ASTM F36-99(2009)

(Test Method)Standard Test Method for Compressibility and Recovery of Gasket Materials

Standard Test Method for Compressibility and Recovery of Gasket Materials

ABSTRACT

This test method covers determination of the short-time compressibility and recovery at room temperature of sheet-gasket materials, form-in-place gaskets, and in certain cases, gaskets cut from sheets. The test shall be conducted with both specimen and apparatus at a required temperature. The compressibility and recovery shall be calculated.

SCOPE

1.1 This test method covers determination of the short-time compressibility and recovery at room temperature of sheet-gasket materials, form-in-place gaskets, and in certain cases, gaskets cut from sheets. It is not intended as a test for compressibility under prolonged stress application, generally referred to as “creep,” or for recovery following such prolonged stress application, the inverse of which is generally referred to as “compression set.” Also, it is not intended for tests at other than room temperature. A resiliency characteristic (the amount recovered expressed as a percentage of the compressed thickness) may also be calculated from the test data where desired.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F36 − 99(Reapproved 2009)

Standard Test Method for

1

Compressibility and Recovery of Gasket Materials

This standard is issued under the fixed designation F36; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

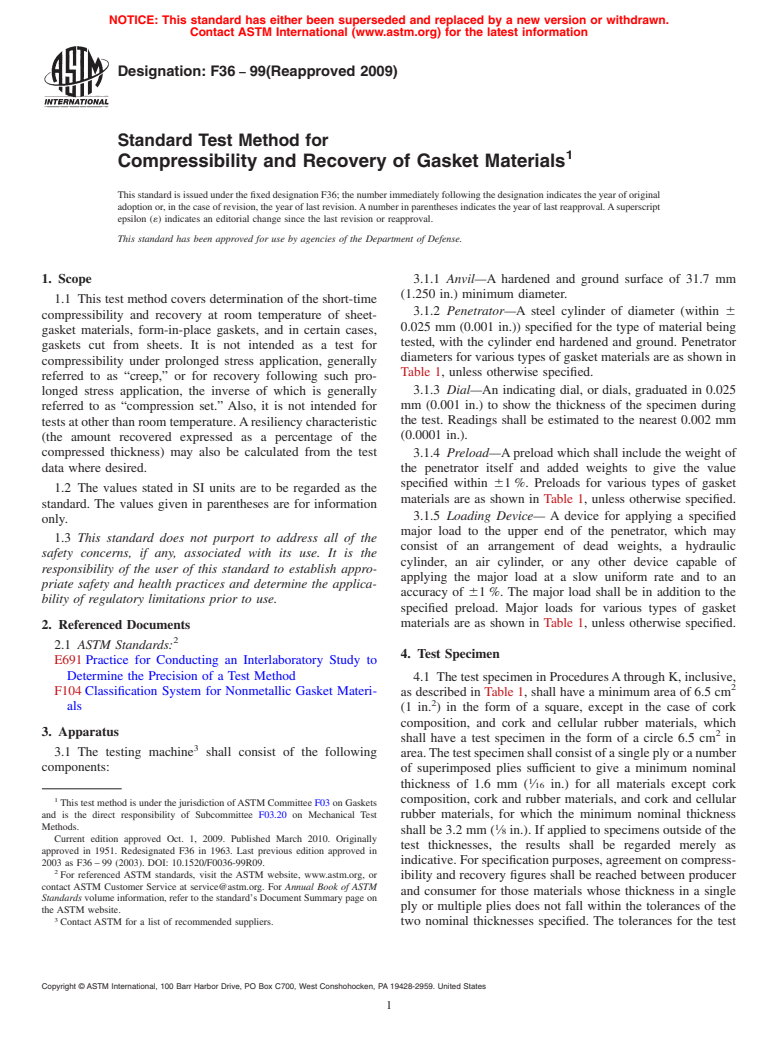

1. Scope 3.1.1 Anvil—A hardened and ground surface of 31.7 mm

(1.250 in.) minimum diameter.

1.1 This test method covers determination of the short-time

3.1.2 Penetrator—A steel cylinder of diameter (within 6

compressibility and recovery at room temperature of sheet-

0.025 mm (0.001 in.)) specified for the type of material being

gasket materials, form-in-place gaskets, and in certain cases,

tested, with the cylinder end hardened and ground. Penetrator

gaskets cut from sheets. It is not intended as a test for

diameters for various types of gasket materials are as shown in

compressibility under prolonged stress application, generally

Table 1, unless otherwise specified.

referred to as “creep,” or for recovery following such pro-

3.1.3 Dial—An indicating dial, or dials, graduated in 0.025

longed stress application, the inverse of which is generally

mm (0.001 in.) to show the thickness of the specimen during

referred to as “compression set.” Also, it is not intended for

the test. Readings shall be estimated to the nearest 0.002 mm

tests at other than room temperature.Aresiliency characteristic

(0.0001 in.).

(the amount recovered expressed as a percentage of the

compressed thickness) may also be calculated from the test

3.1.4 Preload—Apreload which shall include the weight of

data where desired. the penetrator itself and added weights to give the value

specified within 61 %. Preloads for various types of gasket

1.2 The values stated in SI units are to be regarded as the

materials are as shown in Table 1, unless otherwise specified.

standard. The values given in parentheses are for information

3.1.5 Loading Device— A device for applying a specified

only.

major load to the upper end of the penetrator, which may

1.3 This standard does not purport to address all of the

consist of an arrangement of dead weights, a hydraulic

safety concerns, if any, associated with its use. It is the

cylinder, an air cylinder, or any other device capable of

responsibility of the user of this standard to establish appro-

applying the major load at a slow uniform rate and to an

priate safety and health practices and determine the applica-

accuracy of 61 %. The major load shall be in addition to the

bility of regulatory limitations prior to use.

specified preload. Major loads for various types of gasket

materials are as shown in Table 1, unless otherwise specified.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Test Specimen

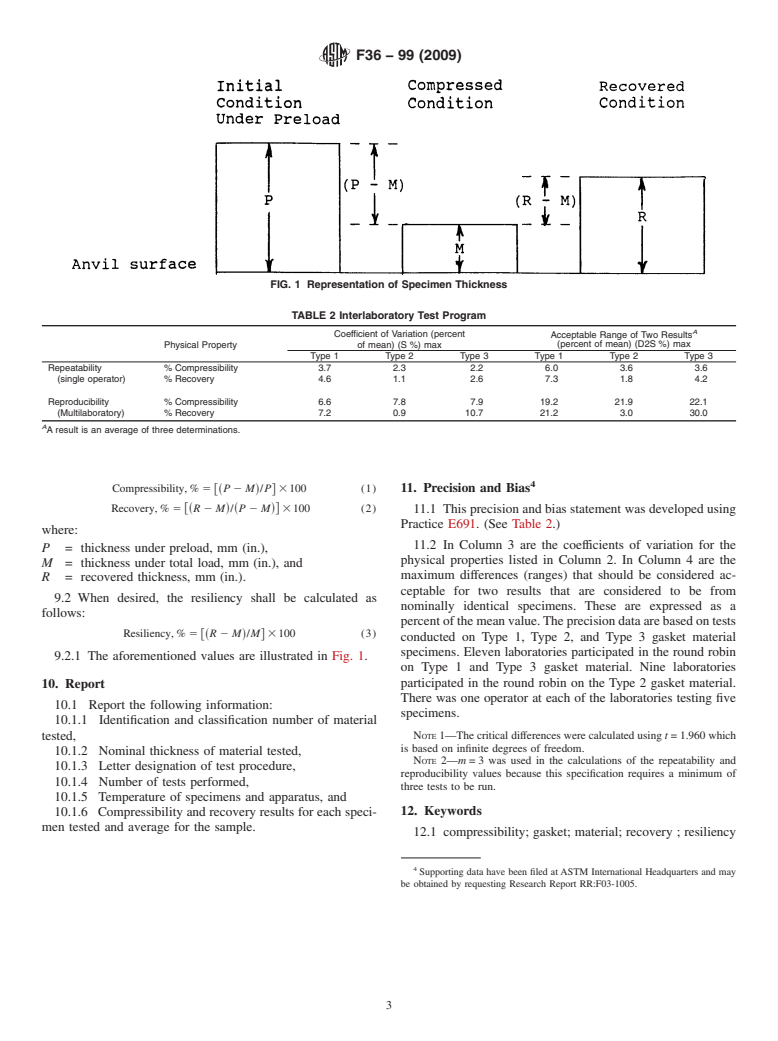

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

4.1 The test specimen in ProceduresAthrough K, inclusive,

2

F104 Classification System for Nonmetallic Gasket Materi-

as described in Table 1, shall have a minimum area of 6.5 cm

2

als

(1 in. ) in the form of a square, except in the case of cork

composition, and cork and cellular rubber materials, which

3. Apparatus 2

shall have a test specimen in the form of a circle 6.5 cm in

3

3.1 The testing machine shall consist of the following

area.Thetestspecimenshallconsistofasingleplyoranumber

components: of superimposed plies sufficient to give a minimum nominal

1

thickness of 1.6 mm ( ⁄16 in.) for all materials except cork

1 composition, cork and rubber materials, and cork and cellular

This test method is under the jurisdiction ofASTM Committee F03 on Gaskets

and is the direct responsibility of Subcommittee F03.20 on Mechanical Test

rubber materials, for which the minimum nominal thickness

Methods.

1

shall be 3.2 mm ( ⁄8 in.). If applied to specimens outside of the

Current edition approved Oct. 1, 2009. Published March 2010. Originally

test thicknesses, the results shall be regarded merely as

approved in 1951. Redesignated F36 in 1963. Last previous edition approved in

indicative. For specification purposes, agreement on compress-

2003 as F36 – 99 (2003). DOI: 10.1520/F0036-99R09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ibility and recovery figures shall be reached between producer

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and consumer for those materials whose thickness in a single

Standards volume information, refer to the standard’s Document Summary page on

ply or multiple plies does not fall within the tolerances of the

the ASTM website.

3

Contact ASTM for a list

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.