ASTM D6195-03(2011)

(Test Method)Standard Test Methods for Loop Tack

Standard Test Methods for Loop Tack

SIGNIFICANCE AND USE

These test methods provide a quantitative measure of the pressure-sensitive tack property of an adhesive.

These test methods are designed to measure the tack property of the adhesive mass. The tack of a given adhesive varies depending on the backing (generally, stiffer backings lead to higher values).

Theses test methods are suitable for quality control and research purposes.

Test Method A (using Tensile Tester) makes use of a specimen strip 7 in. (175 mm) in length. Both the FINAT FTM 9 “Quick Stick” Tack Measurement Test and the TLMI L-IB2 Tensile Tester Loop Tack Test also use a specimen strip of that length.

Test Method B (using Loop Tack Tester) makes use of a specimen strip five in. (125 mm) in length. That is the only length specimen strip that fits properly in the loop tack tester.

If the adhesive is not already otherwise coated, these test methods incorporate the use of a clear 2 mil (0.05 mm) polyester (PET) film backing for specimen preparation. Use of other backing materials changes performance of the specimen to be tested.

SCOPE

1.1 These test methods cover the determination of properties of a pressure-sensitive adhesive. These test methods are applicable to those adhesives that form a bond of measurable strength rapidly upon contact with another surface. Tack force may be measured as the force required to separate the adhesive from the adherend at the interface shortly after they have been brought into contact under a load equal only to the weight of the pressure-sensitive article (for example, tape, label, sticker, etc.) on a 1 in.2 contact area.

1.2 The following test methods are included:

1.2.1 Test Method A (using Tensile Tester), and

1.2.2 Test Method B (using Loop Tack Tester).

1.3 The values stated in inch-pound units are to be regarded as the standard because the industry standard width for pressure-sensitive tape is 1 inch. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6195 − 03 (Reapproved 2011)

Standard Test Methods for

Loop Tack

This standard is issued under the fixed designation D6195; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 These test methods cover the determination of proper-

E691 Practice for Conducting an Interlaboratory Study to

ties of a pressure-sensitive adhesive. These test methods are

Determine the Precision of a Test Method

applicable to those adhesives that form a bond of measurable

strength rapidly upon contact with another surface. Tack force 2.2 European Association for the Pre-Adhesed Labeling

may be measured as the force required to separate the adhesive Industry (FINAT) Standard:

from the adherend at the interface shortly after they have been FTM 9 “Quick-Stick” Tack Measurement

brought into contact under a load equal only to the weight of

2.3 Tag and Label Manufacturers Institute, Inc. (TLMI)

the pressure-sensitive article (for example, tape, label, sticker,

Standard:

etc.) ona1in. contact area.

L-IB1 TLMI Loop Tack Test

L-IB2 Tensile Tester Loop Tack Test

1.2 The following test methods are included:

1.2.1 Test Method A (using Tensile Tester), and

3. Terminology

1.2.2 Test Method B (using Loop Tack Tester).

1.3 The values stated in inch-pound units are to be regarded 3.1 Definitions:

3.1.1 Many of the terms found in these test methods are

as the standard because the industry standard width for

pressure-sensitive tape is 1 inch. The values given in paren- defined in Terminology D907.

theses are mathematical conversions to SI units that are

provided for information only and are not considered standard. 4. Summary of Test Method

1.4 This standard does not purport to address all of the 4.1 These test methods involve allowing a loop of pressure-

safety concerns, if any, associated with its use. It is the

sensitive adhesive with its backing to be brought into con-

responsibility of the user of this standard to establish appro- trolled contact witha1in. (25 by 25 mm) surface of stainless

priate safety and health practices and determine the applica-

steel, with the only force applied being the weight of the

bility of regulatory limitations prior to use.

pressure-sensitivearticleitself.Thepressure-sensitivearticleis

then removed from the substrate, with the force to remove the

2. Referenced Documents

pressure-sensitive article from the adherend measured by a

2.1 ASTM Standards:

recording instrument.

A666 Specification forAnnealed or Cold-WorkedAustenitic

4.2 Test Method A (using a Tensile Tester) applies when a

Stainless Steel Sheet, Strip, Plate, and Flat Bar

TensileTesterisusedtomeasurelooptackandinvolvestheuse

D907 Terminology of Adhesives

of a loop prepared from an 7 in. (175 mm) specimen strip.

D2651 GuideforPreparationofMetalSurfacesforAdhesive

4.3 Test Method B (using a Loop Tack Tester) applies when

Bonding

a Loop Tack Tester is used to measure loop tack and involves

E4 Practices for Force Verification of Testing Machines

the use of a loop prepared from a 5 in. (125 mm) specimen

E171 Practice for Conditioning and Testing Flexible Barrier

strip.

Packaging

1 5. Significance and Use

These test methods are under the jurisdiction of ASTM Committee D10 on

Packaging and are the direct responsibility of Subcommittee D10.14 on Tape and

5.1 These test methods provide a quantitative measure of

Labels.

the pressure-sensitive tack property of an adhesive.

Current edition approved April 1, 2011. Published April 2011. Originally

ε1

approved in 1997. Last previous edition approved in 2003 as D6195 – 03 . DOI:

10.1520/D6195-03R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from FINAT, Laan CopesVan Cattenburch 79, 2585 EW,The Hague,

Standards volume information, refer to the standard’s Document Summary page on Holland.

the ASTM website. Available from TLMI, 40 Shuman Blvd., Ste. 295, Naperville, IL 60563.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6195 − 03 (2011)

TEST METHOD A (Using a Tensile Tester)

6. Apparatus

6.1 Tensile Tester—A constant rate of extension type.

6.2 Test Fixture (Fig. 1 or Fig. 2 )—To be mounted into the

jaws of the tensile tester.Apanel held by the test fixture allows

fora1in. (25by25mm)contactareaofthepressure-sensitive

article. Alternately, the test fixture may include a raised area

that allowsa1in. (25 by 25 mm) contact area of the

pressure-sensitive article.

6.2.1 The panel or the raised area of the test fixture is

FIG. 1 Loop Tack Test Fixture 1

stainless steel as specified in Specification A666.

6.3 Apparatus for Cutting:

6.3.1 Die Cutter—A 1 by 7 in. (25 by 175 mm) rectangular

mallet-type die cutter with mallet for sample preparation.

6.3.2 If a fixed dimension die is unavailable, substitute a

1-in. (25-mm) steel bar with a double razor knife or other

apparatus suitable for cutting the specimen into the specified

dimensions to prepare the 1 in. (25 mm) wide specimen strips.

FIG. 2 Loop Tack Test Fixture 2

6.4 Absorbent Lint-Free Cleaning Material—Materials pro-

duced from entirely virgin raw materials and containing less

than 0.25 % by weight of solvent-leechable materials.

6.5 Masking Tape—1 in. (25 mm) wide.

6.6 2 mil (0.05 mm) PET Film—To be used as a support

medium in evaluating unsupported adhesives such as transfer

tapes, laminating adhesives, or other free-film adhesives.

6.7 Reagents—Appropriate reagents include acetone, diac-

etone alcohol, n-heptane and toluene, reagent or analytical

grade, or an ethanol cleaner for water-based adhesives.

7. Sample Preparation

7.1 Cut sample into 1 by 7 in. (25 by 175 mm) specimen

strips in the machine direction (when known) of the pressure-

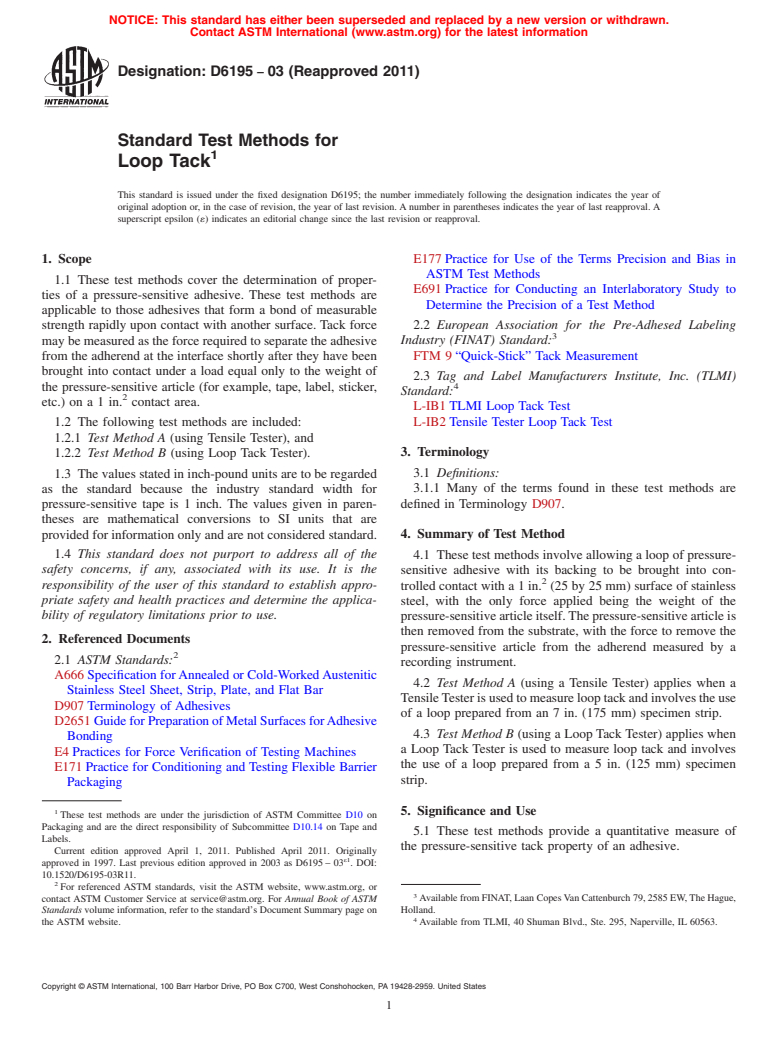

FIG. 3 Loop Tack Sample During Test

sensitive article. Use of strips of other lengths may change

results. Cut at least three specimen strips for each adhesive to

be tested.

NOTE 1—If transfer or unsupported adhesives are to be tested, these are

5.2 These test methods are designed to measure the tack

to be laminated to 2 mil (0.05 mm) PETfilm, used as an adhesive support,

property of the adhesive mass. The tack of a given adhesive

prior to cutting the samples into the 1 by 7 in. (25 by 175 mm) specimen

varies depending on the backing (generally, stiffer backings

strips.

lead to higher values).

7.2 Condition specimens to be tested for at least 24 h in a

5.3 Theses test methods are suitable for quality control and

testing room at 73.4 6 3.6°F (23 6 2°C) and a relative

research purposes.

humidity of 50 6 5 %, in accordance with Specification E171,

5.4 Test Method A (using Tensile Tester) makes use of a prior to conducting the test.

specimen strip 7 in. (175 mm) in length. Both the FINAT FTM

8. Conditioning

9 “Quick Stick” Tack Measurement Test and the TLMI L-IB2

8.1 Testing Room—Test in a standard laboratory

Tensile Tester Loop Tack Test also use a specimen strip of that

atmosphere, at 73.4 6 3.6°F (23 6 2°C) and a relative

length.

humidity of 50 6 5 %, in accordance with Specification E171.

5.5 Test Method B (using Loop Tack Tester) makes use of a

specimen strip five in. (125 mm) in length. That is the only

9. Procedure

length specimen strip that fits properly in the loop tack tester.

9.1 Ensure that the tensile tester is calibrated according to

5.6 Iftheadhesiveisnotalreadyotherwisecoated,thesetest

instructions supplied by the manufacturer and conforming to

methods incorporate the use of a clear 2 mil (0.05 mm)

the requirements of Practices E4.

polyester (PET) film backing for specimen preparation. Use of

other backing materials changes performance of the specimen

Available from Chem Instruments, 510 Commercial Drive, Fairfield, OH

to be tested. 45014-7593.

D6195 − 03 (2011)

9.2 Set the instrument crosshead speed at 12 in. (300 move upward. When the crosshead is at its minimum position,

mm)/min. thespecimenloopwillcompletelycoverthe1in.(25mm)area

of the stainless steel portion of the test fixture without

9.3 Place the test fixture in the lower grip of the tensile

excessive “hang-over” of the edges.

tester. It is important that the test fixture be level and straight

in the lower grip. See Fig. 1, Fig. 2 and Fig. 3.

NOTE 2—If the tensile tester does not have automatic cycling, cycling

must be done manually.

9.4 Set gaps for the crosshead using the minimum and

9.11 Record the maximum force required to remove the

maximumgapsettingontheextensioncycle.Setgaps1 60.05

specimenloopfromthestainlesssteelportionofthetestfixture

in. (25 6 1 mm) (critical) and 4 6 0.1 in. (100 6 3 mm)

as well as the mode of failure.

(optional) from the bottom of the upper grips to the face of the

9.11.1 Record the failure mode as adhesion, cohesion or

stainless steel portion of the test fixture when the test fixture is

transfer.

locked in the lower grips. Set the chart recorder speed for 2 in.

(50 mm)/min. Set the chart recorder load scale to 20 lb (90 N)

9.12 Repeat procedure (9.5 to 9.11.1) at least two additional

full scale.

times for each adhesive to be tested (for a minimum of three

replicates). Use a fresh specimen strip for each test.

9.5 Clean the stainless steel portion of the test fixture (the

area the pressure-sensitive article will contact) prior to use

9.13 When testing is complete, clean the stainless steel

using reagent(s) from 6.7. Use absorbent, lint-free cleaning

portion of the test fixture with approved reagent. Cover with

material. Use a separate piece of cleaning material each time.

masking tape when not in use to protect the surface from

Repeat for a total of three washes after the test fixture appears

scratches.

clean.Allow 2 min to elapse after cleaning to ensure complete

TEST METHOD B (Using a Loop Tack Tester)

evaporation of the cleaning solvent. The user must ensure that

the cleaning method used removes all residue from the test

10. Apparatus

fixture. The water-break test, described in Guide D2651, may

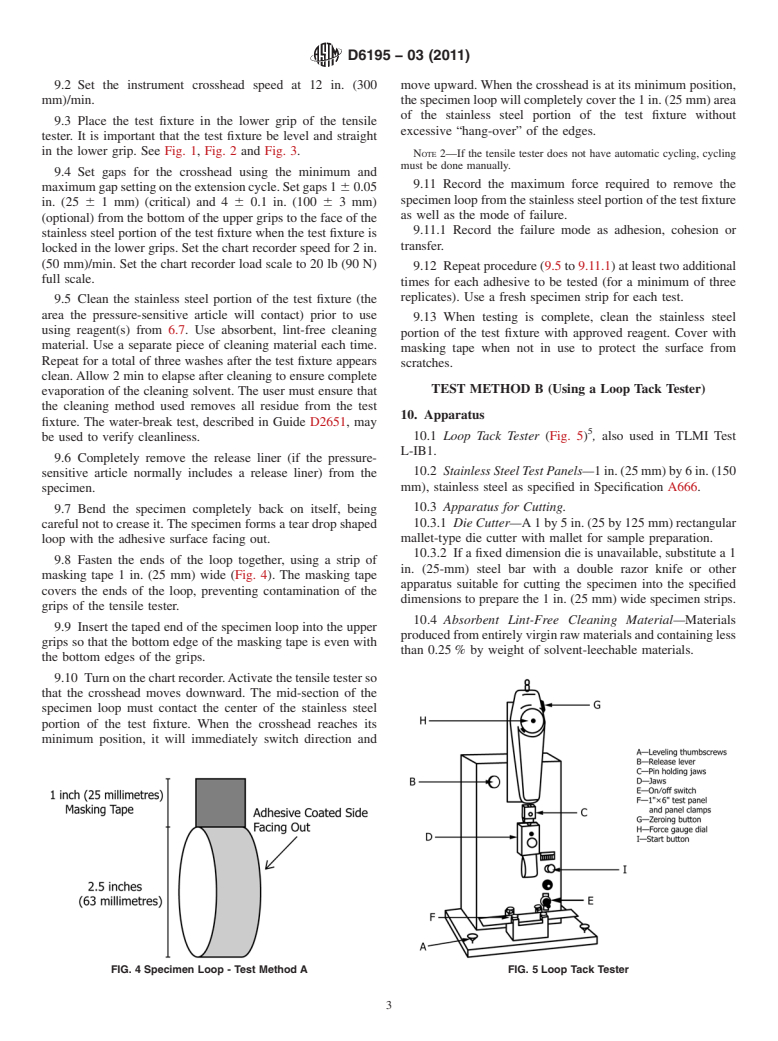

10.1 Loop Tack Tester (Fig. 5) , also used in TLMI Test

be used to verify cleanliness.

L-IB1.

9.6 Completely remove the release liner (if the pressure-

10.2 Stainless Steel Test Panels—1in.(25mm)by6in.(150

sensitive

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.