ASTM B790/B790M-16

(Practice)Standard Practice for Structural Design of Corrugated Aluminum Pipe, Pipe-Arches, and Arches for Culverts, Storm Sewers, and Other Buried Conduits

Standard Practice for Structural Design of Corrugated Aluminum Pipe, Pipe-Arches, and Arches for Culverts, Storm Sewers, and Other Buried Conduits

ABSTRACT

This practice is intended for the structural design of corrugated aluminum pipe and pipe-arches, and aluminum structural plate pipe, pipe-arches, and arches for use as culverts, storm sewers, and other buried conduits. This practice is for pipe installed in a trench or embankment and subjected to highway, railroad, and aircraft loadings. It must be recognized that buried corrugated aluminum pipes are composite structures made up of the aluminum ring and the soil envelope, and both elements play a vital part in the structural design. Corrugated aluminum pipe and pipe-arches shall be of annular fabrication using riveted seams, or of helical fabrication having a continuous lockseam. Structural plate pipe, pipe-arches, and arches shall be fabricated in separate plates that when assembled at the job site by bolting form the required shape. The design load or pressure on a pipe is comprised of earth load, live load, and impact load. Strength requirements for wall strength, buckling strength, and seam strength may be determined by either the allowable stress design (ASD) method (involves calculation of required wall area and critical buckling stress) or the load and resistance factor design (LRFD) method (involves calculation of factored loads, factored thrust, factored resistance, wall resistance, and seam resistance). Requirements for handling and installation rigidity and minimum cover are detailed. Design considerations for deflection, smooth-line pipe, spiral-rib pipe, pipe-arch, pipe materials, soil, minimum spacing, end treatment, abrasive or corrosive conditions, construction and installation, and structural plate arches are provided.

SCOPE

1.1 This practice is intended for the structural design of corrugated aluminum pipe and pipe-arches, and aluminum structural plate pipe, pipe-arches, and arches for use as culverts and storm sewers and other buried conduits. This practice is for pipe installed in a trench or embankment and subjected to highway, railroad, and aircraft loadings. It must be recognized that a buried corrugated aluminum pipe is a composite structure made up of the aluminum ring and the soil envelope, and both elements play a vital part in the structural design of this type of structure.

1.2 Corrugated aluminum pipe and pipe-arches shall be of annular fabrication using riveted seams, or of helical fabrication having a continuous lockseam.

1.3 Structural plate pipe, pipe-arches, and arches are fabricated in separate plates that when assembled at the job site by bolting form the required shape.

1.4 This specification is applicable to design in inch-pound units as Specification B790 or in SI units as Specification B790M. Inch-pound units and SI units are not necessarily equivalent. SI units are shown in brackets in the text for clarity, but they are the applicable values when the design is done in accordance with Specification B790M.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B790/B790M − 16

Standard Practice for

Structural Design of Corrugated Aluminum Pipe, Pipe-

Arches, and Arches for Culverts, Storm Sewers, and Other

1

Buried Conduits

This standard is issued under the fixed designation B790/B790M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice is intended for the structural design of

corrugated aluminum pipe and pipe-arches, and aluminum

2. Referenced Documents

structuralplatepipe,pipe-arches,andarchesforuseasculverts

2

2.1 ASTM Standards:

andstormsewersandotherburiedconduits.Thispracticeisfor

B745/B745MSpecification for Corrugated Aluminum Pipe

pipe installed in a trench or embankment and subjected to

for Sewers and Drains

highway, railroad, and aircraft loadings. It must be recognized

B746/B746MSpecification for CorrugatedAluminumAlloy

that a buried corrugated aluminum pipe is a composite struc-

Structural Plate for Field-Bolted Pipe, Pipe-Arches, and

ture made up of the aluminum ring and the soil envelope, and

Arches

both elements play a vital part in the structural design of this

B788/B788MPractice for Installing Factory-Made Corru-

type of structure.

gated Aluminum Culverts and Storm Sewer Pipe

1.2 Corrugated aluminum pipe and pipe-arches shall be of

B789/B789MPractice for Installing Corrugated Aluminum

annular fabrication using riveted seams, or of helical fabrica-

Structural Plate Pipe for Culverts and Sewers

tion having a continuous lockseam.

B864/B864MSpecification for Corrugated Aluminum Box

1.3 Structural plate pipe, pipe-arches, and arches are fabri- Culverts

cated in separate plates that when assembled at the job site by

D698Test Methods for Laboratory Compaction Character-

3

bolting form the required shape. istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

3

kN-m/m ))

1.4 This specification is applicable to design in inch-pound

D1556Test Method for Density and Unit Weight of Soil in

units as Specification B790 or in SI units as Specification

Place by Sand-Cone Method

B790M. Inch-pound units and SI units are not necessarily

D2167Test Method for Density and Unit Weight of Soil in

equivalent.SIunitsareshowninbracketsinthetextforclarity,

Place by the Rubber Balloon Method

but they are the applicable values when the design is done in

D2487Practice for Classification of Soils for Engineering

accordance with Specification B790M.

Purposes (Unified Soil Classification System)

1.5 This standard does not purport to address all of the

D2937Test Method for Density of Soil in Place by the

safety concerns, if any, associated with its use. It is the

Drive-Cylinder Method

responsibility of the user of this standard to establish appro-

D6938TestMethodsforIn-PlaceDensityandWaterContent

of Soil and Soil-Aggregate by Nuclear Methods (Shallow

Depth)

1

This practice is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on

2

Corrugated Aluminum Pipe and Corrugated Aluminum Structural Plate. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2016. Published December 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1990. Last previous edition approved in 2011 as B790/B790M–11. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/B0790_B0790M-16. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

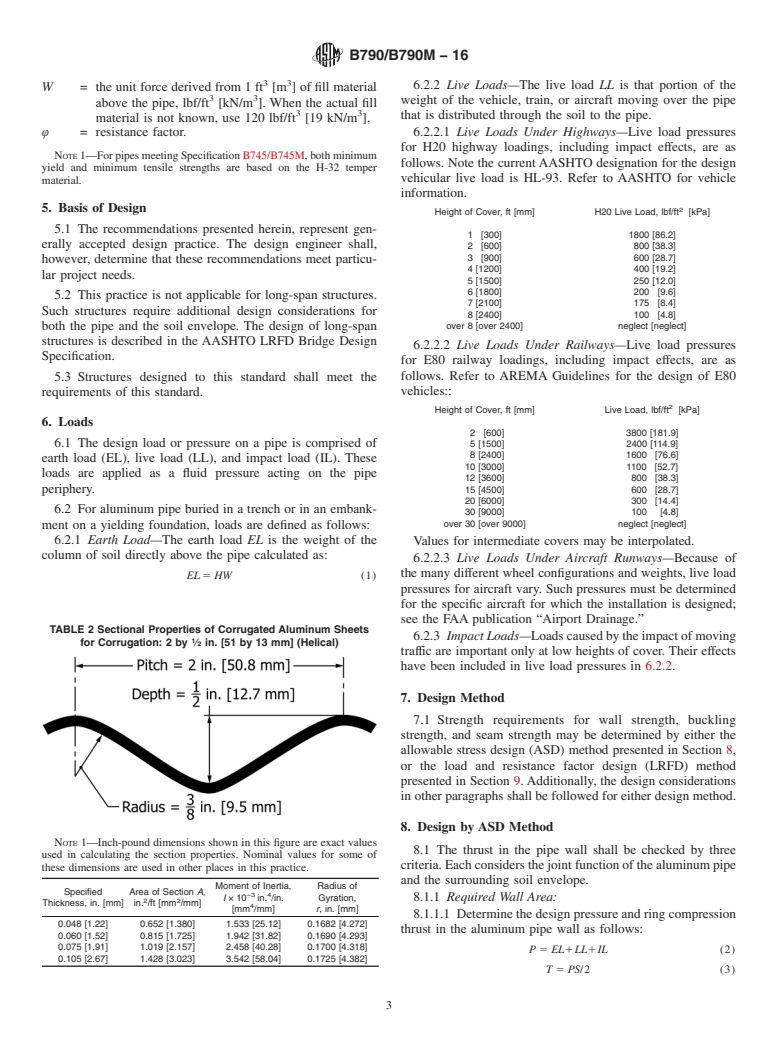

B790/B790M − 16

3

6 2

2.2 FAA Standards:

E = modulus of elasticity, 10 × 10 lbf⁄in.

3

AC No. 150/5320-5DAdvisory Circular, “Airport Drainage

[69×10 MPa],

2

Design” Department of Transportation, Federal Aviation

EL = earth load, lbf/ft [kPa],

2

Administration fc = critical buckling stress, lbf/in. [MPa],

4

FF = flexibility factor, in./lbf [mm/N],

2.3 AASHTO Standards:

Fu = specified minimum tensile strength,

LRFD Bridge Design Specifications

2

= 31000 lbf/in. [215 MPa] for corrugated alumi-

LRFD Bridge Construction Specifications

5

num pipe in accordance with Specification B745/

2.4 Other Standards:

B745M using Alclad Alloy 3004–H34,

American Railway Engineering and Maintenance-Of-Way

2

= 27000 lbf/in. [185 MPa] for corrugated alumi-

Association (AREMA) Guidelines

num pipe in accordance with Specification B745/

3. Termino

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B790/B790M − 11 B790/B790M − 16

Standard Practice for

Structural Design of Corrugated Aluminum Pipe, Pipe-

Arches, and Arches for Culverts, Storm Sewers, and Other

1

Buried Conduits

This standard is issued under the fixed designation B790/B790M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice is intended for the structural design of corrugated aluminum pipe and pipe-arches, and aluminum structural

plate pipe, pipe-arches, and arches for use as culverts and storm sewers and other buried conduits. This practice is for pipe installed

in a trench or embankment and subjected to highway, railroad, and aircraft loadings. It must be recognized that a buried corrugated

aluminum pipe is a composite structure made up of the aluminum ring and the soil envelope, and both elements play a vital part

in the structural design of this type of structure.

1.2 Corrugated aluminum pipe and pipe-arches shall be of annular fabrication using riveted seams, or of helical fabrication

having a continuous lockseam.

1.3 Structural plate pipe, pipe-arches, and arches are fabricated in separate plates that when assembled at the job site by bolting

form the required shape.

1.4 This specification is applicable to design in inch-pound units as Specification B790 or in SI units as Specification B790M.

Inch-pound units and SI units are not necessarily equivalent. SI units are shown in brackets in the text for clarity, but they are the

applicable values when the design is done in accordance with Specification B790M.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B745/B745M Specification for Corrugated Aluminum Pipe for Sewers and Drains

B746/B746M Specification for Corrugated Aluminum Alloy Structural Plate for Field-Bolted Pipe, Pipe-Arches, and Arches

B788/B788M Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

B789/B789M Practice for Installing Corrugated Aluminum Structural Plate Pipe for Culverts and Sewers

B864/B864M Specification for Corrugated Aluminum Box Culverts

3 3

D698 Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft (600 kN-m/m ))

D1556 Test Method for Density and Unit Weight of Soil in Place by Sand-Cone Method

D2167 Test Method for Density and Unit Weight of Soil in Place by the Rubber Balloon Method

D2487 Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)

D2937 Test Method for Density of Soil in Place by the Drive-Cylinder Method

D6938 Test Methods for In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)

3

2.2 FAA Standards:

AC No. 150/5320-5B,150/5320-5D Advisory Circular, “Airport Drainage,” Drainage Design” Department of Transportation,

Federal Aviation Administration, Publication No. SN-050-007-00149-5, 1970Administration

1

This practice is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on Corrugated

Aluminum Pipe and Corrugated Aluminum Structural Plate.

Current edition approved Nov. 1, 2011Nov. 1, 2016. Published December 2011December 2016. Originally approved in 1990. Last previous edition approved in 20062011

as B790B790/B790M – 11.–00 (2006). DOI: 10.1520/B0790_B0790M-11.10.1520/B0790_B0790M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098. http://www.faa.gov/airports/

resources/advisory_circulars/index.cfm/go/document.current/documentNumber/150_5320-5

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

--------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.