ASTM D4349-96(2004)

(Classification)Classification System for Polyphenylene Ether (PPE) Materials

Classification System for Polyphenylene Ether (PPE) Materials

SCOPE

1.1 This classification system covers the basic polymers and copolymers known as polyphenylene ethers and polyphenylene oxides, as well as filled, modified, and reinforced versions. Note 1Addition to the natural polymer or copolymer of pigments, colorants or additives may result in the final composition not meeting the requirements specified for the natural polymer or copolymer. Discussions with the supplier should take place before specifications of altered compositions are established.Note 2

The preferred abbreviation for polyphenylene ether is PPE, as noted in Terminology D 1600.

1.2 This classification system is not intended for the selection of materials, but only as a means to call out plastic materials to be used for the manufacture of parts. The selection of these materials is to be made by personnel with expertise in the plastics field where the environment, inherent properties of the materials, performance of the parts, part design, manufacturing process, and economics are considered.

1.3 There may be other requirements necessary to identify particular characteristics important to specific applications. These may be specified by using the suffixes described in Section .

1.4 The values stated in SI units are to be regarded as the standard. Note 3No ISO standard exists that covers these materials.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4349 – 96 (Reapproved 2004)

Classification System for

Polyphenylene Ether (PPE) Materials

This standard is issued under the fixed designation D4349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

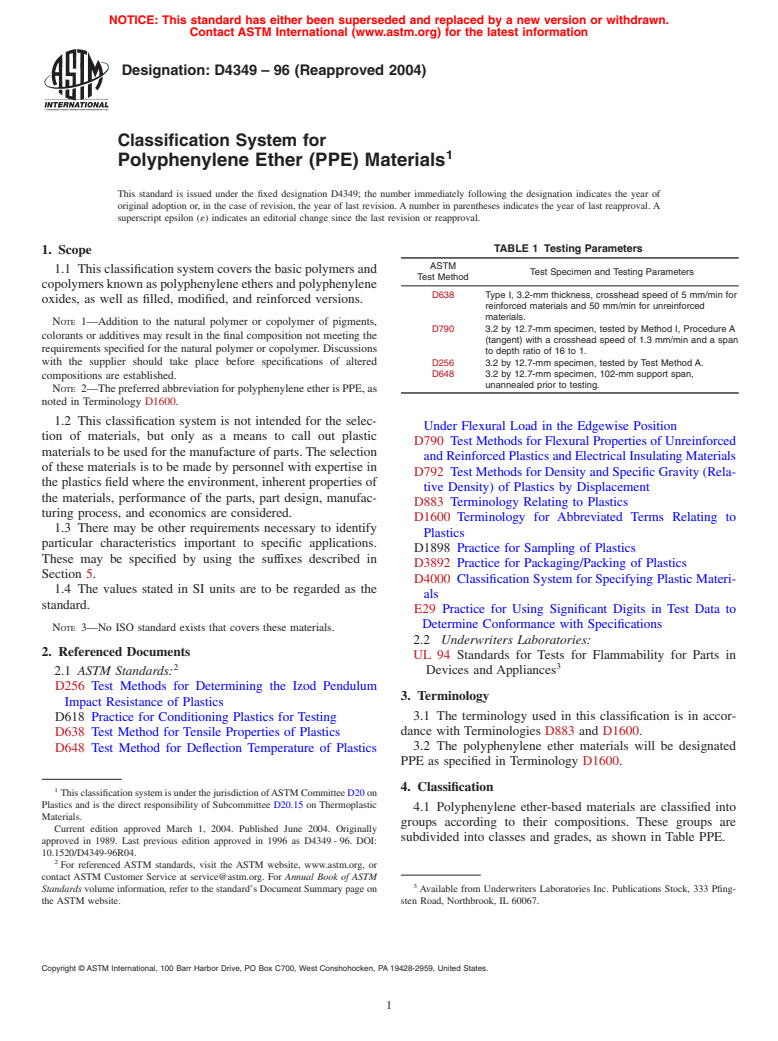

TABLE 1 Testing Parameters

1. Scope

ASTM

1.1 Thisclassificationsystemcoversthebasicpolymersand

Test Specimen and Testing Parameters

Test Method

copolymersknownaspolyphenyleneethersandpolyphenylene

D638 Type I, 3.2-mm thickness, crosshead speed of 5 mm/min for

oxides, as well as filled, modified, and reinforced versions.

reinforced materials and 50 mm/min for unreinforced

materials.

NOTE 1—Addition to the natural polymer or copolymer of pigments,

D790 3.2 by 12.7-mm specimen, tested by Method I, Procedure A

colorants or additives may result in the final composition not meeting the

(tangent) with a crosshead speed of 1.3 mm/min and a span

requirements specified for the natural polymer or copolymer. Discussions

to depth ratio of 16 to 1.

with the supplier should take place before specifications of altered D256 3.2 by 12.7-mm specimen, tested by Test Method A.

D648 3.2 by 12.7-mm specimen, 102-mm support span,

compositions are established.

unannealed prior to testing.

NOTE 2—ThepreferredabbreviationforpolyphenyleneetherisPPE,as

noted in Terminology D1600.

1.2 This classification system is not intended for the selec-

Under Flexural Load in the Edgewise Position

tion of materials, but only as a means to call out plastic

D790 Test Methods for Flexural Properties of Unreinforced

materialstobeusedforthemanufactureofparts.Theselection

andReinforcedPlasticsandElectricalInsulatingMaterials

of these materials is to be made by personnel with expertise in

D792 Test Methods for Density and Specific Gravity (Rela-

the plastics field where the environment, inherent properties of

tive Density) of Plastics by Displacement

the materials, performance of the parts, part design, manufac-

D883 Terminology Relating to Plastics

turing process, and economics are considered.

D1600 Terminology for Abbreviated Terms Relating to

1.3 There may be other requirements necessary to identify

Plastics

particular characteristics important to specific applications.

D1898 Practice for Sampling of Plastics

These may be specified by using the suffixes described in

D3892 Practice for Packaging/Packing of Plastics

Section 5.

D4000 Classification System for Specifying Plastic Materi-

1.4 The values stated in SI units are to be regarded as the

als

standard.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

NOTE 3—No ISO standard exists that covers these materials.

2.2 Underwriters Laboratories:

2. Referenced Documents

UL 94 Standards for Tests for Flammability for Parts in

2.1 ASTM Standards: Devices and Appliances

D256 Test Methods for Determining the Izod Pendulum

3. Terminology

Impact Resistance of Plastics

3.1 The terminology used in this classification is in accor-

D618 Practice for Conditioning Plastics for Testing

dance with Terminologies D883 and D1600.

D638 Test Method for Tensile Properties of Plastics

3.2 The polyphenylene ether materials will be designated

D648 Test Method for Deflection Temperature of Plastics

PPE as specified in Terminology D1600.

1 4. Classification

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

4.1 Polyphenylene ether-based materials are classified into

Materials.

groups according to their compositions. These groups are

Current edition approved March 1, 2004. Published June 2004. Originally

subdivided into classes and grades, as shown in Table PPE.

approved in 1989. Last previous edition approved in 1996 as D4349-96. DOI:

10.1520/D4349-96R04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories Inc. Publications Stock, 333 Pfing-

the ASTM website. sten Road, Northbrook, IL 60067.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4349 – 96 (2004)

TABLE PPE Requirements for Polyphenylene Ether (PPE) Materials

A

NOTE 1—Values given are for natural materials only. Other colors may be different.

Tensile Flexural Izod

Heat Deflection, min

Specific

Strength, Modulus, Impact,

Grade Gravity,

at 1.82 at 0.45 B,C B,C B,D

Group Description Class Description D638, D790, D256,

Description ASTM

MPa, MPa,

MPa, MPa, J/m,

B B

D792,min

D648, °C D648, °C

min min min

E

1 Unmodified 1 general purpose 0 other

F E

2 flame retardant 0 other

E

0 other 0 other

G

2 PS modified materials 1 general purpose 1 90 N/A 1.03 32 1750 265

G

2 100 N/A 1.03 38 1900 240

G

3 100 N/A 1.03 44 2150 185

G

4 110 N/A 1.04 55 2300 160

G

5 130 N/A 1.05 57 2300 160

0 other . . . . . .

F G

2 flame retardant 167 N/A 1.06 36 2200 190

G

280 N/A 1.07 40 2250 130

G

385 N/A 1.07 48 2350 100

G

4 105 N/A 1.07 55 2350 160

G

5 125 N/A 1.08 60 2500 160

0 other . . . . . .

0 other 0 other . . . . . .

G

3 PA modified materials 1 general purpose 1 N/A 145 1.05 50 2000 170

G

2N/A 155 1.05 50 2000 160

G

3N/A 170 1.05 50 1800 530

G

4N/A 180 1.05 55 2000 185

G

5N/A 195 1.05 58 2200 160

0 other . . . . . .

F E

2 flame retardant 0 other

0 other 0 other . . . . . .

4 Other 1 general purpose 0 other . . . . .

F

2 flame retardant 0 other . . . . .

0 other 0 other . . . . .

5 Rework modified 1 general purpose 0 other . . . . .

F

2 flame retardant 0 other . . . . .

0 other 0 other . . . . .

A

Use Tables A and B where necessary for colored materials.

B

See Table 1 for test parameters and conditions.

C

MPa 3 145 = psi.

D

J/m 3 0.01873 = ft·lbf/in.

E

Unfilled materials currently not available. Use Table A.

F

Flammability ratings determined in accordance with UL 94.

G

N/A—Not applicable for grade description.

TABLE A Reinforced Polyphenylene Ether Materials, Details Requirements

Designation Property Cell Limits

Order Number

0 1 23 45 6 7 8 9

A

1 Heat deflection temperature, unspecified 100 110 120 130 140 150 160 170 specify value

B

D648, 1.82 MPa, °C, min

A

2 Heat deflection temperature, unspecified 180 190 200 210 220 230 240 250 specify value

B

D648, 0.45 MPa, °C, min

3 Tensile strength, unspecified 45 55 65 80 100 120 140 160 specify value

B C

D638, MPa, min

4 Flexural modulus, unspecified 2000 3000 4000 5000 6000 7500 9000 10 500 specify value

B C

D790, MPa, min

B

5 Izod impact, D256, unspecified 25 50 75 100 125 150 200 250 specify value

D

J/m, min

A

ForspecifyingHDTusethe“ordernumber”correspondingtotheappropriatetestconditionsforthematerialbeingdefined.Itisintendedthatoneortheotherofthese

requirements be used unless specific agreement between the supplier and the user requires both.

B

SeeTable 1 for test specimen sizes.

C

MPa 3 145 = psi.

D

J/m 3 0.01873 = f·lbf/in.

D4349 – 96 (2004)

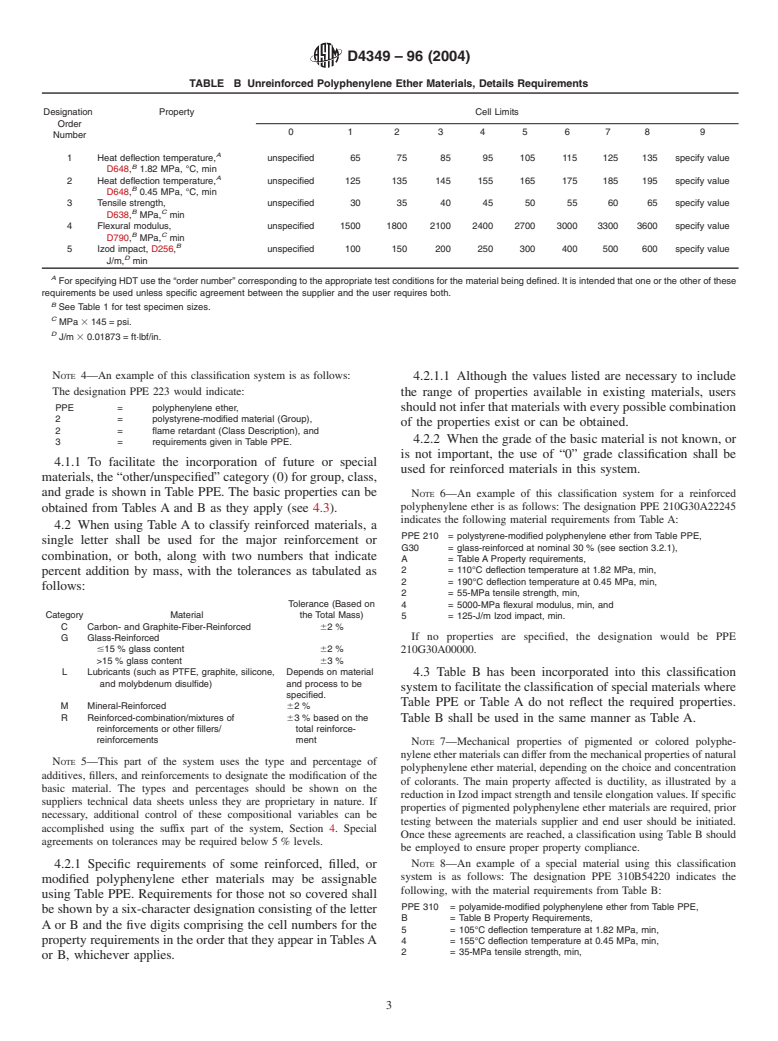

TABLE B Unreinforced Polyphenylene Ether Materials, Details Requirements

Designation Property Cell Limits

Order

0 1 2 3456 7 8 9

Number

A

1 Heat deflection temperature, unspecified 65 75 85 95 105 115 125 135 specify value

B

D648, 1.82 MPa, °C, min

A

2 Heat deflection temperature, unspecified 125 135 145 155 165 175 185 195 specify value

B

D648, 0.45 MPa, °C, min

3 Tensile strength, unspecified 30 35 40 45 50 55 60 65 specify value

B C

D638, MPa, min

4 Flexural modulus, unspecified 1500 1800 2100 2400 2700 3000 3300 3600 specify value

B C

D790, MPa, min

B

5 Izod impact, D256, unspecified 100 150 200 250 300 400 500 600 specify value

D

J/m, min

A

ForspecifyingHDTusethe“ordernumber”correspondingtotheappropriatetestconditionsforthematerialbeingdefined.Itisintendedthatoneortheotherofthese

requirements be used unless specific agreement between the supplier and the user requires both.

B

See Table 1 for test specimen sizes.

C

MPa 3 145 = psi.

D

J/m 3 0.01873 = ft·lbf/in.

NOTE 4—An example of this classification system is as follows:

4.2.1.1 Although the values listed are necessary to include

The designation PPE 223 would indicate:

the range of properties available in existing materials, users

PPE = polyphenylene ether, shouldnotinferthatmaterialswitheverypossiblecombination

2 = polystyrene-modified material (Group),

of the properties exist or can be obtained.

2 = flame retardant (Class Description), and

4.2.2 When the grade of the basic material is not known, or

3 = requirements given in Table PPE.

is not important, the use of “0” grade classification shall be

4.1.1 To facilitate the incorporation of future or special

used for reinforced materials in this system.

materials,the“other/unspecified”category(0)forgroup,class,

and grade is shown in Table PPE. The basic properties can be NOTE 6—An example of this classification system for a reinforced

polyphenylene ether is as follows: The designation PPE 210G30A22245

obtained from Tables A and B as they apply (see 4.3).

indicates the following material requirements from Table A:

4.2 When using Table A to classify reinforced materials, a

PPE 210 = polystyrene-modified polyphenylene ether from Table PPE,

single letter shall be used for the major reinforcement or

G30 = glass-reinforced at nominal 30 % (see section 3.2.1),

combination, or both, along with two numbers that indicate

A = Table A Property requirements,

2 = 110°C deflection temperature at 1.82 MPa, min,

percent addition by mass, with the tolerances as tabulated as

2 = 190°C deflection temperature at 0.45 MPa, min,

follows:

2 = 55-MPa tensile strength, min,

Tolerance (Based on

4 = 5000-MPa flexural modulus, min, and

Category Material the Total Mass) 5 = 125-J/m Izod impact, m

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4349–96 Designation: D 4349 – 96 (Reapproved 2004)

Classification System for

Polyphenylene Ether (PPE) Materials

This standard is issued under the fixed designation D4349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This classification system covers the basic polymers and copolymers known as polyphenylene ethers and polyphenylene

oxides, as well as filled, modified, and reinforced versions.

NOTE 1—Addition to the natural polymer or copolymer of pigments, colorants or additives may result in the final composition not meeting the

requirementsspecifiedforthenaturalpolymerorcopolymer.Discussionswiththesuppliershouldtakeplacebeforespecificationsofalteredcompositions

are established.

NOTE 2—The preferred abbreviation for polyphenylene ether is PPE, as noted in Terminology D1600.

1.2 This classification system is not intended for the selection of materials, but only as a means to call out plastic materials to

beusedforthemanufactureofparts.Theselectionofthesematerialsistobemadebypersonnelwithexpertiseintheplasticsfield

where the environment, inherent properties of the materials, performance of the parts, part design, manufacturing process, and

economics are considered.

1.3 There may be other requirements necessary to identify particular characteristics important to specific applications. These

may be specified by using the suffixes described in Section 5.

1.4 The values stated in SI units are to be regarded as the standard.

NOTE 3—No ISO standard exists that covers these materials.

2. Referenced Documents

2.1 ASTM Standards:

D256 Test Methods for Impact Resistance of Plastics and Electrical Insulating Materials

D618 Practice for Conditioning Plastics and Electrical Insulating Materials for Testing Practice for Conditioning Plastics for

Testing

D638 Test Method for Tensile Properties of Plastics

D648 Test Method for Deflection Temperature of Plastics Under Flexural Load

D790 Test Methods for Flexural Properties of Unreinforced and Plastics and Electrical Insulating Materials

D792 Test Methods for Specific Gravity (Relative Density) and Density of Plastics by Displacements

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1898 Practice for Sampling of Plastics

D3892 Practice for Packaging/Packing of Plastics

D4000 Classification System for Specifying Plastic Material

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

2.2 Underwriters Laboratories:

UL 94 Standards for Tests for Flammability for Parts in Devices and Appliances

3. Terminology

3.1 The terminology used in this classification is in accordance with Terminologies D883 and D1600.

3.2 The polyphenylene ether materials will be designated PPE as specified in Terminology D1600.

This classification system is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials .

Current edition approved Nov. 10, 1996. Published May 1997. Originally published as D4349–89. Last previous edition D4349–93.

Current edition approved March 1, 2004. Published June 2004. Originally approved in 1989. Last previous edition approved in 1996 as D4349-96.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 08.02.

Available from Underwriters Laboratories Inc. Publications Stock, 333 Pfingsten Road, Northbrook, IL 60067.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4349 – 96 (2004)

TABLE 1 Testing Parameters

ASTM

Test Specimen and Testing Parameters

Test Method

D 638 Type I, 3.2-mm thickness, crosshead speed of 5 mm/min for

reinforced materials and 50 mm/min for unreinforced

materials.

D 790 3.2 by 12.7-mm specimen, tested by Method I, Procedure A

(tangent) with a crosshead speed of 1.3 mm/min and a span

to depth ratio of 16 to 1.

D 256 3.2 by 12.7-mm specimen, tested by Test Method A.

D 648 3.2 by 12.7-mm specimen, 102-mm support span,

unannealed prior to testing.

4. Classification

4.1 Polyphenyleneether-basedmaterialsareclassifiedintogroupsaccordingtotheircompositions.Thesegroupsaresubdivided

into classes and grades, as shown in Table PPE.

TABLE PPE Requirements for Polyphenylene Ether (PPE) Materials

A

NOTE 1—Values given are for natural materials only. Other colors may be different.

Tensile Flexural Izod

Heat Deflection, min

Specific

Strength, Modulus, Impact,

Grade Gravity,

at 1.82 at 0.45 B,C B,C B,D

Group Description Class Description D 638, D 790, D 256,

Description ASTM

MPa, MPa,

MPa, MPa, J/m,

B B D 792, min

D 648, °C D 648, °C

min min min

E

1 Unmodified 1 general purpose 0 other

F E

2 flame retardant 0 other

E

0 other 0 other

G

2 PS modified materials 1 general purpose 1 90 N/A 1.03 32 1750 265

G

2 100 N/A 1.03 38 1900 240

G

3 100 N/A 1.03 44 2150 185

G

4 110 N/A 1.04 55 2300 160

G

5 130 N/A 1.05 57 2300 160

0 other . . . . . .

F G

2 flame retardant 167 N/A 1.06 36 2200 190

G

280 N/A 1.07 40 2250 130

G

385 N/A 1.07 48 2350 100

G

4 105 N/A 1.07 55 2350 160

G

5 125 N/A 1.08 60 2500 160

0 other . . . . . .

0 other 0 other . . . . . .

G

3 PA modified materials 1 general purpose 1 N/A 145 1.05 50 2000 170

G

2N/A 155 1.05 50 2000 160

G

3N/A 170 1.05 50 1800 530

G

4N/A 180 1.05 55 2000 185

G

5N/A 195 1.05 58 2200 160

0 other . . . . . .

F E

2 flame retardant 0 other

0 other 0 other . . . . . .

4 Other 1 general purpose 0 other . . . . .

F

2 flame retardant 0 other . . . . .

0 other 0 other . . . . .

5 Rework modified 1 general purpose 0 other . . . . .

F

2 flame retardant 0 other . . . . .

0 other 0 other . . . . .

A

Use Tables A and B where necessary for colored materials.

B

See Table 1 for test parameters and conditions.

C

MPa 3 145 = psi.

D

J/m 3 0.01873 = ft·lbf/in.

E

Unfilled materials currently not available. Use Table A.

F

Flammability ratings determined in accordance with UL 94.

G

N/A—Not applicable for grade description.

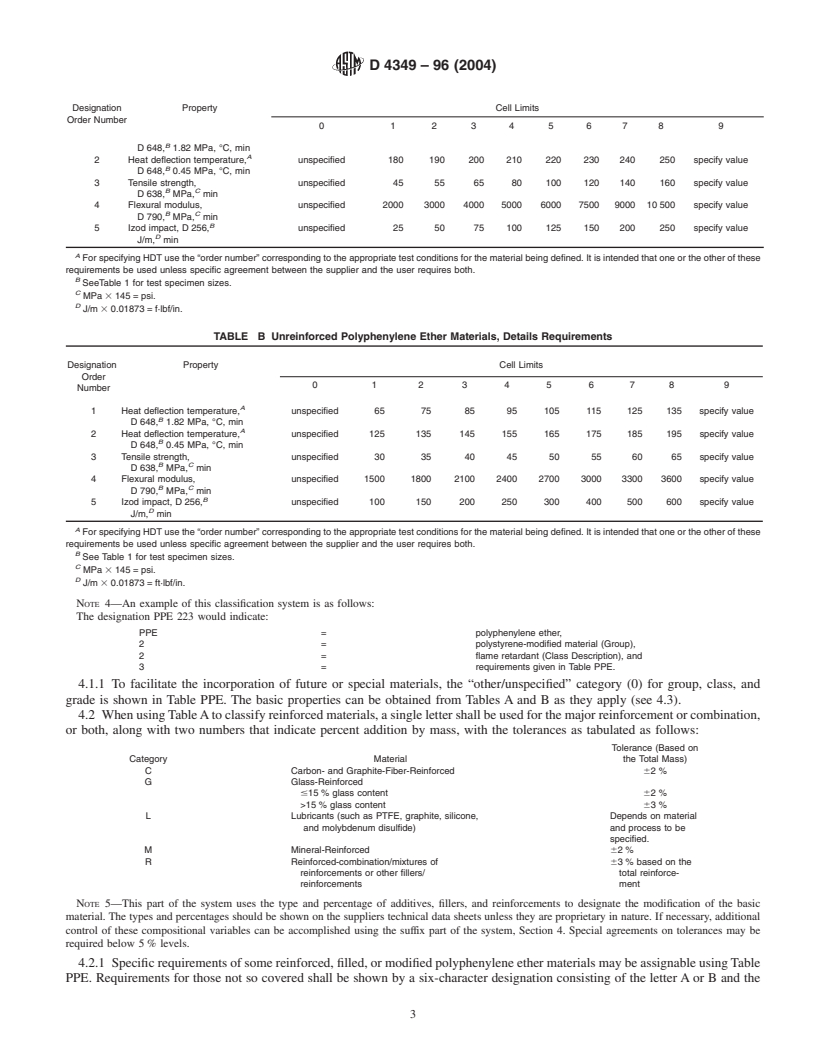

TABLE A Reinforced Polyphenylene Ether Materials, Details Requirements

Designation Property Cell Limits

Order Number

0 1 23 45 6 7 8 9

A

1 Heat deflection temperature, unspecified 100 110 120 130 140 150 160 170 specify value

D 4349 – 96 (2004)

Designation Property Cell Limits

Order Number

0 1 23 45 6 7 8 9

B

D 648, 1.82 MPa, °C, min

A

2 Heat deflection temperature, unspecified 180 190 200 210 220 230 240 250 specify value

B

D 648, 0.45 MPa, °C, min

3 Tensile strength, unspecified 45 55 65 80 100 120 140 160 specify value

B C

D 638, MPa, min

4 Flexural modulus, unspecified 2000 3000 4000 5000 6000 7500 9000 10 500 specify value

B C

D 790, MPa, min

B

5 Izod impact, D 256, unspecified 25 50 75 100 125 150 200 250 specify value

D

J/m, min

A

ForspecifyingHDTusethe“ordernumber”correspondingtotheappropriatetestconditionsforthematerialbeingdefined.Itisintendedthatoneortheotherofthese

requirements be used unless specific agreement between the supplier and the user requires both.

B

SeeTable 1 for test specimen sizes.

C

MPa 3 145 = psi.

D

J/m 3 0.01873 = f·lbf/in.

TABLE B Unreinforced Polyphenylene Ether Materials, Details Requirements

Designation Property Cell Limits

Order

0 1 2 3456 7 8 9

Number

A

1 Heat deflection temperature, unspecified 65 75 85 95 105 115 125 135 specify value

B

D 648, 1.82 MPa, °C, min

A

2 Heat deflection temperature, unspecified 125 135 145 155 165 175 185 195 specify value

B

D 648, 0.45 MPa, °C, min

3 Tensile strength, unspecified 30 35 40 45 50 55 60 65 specify value

B C

D 638, MPa, min

4 Flexural modulus, unspecified 1500 1800 2100 2400 2700 3000 3300 3600 specify value

B C

D 790, MPa, min

B

5 Izod impact, D 256, unspecified 100 150 200 250 300 400 500 600 specify value

D

J/m, min

A

ForspecifyingHDTusethe“ordernumber”correspondingtotheappropriatetestconditionsforthematerialbeingdefined.Itisintendedthatoneortheotherofthese

requirements be used unless specific agreement between the supplier and the user requires both.

B

See Table 1 for test specimen sizes.

C

MPa 3 145 = psi.

D

J/m 3 0.01873 = ft·lbf/in.

NOTE 4—An example of this classification system is as follows:

The designation PPE 223 would indicate:

PPE = polyphenylene ether,

2 = polystyrene-modified material (Group),

2 = flame retardant (Class Description), and

3 = requirements given in Table PPE.

4.1.1 To facilitate the incorporation of future or special materials, the “other/unspecified” category (0) for group, class, and

grade is shown in Table PPE. The basic properties can be obtained from Tables A and B as they apply (see 4.3).

4.2 WhenusingTableAtoclassifyreinforcedmaterials,asinglelettershallbeusedforthemajorreinforcementorcombination,

or both, along with two numbers that indicate percent addition by mass, with the tolerances as tabulated as follows:

Tolerance (Based on

Category Material the Total Mass)

C Carbon- and Graphite-Fiber-Reinforced 62%

G Glass-Reinforced

#15 % glass content 62%

>15 % glass content 63%

L Lubricants (such as PTFE, graphite, silicone, Depends on material

and molybdenum disulfide) and process to be

specified.

M Mineral-Reinforced 62%

R Reinforced-combination/mixtures of 63 % based on the

reinforcements or other fillers/ total reinforce-

reinforcements ment

NOTE 5—This part of the system uses the type and percentage of additives, fillers, and reinforcements to designate the modification of the basic

material. The types and percentages should be shown on the suppliers technical data sheets unless they are proprietary in na

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.