ASTM E2038-99

(Test Method)Standard Test Method for Temperature Calibration of Dielectric Analyzers

Standard Test Method for Temperature Calibration of Dielectric Analyzers

SCOPE

1.1 This test method covers the temperature calibration of dielectric analyzers over the temperature range from -100 to 300°C and is applicable to commercial and custom-built apparatus. The calibration is performed by observing the melting transition of standard reference materials having known transition temperatures within the temperature range of use.

1.2 Electronic instrumentation or automated data analysis and data reductions systems or treatment equivalent to this test method may be used.

1.3 The values stated in SI units are to be reported as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2038 – 99

Standard Test Method for

Temperature Calibration of Dielectric Analyzers

This standard is issued under the fixed designation E 2038; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope equation, for one or more transitions, the temperature scale or

readout of the apparatus is calibrated based upon the known

1.1 This test method covers the temperature calibration of

and observed transition temperatures.

dielectric analyzers over the temperature range from –100 to

300°C and is applicable to commercial and custom-built

5. Significance and Use

apparatus. The calibration is performed by observing the

5.1 This test method permits interlaboratory comparison

melting transition of standard reference materials having

and intralaboratory correlation of instrumental temperature

known transition temperatures within the temperature range of

scale data.

use.

5.2 Dielectric analyzers are used to characterize a broad

1.2 Electronic instrumentation or automated data analysis

range of materials that possess dielectric moments. One of the

and data reductions systems or treatment equivalent to this test

desired values to be assigned by the measurement is the

method may be used.

temperature at which significant changes occur in the proper-

1.3 The values stated in SI units are to be reported as the

ties of the test specimen. In order to obtain consistent results

standard.

from one period of time to another and from one laboratory to

1.4 This standard does not purport to address all of the

another, the temperature signal from the apparatus must be

safety concerns, if any, associated with its use. It is the

calibrated accurately over the temperature range of interest.

responsibility of the user of this standard to establish appro-

priate safety and health practices and to determine the

6. Interferences

applicability of regulatory limitations prior to use.

6.1 Because the specimen size usually is small, care must be

taken to ensure that each specimen is homogeneous and

2. Referenced Documents

representative of the sample as a whole.

2.1 ASTM Standards:

2 6.2 This test method measures dielectric properties under

E 473 Terminology Relating to Thermal Analysis

specific experimental conditions. Should those experimental

E 1142 Terminology Relating to Thermophysical Proper-

2 conditions change, there may be an effect on the calibration of

ties

the apparatus.

3. Terminology 6.3 Contact or adhesion of the specimen to the sensor

should not be lost during the course of the measurement,

3.1 Definitions—Specific technical terms used in this test

otherwise erroneous values will be recorded.

method are defined in accordance with Terminologies E 473

and E 1142.

7. Apparatus

4. Summary of Test Method 7.1 Dielectric Analyzer, consisting of the following items:

7.1.1 Sensors, electrodes for imparting the alternating elec-

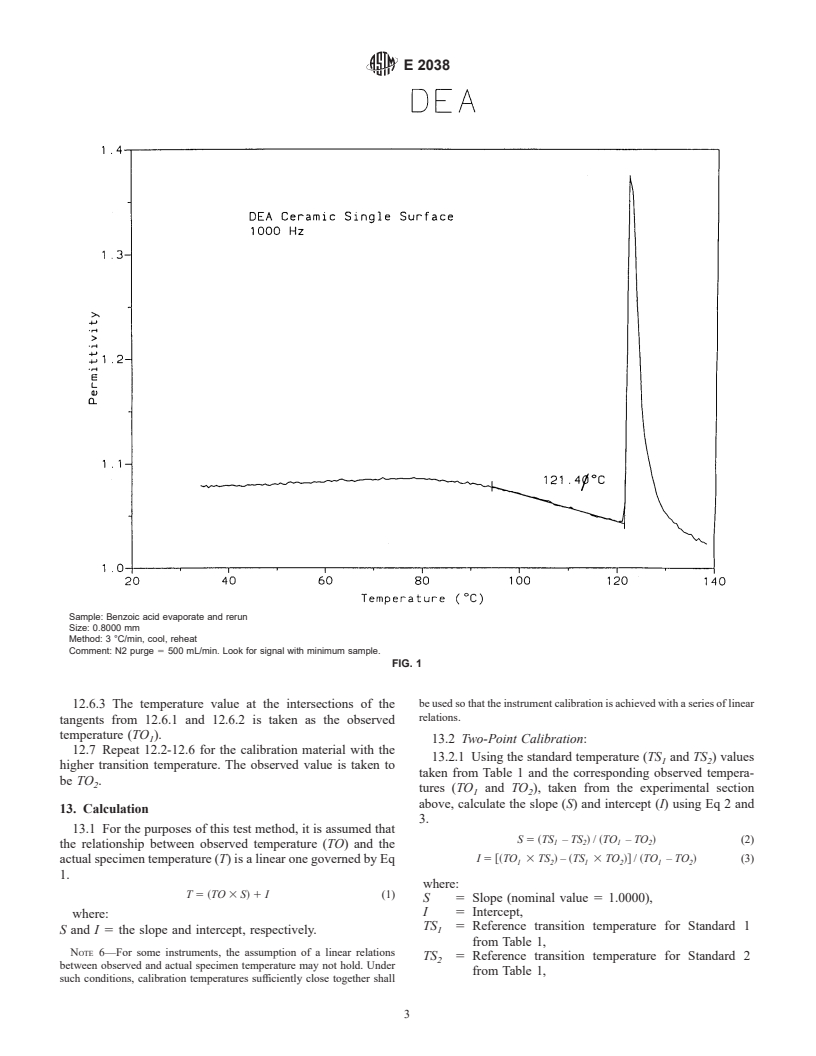

4.1 A test specimen of known solid-solid or solid-liquid

tric field and measuring the induced current and phasing in the

(melting) transition temperature is characterized for its dielec-

specimen. These usually are solid platforms that also serve to

tric properties in a dielectric analyzer of interest as a function

hold the specimen. These may be either two parallel plate

of temperature. At the transition, a sharp change in the

electrodes or a single plate containing a series of interdigitated

dielectric properties is observed. The temperature observed for

electrodes.

the transition by the apparatus is recorded. Using a linear

NOTE 1—When using parallel plate electrodes, provision shall be made

to prevent the electrodes from contacting each other upon the melting of

This test method is under the jurisdiction of ASTM Committee E-37 on

the test specimen.

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on

7.1.2 Temperature Sensor, for measuring the specimen tem-

Test Methods and Recommended Practices.

Current edition approved Sept. 10, 1999. Published November 1999.

perature to within 6 0.1°C.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 2038

7.1.3 Specimen Container, for containing the test specimen 10. Sampling

in liquid form (after it melts).

10.1 Samples usually are analyzed on an “as received”

7.1.4 Temperature Programmer and Furnace, capable of

basis. If some thermal or mechanical treatment, such as

temperature programming the test specimen from –100 to

grinding or sieving, is applied to the sample prior to analysis,

300°C at a rate of at least 1°C/min, or performing isothermal

it shall be indicated in the report.

temperature operation at temperatures over the range of interest

10.2 Since small test specimens are used, they must be

to 6 1°C.

homogeneous and representative of the sample. The mixing or

7.1.5 Cooling Device and Supplies, to provide operating

stirring of samples prior to analysis is recommended.

temperatures below ambient temperatures. This may be a

10.3 The test specimen must cover the entire surface of

mechanical refrigerator or other coolant such as liquid nitro-

parallel plate electrodes. The test specimen thickness depends

gen.

on the dielectric properties of the specimen and the sensor size;

7.1.6 Specimen Atmosphere Control System, capable of however, a minimum thickness of 0.10 mm is recommended.

supplying inert gas, usually nitrogen, argon, or helium, with an 10.4 For interdigitated electrodes the test specimen should

operator selectable flow rate of 50 to 100 mL/min to within 6 cover the electrode array completely. The thickness of the test

5 mL/min. specimen should be at least 1.5 times the electrode spacing.

7.1.7 Recording Device, either digital or analog, to record

11. Calibration and Standardization

and display the dielectric thermal curve consisting of permit-

11.1 Calibrate the permittivity and temperature sensors of

tivity on the Y axis (ordinate) and temperature on the X axis

the apparatus using the procedure described by the manufac-

(abscissa).

turer in the operator’s manual.

7.1.8 While not required, it is convenient to have a data

11.2 Calibration materials with a dielectric moment and

analysis device that will perform and display the calculations

with a solid-solid or solid-liquid (melting) transition of known

of this test method.

value may be used. The 99.9+ % pure materials listed in Table

1 may be used for calibration.

8. Reagents and Materials

8.1 Inert Gas, purified, dry nitrogen, argon, or helium.

12. Procedure

12.1 Select two calibration materials (see Table 1) that have

NOTE 2—If calibration is to be done at low temperatures, that is, below

the dew point, it is essential to have a dry environment as condensed transitions near the extremes of the temperature range of

moisture can affect the results.

interest.

12.2 Load the calibration material with the lower transition

8.2 Calibration Materials, two materials possessing dielec-

temperature into the apparatus as a test specimen.

tric properties that undergo a solid-liquid (melting) or solid-

12.3 Set the initial temperature of the apparatus to a value

solid transition within the temperature range of interest. Sev-

about 30°C below the estimated transition temperature of the

eral suitable materials are listed in Table 1.

calibration material.

12.4 Initiate the measurement of permittivity at a test

9. Hazards

frequency of 1000 Hz. Initiate a temperature program of

9.1 Toxic or corrosive effluents, or bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.