ASTM D5663-97(2011)

(Guide)Standard Guide for Validating Recycled Content in Packaging Paper and Paperboard

Standard Guide for Validating Recycled Content in Packaging Paper and Paperboard

ABSTRACT

This guide covers the standard for the calculation and the substantiation of recycled content of packaging papers and paperboard products. The mass balance approach shall be used to determine absolute recycled content. This guide also covers the recycled content that contain any amount or kind of recycled fiber. Methods to calculate and substantiate levels of such recycled fiber is also covered. Classes and types of paper and paperboard product include, but are not limited to, folding boxboard, set-up boxboard; linearboard and corrugating medium for use in corrugated containers; tubestock; carrier board, bag paper and other related packaging paper and paperboard products.

SCOPE

1.1 This guide provides an approach for both the calculation and the substantiation of recycled content of finished packaging paper and paperboard products. A mass balance approach is recommended for use by manufacturers since no physical or chemical test method is currently available to determine absolute recycled content of a finished paper product.

1.2 This guide covers (1) recycled content of packaging paper and paperboard products that contain any amount or kind of recycled fiber; and (2) methods to calculate and substantiate the level(s) of recycled fiber content claimed by an agreement between the buyer and the seller.

1.2.1 This guide may be used with or without modification to calculate or substantiate the recycled content of packaging paper and paperboard products when recovered nonfibrous materials (for example, filler) are a part of the recycled fiber furnish. Limited guidance is provided for appropriate modifications to this guide for the determination of amount of recycled nonfibrous materials in paper products.

1.3 This guide does not recommend either an amount or a kind of recycled fiber or material to use since (1) the amount and kind of recycled content in a packaging paper or paperboard product should be agreed upon between the buyer and the seller, and (2) the calculation and substantiation procedures recommended may be used for any amount or kind of recycled material agreed upon between the buyer and the seller.

1.4 The mass balance calculation method recommended by this guide may or may not comply with applicable federal, state, or local laws for recycled content statements intended to be received by consumers. Limited guidance on content statements is in Appendix X1.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 10, of this guide: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5663 − 97(Reapproved 2011) An American National Standard

Standard Guide for

Validating Recycled Content in Packaging Paper and

Paperboard

This standard is issued under the fixed designation D5663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

1.1 Thisguideprovidesanapproachforboththecalculation

to use.

and the substantiation of recycled content of finished packag-

ingpaperandpaperboardproducts.Amassbalanceapproachis

2. Referenced Documents

recommended for use by manufacturers since no physical or

2.1 ASTM Standards:

chemical test method is currently available to determine

D1968 Terminology Relating to Paper and Paper Products

absolute recycled content of a finished paper product.

(Withdrawn 2010)

1.2 This guide covers (1) recycled content of packaging

paperandpaperboardproductsthatcontainanyamountorkind 3. Terminology

of recycled fiber; and (2) methods to calculate and substantiate

3.1 Definitions—Definitions shall be in accordance with

the level(s) of recycled fiber content claimed by an agreement 4

Terminology D1968 and the Dictionary of Paper.

between the buyer and the seller.

1.2.1 This guide may be used with or without modification

4. Classification

to calculate or substantiate the recycled content of packaging

4.1 The buyer and seller may agree to packaging paper and

paper and paperboard products when recovered nonfibrous

paperboard product classes and types of their choice, which

materials (for example, filler) are a part of the recycled fiber

may be from among the following classes and types:

furnish. Limited guidance is provided for appropriate modifi-

4.1.1 Classes include, but are not limited to, any of the

cations to this guide for the determination of amount of

following packaging paper and paperboard products: folding

recycled nonfibrous materials in paper products.

boxboard, set-up boxboard; linerboard and corrugating me-

1.3 This guide does not recommend either an amount or a

dium for use in corrugated containers; tubestock; carrier board,

kind of recycled fiber or material to use since (1) the amount

bag paper, and other related packaging paper and paperboard

and kind of recycled content in a packaging paper or paper-

products.

board product should be agreed upon between the buyer and

4.1.2 Two types of products are included: those containing

the seller, and (2) the calculation and substantiation procedures

no virgin fiber and those containing a mixture of recycled and

recommended may be used for any amount or kind of recycled

virgin fiber.

material agreed upon between the buyer and the seller.

5. Ordering Information

1.4 The mass balance calculation method recommended by

5.1 Thebuyerandsellerofpackagingpaperandpaperboard

this guide may or may not comply with applicable federal,

products with recycled content should agree upon at least the

state, or local laws for recycled content statements intended to

following information:

be received by consumers. Limited guidance on content

5.1.1 Class(es) and type(s) of product(s) (see 4.1),

statements is in Appendix X1.

5.1.2 Percent of recycled fiber, by fiber dry weight, and, if

1.5 The following safety hazards caveat pertains only to the

appropriate, recycled material, by total dry weight, to be

test method portion, Section 10, of this guide: This standard

incorporated into a product (see 10.1 through 10.6),

does not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

ThisguideisunderthejurisdictionofASTMCommitteeD10onPackagingand the ASTM website.

is the direct responsibility of Subcommittee D10.19 on Sustainability & Recycling. The last approved version of this historical standard is referenced on

Current edition approved Nov. 1, 2011. Published April 2012. Originally www.astm.org.

published as D5663 – 95. Last previous edition approved in 2003 as D5663 – 97 Available from the Technical Association of the Pulp and Paper Industry, P.O.

(2003). DOI: 10.1520/D5663-97R11. Box 105113, Atlanta, GA 30348.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5663 − 97 (2011)

5.1.3 Degree of variation in recycled fiber or material included of the specific method(s) used to substantiate that

content allowable in shipped product (see 6.2), content, with indication over what time period the measure-

5.1.4 Time period during which recycled content is to be ments will be made.Aseparate sample should be submitted for

calculated (see 10.1.1), eachclassandtypeofpackagingpaperandpaperboardproduct

5.1.5 Method of substantiation used to support the agreed- being bid on, along with supportive data and explanatory

upon recycled content claim for the packaging paper or information for each. Each sample should be clearly marked

paperboard product, with the bidder’s name and address, bid number, and manu-

5.1.6 Format and frequency of recycled content substantia- facturer’s name or code number.

tion and reporting, and

5.1.7 Type and frequency of review by the buyer (see 12.1) 10. Measurement Procedure

of procedures and data used by the seller to monitor compli-

10.1 Recycledfibercontentshouldbecalculatedastheratio

ancewiththeagreed-uponrecycledcontentofproduct(s)under

ofrecycledfiberweighttototalfiberweightinagivenquantity

contract.

of packaging paper or paperboard product and expressed as a

percentage. The basic calculation method is as follows (see

6. Composition

Appendix X1 for an example):

6.1 Recycled content of packaging paper and paperboard

RF 3100

U

products supplied in accordance with this guide should be

RF ,% 5 (1)

C

VF 1RF

U U

agreed upon between the buyer and the seller (see 5.1).

where:

6.2 The average recycled content for a packaging paper or

paperboard product shipped from the seller to the buyer within RF = recycled fiber content, %,

C

a specified time period (see 10.1.1 through 10.1.1.3) should be RF = recycled fiber used, and

U

VF = virgin fiber used.

at least equal to the contracted recycled content or be within a

U

degree of variation (see 6.3) of that content.

10.1.1 The calculation of recycled content should be for a

6.3 The buyer and the seller may agree to a degree of fixedtimeperiodagreeduponbetweenthebuyerandtheseller.

variation in the recycled content in shipped product from the

10.1.1.1 It is recommended that a monthly or quarterly time

seller to the buyer when multiple shipments will take place

period be used, as appropriate to the duration of the contract

over the contract period; however, any degree of variation for

and production runs, for monitoring compliance of shipped

recycled content greater than 10 % is not recommended. In

product with its claimed level of recycled content during the

addition, recycled content of a shipment of product that

term of the buyer-seller agreement.An alternative time period,

exceeds the degree of variation agreed upon by the buyer and

however,maybeagreeduponbetweenthebuyerandtheseller.

the seller should be reported by the seller to the buyer in an

10.1.1.2 When multiple products of varying recycled con-

agreed-upon manner.

tentaremanufacturedwithinaspecifiedtimeperiodonasingle

paper machine, then the recycled content for a specific product

6.4 Recycled content of packaging products composed of

should be calculated based upon those time intervals within

two or more components should be reported as the weighted

that time period during which that specific product was

mean recycled content of the multiple components (see 10.2).

manufactured.

6.5 All measures of recycled content should be on a dry

weight (0 % moisture) basis. NOTE 1—For example, if a calculation of monthly recycled content in

a paperboard product is needed, and that product is manufactured for 10

of the 30 days within that month on a specific paper machine, then only

7. Physical Attributes

the amount and kinds of various recycled and virgin materials used to

7.1 The average value of physical characteristics,

make that paper product on that paper machine during that 10-day period

workmanship, dimensions, and appearance for any product should be used to calculate the recycled content for that product using Eq

1.

shouldmeettherequirementsagreeduponbythebuyerandthe

sellerwithreferencetoappropriateASTMorstandardsofother

10.1.1.3 Whenthesameproductofanagreeduponrecycled

organizations.

content is manufactured within a specified time period on

several paper machines, then the recycled content for that

8. General Attributes

specific product should be calculated based only upon those

8.1 Acceptable defect levels and quality levels should be

intervals within that time period, for each paper machine used,

agreed upon between the buyer and the seller. The use of

during which that specific product was manufactured. For

recycled fiber or other recycled material should not restrict the

example, if a calculation of monthly recycled content in a

usefulnessoftheproductscoveredunderthisguide,norshould

paperboard product is needed, and that product is manufac-

it cause a product to not meet all specified requirements agreed

tured for 10 of the 30 days within that month on one paper

upon between the buyer and the seller.

machine and for 15 of the 30 days within that month on a

second paper machine, then only the amount and kinds of

9. Bid Samples

various recycled and virgin materials used to make that paper

9.1 When requested, the bidder should submit a representa- product during those 10 and 15-day periods on the respective

tive product sample for examination purposes and data to paper machines should be used to calculate the recycled

supporttheclaimedrecycledcontent.Anexplanationshouldbe content for that product by using Eq 1.

D5663 − 97 (2011)

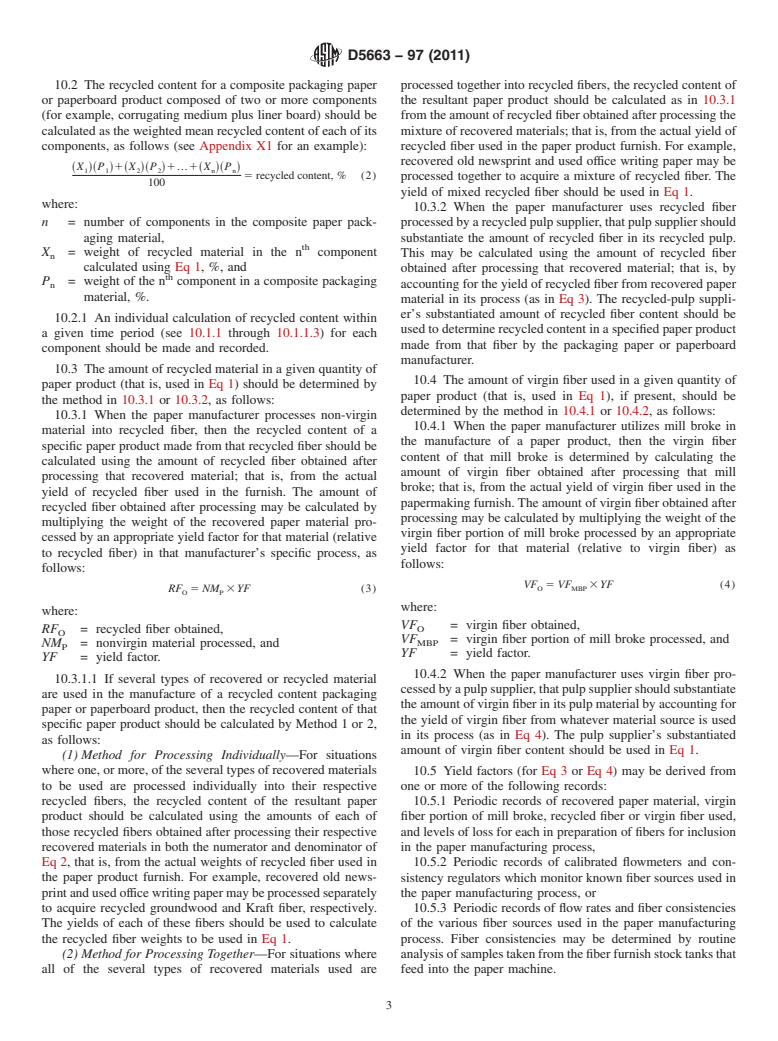

10.2 The recycled content for a composite packaging paper processed together into recycled fibers, the recycled content of

or paperboard product composed of two or more components the resultant paper product should be calculated as in 10.3.1

(for example, corrugating medium plus liner board) should be from the amount of recycled fiber obtained after processing the

calculated as the weighted mean recycled content of each of its mixture of recovered materials; that is, from the actual yield of

components, as follows (see Appendix X1 for an example): recycled fiber used in the paper product furnish. For example,

recovered old newsprint and used office writing paper may be

X P 1 X P 1…1 X P

~ !~ ! ~ !~ ! ~ !~ !

1 1 2 2 n n

5 recycled content, % (2)

processed together to acquire a mixture of recycled fiber. The

yield of mixed recycled fiber should be used in Eq 1.

where:

10.3.2 When the paper manufacturer uses recycled fiber

n = number of components in the composite paper pack- processedbyarecycledpulpsupplier,thatpulpsuppliershould

aging material, substantiate the amount of recycled fiber in its recycled pulp.

th

X = weight of recycled material in the n component

This may be calculated using the amount of recycled fiber

n

calculated using Eq 1,%,and

obtained after processing that recovered material; that is, by

th

P = weight of the n component in a composite packaging

n accounting for the yield of recycled fiber from recovered paper

material, %.

material in its process (as in Eq 3). The recycled-pulp suppli-

er’s substantiated amount of recycled fiber content should be

10.2.1 An individual calculation of recycled content within

used to determine recycled content in a specified paper product

a given time period (see 10.1.1 through 10.1.1.3) for each

made from that fiber by the packaging paper or paperboard

component should be made and recorded.

manufacturer.

10.3 The amount of recycled material in a given quantity of

10.4 The amount of virgin fiber used in a given quantity of

paper product (that is, used in Eq 1) should be determined by

paper product (that is, used in Eq 1), if present, should be

the method in 10.3.1 or 10.3.2, as follows:

determined by the method in 10.4.1 or 10.4.2, as follows:

10.3.1 When the paper manufacturer processes non-virgin

10.4.1 When the paper manufacturer utilizes mill broke in

material into recycled fiber, then the recycled content of a

the manufacture of a paper product, then the virgin fiber

specific paper product made from that recycled fiber should be

content of that mill broke is determined by calculating the

calculated using the amount of recycled fiber obtained after

amount of virgin fiber obtained after processing that mill

processing that recovered material; that is, from the actual

broke; that is, from the actual yield of virgin fiber used in the

yield of recycled fiber used in the furnish. The amount of

papermaking furnish.The amount of virgin fiber obtained after

recycled fiber obtained after processing may be calculated by

processing may be calculated by multiplying the weight of the

multiplying the weight of the recovered paper material pro-

virgin fiber portion of mill broke processed by an appropriate

cessed by an appropriate yield factor for that material (relative

yield factor for that material (relative to virgin fiber) as

to recycled fiber) in that manufacturer’s specific process, as

follows:

follows:

VF 5 VF 3YF (4)

O MBP

RF 5 NM 3YF (3)

O P

where:

where:

VF = virgin fiber obtained,

O

RF = recycled fiber obtained,

O

VF = virgin fiber portion of mill broke processed, and

MBP

NM = nonvirgin material processed, and

P

YF = yield factor.

YF = yield factor.

10.4.2 When the paper manufacturer uses virgin fiber pro-

10.3.1.1 If several types of recovered or recycled material

cessedbyapulpsupplier,thatpulpsuppliershouldsubstantiate

are used in the manufacture of a recycled content packaging

theamountofvirginfiberinitspulpmaterialbyaccountingfor

paper or paperboard product, then the recycled content of that

the yield of virgin fiber from whatever material source is used

specific paper product should be calculated by Method 1 or 2,

in its process (as in Eq 4). The pulp supplier’s substantiated

as follows:

amount of virgin fiber content should be used in Eq 1.

(1) Method for Processing Individually—For situations

where one, or more, of the several types of recovered materials 10.5 Yield factors (for Eq 3 or Eq 4)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.