ASTM D7596-23

(Test Method)Standard Test Method for Automatic Particle Counting and Particle Shape Classification of Oils Using a Direct Imaging Integrated Tester

Standard Test Method for Automatic Particle Counting and Particle Shape Classification of Oils Using a Direct Imaging Integrated Tester

SIGNIFICANCE AND USE

5.1 This test method is intended for use in analytical laboratories including on-site in-service oil analysis laboratories. Periodic sampling and analysis of lubricants have long been used as a means to determine overall machinery health. Atomic emission spectroscopy (AES) is often employed for wear metal analysis (Test Methods D5185 and D6595). A number of physical property tests complement wear metal analysis and are used to provide information on lubricant condition (Test Methods D445, D2896, D6304, and D7279). Molecular spectroscopy (Practice E2412) provides direct information on molecular species of interest including additives, lubricant degradation products and contaminating fluids such as water, fuel and glycol. Direct imaging integrated testers provide complementary information on particle count, particle size, particle type, and soot content.

5.2 Particles in lubricating and hydraulic oils are detrimental because they increase wear, clog filters and accelerate oil degradation.

5.3 Particle count may aid in assessing the capability of a filtration system to clean the fluid, determine if off-line recirculating filtration is needed to clean the fluid, or aid in the decision whether or not to change the fluid.

5.4 An increase in the concentration and size of wear particles is indicative of incipient failure or component change out. Predictive maintenance by oil analysis monitors the concentration and size of wear particles on a periodic basis to predict failure.

5.5 High soot levels in diesel engine lubricating oil may indicate abnormal engine operation.

SCOPE

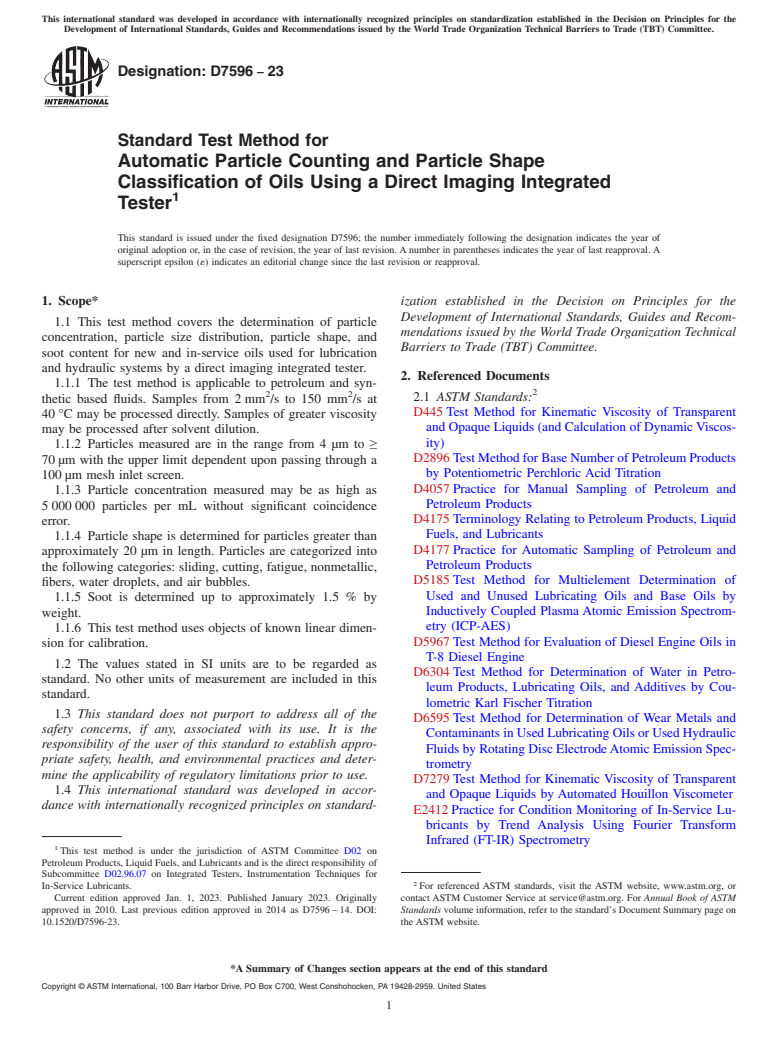

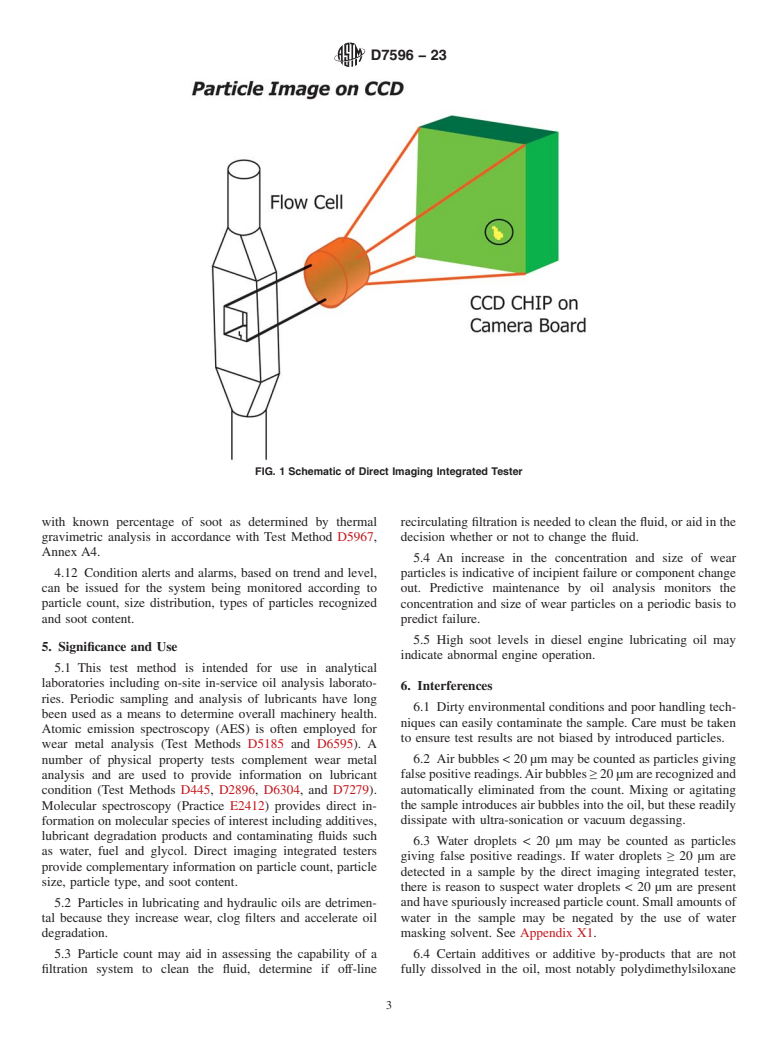

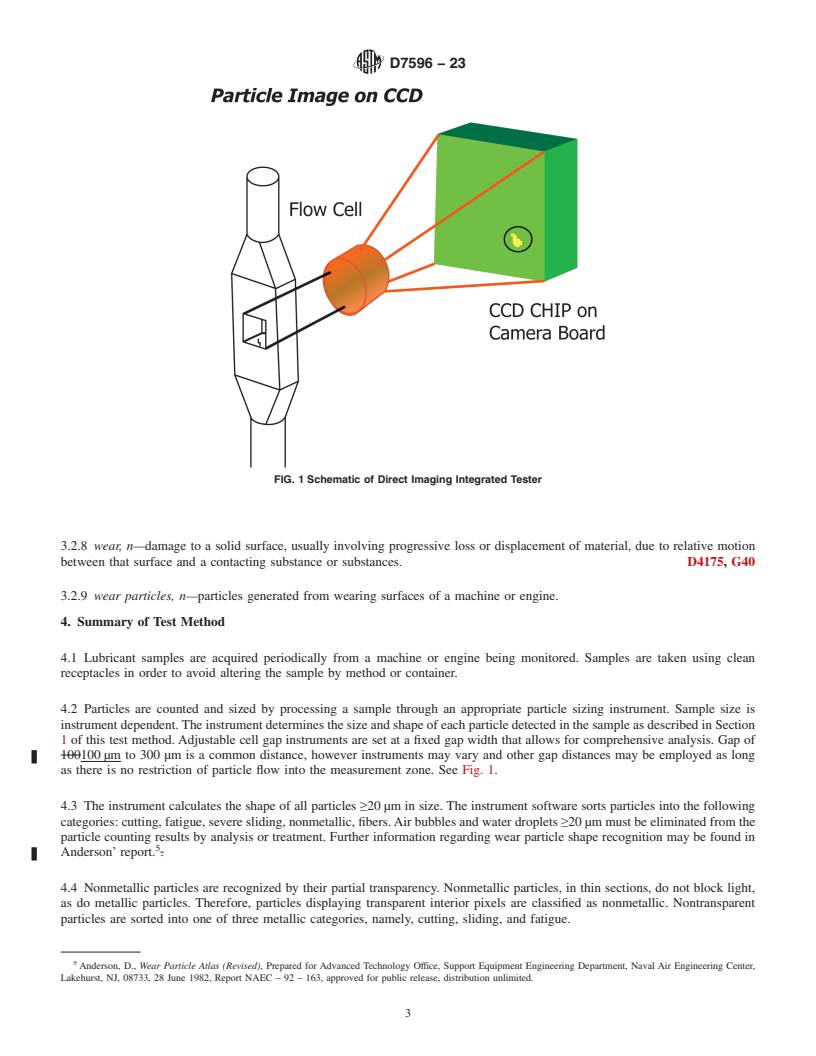

1.1 This test method covers the determination of particle concentration, particle size distribution, particle shape, and soot content for new and in-service oils used for lubrication and hydraulic systems by a direct imaging integrated tester.

1.1.1 The test method is applicable to petroleum and synthetic based fluids. Samples from 2 mm2/s to 150 mm2/s at 40 °C may be processed directly. Samples of greater viscosity may be processed after solvent dilution.

1.1.2 Particles measured are in the range from 4 μm to ≥ 70 μm with the upper limit dependent upon passing through a 100 μm mesh inlet screen.

1.1.3 Particle concentration measured may be as high as 5 000 000 particles per mL without significant coincidence error.

1.1.4 Particle shape is determined for particles greater than approximately 20 µm in length. Particles are categorized into the following categories: sliding, cutting, fatigue, nonmetallic, fibers, water droplets, and air bubbles.

1.1.5 Soot is determined up to approximately 1.5 % by weight.

1.1.6 This test method uses objects of known linear dimension for calibration.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7596 −23

Standard Test Method for

Automatic Particle Counting and Particle Shape

Classification of Oils Using a Direct Imaging Integrated

1

Tester

This standard is issued under the fixed designation D7596; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers the determination of particle

mendations issued by the World Trade Organization Technical

concentration, particle size distribution, particle shape, and

Barriers to Trade (TBT) Committee.

soot content for new and in-service oils used for lubrication

and hydraulic systems by a direct imaging integrated tester.

2. Referenced Documents

1.1.1 The test method is applicable to petroleum and syn-

2

2 2

2.1 ASTM Standards:

thetic based fluids. Samples from 2 mm /s to 150 mm /s at

D445 Test Method for Kinematic Viscosity of Transparent

40 °C may be processed directly. Samples of greater viscosity

and Opaque Liquids (and Calculation of Dynamic Viscos-

may be processed after solvent dilution.

ity)

1.1.2 Particles measured are in the range from 4 µm to ≥

D2896 Test Method for Base Number of Petroleum Products

70 µm with the upper limit dependent upon passing through a

by Potentiometric Perchloric Acid Titration

100 µm mesh inlet screen.

D4057 Practice for Manual Sampling of Petroleum and

1.1.3 Particle concentration measured may be as high as

Petroleum Products

5 000 000 particles per mL without significant coincidence

D4175 Terminology Relating to Petroleum Products, Liquid

error.

Fuels, and Lubricants

1.1.4 Particle shape is determined for particles greater than

D4177 Practice for Automatic Sampling of Petroleum and

approximately 20 µm in length. Particles are categorized into

Petroleum Products

the following categories: sliding, cutting, fatigue, nonmetallic,

D5185 Test Method for Multielement Determination of

fibers, water droplets, and air bubbles.

Used and Unused Lubricating Oils and Base Oils by

1.1.5 Soot is determined up to approximately 1.5 % by

Inductively Coupled Plasma Atomic Emission Spectrom-

weight.

etry (ICP-AES)

1.1.6 This test method uses objects of known linear dimen-

D5967 Test Method for Evaluation of Diesel Engine Oils in

sion for calibration.

T-8 Diesel Engine

1.2 The values stated in SI units are to be regarded as

D6304 Test Method for Determination of Water in Petro-

standard. No other units of measurement are included in this

leum Products, Lubricating Oils, and Additives by Cou-

standard.

lometric Karl Fischer Titration

1.3 This standard does not purport to address all of the

D6595 Test Method for Determination of Wear Metals and

safety concerns, if any, associated with its use. It is the

Contaminants in Used Lubricating Oils or Used Hydraulic

responsibility of the user of this standard to establish appro-

Fluids by Rotating Disc ElectrodeAtomic Emission Spec-

priate safety, health, and environmental practices and deter-

trometry

mine the applicability of regulatory limitations prior to use.

D7279 Test Method for Kinematic Viscosity of Transparent

1.4 This international standard was developed in accor-

and Opaque Liquids by Automated Houillon Viscometer

dance with internationally recognized principles on standard-

E2412 Practice for Condition Monitoring of In-Service Lu-

bricants by Trend Analysis Using Fourier Transform

Infrared (FT-IR) Spectrometry

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.96.07 on Integrated Testers, Instrumentation Techniques for

2

In-Service Lubricants. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2023. Published January 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2010. Last previous edition approved in 2014 as D7596 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7596-23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7596−23

G40 Terminology Relating to Wear and Erosion 4. Summary of Test Met

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7596 − 14 D7596 − 23

Standard Test Method for

Automatic Particle Counting and Particle Shape

Classification of Oils Using a Direct Imaging Integrated

1

Tester

This standard is issued under the fixed designation D7596; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of particle concentration, particle size distribution, particle shape, and soot content

for new and in-service oils used for lubrication and hydraulic systems by a direct imaging integrated tester.

2 2

1.1.1 The test method is applicable to petroleum and synthetic based fluids. Samples from 22 mm /s to 150 mm /s at 40°C40 °C

may be processed directly. Samples of greater viscosity may be processed after solvent dilution.

1.1.2 Particles measured are in the range from 4 μm to ≥ 70 μm with the upper limit dependent upon passing through a 100 μm

mesh inlet screen.

1.1.3 Particle concentration measured may be as high as 5 000 000 particles per mL without significant coincidence error.

1.1.4 Particle shape is determined for particles greater than approximately 20 μm in length. Particles are categorized into the

following categories: sliding, cutting, fatigue, nonmetallic, fibers, water droplets, and air bubbles.

1.1.5 Soot is determined up to approximately 1.5 % by weight.

1.1.6 This test method uses objects of known linear dimension for calibration.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.96.07 on Integrated Testers, Instrumentation Techniques for In-Service Lubricants.

Current edition approved June 1, 2014Jan. 1, 2023. Published July 2014January 2023. Originally approved in 2010. Last previous edition approved in 20102014 as

D7596 – 10.D7596 – 14. DOI: 10.1520/D7596-14.10.1520/D7596-23.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7596 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D2896 Test Method for Base Number of Petroleum Products by Potentiometric Perchloric Acid Titration

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D5185 Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively

Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

D5967 Test Method for Evaluation of Diesel Engine Oils in T-8 Diesel Engine

D6304 Test Method for Determination of Water in Petroleum Products, Lubricating Oils, and Additives by Coulometric Karl

Fischer Titration

D6595 Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by

Rotating Disc Electrode Atomic Emission Spectrometry

D7279 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer

E2412 Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR)

Spectrometry

G40 Terminology Relating to Wear and Erosion

3

2.2 ISO Standards:

ISO 12103-1 1997 Road Vehicles—Test Dust for Filter Evaluation—Part 1: Arizon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.