ASTM D3427-99

(Test Method)Standard Test Method for Air Release Properties of Petroleum Oils

Standard Test Method for Air Release Properties of Petroleum Oils

SCOPE

1.1 This test method covers the ability of a petroleum-type steam turbine oil to separate entrained air.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 3427 – 99 An American National Standard

Standard Test Method for

1

Air Release Properties of Petroleum Oils

This standard is issued under the fixed designation D 3427; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers the ability of turbine, hydraulic, 5.1 Agitation of lubricating oil with air in equipment, such

and gear oils to separate entrained air. as bearings, couplings, gears, pumps, and oil return lines, may

produce a dispersion of finely divided air bubbles in the oil. If

NOTE 1—This test method was developed for mineral based oils. It may

the residence time in the reservoir is too short to allow the air

be used for some synthetic fluids; however, the precision statement applies

bubbles to rise to the oil surface, a mixture of air and oil will

only to petroleum oils.

circulate through the lubricating oil system. This may result in

1.2 This standard does not purport to address all of the

an inability to maintain oil pressure (particularly with centrifu-

safety concerns, if any, associated with its use. It is the

gal pumps), incomplete oil films in bearings and gears, and

responsibility of the user of this standard to establish appro-

poor hydraulic system performance or failure.

priate safety and health practices and determine the applica-

5.2 This test method measures the time for the entrained air

bility of regulatory limitations prior to use.

content to fall to the relatively low value of 0.2 % volume

under a standardized set of test conditions and hence permits

2. Referenced Documents

the comparison of the ability of oils to separate entrained air

2.1 ASTM Standards:

under conditions where a separation time is available. The

2

D 329 Specification for Acetone

significance of this test method has not been fully established.

3

D 1193 Specification for Reagent Water

However, entrained air can cause sponginess and lack of

D 1401 Test Method for Water Separability of Petroleum

sensitivity of the control of turbine and hydraulic systems. This

4

Oils and Synthetic Fluids

test may not be suitable for ranking oils in applications where

5

E 1 Specification for ASTM Thermometers

residence times are short and gas contents are high.

6

2.2 DIN Standard:

DIN 51 381

6. Apparatus

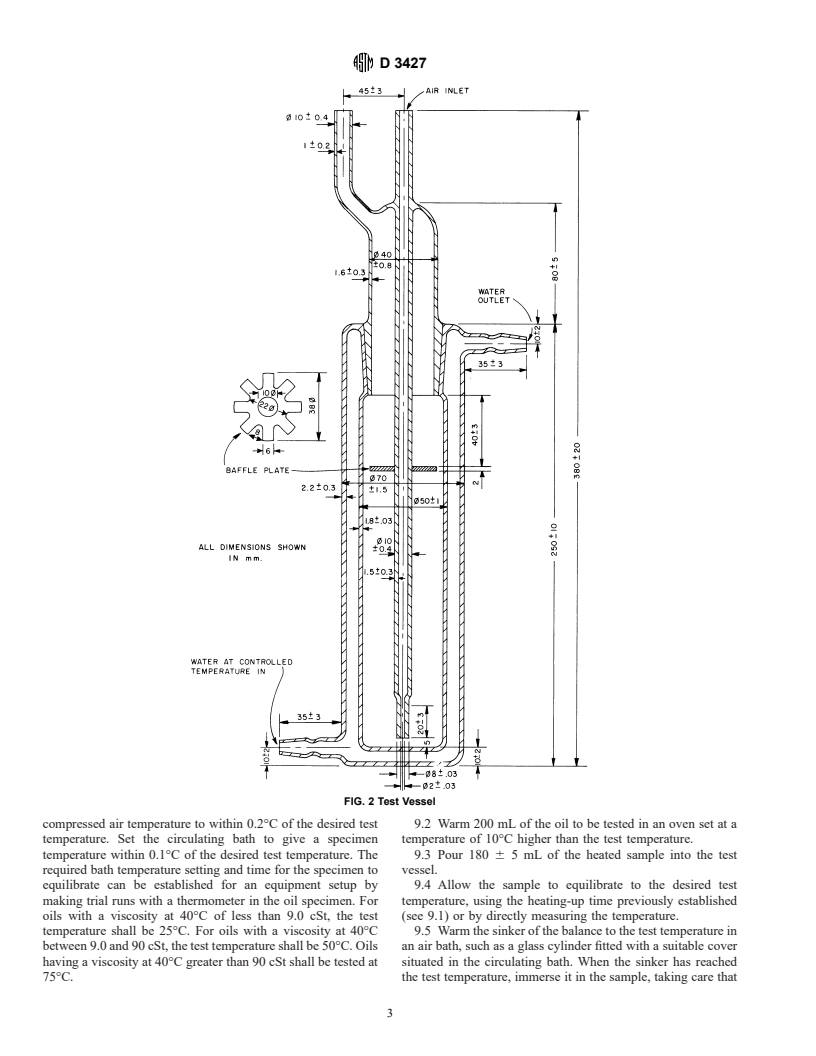

6.1 A schematic diagram of the apparatus is shown in Fig. 1.

3. Terminology

The component parts are described as follows:

3.1 Definition of Term Specific to This Standard:

6.1.1 Test Vessel, made of borosilicate glass as shown in Fig.

3.1.1 air release time, n—the number of minutes needed for

2, consisting of a jacketed sample tube fitted with an air inlet

air entrained in the oil to reduce in volume to 0.2 % under the

capillary, baffle plate, and air outlet tube. The two parts of each

conditions of this test and at the specified temperature.

test vessel should be marked and preferably used as a pair.

Interchanged parts may be used so long as the resultant test

4. Summary of Test Method

vessel conforms to the stated dimensions.

4.1 Compressed air is blown through the test oil, which has

6.1.2 Pressure Gage, covering the range from 0 to 35 kPa,

been heated to a temperature of 25, 50, or 75°C. After the air

with divisions at least every 2 kPa, and an accuracy of 1.5 kPa.

flow is stopped, the time required for the air entrained in the oil

6.1.3 Thermometers:

to reduce in volume to 0.2 % is recorded as the air release time.

6.1.3.1 Air Thermometer, for measuring compressed air

temperature. ASTM Precision Thermometer having a range

from −20 to 102°C, graduated in 0.2°C and conforming to the

1

This test method is under the jurisdiction of ASTM Committee D-2 on

requirements for Thermometer 12C as prescribed in Specifi-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.C0.02 on Corrosion and Water/Air Separability. cation E 1 is suitable. A temperature sensor of at least equiva-

Current edition approved Nov. 10, 1999. Published January 2000. Originally

lent performance is also suitable. Care shall be taken to avoid

published as D 3427 – 75. Last previous edition D 3427 – 96.

restricting the air path with the thermometer bulb or any

2

Annual Book of ASTM Standards, Vol 06.04.

3

adapter used.

Annual Book of ASTM Standards, Vol 11.01.

4

Annual Book of ASTM Standards, Vol 05.01.

6.1.3.2 Sample Thermometer, for measuring the tempera-

5

Annual Book of ASTM Standards, Vol 14.03.

ture of the sample during preparation and trial runs. ASTM

6

Available from Beuth Verlag GmbH, Burggrafenstrasse 6, 1000 Berlin 30,

Precision Thermometer having a range from –20 to 102°C,

Germany.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.