ASTM D5579-00

(Test Method)Standard Test Method for Evaluating the Thermal Stability of Manual Transmission Lubricants in a Cyclic Durability Test

Standard Test Method for Evaluating the Thermal Stability of Manual Transmission Lubricants in a Cyclic Durability Test

SCOPE

1.1 This test method covers the thermal stability of fluids for use in heavy duty manual transmissions when operated at high temperatures.

1.2 The lubricant performance is measured by the number of shifting cycles that can be performed without failure of synchronization when the transmission is operated while continuously cycling between high and low range.

1.3 Correlation of test results with truck transmission service has not been established. However, the procedure has been shown to appropriately separate two transmission lubricants, which have shown satisfactory and unsatisfactory field performance in the trucks of one manufacturer.

1.4 Changes in this test method may be necessary due to refinements in the procedure, obsolescence of parts, or reagents, and so forth. These changes will be incorporated by Information Letters issued by the ASTM Test Monitoring Center (TMC). The test method will be revised to show the content of all the letters, as issued.

1.5 The values stated in inch-pound units are to be regarded as standard. When materials, products, or equipment are available only in inch-pound units, SI units are omitted.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This test method is arranged as follows: SectionScope1 Referenced Documents2Terminology3 Summary of Test Method4Significance and Use5Apparatus6Test Transmission6.2Transmission Mounts6.3 Oil Circulating System6.4Oil Return Hole6.5Air Pressure Controls6.6Drive System6.7Instrumentation6.8 Thermocouple Placement6.9Reagents and Materials7Safety8Preparation of Apparatus9Cleaning of Parts9.1Assembly9.2 Calibration10Transmission and Test Stand Calibration10.1Reference Oils10.2 Reference Oil Test Frequency10.3Instrumentation Calibration10.4Shift Time Calibration10.5 Operating Procedure11System Flush and Charge11.1Test Operation11.2Shut Down Procedure11.3Transmission Disassembly 11.4Determination of Test Results12Failure Criteria12.1Shifter Fork Wear12.2Test Validity Determination12.3Report13 Precision and Bias14Keywords15 Test Validity Calculations and LimitsAnnex A1Test Kit PartsAnnex A2Report FormsAnnexA3Data DictionaryAnnex A4Manual Transmission Cyclic Durability Test Parts Inspection and Wear MeasurementsAnnex A5

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5579 – 00 An American National Standard

Standard Test Method for

Evaluating the Thermal Stability of Manual Transmission

Lubricants in a Cyclic Durability Test

This standard is issued under the fixed designation D 5579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Oil Circulating System 6.4

Oil Return Hole 6.5

1.1 This test method covers the thermal stability of fluids for

Air Pressure Controls 6.6

use in heavy duty manual transmissions when operated at high

Drive System 6.7

Instrumentation 6.8

temperatures.

Thermocouple Placement 6.9

1.2 The lubricant performance is measured by the number

Reagents and Materials 7

of shifting cycles that can be performed without failure of Safety 8

Preparation of Apparatus 9

synchronization when the transmission is operated while con-

Cleaning of Parts 9.1

tinuously cycling between high and low range.

Assembly 9.2

1.3 Correlation of test results with truck transmission ser- Calibration 10

Transmission and Test Stand Calibration 10.1

vice has not been established. However, the procedure has been

Reference Oils 10.2

shown to appropriately separate two transmission lubricants,

Reference Oil Test Frequency 10.3

which have shown satisfactory and unsatisfactory field perfor-

Instrumentation Calibration 10.4

Shift Time Calibration 10.5

mance in the trucks of one manufacturer.

Operating Procedure 11

1.4 Changes in this test method may be necessary due to

System Flush and Charge 11.1

refinements in the procedure, obsolescence of parts, or re- Test Operation 11.2

Shut Down Procedure 11.3

agents, and so forth. These changes will be incorporated by

Transmission Disassembly 11.4

Information Letters issued by the ASTM Test Monitoring

Determination of Test Results 12

Center (TMC). The test method will be revised to show the Failure Criteria 12.1

Shifter Fork Wear 12.2

content of all the letters, as issued.

Test Validity Determination 12.3

1.5 The values stated in inch-pound units are to be regarded

Report 13

Precision and Bias 14

as standard. When materials, products, or equipment are

Keywords 15

available only in inch-pound units, SI units are omitted.

Test Validity Calculations and Limits Annex A1

1.6 This standard does not purport to address all of the

Test Kit Parts Annex A2

safety concerns, if any, associated with its use. It is the Report Forms Annex A3

Data Dictionary Annex A4

responsibility of the user of this standard to establish appro-

Manual Transmission Cyclic Durability Test Parts Annex A5

priate safety and health practices and determine the applica-

Inspection and Wear Measurements

bility of regulatory limitations prior to use.

2. Referenced Documents

1.7 This test method is arranged as follows:

2.1 ASTM Standards:

Section

Scope 1

D 235 Specification for Mineral Spirits (Petroleum Spirits)

Referenced Documents 2

(Hydrocarbon Dry Cleaning Solvent)

Terminology 3

2.2 SAE Standard:

Summary of Test Method 4

Significance and Use 5

SAE J308 Axle and Manual Transmission Lubricants

Apparatus 6

2.3 Military Standard:

Test Transmission 6.2

MIL-L-2105 Lubricating Oil, Gear, Multipurpose

Transmission Mounts 6.3

2.4 Other Standard:

This test method is under the jurisdiction of ASTM Committee D02 on

Annual Book of ASTM Standards, Vol 06.04.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

D02.B0.03 on Gear Lubricants.

Warrendale, PA 15096-0001.

Current edition approved June 10, 2000. Published August 2000. Originally

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as D 5579-94. Last previous edition D 5579-98.

Robbins Avenue, Philadelphia, PA 19111-5094, Attn: NPODS.

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 15206-4489.

This edition incorporates revisions in all Information Letters through No. 99-2.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5579

GO-H Mack Trucks Oil,Gear: Multi-Purpose 5.2 This test method may also be utilized in other specifi-

cations and classifications of transmission and gear lubricants

3. Terminology

such as the following:

3.1 Definitions:

5.2.1 (final API designation of PG-1),

3.1.1 wear—the loss of material from two or more surfaces

5.2.2 Military Specification MIL-L-2105,

in relative motion.

5.2.3 SAE Information Report J308 Axle and Manual

3.2 Definitions of Terms Specific to This Standard:

Transmission Lubricants, and

3.2.1 dual-range transmission—a type of transmission in

5.2.4 Mack Truck GO-H Gear Lubricant Specification.

which the driver first shifts through all of the mainbox gear

6. Apparatus

ratios in low range, and then shifts to high range and shifts

through the mainbox again. The section containing the high- 6.1 Table 1 is a list of the make and model of recommended

low range is the compound section. instruments and equipment.

3.2.2 friction disk—a steel circular plate to which a friction 6.2 Test Transmission—The test transmission is a MACK

material has been bonded. T2180, configuration 11KBA51431 (see Fig. 1). Some parts in

3.2.3 glazed—the condition of the friction disks when the transmission are to be removed and some are to be added

precipitates have filled the pores in the friction material, before testing, as listed in Table 2. The main box shift rail cover

polishing the surface, and changing the frictional properties.

can be replaced with an aluminum plate to facilitate transmis-

3.2.4 reaction disk—a steel disk that mates with the friction sion cleaning at end of test.

disk during synchronization.

6.3 Transmission Mounts—The transmission is mounted as

3.2.5 shift time—the period of time required for the coun- shown in Fig. 2.

tershaft speed to increase from 500 to 700 r/min (high-to-low)

6.4 Oil-Circulating System—The system heats the oil to the

or from 1700 to 500 r/min (low-to-high) shift. specified operating temperature of 250 6 5°F (121 6 2.7°C)

3.2.6 synchronizer—a pack of friction and reaction plates

and maintains this temperature throughout the duration of the

used to match the speeds of the low- and high-range gears prior test. The power density of the heater is not high enough to

to engagement.

cause degradation of the oil (22 to 25 W/in. (3.4 to 3.9

3.2.7 unsynchronized shift—a shift in which the speed of the W/cm )). The oil flow rate is between 6 and 10 gal/min (23 to

mating gears is not matched to the speed of the transmission

TABLE 1 Recommended Test Stand Components

output shaft by the synchronizer.

Item Manufacturer Part No.

4. Summary of Test Method

Panel Meters

4.1 Prior to each test run, the transmission is disassembled

Tailshaft rpm Newport P-6031D20D

and all parts, including the case and the oil-circulating and

Countershaft rpm Newport P-6031D20D

heating systems, are thoroughly cleaned. The transmission is Shift time Newport P-6031D20D

Coast down time Newport P-6031D20D

rebuilt with a new synchronizer assembly, including measured

Control Indication

shifter fork, friction, and reaction disks. All other worn or

Temperature controller Omron ESEX-AF

defective parts are replaced.

Temperature indicator Newport INF-0-0-0-0-JF

4.2 The rebuilt transmission is installed on a test stand.

Cycle counter Redington P2-1006-115AC

4.3 The transmission and oil system are flushed with the test

Cycle timer Omron H5BR-B-AC100-240

T/C selector switch Thermo Electric 33112

oil in accordance with the flush procedure.

Oil psi gage/safety Murphy A-20EO, O-30 psi

4.4 The flush oil is drained, and the test oil is measured and

Air supply gage U.S. Gage P44U, O-160 psi

charged to the transmission.

Air regulator Norgren RO-8-300 RNMA

Shift solenoid Asco 8317G35, 3-way

4.5 The transmission is started and operated in low range

solenoid

until the oil temperature reaches the test operating range.

Mag. pickup Electro 3010AN

4.6 The transmission is automatically cycled between low

12 VDC Power supply Sola SLS-12-017

Air pressure switch Penn P61AG-1

and high range until two unsynchronized shifts occur or the

Relays—A.C. Potter & Brumfield KUP14A15

desired length of test is reached without failure. The time

Relays—D.C. Potter & Brumfield KUP14D15

required to shift from high range to low range is recorded each

Mechanical Components

hour.

Air lines Mack 101AX24R, ⁄8 in. OD

4.7 At the conclusion of the test, the test parts are removed

Pump Brown & Sharp No. 2

and visually inspected. The shifter fork and friction plates are

Heater element Chromalox MOT330A, 220v, 1Ph

Oil lines Aeroquip EC-350, No. 12

measured again to determine wear.

U Joint yoke Mack 1710 Series,

38MU3413M

5. Significance and Use

Drive shaft Rockwell 1710 Series, 52 in.

5.1 This test method is used to evaluate automotive manual collapsed

Drive motor General Electric 25-hp Induction Motor,

transmission fluids for thermal instability, which results in

1760 rpm

deterioration of synchronizer performance.

High-Speed Recording System

Pressure transducers Sensotec A-5/1034, 0-100 psi

Available from Mack Trucks, Inc., 13302 Pennsylvania Ave., Hagerstown, MD

Oscillograph Astro-Med Dash 4

21742.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5579

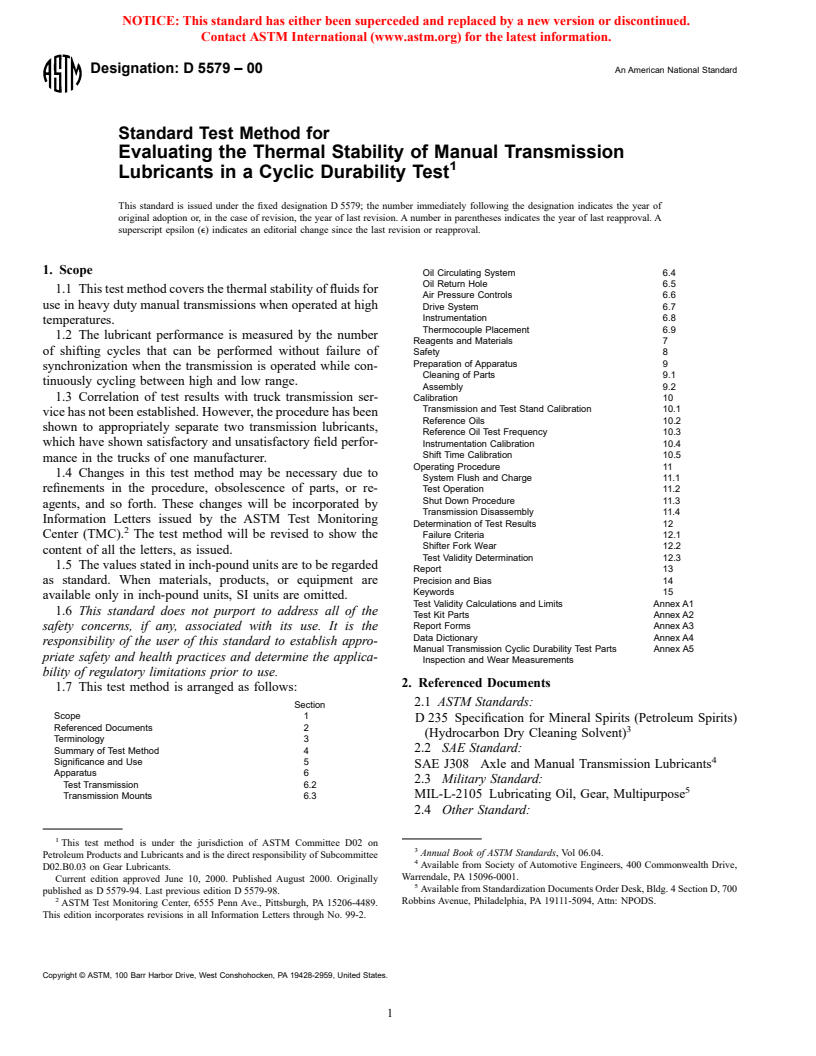

NOTE 1—Left side view.

NOTE 2—See Table 2 for references to letters in brackets.

FIG. 1 Transmission Modified for Testing

TABLE 2 Transmission Parts to Be Added or Removed Before

6.6 Air Pressure Controls—The transmission is shifted by

Testing

air pressure applied to alternating sides of the range shift

piston. The air pressure is provided by a pilot valve, which is

NOTE 1—Letters in brackets, [ ], refer to locations indicated on Fig. 1.

cycled by a solenoid valve at a rate of 5 cpm. These cycles are

Parts to Be Removed

recorded by a counter, which provides the cycles to mis-shift

Rails, forks, springs, and ball from the mainbox shift cover [A]

data for the pass/fail criteria of the test. A typical air control

All main box gesting [B]:

Mainshaft gears and thrust washers

system is shown in Fig. 6.

Countershaft assemblies

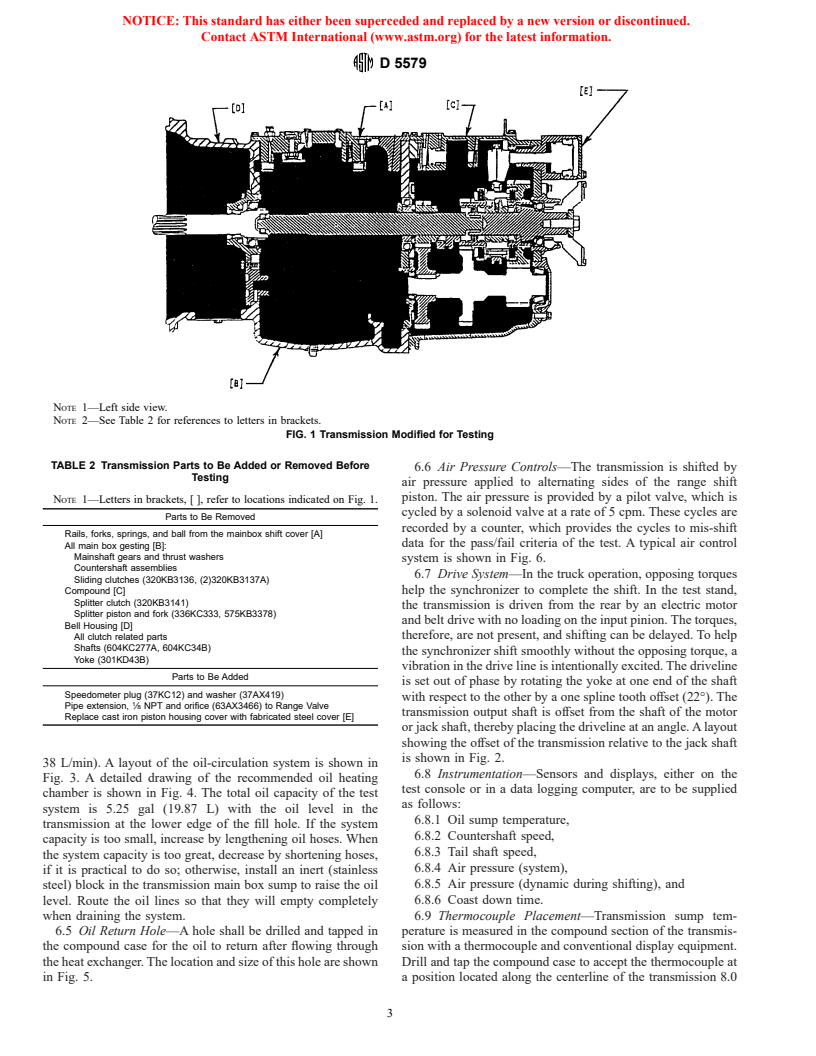

6.7 Drive System—In the truck operation, opposing torques

Sliding clutches (320KB3136, (2)320KB3137A)

Compound [C] help the synchronizer to complete the shift. In the test stand,

Splitter clutch (320KB3141)

the transmission is driven from the rear by an electric motor

Splitter piston and fork (336KC333, 575KB3378)

and belt drive with no loading on the input pinion. The torques,

Bell Housing [D]

All clutch related parts therefore, are not present, and shifting can be delayed. To help

Shafts (604KC277A, 604KC34B)

the synchronizer shift smoothly without the opposing torque, a

Yoke (301KD43B)

vibration in the drive line is intentionally excited. The driveline

Parts to Be Added

is set out of phase by rotating the yoke at one end of the shaft

Speedometer plug (37KC12) and washer (37AX419)

with respect to the other by a one spline tooth offset (22°). The

Pipe extension, ⁄8 NPT and orifice (63AX3466) to Range Valve

transmission output shaft is offset from the shaft of the motor

Replace cast iron piston housing cover with fabricated steel cover [E]

or jack shaft, thereby placing the driveline at an angle. A layout

showing the offset of the transmission relative to the jack shaft

is shown in Fig. 2.

38 L/min). A layout of the oil-circulation system is shown in

6.8 Instrumentation—Sensors and displays, either on the

Fig. 3. A detailed drawing of the recommended oil heating

test console or in a data logging computer, are to be supplied

chamber is shown in Fig. 4. The total oil capacity of the test

as follows:

system is 5.25 gal (19.87 L) with the oil level in the

6.8.1 Oil sump temperature,

transmission at the lower edge of the fill hole. If the system

6.8.2 Countershaft speed,

capacity is too small, increase by lengthening oil hoses. When

6.8.3 Tail shaft speed,

the system capacity is too great, decrease by shortening hoses,

6.8.4 Air pressure (system),

if it is practical to do so; otherwise, install an inert (stainless

6.8.5 Air pressure (dynamic during shifting), and

steel) block in the transmission main box sump to raise the oil

6.8.6 Coast down time.

level. Route the oil lines so that they will empty completely

when draining the system. 6.9 Thermocouple Placement—Transmission sump tem-

6.5 Oil Return Hole—A hole shall be drilled and tapped in perature is measured in the compound section of the transmis-

the compound case for the oil to return after flowing through sion with a thermocouple and conventional display equipment.

the heat exchanger. The location and size of this hole are shown Drill and tap the compound case to accept the thermocouple at

in Fig. 5. a position located along the centerline of the transmission 8.0

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5579

FIG. 2 Typical Layout of Drive System

required. The integrity of the test oil is the responsibility of the

oil supplier.

7.2 Cleaning Materials—A solvent meeting Specification

D 235 (Stoddard solvent), or equivalent, is required for clean-

ing parts.

8. Safety

8.1 The following are suggestions of procedures and equip-

ment that may assist in reducing safety hazards. No attempt has

been made to address all possible safety problems. The user of

this test method is responsible for establishing appropriate

safety and health practices.

8.2 The operating of transmission tests can expose person-

nel and facilities to a number of safety hazards. Only personnel

who are thoroughly trained and experienced in transmission

testing should undertake the design, installation, and operation

of transmission test stands.

8.3 Each laboratory conducting transmission tests should

FIG. 3 Schematic of Oil System have its test installation inspected and approved by its safety

department. Personnel working on the transmissions should be

provided with the proper tools, be alert to common sense safety

in. (203 mm) forward of the back wall of the main case.

practices, and avoid contact with moving or hot transmission

Position the tip of the thermocouple to extend 1.5 in. (38 mm)

parts, o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.