ASTM F3510-21

(Guide)Standard Guide for Characterizing Fiber-Based Constructs for Tissue-Engineered Medical Products

Standard Guide for Characterizing Fiber-Based Constructs for Tissue-Engineered Medical Products

SIGNIFICANCE AND USE

5.1 The test methods contained herein guide characterization of the structural, physical, chemical, mechanical, and biological properties of a fiber-based construct. Such properties may be important for the success of a TEMP, especially if they affect cell retention; activity and organization; tensile strength; the delivery of bioactive agents; or the biocompatibility and bioactivity of the construct.

5.2 Tests described herein may be used for quality control during manufacturing or to assess how the product may perform its intended clinical function.

5.3 Plans for product development, product characterization, and the regulatory pathway should be discussed with the appropriate regulatory body.

SCOPE

1.1 This guide is a resource for the characterization of fiber-based constructs intended for use in a tissue-engineered medical product (TEMP). There are existing standards that broadly cover scaffolds in a more generalized fashion (Guides F2150, F2450, F2900, F2902, ISO 21560). This guide focuses specifically on fiber-based constructs.

1.2 Fiber-based constructs may be fabricated by many different methods including, but not limited to the following: electrospinning, forcespinning, meltspinning, pneumatospinning, blowspinning, melt-electrowriting, melt extrusion, wet extrusion, fused deposition, liquid crystal deposition, electrochemical alignment, drawing, spinning, knitting, weaving, braiding, powder bed fusion (laser sintering), vat photopolymerization (stereolithography), binder jetting, directed energy deposition, self-assembly (for example, fibrillogenesis), and hybrid approaches. This document is intended to address fibers made by any of these methods, although electrospun fibers are addressed in greater detail in some sections.

1.3 This guide will focus on constructs made of fibers wherein the average fiber diameter is within the range of approximately 100 nm to 100 µm.

1.4 For the purposes of this standard, a “fiber-based construct” is defined as a construct composed of slender, elongated filaments.

1.5 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3510 − 21

Standard Guide for

Characterizing Fiber-Based Constructs for Tissue-

1

Engineered Medical Products

This standard is issued under the fixed designation F3510; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This guide is a resource for the characterization of

ization established in the Decision on Principles for the

fiber-based constructs intended for use in a tissue-engineered

Development of International Standards, Guides and Recom-

medical product (TEMP). There are existing standards that

mendations issued by the World Trade Organization Technical

broadly cover scaffolds in a more generalized fashion (Guides

Barriers to Trade (TBT) Committee.

F2150, F2450, F2900, F2902, ISO 21560). This guide focuses

specifically on fiber-based constructs.

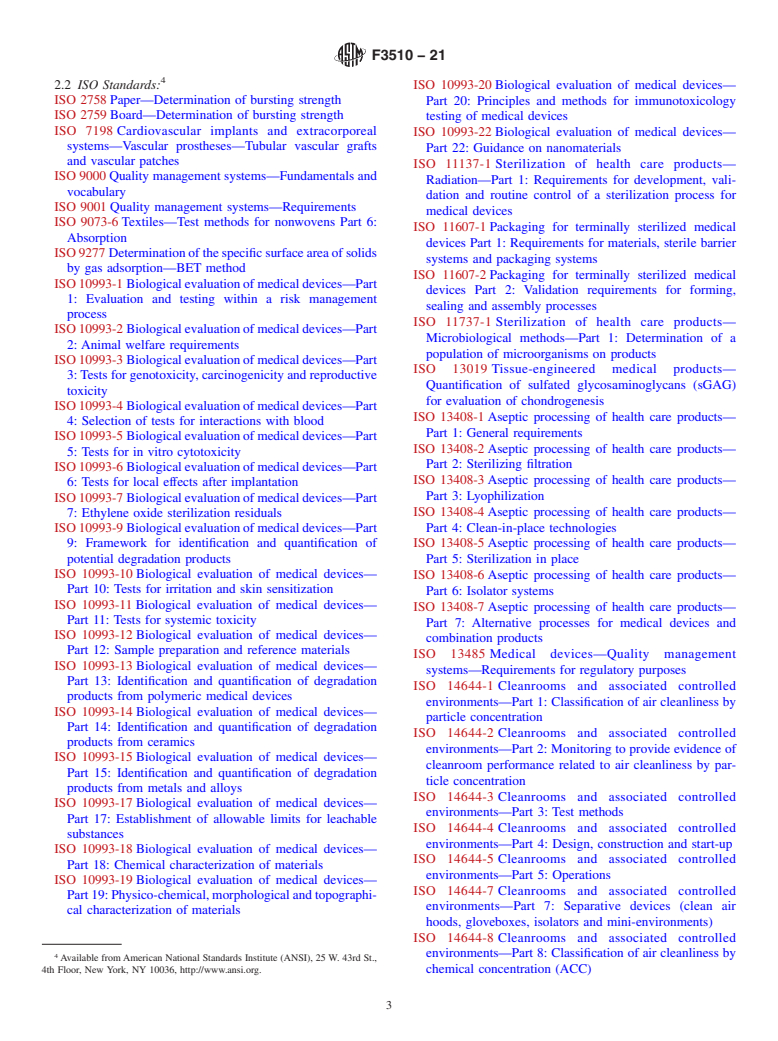

2. Referenced Documents

1.2 Fiber-based constructs may be fabricated by many

2

2.1 ASTM Standards:

different methods including, but not limited to the following:

C1559 Test Method for Determining Wicking of Fibrous

electrospinning, forcespinning, meltspinning,

Glass Blanket Insulation (Aircraft Type)

pneumatospinning, blowspinning, melt-electrowriting, melt

D257 Test Methods for DC Resistance or Conductance of

extrusion, wet extrusion, fused deposition, liquid crystal

Insulating Materials

deposition, electrochemical alignment, drawing, spinning,

D412 Test Methods forVulcanized Rubber andThermoplas-

knitting, weaving, braiding, powder bed fusion (laser

tic Elastomers—Tension

sintering), vat photopolymerization (stereolithography), binder

D638 Test Method for Tensile Properties of Plastics

jetting,directedenergydeposition,self-assembly(forexample,

D648 Test Method for Deflection Temperature of Plastics

fibrillogenesis), and hybrid approaches. This document is

Under Flexural Load in the Edgewise Position

intended to address fibers made by any of these methods,

D695 Test Method for Compressive Properties of Rigid

although electrospun fibers are addressed in greater detail in

Plastics

some sections.

D790 Test Methods for Flexural Properties of Unreinforced

1.3 This guide will focus on constructs made of fibers

and Reinforced Plastics and Electrical Insulating Materi-

wherein the average fiber diameter is within the range of

als

approximately 100 nm to 100 µm.

D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.4 For the purposes of this standard, a “fiber-based con-

D854 Test Methods for Specific Gravity of Soil Solids by

struct”isdefinedasaconstructcomposedofslender,elongated

Water Pycnometer

filaments.

D882 Test Method for Tensile Properties of Thin Plastic

1.5 Units—The values stated in SI units are to be regarded

Sheeting

as the standard. No other units of measurement are included in

D1388 Test Method for Stiffness of Fabrics

this standard.

D1621 Test Method for Compressive Properties of Rigid

1.6 This standard does not purport to address all of the Cellular Plastics

D1623 Test Method for Tensile and Tensile Adhesion Prop-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- erties of Rigid Cellular Plastics

D1708 Test Method forTensile Properties of Plastics by Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. of Microtensile Specimens

D1777 Test Method for Thickness of Textile Materials

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

2

Surgical Materials and Devices and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F04.42 on Biomaterials and Biomolecules for TEMPs. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2021. Published April 2021. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3510-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3510 − 21

D1876 Test Method for Peel Resistance of Adhesives (T- F2027 Guide for Characterization and Testing of Raw or

Peel Test) Starting Materials for Tissue-Engineered Medical Prod-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.