ASTM D2513-03

(Specification)Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings

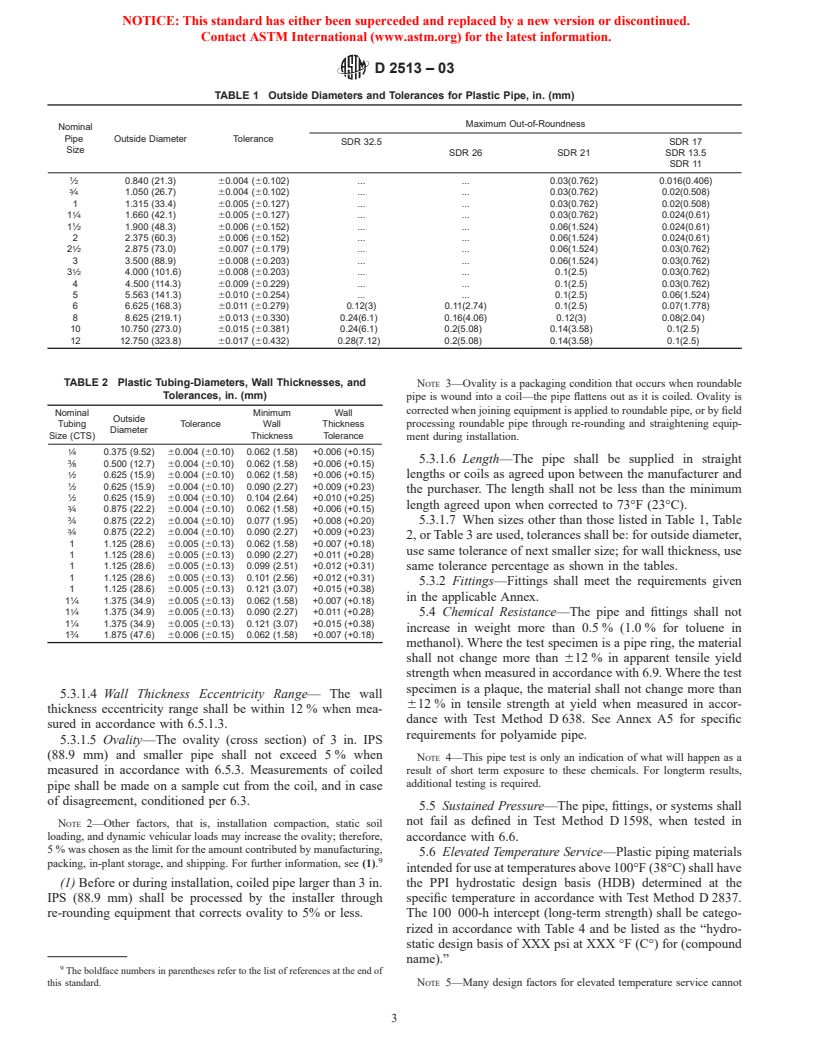

Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings

SCOPE

1.1 This specification covers requirements and test methods for material (see Appendix X1) dimensions and tolerances, hydrostatic burst strength, chemical resistance, and impact resistance of plastic pipe, tubing, and fittings for use in fuel gas mains and services for direct burial and reliner applications. The annexes provide specific requirements and test methods for each of the materials currently approved. If and when additional materials are available, specific annex requirements will be added. The pipe and fittings covered by this specification are intended for use in the distribution of natural gas. Requirements for the qualifying of polyethylene systems for use with liquefied petroleum gas are covered in Annex A1.

1.1.1 This specification does not cover threaded pipe. Design considerations are discussed in Appendix X2. In-plant quality control programs are specified in Annex A3 and Annex A4.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 The following is an index of the annexes and appendixes in this specification:Annex SubjectA1Polyethylene (PE) Pipe and FittingsA2Poly (Vinyl Chloride) (PVC) Pipe and Fittings for Maintenance or RepairA3 In-Plant Quality Control for all materials up to 12 in. A4In-Plant Quality Control for PE materials between 14 and 24 in. A5Polyamide (PA) Pipe and Fittings A6Magnetic-detectable Polyethylene PipeAppendixesSubjectX1New MaterialsX2Design Consideration

The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2513 – 03

Standard Specification for

1

Thermoplastic Gas Pressure Pipe, Tubing, and Fittings

This standard is issued under the fixed designation D 2513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

A6 Magnetic-detectable

Polyethylene Pipe

1.1 This specification covers requirements and test methods

Appendixes Subject

for material (see Appendix X1) dimensions and tolerances, X1 New Materials

X2 Design Consideration

hydrostatic burst strength, chemical resistance, and impact

resistance of plastic pipe, tubing, and fittings for use in fuel gas

1.5 The following precautionary caveat pertains only to the

mains and services for direct burial and reliner applications.

test method portion, Section 6, of this specification. This

The annexes provide specific requirements and test methods

standard does not purport to address all of the safety concerns,

for each of the materials currently approved. If and when

if any, associated with its use. It is the responsibility of the user

additional materials are available, specific annex requirements

of this standard to establish appropriate safety and health

will be added. The pipe and fittings covered by this specifica-

practices and determine the applicability of regulatory limita-

tion are intended for use in the distribution of natural gas.

tions prior to use.

Requirements for the qualifying of polyethylene systems for

2. Referenced Documents

use with liquefied petroleum gas are covered in Annex A1.

1.1.1 This specification does not cover threaded pipe. De-

2.1 ASTM Standards:

sign considerations are discussed in Appendix X2. In-plant

2.1.1 Terminology:

2

quality control programs are specified in Annex A3 and Annex

D 1600 for Abbreviated Terms Relating to Plastics

3

A4.

F 412 Relating to Plastic Piping Systems

1.2 The text of this specification references notes, footnotes,

2.1.2 Test Methods for:

2

and appendixes which provide explanatory material. These

D 638 Tensile Properties of Plastics

notes and footnotes (excluding those in tables and figures) shall

D 1238 Melt Flow Rates of Thermoplastics by Extrusion

2

not be considered as requirements of the specification.

Plastometer

1.3 The values stated in inch-pound units are to be regarded

D 1598 Time-to-Failure of Plastic Pipe Under Constant

3

as the standard. The values given in parentheses are provided

Internal Pressure

for information purposes only.

D 1599 Resistance to Short-Time Hydraulic Pressure of

3

1.4 The following is an index of the annexes and appendixes

Plastic Pipe, Tubing, and Fittings

in this specification:

D 2122 Determining Dimensions of Thermoplastic Pipe

3

Annex Subject and Fittings

A1 Polyethylene (PE)

D 2290 Apparent Hoop Tensile Strength of Plastic or Rein-

Pipe and Fittings

3

forced Plastic Pipe by Split Disk Method

A2 Poly (Vinyl Chloride)

(PVC) Pipe and Fit-

D 2837 Obtaining Hydrostatic Design Basis for Thermo-

tings for Maintenance 3

plastic Pipe Materials

or Repair

F 1473 Notch Tensile Test to Measure the Resistance to

A3 In-Plant Quality Con-

3

trol for all materials up

Slow Crack Growth of Polyethylene Pipes and Resins

to 12 in.

2.1.3 Practices for:

A4 In-Plant Quality Con-

D 543 Evaluating the Resistance of Plastics to Chemical

trol for PE materials

2

between 14 and 24 in.

Reagents

A5 Polyamide (PA) Pipe

2

D 618 Conditioning Plastics for Testing

and Fittings

4

D 1898 Sampling of Plastics

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. Annual Book of ASTM Standards, Vol 08.01.

3

Current edition approved Jan. 10, 2003. Published July 2003. Originally Annual Book of ASTM Standards, Vol 08.04.

4

approved in 1966. Last previous edition approved in 2002 as D 2513 – 02. Discontinued; see 1997 Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D2513–03

3

D 2657 Heat Fusion Joining of Polyolefin Pipe and Fittings with a 630 psi design stress for water at 73.4°F (23°C). The

D 2774 Underground Installation of Thermoplastic Pressure hydrostatic design stresses for gas are not used in this desig-

3

Piping nation code.

2.1.4 Specificat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.