ASTM F1957-99(2004)

(Test Method)Standard Test Method for Composite Foam Hardness-Durometer Hardness

Standard Test Method for Composite Foam Hardness-Durometer Hardness

SIGNIFICANCE AND USE

This test method is based on the penetration by a specific type of indentor when forced into the material under specified conditions. The indentation hardness is related inversely to the penetration and is dependent on the elastic modulus and viscoelastic behavior of the material. The geometry of the indentor and the applied force influence the measurements, such that no simple relationship exists between the measurements obtained with one type of durometer and those obtained with another type of durometer or other instruments used for measuring hardness. This test method is an empirical test intended primarily for control purposes. No simple relationship exists between indentation hardness determined by this test method and any fundamental property of the material tested. For specification purposes it is recommended that Test Method D 785 be used for hard materials and Test Method D 2240 be used for solid elatomers.

SCOPE

1.1 This test method describes a type of composite foam hardness measurement device known as durometer: Type CF. The procedure for determining indentation hardness of substances comprised of two or more elastomeric materials, one of which is a foam or foam like material. These are classified as composite foam structures. The composite foam product may have an armature made of a material suitable for adding structural integrity including but not limited to metal, plastic, or wood. This construction is typical for lapbar restraints, seating, and other restraint devices, as well as some show elements.

1.2 This test method is not equivalent to other indentation hardness methods and instrument types, specifically those described in Test Methods D 1415 and D 2240.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only. Many of the stated dimensions in SI are direct conversions from the U.S. customary system to accommodate the instrumentation, practices, and procedures that existed prior to the Metric Conversion Act of 1975.

1.4 All materials, instruments, or equipment used for the determination of mass or dimension shall have traceability to the National Institute for Standards and Technology (NIST) or other internationally recognized organizations.

1.5 This test method is not a safety standard as it pertains to ride legislation. The use of this test method is optional based upon an agreement between customers and suppliers of foam products.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1957–99(Reapproved 2004)

Standard Test Method for

Composite Foam Hardness-Durometer Hardness

This standard is issued under the fixed designation F1957; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes a type of composite foam 2.1 ASTM Standards:

hardness measurement device known as durometer: Type CF. D374 Test Methods for Thickness of Solid Electrical Insu-

The procedure for determining indentation hardness of sub- lation

stancescomprisedoftwoormoreelastomericmaterials,oneof D618 Practice for Conditioning Plastics for Testing

which is a foam or foam like material. These are classified as D785 Test Method for Rockwell Hardness of Plastics and

composite foam structures. The composite foam product may Electrical Insulating Materials

have an armature made of a material suitable for adding D1349 Practice for Rubber—Standard Temperatures for

structural integrity including but not limited to metal, plastic, Testing

or wood. This construction is typical for lapbar restraints, D1415 Test Method for Rubber Property—International

seating, and other restraint devices, as well as some show Hardness

elements. D2240 Test Method for Rubber Property—Durometer

1.2 This test method is not equivalent to other indentation Hardness

hardness methods and instrument types, specifically those D4483 Practice for Evaluating Precision for Test Method

described in Test Methods D1415 and D2240. Standards in the Rubber and Carbon Black Manufacturing

1.3 The values stated in SI units are to be regarded as Industries

standard. The values given in parentheses are for information

3. Summary of Test Method

only. Many of the stated dimensions in SI are direct conver-

3.1 This test method permits hardness measurements based

sions from the U.S. customary system to accommodate the

instrumentation, practices, and procedures that existed prior to on either initial indentation or indentation after a specified

period of time, or both.

the Metric Conversion Act of 1975.

3.2 Those specimens, which have a durometer hardness

1.4 All materials, instruments, or equipment used for the

determination of mass or dimension shall have traceability to range other than specified, shall use another suitable procedure

for determining durometer hardness.

the National Institute for Standards and Technology (NIST) or

other internationally recognized organizations.

4. Significance and Use

1.5 This test method is not a safety standard as it pertains to

4.1 This test method is based on the penetration by a

ride legislation. The use of this test method is optional based

specific type of indentor when forced into the material under

upon an agreement between customers and suppliers of foam

specified conditions. The indentation hardness is related in-

products.

versely to the penetration and is dependent on the elastic

1.6 This standard does not purport to address all of the

modulus and viscoelastic behavior of the material. The geom-

safety concerns, if any, associated with its use. It is the

etry of the indentor and the applied force influence the

responsibility of the user of this standard to establish appro-

measurements, such that no simple relationship exists between

priate safety and health practices and determine the applica-

the measurements obtained with one type of durometer and

bility of regulatory limitations prior to use.

those obtained with another type of durometer or other

instruments used for measuring hardness. This test method is

This test method is under the jurisdiction of ASTM Committee F24 on

Amusement Rides and Devices and is the direct responsibility of F24.10 on Test

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2004. Published October 2004. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 1999 as F1957 – 99. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1957-99R04. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1957–99 (2004)

an empirical test intended primarily for control purposes. No

simple relationship exists between indentation hardness deter-

mined by this test method and any fundamental property of the

material tested. For specification purposes it is recommended

that Test Method D785 be used for hard materials and Test

Method D2240 be used for solid elatomers.

5. Apparatus

5.1 Hardnessmeasurementapparatus,ordurometer,consist-

ing of the following components:

5.1.1 Presser Foot, with an orifice (to allow for the protru-

sion of the indentor) having a diameter as specified in Fig. 1

with the center a minimum of 38.0 mm (1.5 in.) from any edge

of the flat circular presser foot.

5.1.2 Indentor, formed from steel rod, shaped in accordance

with Fig. 2, polished over the contact area so that no flaws are

visible under 203 magnification and with an indentor exten-

sion of 7.62 6 0.04 mm (.300 6 0.002 in.).

FIG. 2 Indentor Detail

5.1.3 Indentor Extension Indicating Display, (analog or

digital electronic), having a display that is an inverse function

of the indentor extension.

5.1.3.1 Digital Electronic Indicating Displays shall indi-

cate from 0 to 100, with no less than 100 equal divisions

throughout the range, at a rate of one hardness point for each

0.50 mm (0.002 in.) of indentor movement.

5.1.3.2 Analog Indicating Displays shall indicate from 0 to

100, with no less 100 equal divisions throughout the range or

alternatively with no less than 90 equal divisions throughout a

range from 10 to 100, at a rate of one hardness point for each

0.050 mm (0.002 in.) of indentor movement.

5.1.4 Maximum Indicators (optional), maximum indicating

FIG. 1 Presser Foot Detail pointers are auxiliary analog indicating hands designed to

F1957–99 (2004)

remain at the maximum hardness value attained until reset by supported suitably to provide for positioning and stability. A

the operator. Electronic maximum indicators are digital dis- suitablehardnessdeterminationmaybedifficulttoobtainonan

plays electronically indicating and maintaining the maximum uneven or rough point of contact with the indentor.

value hardness value achieved, until reset by the operator.

7. Calibration

5.1.4.1 Analog maximum indicating pointers have been

7.1 Calibration Device—The durometer spring shall be

shown to have a nominal influence on the values attained;

calibrated by supporting the durometer in a calibrating device

however, this influence is greater on durometers of lesser total

in a vertical position and applying a measurable force to the

mainspring forces. The influence of a maximum indicating

indentortip.Theforcemaybemeasuredbymeansofabalance

pointer shall be noted at the time of calibration in the

or by an electronic force cell. The calibrating device shall be

calibration report (see 10.1.4) and when reporting hardness

capable of measuring applied force to within 50 % of the

determinations (see 10.2.4).

calibrationtolerancedescribedinTable1.Careshouldbetaken

5.1.4.2 Digital electronic durometers may be equipped with

to ensure that the force is applied vertically to the indentor tip,

electronic maximum indicators that shall not influence the

as lateral force will cause errors in calibration.

indicated reading or determinations attained by more than one

7.2 Indentor Extension—Indentor extension and shape shall

half of the calibration tolerance stated in Table 1.

be in accordance with 5.1.2 and Fig. 2.

5.1.5 Calibrated Spring, for applying force to the indentor

7.3 Indentor Extension Adjustment Procedure:

and capable of applying the forces as specified in Table 1.

7.3.1 Dimensional Gage Blocks:

6. Test Specimen

7.3.1.1 The presser foot must be attached to the durometer

gage before adjustment. This allows a nominal indentor exten-

6.1 The test specimen, herein referred to as “specimen” or

sion of 7.62 mm (.300 in.).

“test specimen” interchangeably, shall be at least 25.4 mm

7.3.1.2 Placeprecisiongrounddimensionalblocks(GradeB

(1.00 in.) thick, herein, unless it is known that results equiva-

or better) on the test specimen support table and beneath the

lenttothe25.4mm(1.00in.)valuesareobtainedwithathinner

durometer presser foot and indentor.Arrange the blocks so that

test specimen. On specimens with solid armatures, it is

the durometer presser foot contacts the larger block and the

suggested that readings not be taken in areas close to the

indentor tip is at the moment of contact with the smaller block

armature as this may affect the readings.

(Fig. 3).

6.1.1 The lateral dimensions of the test specimen shall be

7.3.1.3 A combination of dimensional gage blocks may be

sufficient to permit measurements at least 12.0 mm (0.48 in.)

usedtoachieveadifferenceof7.62+0.00,–0.0254mm(0.300

from any edge unless it is known that identical results are

+0.00, –0.001 in.) between them:

obtained when measurements are made at a lesser distance

7.3.2 Indentor Extension Adjustment:

from an edge.

7.3.2.1 Carefully lower the durometer presser foot until

6.1.2 The surfaces of the test specimen shall be flat and

contact with the largest dimensional block, the indentor tip

parallel over a sufficient area to permit the presser foot to

should be at the point of contact with the smaller block,

contact the specimen over an area having a radius of at least

verifying full indentor extension.

30.0 mm (1.18 in.) from the indentor point if possible.

7.3.2.2 Adjust the indentor extension to 7.620 6 0.04 mm

Variations are acceptable as agreed upon between laboratories

(0.300 6 0.002 in.), following the manufacturer’s recom-

or between customer and supplier. The test specimen shall be

mended procedure.

7.3.2.3 When performing the procedures in 7.3, care should

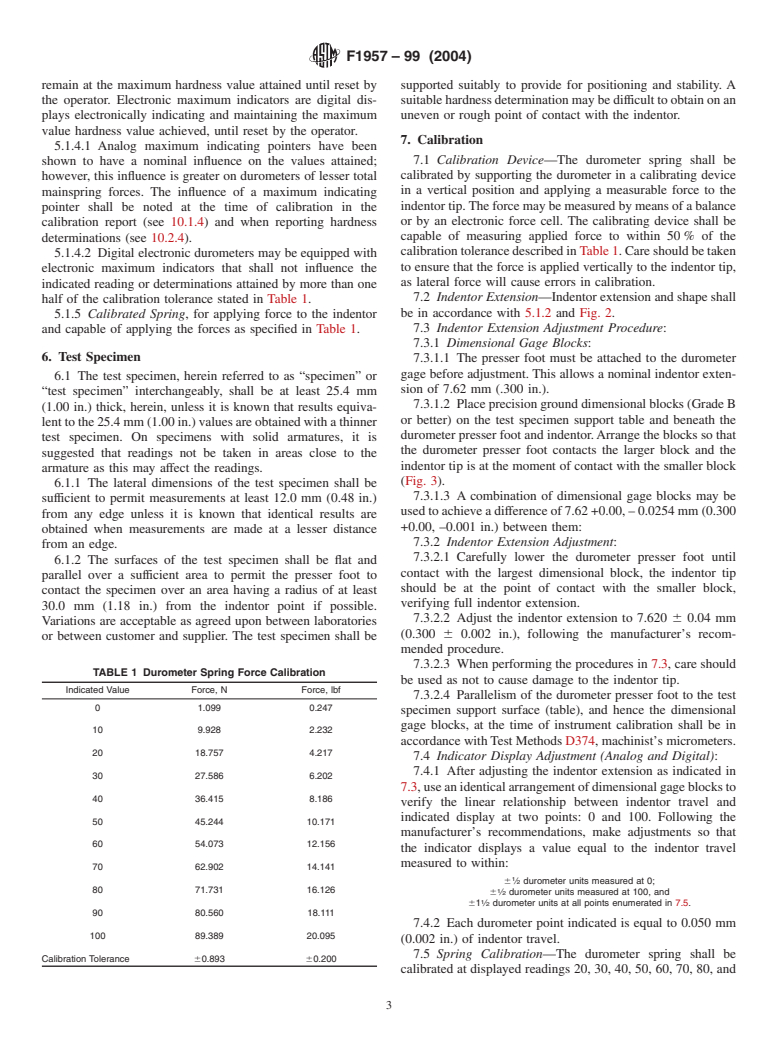

TABLE 1 Durometer Spring Force Calibration

be used as not to cause damage to the indentor tip.

Indicated Value Force, N Force, lbf

7.3.2.4 Parallelism of the durometer presser foot to the test

0 1.099 0.247

specimen support surface (table), and hence the dimensional

gage blocks, at the time of instrument calibration shall be in

10 9.928 2.232

accordance withTest Methods D374, machinist’s micrometers.

20 18.757 4.217

7.4 Indicator Display Adjustment (Analog and Digital):

7.4.1 After adjusting the indentor extension as indicated in

30 27.586 6.202

7.3,useanidenticalarrangementofdimensionalgageblocksto

40 36.415 8.186

verify the linear relationship between indentor travel and

indicated display at two points: 0 and 100. Following the

50 45.244 10.171

manufacturer’s recommendations, make adjustments so that

60 54.073 12.156

the indicator displays a value equal to the indentor travel

measured to within:

70 62.902 14.141

6 ⁄2 durometer units measured at 0;

80 71.731 16.126 1

6 ⁄2 durometer units measured at 100, and

61 ⁄2 durometer units at all points enumerated in 7.5.

90 80.560 18.111

7.4.2 Each durometer point indicated is equal to 0.050 mm

100 89.389 20.095

(0.002 in.) of indentor travel.

7.5 Spring Calibration—The durometer spring shall be

Calibration Tolerance 60.893 60.200

calibrated at displayed readings 20, 30, 40, 50, 60, 70, 80, and

F1957–99 (2004)

7.7 The metal or rubber reference blocks provided for

checkingdurometeroperationandstateofcalibrationarenotto

be relied upon as calibration standards. The calibration proce-

dures outlined in Section 7 are the only valid calibration

procedures.

7.8 Spring force calibration tolerance is 61.0 durometer

unit. Spring force calibration tolerance is calculated as 1 %.

7.9 Spring Force Combinations:

7.9.1 For Type CF Durometers:

force, N 5 1.0987 1 0.8829 H (1)

CF

where:

H = one durometer unit on Type CF durometers.

CF

8. Instrument and Test Specimen Conditioning

8.1 Tests or instrument calibrations shall be conducted at

23.0 6 2.0° C (73.4 6 3.6° F).

8.2 The instrument and specimen(s) to be tested shall be

maintained at 23.0 6 2.0° C (73.4 6 3.6° F) for a minimum of

12 h prior to performing a test or calibration.

8.3 For materials whose hardness depends on relative hu-

midity, the test specimens shall be conditioned in accordance

with Procedure A of Practice D618 and tested under the same

conditions.

8.3.1 Accordingly, the relative humidity at the time of a test

shall be reported in 10.2.2.

8.3.2 The relative humidity may be reported in 10.2.2 when

the influence of relative humidity on the hardness of the test

specimen is not known.

8.3.3 The relative humidity at the time of instrument cali-

bration shall be reported in 10.1.6.

8.4 No conclusive evaluation has been made on durometers

at temperatures other than 23.0 6 2.0 °C (73.4 6 3.6 °F).

Conditioning at temperatures other than the above may show

changes in calibration. Durometer use at temperatures other

than the above should be decided between customer and

supplier (see Practice D1349).

8.5 These procedures may be modified if agreed upon

between laboratories or between customer and supplier.

9. Procedure

9.1 Manual (Hand-Held) Durometer Testing:

FIG. 3 Indentor Extension Calibration Setup

9.1.1 Care shall be exercised to minimize the exposure of

the instrument to environmental conditions that are adverse to

the performance of the instrument or adversely influence test

90. The measured force (9.8 3 mass in kilograms) shall be results.

within the calibration tolerance specified in Table 1, which 9.1.2 Place the test specimen on a flat, hard, horizontal

identifies the measured force applied to the indentor for the surface. Hold the durometer in a vertical position with the

entire range of the instrument, although it is necessary only to indentor tip at a distance from any edge of the test specimen as

verify the spring calibration at points listed herein. described in Section 6, unless it is known that identical results

7.6 Spring Calibration Procedure: are obtained when measurements are made with the indentor at

7.6.1 Assure that the indentor extension has been adjusted a lesser distance.

in accordance with 7.3 and the linear relationship between 9.1.3 Apply the indentor to the test specimen, maintaining

indentor travel and indicated display is as specified in 7.4. the durometer in a vertical position keeping the presser foot

7.6.2 Place the durometer in the calibration device (see 7.1). parallel to the test specimen, with a firm smooth downward

App

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.