ASTM C1699-09

(Test Method)Standard Test Method for Moisture Retention Curves of Porous Building Materials Using Pressure Plates

Standard Test Method for Moisture Retention Curves of Porous Building Materials Using Pressure Plates

SIGNIFICANCE AND USE

The purpose of this test is to obtain, by means of a specified laboratory procedure, the values of the equilibrium moisture content at higher RH levels ((≈ 95 to 100%). These values are used either as means to characterize the material or as material characteristics needed as input to appropriate computer models that can simulate wetting or drying potential of individual building materials or material assemblies under specified environmental conditions.

SCOPE

1.1 This test method specifies a laboratory procedure for the determination of the water retention curve (or moisture storage capacity) of porous building materials at very high relative humidity (RH) levels (≈ 95 to 100% RH) corresponding to the capillary moisture region of the sorption isotherm. This is achieved by using the pressure plate test apparatus. This technique was originally developed to study soil moisture content and eventually had been adapted to building construction materials.

1.2 At higher RH levels (≈ 95 to 100% RH) of the sorption isotherm (see Test Method C 1498), use of climatic chamber is not an option. This technique uses overpressure to extract water out of the pore structure of porous materials until equilibrium between the moisture content in the specimens and the corresponding overpressure is achieved. Using the pressure plate extractors, equilibrium can only be reached by desorption.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1699 − 09

StandardTest Method for

Moisture Retention Curves of Porous Building Materials

1

Using Pressure Plates

This standard is issued under the fixed designation C1699; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2325 Test Method for Capillary-Moisture Relationships

for Coarse- and Medium-Textured Soils by Porous-Plate

1.1 This test method specifies a laboratory procedure for the

3

Apparatus (Withdrawn 2007)

determination of the water retention curve (or moisture storage

D3152 Test Method for Capillary-Moisture Relationships

capacity) of porous building materials at very high relative

for Fine-Textured Soils by Pressure-MembraneApparatus

humidity (RH) levels (≈ 95 to 100% RH) corresponding to the

3

(Withdrawn 2007)

capillary moisture region of the sorption isotherm. This is

E337 Test Method for Measuring Humidity with a Psy-

achieved by using the pressure plate test apparatus. This

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

technique was originally developed to study soil moisture

peratures)

content and eventually had been adapted to building construc-

tion materials.

3. Terminology

1.2 At higher RH levels (≈ 95 to 100% RH) of the sorption

3.1 Definitions of Terms Specific to This Standard:

isotherm (see Test Method C1498), use of climatic chamber is

3.1.1 desorption isotherm—the sorption isotherm measured

not an option. This technique uses overpressure to extract

exclusively during the hygroscopic desorption process started

water out of the pore structure of porous materials until

from the condition of full water saturation of the material.

equilibrium between the moisture content in the specimens and

3.1.2 sorption isotherm—relationship between the relative

the corresponding overpressure is achieved. Using the pressure

humidity (seeTest Method E337) and the equilibrium moisture

plate extractors, equilibrium can only be reached by desorp-

content of the material, at a specified temperature.

tion.

3.1.3 pressure-plate facility—Heavy steel vessel capable of

1.3 The values stated in SI units are to be regarded as

holding different pressure levels.

standard. No other units of measurement are included in this

standard. 3.1.4 moisture content, by mass—mass of water retained in

the specimen divided by the dry mass of the specimen.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 The purpose of this test is to obtain, by means of a

priate safety and health practices and determine the applica-

specified laboratory procedure, the values of the equilibrium

bility of regulatory limitations prior to use.

moisture content at higher RH levels ((≈ 95 to 100%). These

values are used either as means to characterize the material or

2. Referenced Documents

as material characteristics needed as input to appropriate

2

2.1 ASTM Standards:

computer models that can simulate wetting or drying potential

C1498 Test Method for Hygroscopic Sorption Isotherms of

of individual building materials or material assemblies under

Building Materials

specified environmental conditions.

5. Apparatus

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

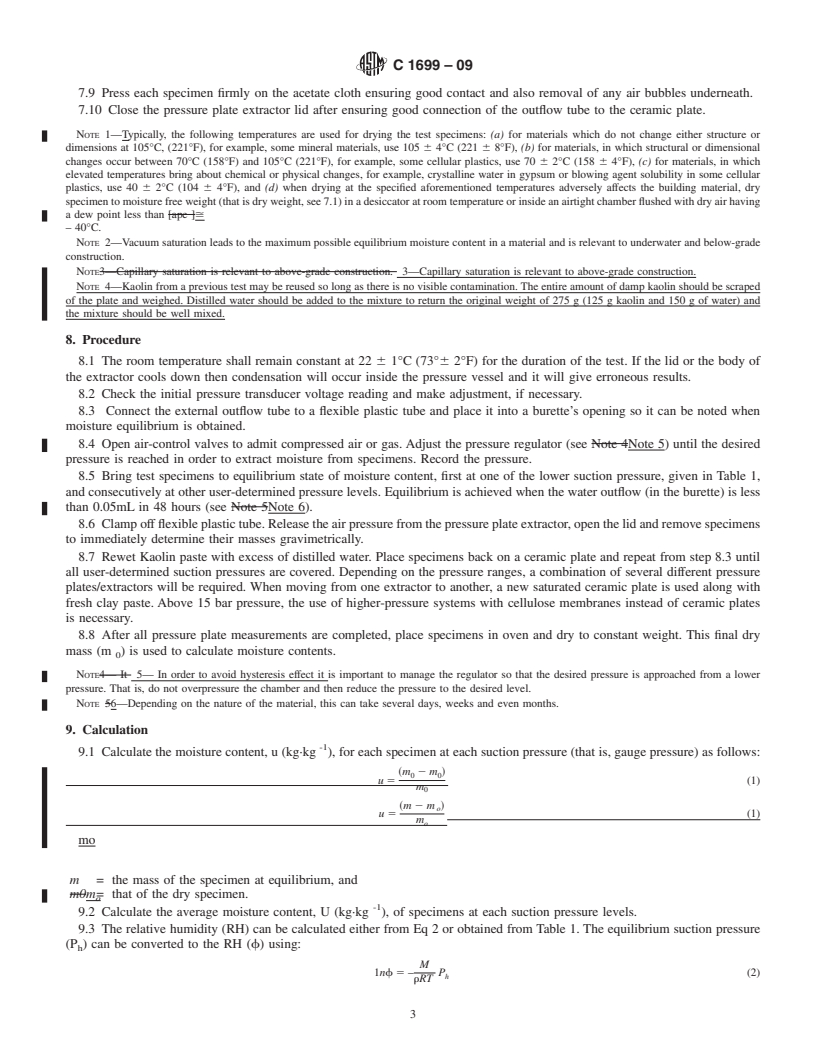

5.1 Pressure vessel—Heavy-duty steel vessels of approxi-

Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation

mately 305 mm in diameter and about 75 mm or 250 mm high

Finishes and Moisture.

Current edition approved May 1, 2009. Published August 2009. Originally

with heavy top lid tightly-held against O-ring gasket by

approved in 2008. Last previous edition approved in 2008 as C1699–08. DOI:

clamping bolts (see Fig. 1).

10.1520/C1699-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1699 − 09

FIG. 1 Pressure Plate Test Apparatus

5.2 Porous ceramic plates—Thisistheplateuponwhichthe 6.2 A minimum of five specimens shall be tested in each

specimens sit and is composed of microscopic pores allowing pressure environment. The test procedure, as specified below,

only water to flow through it.The plate assembly is ex

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1699–08 Designation:C1699–09

Standard Test Method for

Moisture Retention Curves of Porous Building Materials

1

Using Pressure Plates

This standard is issued under the fixed designation C 1699; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method specifies a laboratory procedure for the determination of the water retention curve (or moisture storage

capacity)ofporousbuildingmaterialsatveryhighrelativehumidity(RH)levels('95to100%RH)correspondingtothecapillary

moisture region of the sorption isotherm. This is achieved by using the pressure plate test apparatus. This technique was originally

developed to study soil moisture content and eventually had been adapted to building construction materials.

1.2 At higher RH levels (' 95 to 100% RH) of the sorption isotherm (see Test Method C 1498), use of climatic chamber is not

an option.This technique uses overpressure to extract water out of the pore structure of porous materials until equilibrium between

the moisture content in the specimens and the corresponding overpressure is achieved. Using the pressure plate extractors,

equilibrium can only be reached by desorption.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 1498 Test Method for Hygroscopic Sorption Isotherms of Building Materials

D 2325 Test Method for Capillary-Moisture Relationships for Coarse- and Medium-Textured Soils by Porous-Plate Apparatus

D 3152 Test Method for Capillary-Moisture Relationships for Fine-Textured Soils by Pressure-Membrane Apparatus

E 337 Test Method for Measuring Humidity with a Psychrometer (the Measurement of Wet- and Dry-Bulb Temperatures)

3. Terminology

3.1 Definitions of Terms Specific to this Standard:

3.1.1 desorption isotherm—the sorption isotherm measured exclusively during the hygroscopic desorption process started from

the condition of full water saturation of the material.

3.1.2 sorption isotherm—relationship between the relative humidity (see Test Method E 337) and the equilibrium moisture

content of the material, at a specified temperature.

3.1.3 pressure-plate facility—Heavy steel vessel capable of holding different pressure levels.

3.1.4 moisture content, by mass—mass of water retained in the specimen divided by the dry mass of the specimen.

4. Significance and Use

4.1 The purpose of this test is to obtain, by means of a specified laboratory procedure, the values of the equilibrium moisture

content at higher RH levels ((' 95 to 100%). These values are used either as means to characterize the material or as material

characteristics needed as input to appropriate computer models that can simulate wetting or drying potential of individual building

materials or material assemblies under specified environmental conditions.

5. Apparatus

5.1 Pressure vessel—Heavy-duty steel vessels of approximately 305 mm in diameter and about 75 mm or 250 mm high with

heavy top lid tightly-held against O-ring gasket by clamping bolts (see Fig. 1).

1

This test method is under the jurisdiction ofASTM Committee C16 onThermal Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation Finishes

and Moisture.

Current edition approved Oct. 15, 2008. Published November 2008.

Current edition approved May 1, 2009. Published August 2009. Originally approved in 2008. Last previous edition approved in 2008 as C 1699–08.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1699–09

FIG. 1 Pressure Plate Test Apparatus

5.2 Porous ceramic plates—This is the plate upon which the specimens sit and is compos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.