ASTM D5179-16

(Test Method)Standard Test Method for Measuring Adhesion of Organic Coatings in the Laboratory by Direct Tensile Method

Standard Test Method for Measuring Adhesion of Organic Coatings in the Laboratory by Direct Tensile Method

SIGNIFICANCE AND USE

4.1 The pull-off strength (commonly referred to as adhesion) of a coating is an important performance property that has been used in specifications. This test method serves as a means for uniformly preparing and testing organic coatings on plastic or other substrates.4 Further information may be found in Appendix X1.

SCOPE

1.1 This test method covers the laboratory determination of organic coating adhesion to plastic substrates by mounting and removing a metal stud from the surface of the coating and measuring the force required to break the coating/substrate bond with a tensile tester. This test method may also be applied to substrates other than plastic.

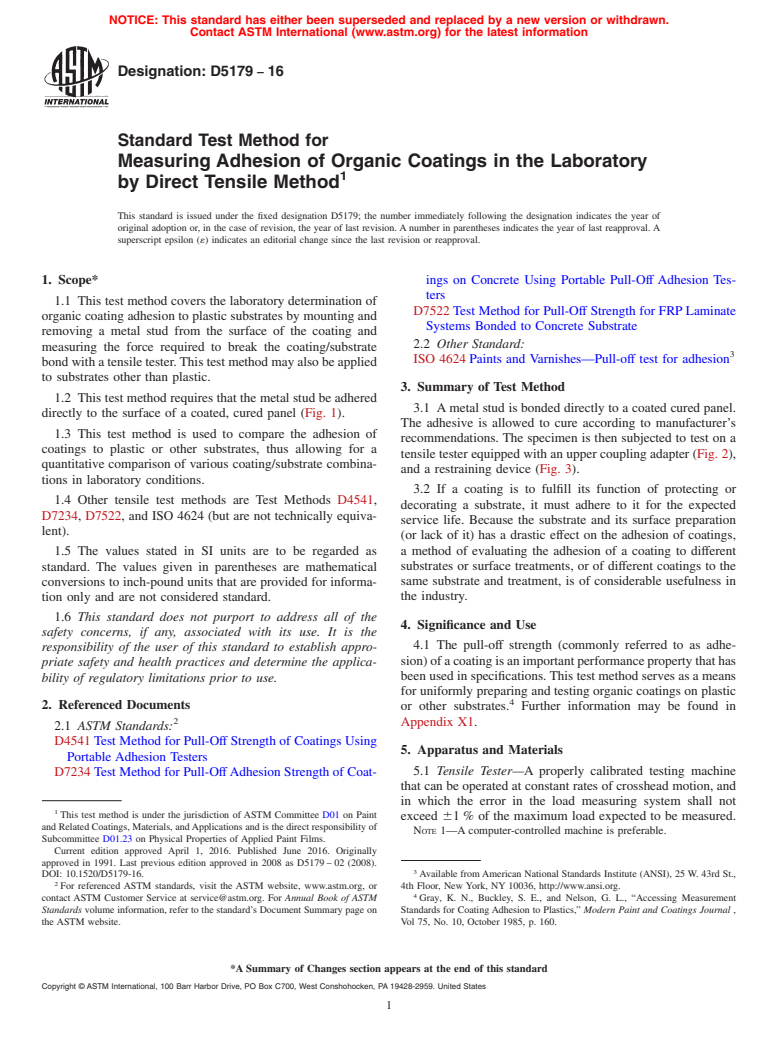

1.2 This test method requires that the metal stud be adhered directly to the surface of a coated, cured panel (Fig. 1).

1.3 This test method is used to compare the adhesion of coatings to plastic or other substrates, thus allowing for a quantitative comparison of various coating/substrate combinations in laboratory conditions.

1.4 Other tensile test methods are Test Methods D4541, D7234, D7522, and ISO 4624 (but are not technically equivalent).

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5179 − 16

Standard Test Method for

Measuring Adhesion of Organic Coatings in the Laboratory

1

by Direct Tensile Method

This standard is issued under the fixed designation D5179; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* ings on Concrete Using Portable Pull-Off Adhesion Tes-

ters

1.1 This test method covers the laboratory determination of

D7522 Test Method for Pull-Off Strength for FRP Laminate

organic coating adhesion to plastic substrates by mounting and

Systems Bonded to Concrete Substrate

removing a metal stud from the surface of the coating and

2.2 Other Standard:

measuring the force required to break the coating/substrate

3

ISO 4624 Paints and Varnishes—Pull-off test for adhesion

bond with a tensile tester.This test method may also be applied

to substrates other than plastic.

3. Summary of Test Method

1.2 This test method requires that the metal stud be adhered

3.1 Ametal stud is bonded directly to a coated cured panel.

directly to the surface of a coated, cured panel (Fig. 1).

The adhesive is allowed to cure according to manufacturer’s

1.3 This test method is used to compare the adhesion of

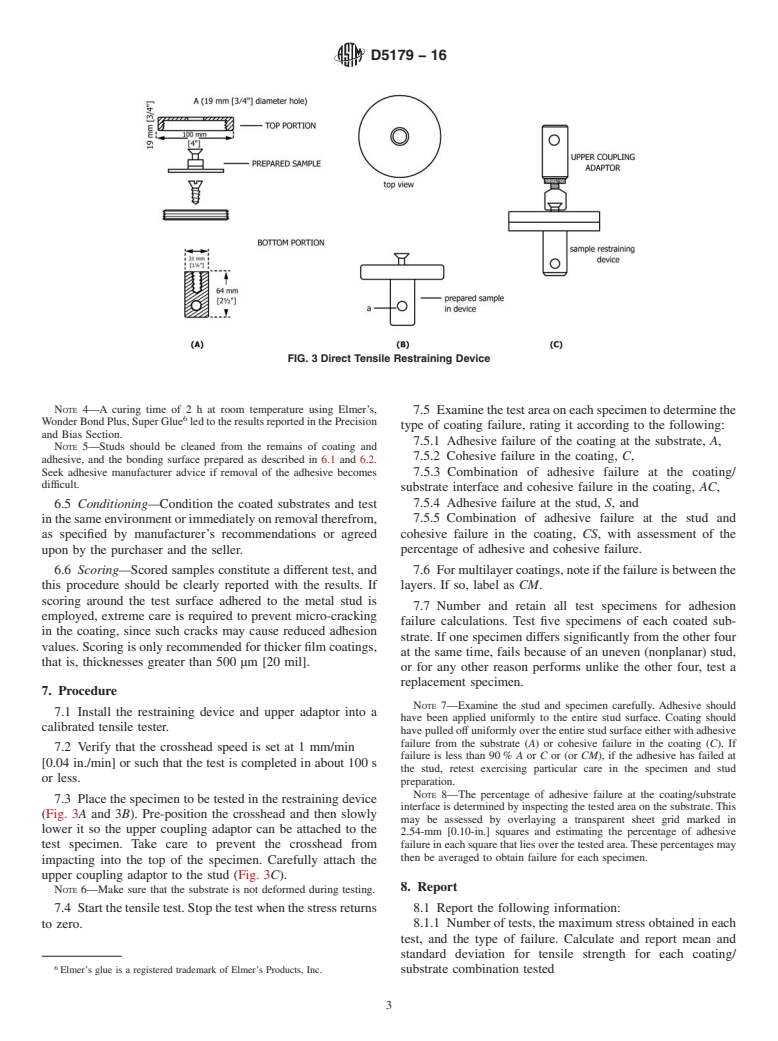

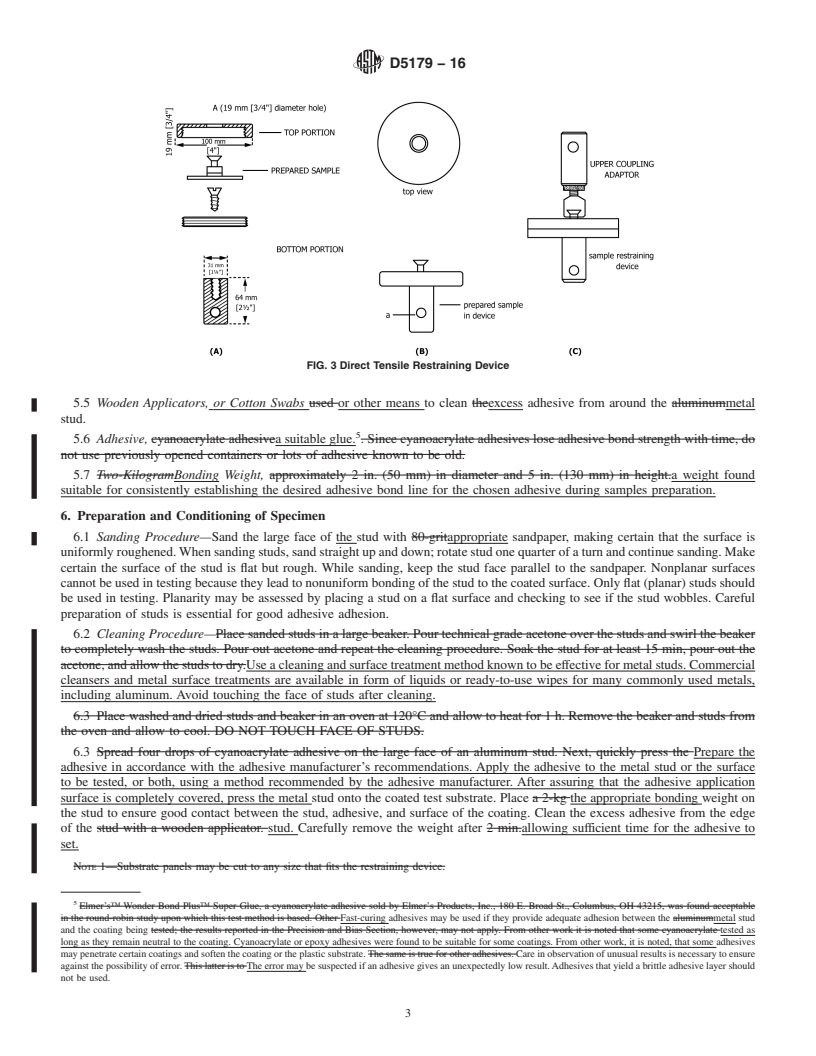

recommendations. The specimen is then subjected to test on a

coatings to plastic or other substrates, thus allowing for a

tensile tester equipped with an upper coupling adapter (Fig. 2),

quantitative comparison of various coating/substrate combina-

and a restraining device (Fig. 3).

tions in laboratory conditions.

3.2 If a coating is to fulfill its function of protecting or

1.4 Other tensile test methods are Test Methods D4541,

decorating a substrate, it must adhere to it for the expected

D7234, D7522, and ISO 4624 (but are not technically equiva-

service life. Because the substrate and its surface preparation

lent).

(or lack of it) has a drastic effect on the adhesion of coatings,

a method of evaluating the adhesion of a coating to different

1.5 The values stated in SI units are to be regarded as

substrates or surface treatments, or of different coatings to the

standard. The values given in parentheses are mathematical

same substrate and treatment, is of considerable usefulness in

conversions to inch-pound units that are provided for informa-

the industry.

tion only and are not considered standard.

1.6 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 The pull-off strength (commonly referred to as adhe-

responsibility of the user of this standard to establish appro-

sion)ofacoatingisanimportantperformancepropertythathas

priate safety and health practices and determine the applica-

been used in specifications.This test method serves as a means

bility of regulatory limitations prior to use.

for uniformly preparing and testing organic coatings on plastic

4

2. Referenced Documents

or other substrates. Further information may be found in

2

Appendix X1.

2.1 ASTM Standards:

D4541 Test Method for Pull-Off Strength of Coatings Using

5. Apparatus and Materials

Portable Adhesion Testers

5.1 Tensile Tester—A properly calibrated testing machine

D7234 Test Method for Pull-OffAdhesion Strength of Coat-

that can be operated at constant rates of crosshead motion, and

in which the error in the load measuring system shall not

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

exceed 61 % of the maximum load expected to be measured.

and Related Coatings, Materials, andApplications and is the direct responsibility of

NOTE 1—A computer-controlled machine is preferable.

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved April 1, 2016. Published June 2016. Originally

approved in 1991. Last previous edition approved in 2008 as D5179 – 02 (2008).

3

DOI: 10.1520/D5179-16. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Gray, K. N., Buckley, S. E., and Nelson, G. L., “Accessing Measurement

Standards volume information, refer to the standard’s Document Summary page on Standards for CoatingAdhesion to Plastics,” Modern Paint and Coatings Journal ,

the ASTM website. Vol 75, No. 10, October 1985, p. 160.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5179 − 02 (Reapproved 2008) D5179 − 16

Standard Test Method for

Measuring Adhesion of Organic Coatings to Plastic

Substratesin the Laboratory by Direct Tensile

1

TestingMethod

This standard is issued under the fixed designation D5179; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the laboratory determination of organic coating adhesion to plastic substrates by mounting and

removing an aluminuma metal stud from the surface of the coating and measuring the force required to break the coating/substrate

bond with a tensile tester. This test method may also be applied to substrates other than plastic.

1.2 This test method requires that the aluminummetal stud be adhered directly to the surface of a coated, cured panel (Fig. 1).

1.3 This test method is used to compare the adhesion of coatings to various plastic or other substrates, thus allowing for a

quantitative comparison of various coating/substrate combinations.combinations in laboratory conditions.

1.4 Other tensile test methods are Test MethodMethods D4541, D7234, D7522, and ISO 4624 (but are not technically

equivalent).

1.5 The values stated in inch-poundSI units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SIinch-pound units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4541 Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers

D7234 Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers

D7522 Test Method for Pull-Off Strength for FRP Laminate Systems Bonded to Concrete Substrate

2.2 Other Standard:

3

ISO 4624 Paints and Varnishes—Pull-off test for adhesion

3. Summary of Test Method

3.1 An aluminumA metal stud is bonded directly to a coated cured panel. The adhesive is allowed to cure for 2 h at room

temperature. according to manufacturer’s recommendations. The specimen is then subjected to test on a tensile tester equipped with

an upper coupling adapter (Fig. 2), and a restraining device (Fig. 3).

3.2 If a coating is to fulfill its function of protecting or decorating a substrate, it must adhere to it for the expected service life.

Because the substrate and its surface preparation (or lack of it) has a drastic effect on the adhesion of coatings, a method of

evaluation evaluating the adhesion of a coating to different substrates or surface treatments, or of different coatingcoatings to the

same substrate and treatment, is of considerable usefulness in the industry.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved July 1, 2008April 1, 2016. Published July 2008June 2016. Originally approved in 1991. Last previous edition approved in 20022008 as

D5179 – 02.D5179 – 02 (2008). DOI: 10.1520/D5179-02R08.10.1520/D5179-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5179 − 16

FIG. 1 Direct Tensile Model

FIG. 2 Upper Coupling Adaptor

4. Significance and Use

4.1 The pull-off strength (commonly referred to as adhesion) of a coating is an important performance property that has been

used in specifications. This test method serves as a means for uniformly preparing and testing organic co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.