ASTM A269-00

(Specification)Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

SCOPE

1.1 This specification covers grades of nominal-wall-thickness, stainless steel tubing for general corrosion-resisting and low- or high-temperature service, as designated in .

1.2 The tubing sizes and thicknesses usually furnished to this specification are ¼ in. (6.4 mm) in inside diameter and larger and 0.020 in. (0.51 mm) in nominal wall-thickness and heavier.

1.3 Mechanical property requirements do not apply to tubing smaller than 1/8 in. (3.2 mm) in inside diameter or 0.015 in. (0.38 mm) in thickness.

Note 1--When the impact test criterion for a low-temperature service would be 15 ft-lbf (20 J) energy absorption or 15 mils lateral expansion, some of the austenitic stainless steel grades covered by this specification are accepted by certain pressure vessel or piping codes without the necessity of making the actual test. For example, Grades 304, 304L, and 347 are accepted by the ASME Pressure Vessel Code, Section VIII Division 1, and by ANSI B31.3, for service at temperatures as low as 425oF (254oC) without qualification by impact tests. Other AISI stainless steel grades are usually accepted for service temperatures as low as 325oF (198oC) without impact testing. Impact testing may, under certain circumstances, be required. For example, materials with chromium or nickel content outside the AISI ranges, and for material with carbon content exceeding 0.10 %, are required to be impact tested under the rules of ASME Section VIII Division 1 when services temperatures are lower than 50oF (46oC).

1.4 Optional supplementary requirements are provided and, when one or more of these are desired, each shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 269 – 00 An American National Standard

Standard Specification for

Seamless and Welded Austenitic Stainless Steel Tubing for

General Service

This standard is issued under the fixed designation A 269; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope A 450/A450M Specification for General Requirements for

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

1.1 This specification covers grades of nominal-wall-

A 480/A480M Specification for General Requirements for

thickness, stainless steel tubing for general corrosion-resisting

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

and low- or high-temperature service, as designated in Table 1.

Sheet, and Strip

1.2 The tubing sizes and thicknesses usually furnished to

1 A 632 Specification for Seamless and Welded Austenitic

this specification are ⁄4 in. (6.4 mm) in inside diameter and

Stainless Steel Tubing (Small-Diameter) for General Ser-

larger and 0.020 in. (0.51 mm) in nominal wall-thickness and

vice

heavier.

2.2 ANSI Standard:

1.3 Mechanical property requirements do not apply to

B 31.3 Chemical Plant and Petroleum Refinery Piping

tubing smaller than ⁄8 in. (3.2 mm) in inside diameter or 0.015

2.3 ASME Pressure Vessel Code:

in. (0.38 mm) in thickness.

Section VIII Division 1, Pressure Vessels

NOTE 1—When the impact test criterion for a low-temperature service

would be 15 ft·lbf (20 J) energy absorption or 15 mils lateral expansion,

3. Ordering Information

some of the austenitic stainless steel grades covered by this specification

3.1 Orders for material under this specification should

are accepted by certain pressure vessel or piping codes without the

include the following, as required, to describe the desired

necessity of making the actual test. For example, Grades 304, 304L, and

material adequately:

347 are accepted by the ASME Pressure Vessel Code, Section VIII

Division 1, and by ANSI B 31.3, for service at temperatures as low as

3.1.1 Quantity (feet, metres, or number of lengths),

−425°F (−254°C) without qualification by impact tests. Other AISI

3.1.2 Name of material (seamless or welded tubes),

stainless steel grades are usually accepted for service temperatures as low

3.1.3 Grade (Table 1),

as −325°F (−198°C) without impact testing. Impact testing may, under

3.1.4 Size (outside diameter and nominal wall thickness),

certain circumstances, be required. For example, materials with chromium

3.1.5 Length (specific or random),

or nickel content outside the AISI ranges, and for material with carbon

3.1.6 Optional requirements (9.6 and Section 11),

content exceeding 0.10 %, are required to be impact tested under the rules

of ASME Section VIII Division 1 when services temperatures are lower 3.1.7 Test report required (see Section on Inspection of

than −50°F (−46°C).

Specification A 450/A 450M),

3.1.8 Specification designation, and

1.4 Optional supplementary requirements are provided and,

3.1.9 Special requirements and any supplementary require-

when one or more of these are desired, each shall be so stated

ments selected.

in the order.

1.5 The values stated in inch-pound units are to be regarded

4. General Requirements

as the standard.

4.1 Material furnished under this specification shall con-

2. Referenced Documents

form to the applicable requirements of the current edition of

Specification A 450/A 450M, unless otherwise provided

2.1 ASTM Standards:

herein.

A 262 Practices for Detecting Susceptibility to Intergranu-

lar Attack in Austenitic Stainless Steels

5. Manufacture

A 370 Test Methods and Definitions for Mechanical Testing

5.1 The tubes shall be made by the seamless or welded

of Steel Products

process.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.01.

A01.10 on Tubing. Available from American National Standards Institute, 11 West 42nd St., 13th

Current edition approved March 10, 2000. Published June 2000. Originally Floor, New York, NY 10036.

published as A 269 – 44 T. Last previous edition A 269 – 98. Available from ASME International, Three Park Avenue, New York, NY

Annual Book of ASTM Standards, Vol 01.03. 10016-5990.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 269

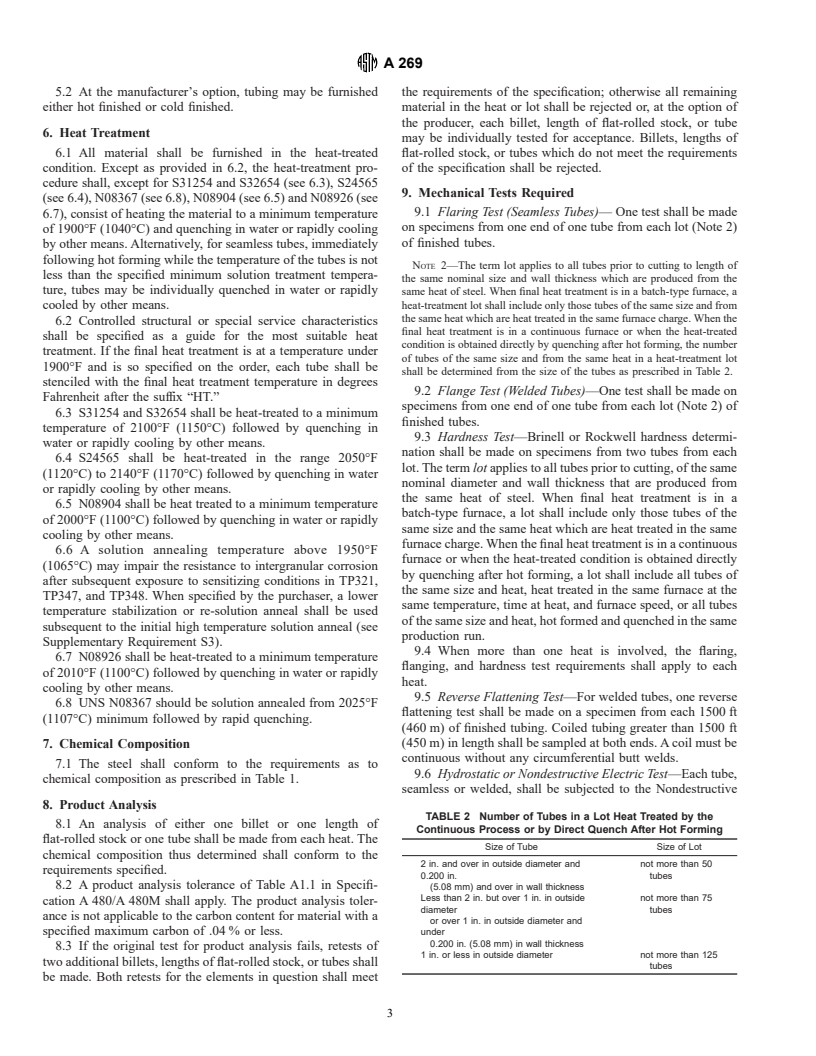

TABLE 1 Chemical Requirements %

Composition, %

Grade

TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP

... ... ... ... ... ... ... ... ...

304 304L 304LN 316 316L 316LN 317 321 347 348 XM-10 XM-11 XM-15 XM-19 XM-29

UNS

A

S30400 S30403 S30453 S31600 31603 S31653 S31700 S32100 S34700 S34800 S21900 S21904 S38100 S20910 S24000 S31254 S31725 S31726 S30600 S24565 S32654 N08367 N08926 N08904

A

Designation

Carbon 0.08 0.035 0.035 0.08 0.035 0.035 0.08 0.08 0.08 0.08 0.08 0.04 0.08 0.06 0.08 0.020 0.035 0.035 0.018 0.030 0.020 0.030 0.020 0.020

B B B B

max max max max max max max max max max max max max max max max max max max max max max max max

Manganese, 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 8.00– 8.00– 2.00 4.0– 11.5– 1.00 2.00 2.00 2.0 5.0– 2.0– 2.00 2.00 2.00

C

max 10.00 10.00 6.0 14.5 7.0 4.0

Phosphorus, 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.030 0.045 0.060 0.030 0.045 0.045 0.020 0.030 0.030 0.040 0.030 0.040

max.

Sulfur, max. 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.015 0.030 0.030 0.020 0.010 0.005 0.030 0.010 0.030

C

Silicon 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.50– 1.00 1.00 0.80 1.00 1.00 3.7–4.3 1.00 0.50 1.00 0.50 1.00

2.50

Nickel 8.0– 8.0– 8.0– 10.0– 10.0– 10.0– 11.0– 9.0– 9.0– 9.0– 5.5– 5.5– 17.5– 11.5– 2.3– 17.5– 13.5– 14.5– 14.0– 16.0– 21.0– 23.5– 24.0– 19.0–

11.0 12.0 11.0 14.0 14.0 13.0 15.0 12.0 12.0 12.0 7.5 7.5 18.5 13.5 3.7 18.5 17.5 17.5 15.5 18.0 23.0 25.5 26.0 23.0

Chromium 18.0– 18.0– 18.0– 16.0– 16.0– 16.0– 18.0– 17.0– 17.0– 17.0– 19.0– 19.0– 17.0– 20.5– 17.0– 19.5– 18.0– 17.0– 17.0– 23.0– 24.0– 20.0– 19.0– 23.0–

20.0 20.0 20.0 18.0 18.0 18.0 20.0 19.0 19.0 19.0 21.5 21.5 19.0 23.5 19.0 20.5 20.0 20.0 18.5 25.0 25.0 22.0 21.0 28.0

Molybdenum . . . . . . . . . 2.00– 2.00– 2.00– 3.0– . . . . . . . . . . . . . . . . . . 1.50– . 6.0– 4.0– 4.0– 0.20 4.0– 7.0– 6.0– 6.0– 4.0–

3.00 3.00 3.00 4.0 3.00 6.5 5.0 5.0 max 5.0 8.0 7.0 7.0 5.0

D

Titanium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E

Columbium . . . . . . . . . . . . . . . . . . . . . . . . 10 3 C . . . . . . . . . 0.10– . . . . . . . . . . . . . . . 0.10 . . . .

min 0.30 max

1.10

max

Tantalum, . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

max

F

Nitrogen . . . . . . 0.10– . . . . . . 0.10– . . . . . . . . . . . . 0.15– 0.15– . . . 0.20– 0.20– 0.18– 0.20 0.10– 0.40– 0.45– 0.18– 0.15– 0.10

0.16 0.16 0.40 0.40 0.40 0.40 0.22 max 0.20 0.60 0.55 0.25 0.25 max

Vanadium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10– . . . . . . .

0.30

Copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50– . . . . . . 0.50 . . . 0.30– 0.75 0.50– 1.00–

1.00 max 0.60 max 1.50 2.00

Others . . . . . . . . . . . . . . . . . . . . . . . . . . . Co 0.20 . . . . . . . . . . . . . .

max

A

New designation established in accordance with Practice E 527 and SAE J1086, Practice of Numbering Metals and Alloys (UNS).

B

For small diameter or thin walls, or both, where many drawing passes are required, a carbon maximum of 0.040 % is necessary in grades TP 304L, TP 304LN, 316L and 316LN. Small outside diameter tubes are

defined as those with less than 0.500 in. [12.7 mm] in outside diameter and light walls are those less than 0.049 in. [1.2 mm] in minimum wall thickness.

C

Maximum, unless otherwise indicated.

D

Grade TP 321 shall have a titanium content of not less than five times the sum of the carbon and nitrogen content and not more than 0.70 %.

E

Grade TP 348 shall have a columbium plus tantalum content of not less than ten times the carbon content and not more than 1.10 %.

F

The method of analysis for nitrogen shall be a matter of agreement between the purchaser and manufacturer.

A 269

5.2 At the manufacturer’s option, tubing may be furnished the requirements of the specification; otherwise all remaining

either hot finished or cold finished. material in the heat or lot shall be rejected or, at the option of

the producer, each billet, length of flat-rolled stock, or tube

6. Heat Treatment

may be individually tested for acceptance. Billets, lengths of

6.1 All material shall be furnished in the heat-treated flat-rolled stock, or tubes which do not meet the requirements

condition. Except as provided in 6.2, the heat-treatment pro-

of the specification shall be rejected.

cedure shall, except for S31254 and S32654 (see 6.3), S24565

9. Mechanical Tests Required

(see 6.4), N08367 (see 6.8), N08904 (see 6.5) and N08926 (see

9.1 Flaring Test (Seamless Tubes)— One test shall be made

6.7), consist of heating the material to a minimum temperature

on specimens from one end of one tube from each lot (Note 2)

of 1900°F (1040°C) and quenching in water or rapidly cooling

of finished tubes.

by other means. Alternatively, for seamless tubes, immediately

following hot forming while the temperature of the tubes is not

NOTE 2—The term lot applies to all tubes prior to cutting to length of

less than the specified minimum solution treatment tempera-

the same nominal size and wall thickness which are produced from the

ture, tubes may be individually quenched in water or rapidly

same heat of steel. When final heat treatment is in a batch-type furnace, a

heat-treatment lot shall include only those tubes of the same size and from

cooled by other means.

the same heat which are heat treated in the same furnace charge. When the

6.2 Controlled structural or special service characteristics

final heat treatment is in a continuous furnace or when the heat-treated

shall be specified as a guide for the most suitable heat

condition is obtained directly by quenching after hot forming, the number

treatment. If the final heat treatment is at a temperature under

of tubes of the same size and from the same heat in a heat-treatment lot

1900°F and is so specified on the order, each tube shall be

shall be determined from the size of the tubes as prescribed in Table 2.

stenciled with the final heat treatment temperature in degrees

9.2 Flange Test (Welded Tubes)—One test shall be made on

Fahrenheit after the suffix “HT.”

specimens from one end of one tube from each lot (Note 2) of

6.3 S31254 and S32654 shall be heat-treated to a minimum

finished tubes.

temperature of 2100°F (1150°C) followed by quenching in

9.3 Hardness Test—Brinell or Rockwell hardness determi-

water or rapidly cooling by other means.

nation shall be made on specimens from two tubes from each

6.4 S24565 shall be heat-treated in the range 2050°F

lot. The term lot applies to all tubes prior to cutting, of the same

(1120°C) to 2140°F (1170°C) followed by quenching in water

nominal diameter and wall thickness that are produced from

or rapidly cooling by other means.

the same heat of steel. When final heat treatment is in a

6.5 N08904 shall be heat treated to a minimum temperature

batch-type furnace, a lot shall include only those tubes of the

of 2000°F (1100°C) followed by quenching in water or rapidly

same size and the same heat which are heat treated in the same

cooling by other means.

furnace charge. When the final heat treatment is in a continuous

6.6 A solution annealing temperature above 1950°F

furnace or when the heat-treated condition is obtained directly

(1065°C) may impair the resistance to intergranular corrosion

by quenching after hot forming, a lot shall include all tubes of

after subsequent exposure to sensitizing conditions in TP321,

the same size and heat, heat treated in the same furnace at the

TP347, and TP348. When specified by the purchaser, a lower

same temperature, time at heat, and furnace speed, or all tubes

temperature stabilization or re-solution anneal shall be used

of the same size and heat, hot formed and quenched in the same

subsequent to the initial high temperature solution anneal (see

production run.

Supplementary Requirement S3).

9.4 When more than one heat is involved, the flaring,

6.7 N08926 shall be heat-treated to a minimum temperature

flanging, and hardness test requirements shall apply to each

of 2010°F (1100°C) followed by quenching in water or rapidly

heat.

cooling by other means.

9.5 Reverse Flattening Test—For welded tubes, one reverse

6.8 UNS N08367 should be solution annealed from 2025°F

flattening test shall be made on a specimen from each 1500 ft

(1107°C) minimum followed by rapid quenching.

(460 m) of finished tubing. Coiled tubing greater than 1500 ft

(450 m) in length shall be sampled at both ends. A coil must be

7. Chemical Composition

continuous without any circumferential butt welds.

7.1 The steel shall conform to the requirements as to

9.6 Hydrostatic or Nondestructive Electric Test—Each tube,

chemical composition as prescribed in Table 1.

seamless or welded, shall be subjected to the Nondestructive

8. Product Analysis

TABLE 2 Number of Tubes in a Lot Heat Treated by the

8.1 An analysis of either one billet or one length of

Continuous Process or by Direct Quench After Hot Forming

flat-rolled stock or one tube shall be made from each heat. The

Size of Tube Size of Lot

chemical composition thus determined shall conform to the

2 in. and over in outside diameter and not more than 50

requirements specified.

0.200 in. tubes

8.2 A product analysis tolerance of Table A1.1 in Specifi-

(5.08 mm) and over in wall thickness

Less than 2 in. but over 1 in. in outside not more than 75

cation A 480/A 480M shall apply. The product analysis toler-

diameter tubes

ance is not applicable to the carbon content for material with a

or over 1 in. in outside diameter and

specified maximum carbon of .04 % or less. under

0.200 in. (5.08 mm) in wall thickness

8.3 If the original test for product analysis fails, retests of

1 in. or less in outside diameter not more than 125

two additional billets, lengths of flat-rolled stock, or tubes shall

tubes

be made. Both retests for the elements in question shall meet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.