ASTM E130-87(2003)

(Practice)Standard Practice for Designation of Shapes and Sizes of Graphite Electrodes

Standard Practice for Designation of Shapes and Sizes of Graphite Electrodes

SIGNIFICANCE AND USE

This practice is intended as a reference for spectrochemical methods that utilize graphite electrodes. Methods should employ and reference one of the electrode shapes in this practice, but if this is not possible, the method should include electrode specifications for the specific shape used.

This practice should be referred to in a method by including a statement such as the following in the section on Reagents and Materials:

Graphite Electrodes—The electrode(s) shall be of high-purity graphite and conform to type(s) (insert designation from this method) as depicted in Practice E 130.

SCOPE

1.1 This practice describes a number of specific graphite electrode shapes and sizes that are useful in spectrochemical analysis.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E130–87(Reapproved2003)

Standard Practice for

Designation of Shapes and Sizes of Graphite Electrodes

This standard is issued under the fixed designation E 130; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

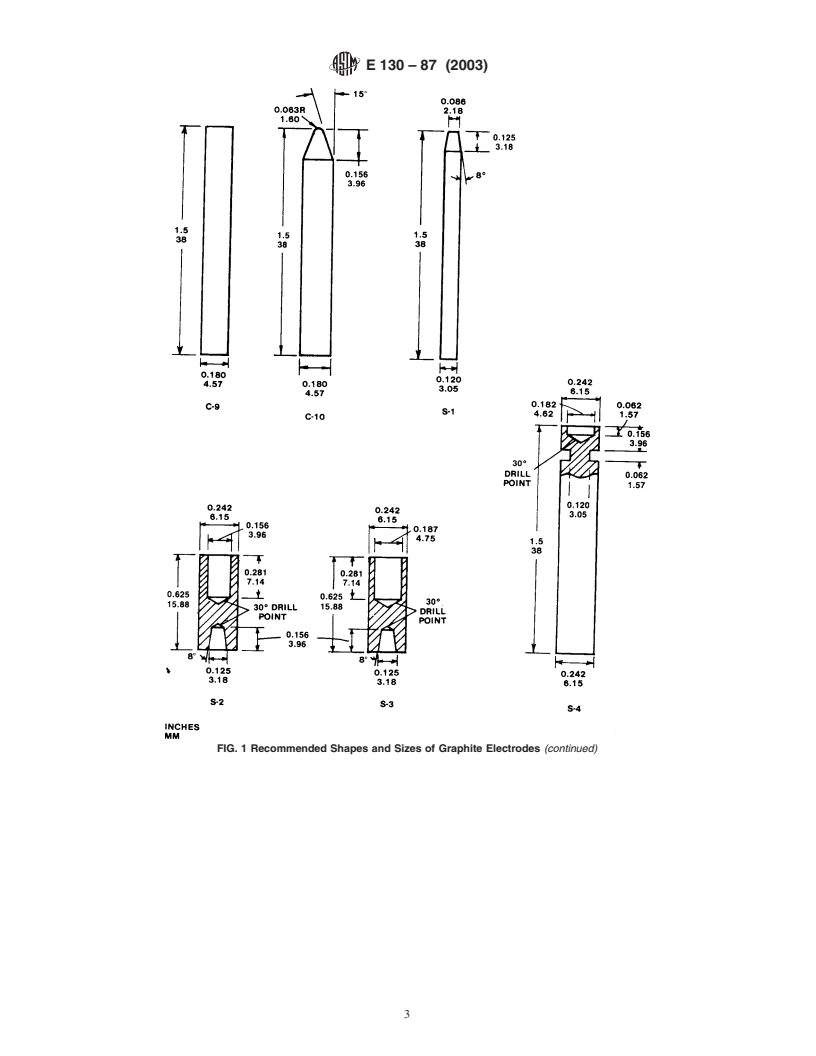

1. Scope 5.1.2 Class S—Specimen Electrodes, for use with liquid or

particulate specimens. Thin-wall cups allow faster burn off of

1.1 This practice covers a number of specific graphite

graphite and faster consumption of the specimen. Undercut

electrode shapes and sizes that are useful in spectrochemical

cups provide greater heating of the specimen.

analysis.

5.1.3 Class P—Specimen Electrodes, for use with noncon-

1.2 The values stated in inch-pound units are to be regarded

ducting specimens or with specimens that require a center post

as the standard. The values given in parentheses are for

that tends to stabilize the excitation.

information only.

5.1.4 ClassPC—PorousCupElectrodes, for use with liquid

2. Terminology

specimens only.

5.1.5 Class D—Specimen Electrodes, of disk shape for use

2.1 preform—a descriptive word applied to a commercially

with liquid specimens.

produced spectroscopic electrode which is purified after ma-

5.1.6 Class VC and VCE—Vacuum Cups and Specimen

chining.

Electrodes, consisting of a tubular graphite electrode over

3. Summary of Practice

which is positioned a tetrafluorethylene (TFE) cup which holds

a liquid specimen.

3.1 The practice classifies electrodes by application and

5.1.7 Class DCP—Electrodes, for use as anodes on direct-

provides dimensional specifications.

current plasma spectrometers.

4. Significance and Use

6. Dimensions

4.1 This practice is intended as a reference for spectro-

6.1 The dimensions of the electrodes of the various classes

chemical methods that utilize graphite electrodes. Methods

are given in Fig. 1. Unless exceptions are indicated, the

should employ and reference one of the electrode shapes in this

following tolerances apply:

practice, but if this is not possible, the method should include

6mm 6in.

electrode specifications for the specific shape used.

4.2 This practice should be referred to in a method by

Outside diameter 0.05 0.002

including a statement such as the following in the section on

Length 0.41 0.016

Cavity, inside diameter 0.08 0.003

Reagents and Materials:

Cavity, depth 0.08 0.003

Graphite Electrodes—The electrode(s) shall be of high-

Neck, outside diameter 0.13 0.005

purity graphite and conform to type(s) (insert designation from

Neck, location 0.13 0.005

Neck, length 0.13 0.005

this method) as depicted in Practice E 130.

Concentricity, total indicator reading:

Holes under 12.7 mm (0.5 in.) deep and 0.13 0.005

5. Classes

undercuts

Holes over 12.7 mm (0.5 in.) deep 0.25 0.010

5.1 Seven classes of graphite electrodes are designated as

Rotating disks, inside diameter 0.03 0.001

follows:

Rotating disks, thickness 0.13 0.005

5.1.1 Class C—Counter Electrodes, for use opposite the

Boiler caps, inside diameter 0.02 0.001

Porous cups, bottom thickness:

specimen or opposite the electrode that contains the specimen.

Under 25.4 mm (1 in.) long +0.05 +0.002

−0.00 −0.000

Over 25.4 mm (1 in.) long +0.08 +0.003

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

−0.00 −0.000

Chemistry for Metals, Ores

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.