ASTM A540/A540M-00

(Specification)Standard Specification for Alloy-Steel Bolting Materials for Special Applications

Standard Specification for Alloy-Steel Bolting Materials for Special Applications

SCOPE

1.1 This specification covers regular and special-quality alloy steel bolting materials which may be used for nuclear and other special applications. Bolting materials as used in this specification cover rolled or forged bars, rotary pierced or extruded seamless tubes, bored bars, or forged hollows from forged or rolled bar segments to be manufactured into bolts, studs, washers, and nuts.

1.2 Several grades of steel are covered. The grade and class shall be specified by the purchaser.

1.3 Supplementary requirements of an optional nature are provided for use when special quality is desired. These supplementary requirements call for additional tests to be made and when desired shall be so stated in the order, together with the acceptance limits required.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 540/A 540M – 00

Standard Specification for

Alloy-Steel Bolting Materials for Special Applications

This standard is issued under the fixed designation A 540/A 540M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 45 Test Methods for Determining the Inclusion Content

2 of Steel

1.1 This specification covers regular and special-quality

2.2 AIAG Standard:

alloy steel bolting materials which may be used for nuclear and

AIAG B-5 02.00 Primary Metals Identification Tag Appli-

other special applications. Bolting materials as used in this

cation Standard

specification cover rolled or forged bars, rotary pierced or

2.3 ANSI Standards:

extruded seamless tubes, bored bars, or forged hollows from

B 1.1 Unified Screw Threads

forged or rolled bar segments to be manufactured into bolts,

B 18.2.1 Square and Hex Bolts and Screws Including Hex

studs, washers, and nuts.

Cap Screws and Lag Bolts

1.2 Several grades of steel are covered. The grade and class

B 18.2.2 Square and Hex Nuts

shall be specified by the purchaser.

B 18.3 Hexagon Socket and Spline Socket Screws

1.3 Supplementary requirements of an optional nature are

provided for use when special quality is desired. These

3. Ordering Information

supplementary requirements call for additional tests to be made

3.1 Material supplied to this material specification shall

and when desired shall be so stated in the order, together with

conform to Specification A 962/A 962M. These requirements

the acceptance limits required.

outline the testing and retesting methods and procedures,

1.4 This specification is expressed in both inch-pound units

permissible variations in dimensions, and mass, quality and

and in SI units. However, unless the order specifies the

repair of defects, marking, etc.

applicable“ M” specification designation (SI units), the mate-

3.2 In addition to the ordering information specified in

rial shall be furnished to inch-pound units.

Specification A 962/A 962M, orders for material under this

1.5 The values stated in either inch-pound units or SI units

specification shall include the following, as required, to de-

are to be regarded separately as standard. Within the text, the

scribe the desired material adequately:

SI units are shown in brackets. The values stated in each

3.2.1 Condition (Section 4),

system are not exact equivalents; therefore, each system must

3.2.2 Heat treatment (Section 5),

be used independently of the other. Combining values from the

3.2.3 Supplementary Requirements (S1 to S9),

two systems may result in nonconformance with the specifi-

3.2.4 Reports required (Section 16),

cation.

3.2.5 End use, and

2. Referenced Documents 3.2.6 Any special requirements.

3.3 The purchaser is referred to the listed supplementary

2.1 ASTM Standards:

requirements in this specification and to the detailed require-

A 962/A 962M Specification for Common Requirements

ments in Specification A 962/A 962M.

for Steel Fasteners or Fastener Materials, or Both, Intended

3.4 If the requirements of this specification are in conflict

for Use at Any Temperature from Cryogenic to the Creep

with the requirements of Specification A 962/A 962M, the

Range

requirements of this specification shall prevail.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting

Materials for Piping and Special Purpose Applications.

Current edition approved March 10, 2000. Published June 2000. Originally Annual Book of ASTM Standards, Vol 03.01.

published as A 540 – 65. Last previous edition A 540/A 540M – 98. Available from Automotive Industry Action Group, 26200 Lahser, Suite 200,

For ASME Boiler and Pressure Vessel Code Applications see related Specifi- Southfield, MI 48034.

cation SA-540 in Section II of that Code. Available from American National Standards Institute, 11 West 42nd Street,

Annual Book of ASTM Standards, Vol 01.01. 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 540/A 540M – 00

4. Manufacture 7.2 Material in the quenched and tempered or quenched,

tempered and stress-relieved condition shall conform to prop-

4.1 The material shall be supplied hot-rolled or hot-forged

erties shown in Table 2 for the specified class.

or cold-finished at the option of the producer. However, if

desired by the purchaser, cold finishing may be specified.

8. Hardness Requirements

5. Heat Treatment

8.1 The hardness shall be determined on the surface of the

5.1 Material which is ordered in the annealed condition

material after removal of decarburization.

shall have a structure suitable for machining. Such annealed

8.2 The hardness of material in the annealed condition shall

bolting material is not intended to be used without subsequent

not be greater than 235 HB.

quenching and tempering as specified in 5.2

8.3 The hardness of material in the quenched and tempered

5.2 Material which is ordered in the liquid-quenched and

or quenched, tempered and stress-relieved condition shall be

tempered condition shall be uniformly reheated from a tem-

within the limits in Table 2 for the specified class.

perature below the cooling transformation range to the proper

austenitizing temperature. It shall be quenched in a liquid

9. Impact Requirements

medium under substantially uniform conditions and then uni-

9.1 Annealed material after proper heat treatment shall be

formly reheated for tempering. The minimum tempering tem-

capable of meeting the impact requirements in Table 2 or of

perature shall be 850°F [455°C].

Supplementary Requirement S8, if so specified (see Supple-

5.3 Material that has been straightened after quenching and

mentary Requirement S4).

tempering shall be stress relieved by reheating to a temperature

9.2 Material in the quenched and tempered or quenched,

not lower than 100°F [55°C] under the tempering temperature.

tempered, and stress-relieved condition shall conform to the

6. Chemical Composition impact requirements in Table 2, or of Supplementary Require-

ment S8 if so specified.

6.1 The steel shall conform to the chemical requirements

9.3 The percent of shear (ductility or fibrous) fracture shall

prescribed in Table 1.

be computed. The computed value shall be recorded for all

7. Tensile Requirements

impact specimens.

9.4 The amount of lateral expansion shall be measured. The

7.1 Material furnished in the annealed condition shall be

measured value shall be recorded for all impact specimens.

capable of meeting the specified tensile properties for the class

as specified in Table 2 when heat treated in accordance with 5.2 9.5 The percent shear and the amount of lateral expansion

and 5.3 (see Supplementary Requirement S4). shall be reported for information purposes (see 16.1).

A

TABLE 1 Chemical Requirements

Identification B21 B22 B23 B24 B24V

$

Symbol

(Cr-Mo-V) (4142-H) (E-4340-H) (4340 Mod.) (4340V Mod.)

Grade

Chromium- Chromium- Chromium-Nickel- Chromium-Nickel- Chromium-Nickel-

Molybdenum- Molybdenum Molybdenum Molybdenum Molybdenum-

Vanadium Vanadium

Range, % Product Range, % Product Range, % Product Range, % Product Product

Variation, Variation, Variation, Variation, Variation,

Over or Over or Over or Over or Over or

B B B B B

Under, % Under, % Under, % Under, % Under, %

Carbon 0.36–0.44 0.02 0.39–0.46 0.02 0.37–0.44 0.02 0.37–0.44 0.02 0.37–0.44 0.02

Manganese 0.45–0.70 0.03 0.65–1.10 0.04 0.60–0.95 0.04 0.70–0.90 0.04 0.60–0.95 0.04

C C C C C

Phosphorus, max 0.025 0.005 0.025 0.005 0.025 0.005 0.025 0.005 0.025 0.005

C C C C C

Sulfur, max 0.025 0.005 0.025 0.005 0.025 0.005 0.025 0.005 0.025 0.005

D

Silicon 0.15–0.35 0.02 0.15–0.35 0.02 0.15–0.35 0.02 0.15–0.35 0.02 0.15–0.35 0.02

Chromium 0.80–1.15 0.05 0.75–1.20 0.05 0.65–0.95 0.05 0.70–0.95 0.05 0.60–0.95 0.05

Nickel . . . . . . . . . . . . 1.55–2.00 0.05 1.65–2.00 0.05 1.55–2.00 0.05

Molybdenum 0.50–0.65 0.03 0.15–0.25 0.02 0.20–0.30 0.02 0.30–0.40 0.02 0.40–0.60 0.03

Vanadium 0.25–0.35 0.03 . . . . . . . . . . . . . . . . . . 0.04–0.10 0.01

A

The intentional addition of Bi, Se, Te, and Pb is not permitted.

B

Unless otherwise specified, separate determinations may vary from the specified ranges, except that elements in any heat must not vary both above and below the

specified range.

C

Phosphorus and sulfur content is 0.04 % max when open-hearth steel is specified.

D

Silicon content is 0.35 % max if vacuum-carbon deoxidized.

A 540/A 540M – 00

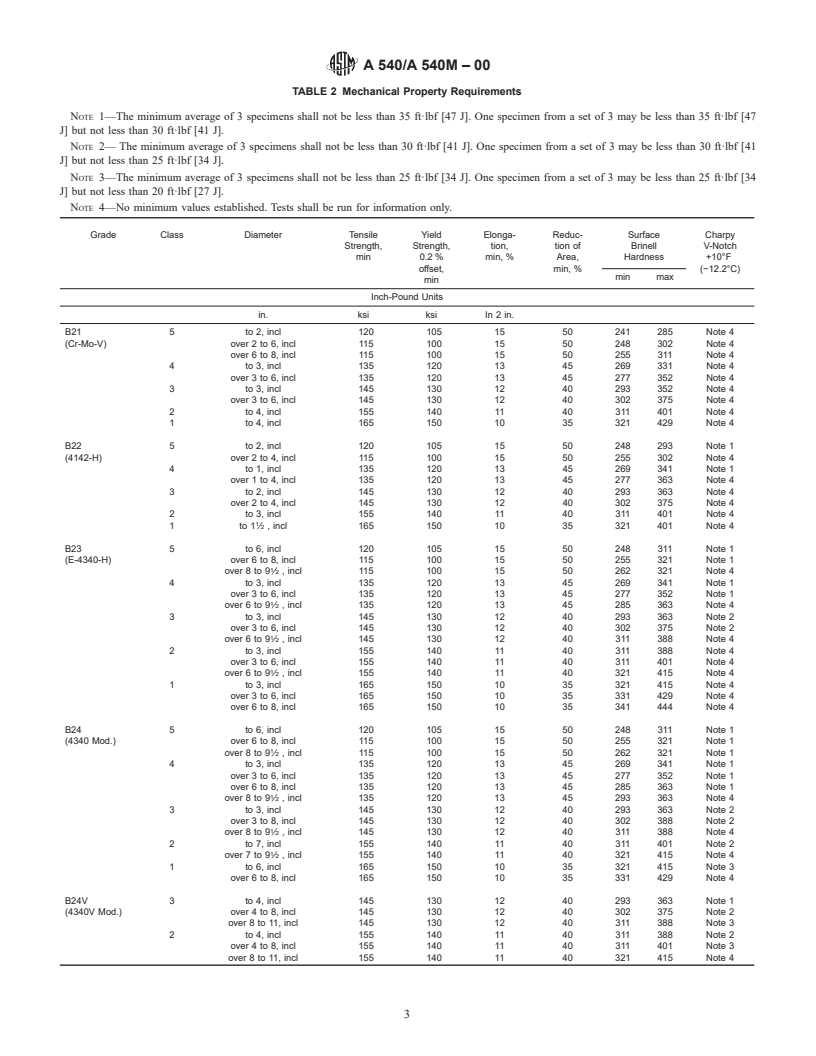

TABLE 2 Mechanical Property Requirements

NOTE 1—The minimum average of 3 specimens shall not be less than 35 ft·lbf [47 J]. One specimen from a set of 3 may be less than 35 ft·lbf [47

J] but not less than 30 ft·lbf [41 J].

NOTE 2— The minimum average of 3 specimens shall not be less than 30 ft·lbf [41 J]. One specimen from a set of 3 may be less than 30 ft·lbf [41

J] but not less than 25 ft·lbf [34 J].

NOTE 3—The minimum average of 3 specimens shall not be less than 25 ft·lbf [34 J]. One specimen from a set of 3 may be less than 25 ft·lbf [34

J] but not less than 20 ft·lbf [27 J].

NOTE 4—No minimum values established. Tests shall be run for information only.

Grade Class Diameter Tensile Yield Elonga- Reduc- Surface Charpy

Strength, Strength, tion, tion of Brinell V-Notch

min 0.2 % min, % Area, Hardness +10°F

offset, min, % (−12.2°C)

min max

min

Inch-Pound Units

in. ksi ksi In 2 in.

B21 5 to 2, incl 120 105 15 50 241 285 Note 4

(Cr-Mo-V) over 2 to 6, incl 115 100 15 50 248 302 Note 4

over 6 to 8, incl 115 100 15 50 255 311 Note 4

4 to 3, incl 135 120 13 45 269 331 Note 4

over 3 to 6, incl 135 120 13 45 277 352 Note 4

3 to 3, incl 145 130 12 40 293 352 Note 4

over 3 to 6, incl 145 130 12 40 302 375 Note 4

2 to 4, incl 155 140 11 40 311 401 Note 4

1 to 4, incl 165 150 10 35 321 429 Note 4

B22 5 to 2, incl 120 105 15 50 248 293 Note 1

(4142-H) over 2 to 4, incl 115 100 15 50 255 302 Note 4

4 to 1, incl 135 120 13 45 269 341 Note 1

over 1 to 4, incl 135 120 13 45 277 363 Note 4

3 to 2, incl 145 130 12 40 293 363 Note 4

over 2 to 4, incl 145 130 12 40 302 375 Note 4

2 to 3, incl 155 140 11 40 311 401 Note 4

1to1 ⁄2 , incl 165 150 10 35 321 401 Note 4

B23 5 to 6, incl 120 105 15 50 248 311 Note 1

(E-4340-H) over 6 to 8, incl 115 100 15 50 255 321 Note 1

over8to9 ⁄2 , incl 115 100 15 50 262 321 Note 4

4 to 3, incl 135 120 13 45 269 341 Note 1

over 3 to 6, incl 135 120 13 45 277 352 Note 1

over6to9 ⁄2 , incl 135 120 13 45 285 363 Note 4

3 to 3, incl 145 130 12 40 293 363 Note 2

over 3 to 6, incl 145 130 12 40 302 375 Note 2

over6to9 ⁄2 , incl 145 130 12 40 311 388 Note 4

2 to 3, incl 155 140 11 40 311 388 Note 4

over 3 to 6, incl 155 140 11 40 311 401 Note 4

over6to9 ⁄2 , incl 155 140 11 40 321 415 Note 4

1 to 3, incl 165 150 10 35 321 415 Note 4

over 3 to 6, incl 165 150 10 35 331 429 Note 4

over 6 to 8, incl 165 150 10 35 341 444 Note 4

B24 5 to 6, incl 120 105 15 50 248 311 Note 1

(4340 Mod.) over 6 to 8, incl 115 100 15 50 255 321 Note 1

over8to9 ⁄2 , incl 115 100 15 50 262 321 Note 1

4 to 3, incl 135 120 13 45 269 341 Note 1

over 3 to 6, incl 135 120 13 45 277 352 Note 1

over 6 to 8, incl 135 120 13 45 285 363 Note 1

over8to9 ⁄2 , incl 135 120 13 45 293 363 Note 4

3 to 3, incl 145 130 12 40 293 363 Note 2

over 3 to 8, incl 145 130 12 40 302 388 Note 2

over8to9 ⁄2 , incl 145 130 12 40 311 388 Note 4

2 to 7, incl 155 140 11 40 311 401 Note 2

over7to9 ⁄2 , incl 155 140 11 40 321 415 Note 4

1 to 6, incl 165 150 10 35 321 415 Note 3

over 6 to 8, incl 165 150 10 35 331 429 Note 4

B24V 3 to 4, incl 145 130 12 40 293 363 Note 1

(4340V Mod.) over 4 to 8, incl 145 130 12 40 302 375 Note 2

over 8 to 11, incl 145 130 12 40 311 388 Note 3

2 to 4, incl 155 140 11 40 311 388 Note 2

over 4 to 8, incl 155 140 11 40 311 401 Note 3

over 8 to 11, incl 155 140 11 40 321 415 Note 4

A 540/A 540M – 00

TABLE 2 Continued

Grade Class Diameter Tensile Yield Elonga- Reduc- Surface Charpy

Strength, Strength, tion, tion of Brinell V-Notch

min 0.2 % min, % Area, Hardness +10°F

offset, min, % (−12.2°C)

min max

min

1 to 4, incl 165 150 10 35 321 415 Note 3

over 4 to 8, incl 165 150 10 35 331 429 Note 4

over 8 to 11, incl 165 150 10 35 331 444 Note 4

Metric Units

In 50

mm MPa MPa mm

B21 5 to 50.8, incl 827 724 15 50 241 285 Note 4

(Cr-Mo-V) over 50.8 to 152.4, incl 793 689 15 50 248 302 Note 4

over 152.4 to 203.2, incl 793 689 15 50 255 311 Note 4

4 to 76.2, incl 931 827 13 45 269 331 Note 4

over 76.2 to 152.4, incl 931 827 13 45 277 352 Note 4

3 to 76.2, incl 1000 896 12 40 293 352 Note 4

over 76.2 to 152.4, incl 1000 896 12 40 302 375 Note 4

2 to 101.6, incl 1069 965 11 40 311 401 Note 4

1 to 101.6, incl 1138 1034 10 35 321 429 Note 4

B22 5 to 50.8, incl 827 724 15 50 248 293 Note 1

(4142-H) over 50.8 to 101.6, incl 793 689 15 50 255 302 Note 4

4 to 25.4, incl 931 827 13 45 269 341 Note 1

over 25.4 to 101.6, incl 931 827 13 45 277 363 Note 4

3 to 50.8, incl 1000 896 12 40 293 363 Note 4

over 50.8 to 101.6, incl 1000 896 12 40 302 375 Note 4

2 to 76.2 incl 1069 965 11 40 311 401 Note 4

1 to 38.1, incl 1138 1034 10 35 321 401 Note 4

B23 5 to 152.4, incl 827 724 15 50 248 311 Note 1

(E-4340-H) over 152.4 to 203.2 incl 793 689 15 50 255 321 Note 1

over 203.2 to 241.3, incl 793 689 15 50 262 321 Note 4

4 to 76.2, incl 931 827 13 45 269 341 Note 1

over 76.2 to 152.4, incl 931 827 13 45 277 352 Note 1

over 152.4 to 241.3, incl 931 827 13 45 285 363 Note 4

3 to 76.2, incl 1000 896 12 40 293 363 Note 2

over 76.2 to 152.4, incl 1000 896 12 40 302 375 Note 2

over 152.4 to 241.3, incl 1000 896 12 40 311 388 Note 4

2 to 76.2, incl 1069 965 11 40 311 388 Note 2

over 76.2 to 152.4, incl 1069 965 11 40 311 401 Note 4

over 152.4 to 241.3, incl 1069 965 11 40 321 415 Note 4

1 to 76.2, incl 1138 1034 10 35 321 415 Note 4

over 76.2 to 152.4, incl 1138 1034 10 35 331 429 Note 4

over 152.4 to 203.2, incl 1138 1034 10 35 341 444 Note 4

B24 5 to 152.4, incl 827 724 15 50 248 311 Note 1

(4340 Mod.) over 152.4 to 203.2, incl 793 689 15 50 255 321 Note 1

over 203.2 to 241.3, incl 793 689 15 50 262 321 Note 1

4 to 76.2, incl 931 827 13 45 269 341 Note 1

over 76.2 to 152.4, incl 931 827 13 45 277 352 Note 1

over 152.4 to 203.2, incl 931 827 13 45 285 363 Note 1

over 203.2 to 241.3, incl 931 827 13 45 293 363 Note 4

3 to 76.2, incl 1000 896 12 40 293 363 Note 2

over 76.2 to 203.2, incl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.