of the instru- that the carrier gas flow is reversed. After the flow has

ment.WhenalloftheC andlighterhydrocarbonsplusinternal stabilized, adjust the base line. Attenuate for the C + portion

5 6

standard, if used, have entered the analyzer column, position as necessary. The run is complete when the recorder returns to

the valves so that backflushing of the precut column is the base line after elution of the C portion. This part of the

initiated. The time at which backflushing is commenced is sample will generally emerge as one broad peak with only

critical and may have to be determined by trial and error. If slight indications of any separation. Proceed as described in

properly done, it results in the elimination of any interference 9.1.2.

Column:

Precut: SF96-50 silicone fluid

Analyzer: tricresylphosphate plus DC 550 silicone fluid 4.5/1 by wt followed by ethylene glycol in series.

FIG. 1 Typical Chromatogram of Light Components in a Catalytic Gasoline

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.