ASTM D6594-00

(Test Method)Standard Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 135oC

Standard Test Method for Evaluation of Corrosiveness of Diesel Engine Oil at 135<sup>o</sup>C

SCOPE

1.1 This test method is used to test diesel engine lubricants to determine their tendency to corrode various metals, specifically alloys of lead and copper commonly used in cam followers and bearings.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6594 – 00 An American National Standard

Standard Test Method for

Evaluation of Corrosiveness of Diesel Engine Oil at 135°C

This standard is issued under the fixed designation D 6594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Any properly equipped laboratory, without outside assistance, can use the procedure described in

this test method. However, the ASTM Test Monitoring Center (TMC) provides reference oils and an

assessment of the test results obtained on those oils by the laboratory (see Annex A1). By these means,

the laboratory will know whether their use of the test method gives results statistically similar to those

obtained by other laboratories. Furthermore, various agencies require that a laboratory utilize the TMC

services in seeking qualification of oils against specifications. For example, the U.S. Army imposes

such a requirement in connection with several Army engine lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of information letters issued by the TMC. In addition,

the TMC may issue supplementary memoranda related to the method (see Annex A1). For other

information, refer to the research report of this test method .

1. Scope ing Oils and Determination of Selected Elements in Base

Oils by Inductively Coupled Plasma Atomic Emission

1.1 This test method is used to test diesel engine lubricants

Spectrometry (ICP-AES)

to determine their tendency to corrode various metals, specifi-

D 5844 Test Method for Evaluation of Automotive Engine

cally alloys of lead and copper commonly used in cam

Oils for Inhibition of Rusting (Sequence IID)

followers and bearings.

D 6557 Test Method forEvaluation of the Rust Preventive

1.2 The values stated in SI units are to be regarded as the

Characteristics of Automotive Engine Oils

standard.

E 691 Practice for Conducting an Inter-Laboratory Study to

1.3 This standard does not purport to address all of the

Determine the Precision of a Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions:

bility of regulatory limitations prior to use.

3.1.1 corrosion, n—the chemical or electrochemical reac-

2. Referenced Documents tion between a material, usually a metal surface, and its

environment that can produce a deterioration of the material

2.1 ASTM Standards:

and its properties. D 5844

D 130 Test Method for Detection of Copper Corrosion from

3.1.2 developer, n—of an ASTM test method, the assigned

Petroleum Products by the Copper Strip Tarnish Test

ASTM group, working under the supervision of its governing

D 5185 Test Method for Determination of Additive Ele-

subcommittee and main committee, that formats the test

ments, Wear Metals, and Contaminants in Used Lubricat-

method in accordance with the Form and Style for ASTM

Standards, and continually refines the test method.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.3 developer, n—of a test procedure, an individual or

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.B0 on Automotive Lubricants.

organization that selects the test apparatus and operating

Current edition approved Nov. 10, 2000. Published January 2001.

conditions.

The ASTM Test Monitoring Center will update changes in this test method by

3.1.4 non-reference oil, n—any oil other than a reference

means of Information Letters. This edition incorporates revisions contained in all

Information Letters through 00-1. Information Letters may be obtained from the

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 15206-4489,

Attention: Administrator.

3 5

Available from ASTM Headquarters. Request the High Temperature Corrosion Annual Book of ASTM Standards, Vol 05.03.

Bench Test Research Report, RR:D02-1443. Annual Book of ASTM Standards, Vol 05.04.

4 7

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 6594

oil; such as a research formulation, commercial oil, or candi-

date oil. D 5844

3.1.5 reference oil, n—an oil of known performance char-

acteristics, used as a basis for comparison. D 5844

3.1.5.1 Discussion—Reference oils are used to calibrate

testing facilities, to compare the performance of other oils, or

to evaluate other materials (such as seals) that interact with

oils.

3.1.6 specimen, n—a piece or portion of a sample used to

make a test.

3.1.7 sponsor, n—of an ASTM test method, an organization

that is responsible for ensuring supply of the apparatus used in

the test procedure portion of the test method.

3.1.7.1 Discussion—In some instances, such as a test

method for chemical analysis, an ASTM working group can be

the sponsor of a test method. In other instances, a company

with a self-interest may or may not be the developer of the test

procedure used within the test method, but is the sponsor of the

test method.

3.1.8 test oil, n—any oil subjected to evaluation in an

established procedure. D 6557

4. Summary of Test Method

4.1 Four metal specimens of copper, lead, tin, and phosphor

FIG. 1 Sample Tube

bronze are immersed in a measured amount of engine oil. The

oil, at an elevated temperature, is blown with air for a period of

time. When the test is completed, the copper specimen and the

stressed oil are examined to detect corrosion and corrosion

products, respectively.

4.2 A reference oil is tested with each group of tests to

verify test acceptability.

5. Significance and Use

5.1 This test method is intended to simulate the corrosion

process of non-ferrous metals in diesel lubricants. The corro-

sion process under investigation is that believed to be induced

primarily by inappropriate lubricant chemistry rather than

lubricant degradation or contamination. This test method has

been found to correlate with an extensive fleet database

containing corrosion-induced cam and bearing failures.

6. Apparatus

6.1 The main apparatus consists of the following items of

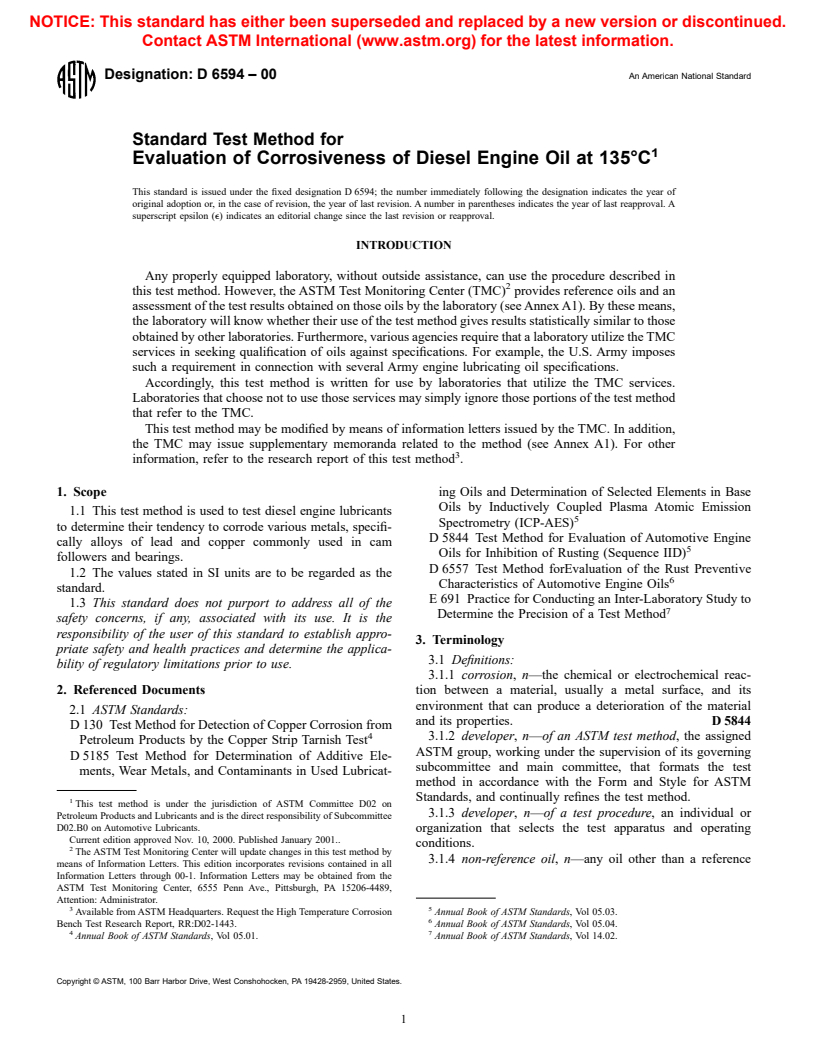

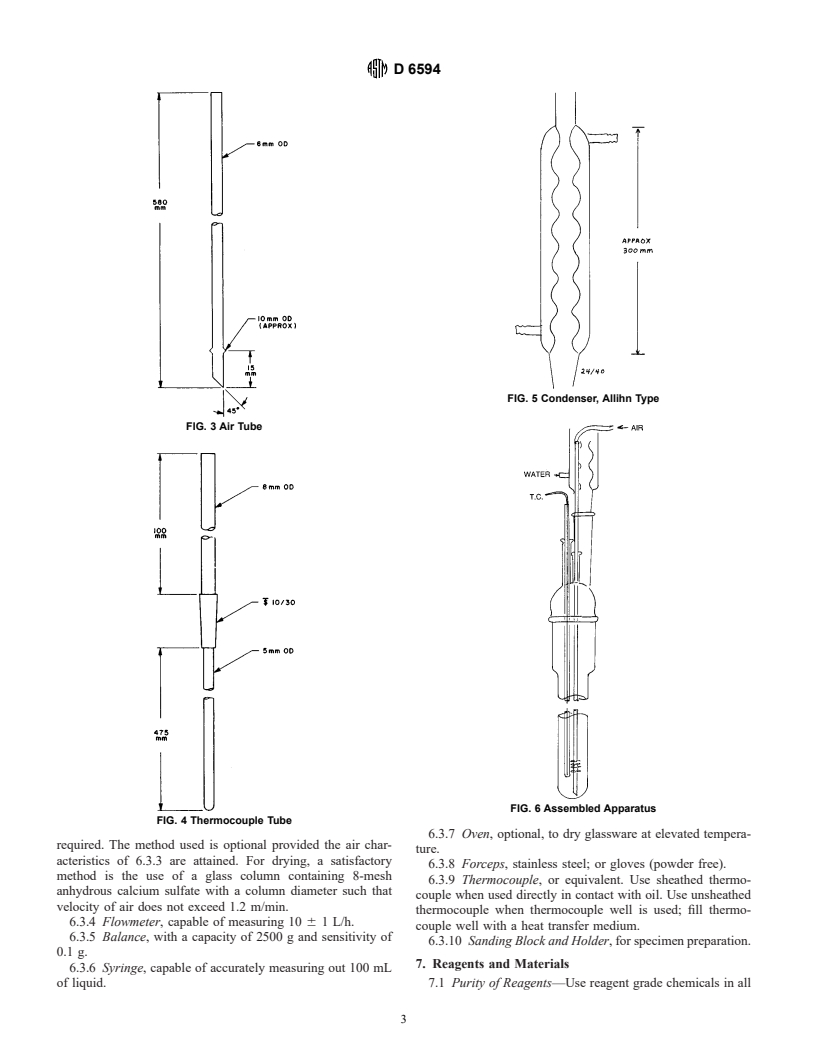

standard wall borosilicate glassware as shown in Figs. 1-6.

6.1.1 Main Sample Tube, Fig. 1.

6.1.2 Sample Tube Head, Fig. 2.

6.1.3 Air Tube, Fig. 3.

6.1.4 Thermocouple Tube, Fig. 4.

6.1.5 Condenser, Allihn Type, Fig. 5.

6.1.6 Assembled Apparatus, Fig. 6.

FIG. 2 Sample Tube Head

6.2 Additional glassware items and assembly accessories

needed are:

6.2.1 Hanger (for metal specimens), of stainless steel, hav- of 250 6 20 mm. Oil baths are recommended. (Warning—

ing the dimensions listed in Fig. 7. There are exposed hot surfaces on apparatus. Avoid skin

6.2.2 Adapter, polytetrafluoroethylene for 10/18 joint for contact by use of protective equipment.)

sealing of the air tube to the sample tube head. 6.3.2 Ventilation, to adequately remove fumes during heat-

6.3 Other items and equipment are: ing.

6.3.1 Heating bath, with constant temperature control within 6.3.3 Dry Air Supply, with a dew point of −68°C.

6 0.5°C (6 1°F) of test temperature with an immersion depth 6.3.3.1 When air needs to be conditioned an air drier is

D 6594

FIG. 5 Condenser, Allihn Type

FIG. 3 Air Tube

FIG. 6 Assembled Apparatus

FIG. 4 Thermocouple Tube

6.3.7 Oven, optional, to dry glassware at elevated tempera-

required. The method used is optional provided the air char-

ture.

acteristics of 6.3.3 are attained. For drying, a satisfactory

6.3.8 Forceps, stainless steel; or gloves (powder free).

method is the use of a glass column containing 8-mesh

6.3.9 Thermocouple, or equivalent. Use sheathed thermo-

anhydrous calcium sulfate with a column diameter such that

couple when used directly in contact with oil. Use unsheathed

velocity of air does not exceed 1.2 m/min.

thermocouple when thermocouple well is used; fill thermo-

6.3.4 Flowmeter, capable of measuring 10 6 1 L/h.

couple well with a heat transfer medium.

6.3.5 Balance, with a capacity of 2500 g and sensitivity of

6.3.10 Sanding Block and Holder, for specimen preparation.

0.1 g.

7. Reagents and Materials

6.3.6 Syringe, capable of accurately measuring out 100 mL

of liquid. 7.1 Purity of Reagents—Use reagent grade chemicals in all

D 6594

NOTE 1—All dimensions in mm.

FIG. 7 Specimen Hanger

tests. Unless otherwise indicated, it is intended that all reagents 7.8 Degreasing Solvent, (THF recommended).

conform to the specifications maintained by the Committee on 7.9 Naphtha, Aromatic. (Warning—Flammable. Health

Analytical Reagents of the American Chemical Society . hazard.)

9,10 2

7.2 Metal Specimens 7.10 Reference Oil .

7.2.1 Specimens are 0.081 cm thick by 2.5 cm square,

8. Preparation of Apparatus

except that lead specimen that is 0.178 cm thick. One specimen

from each of the following metal types, each with two drilled

8.1 Cleaning of Glassware:

holes, is required:

8.1.1 Rinse all glassware items and the air tube adapter with

7.2.1.1 Copper (R401-A),

degreasing solvent to remove residual oil, and air-dry.

7.2.1.2 Lead (R401-lead),

8.1.2 Wash all glassware items and the air tube adapter with

7.2.1.3 Tin (R401-tin), and

detergent. Rinse with tap water, distilled water, and dry.

7.2.1.4 Phosphor Bronze (R401-PBz).

8.1.3 Store all items in a dust-free cabinet until needed for

7.3 Abrasive Paper , 240-grit aluminum oxide and 400-grit

test. If stored longer than one week, rinse again with distilled

silicon carbide. Do not use iron-containing abrasives such as

water before use, and dry.

natural emery.

8.1.4 The following more thorough glassware cleaning

7.4 Cotton, 100 %.

procedure can be used, if it is required for a given situation:

7.5 Acetone (ACS), sulfur free. (Warning—Flammable.

8.1.4.1 Fill and immerse all glassware items with glassware

Health hazard.)

cleaning solution (see 7.6) and soak for 3 to 16 h. (Warning—

,

12 10

7.6 Glassware Cleaning Solution, NOCHROMIX .

Corrosive, causes severe burns.)

(Warning—Causes severe burns.)

8.1.4.2 Remove glassware from cleaning solution; rinse

7.7 Tetrahydrofuran (THF).(Warning—Toxic and flam-

several times with tap water, followed by distilled water, and

mable. Health hazard.)

oven-dry.

8.1.4.3 This more thorough glass cleaning procedure is

8 necessary in a referee situation, unless an alternative glassware

Reagent Chemicals, American Chemical Society Specifications, American

cleaning solution is available which is satisfactory to all parties

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

involved.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

8.2 Assembled Apparatus, shown in Fig. 6.

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC).

8.3 Preparation of Metal Specimens:

Obtain metal specimens from Test Engineering, Inc. (TEI), 12718 Cimarron

Path, San Antonio, TX 78249-3423. 8.3.1 In all succeeding steps, handle the specimens only

The sole source of supply of the apparatus known to the committee at this time

with stainless steel forceps or powder-free gloves until the final

is noted in the adjoining footnote. If you are aware of alternative suppliers, please

weighing. If large defects or particles are present on the metal

provide this information to ASTM Headquarters. Your comments will receive

specimens, remove them first using coarse sandpaper, followed

careful consideration at a meeting of the responsible technical committee, which

you may attend.

by polishing with the 240 and 400-grit abrasive papers, as

Suitable abrasive paper meeting these specifications is included with the metal

described in 8.3.2.

specimens when the specimens are ordered.

12 8.3.2 Using a sanding block with a specimen holder, remove

Obtain NOCHROMIX from Godax Laboratories, Inc., 720-B Erie Avenue,

Takoma Park, MD 20912. all surface blemishes from both sides and all four edges of each

D 6594

specimen with 240-grit abrasive paper. Remove any burrs from 10. Test Results

the drilled holes with a ⁄16 in. drill bit. Finish polishing with

10.1 Remove the air tube with the attached specimens from

400-grit paper wetted by acetone to remove marks from

the sample tube. Do not touch the specimens with hands.

previous polishing.

Retain the sample tube and test oil for further examination.

8.3.2.1 A good technique is to rub the specimen with

10.2 Using forceps or gloves, wash the copper specimen in

longitudinal strokes in direction perpendicular to that used with

tetrahydrofuran, and discard the other specimens.

240-grit paper. Use a different sheet of paper for each metal

10.3 Rate the copper specimen for tarnish according to the

type.

Strip Examination, Interpretation, and Report sections of Test

8.3.2.2 Make sure that the specimen edges are polished in

Method D 130.

the same manner as the surfaces. Carry out this procedure

10.4 Immediately after calibration of the ICP-AES instru-

using normal room lighting and without magnification of the

ment (as specified in Test Method D 5185), use Test Method

specimen surface. Do not scribe or otherwise mark the sur-

D 5185 to determine the concentration of copper, lead, and tin

faces.

in both the new and used oil.

8.3.3 Store the polished metal specimens in tetrahydrofuran.

10.5 Calculations:

8.3.4 Just prior to a test start, remove each specimen from

10.5.1 Evaporation Loss:

the tetrahydrofuran, and clean all metal dust from the specimen

L 5 W 2 W /W 3 100 (1)

@~ ! #

1 2 3

using 100 % cotton. Rub with a light-to-medium touch to

remove particles but do not polish the specimen further.

where:

8.3.5 Wash specimens in tetrahydrofuran and allow them to L = percent evaporation loss,

W = initial weight of air tube, sample tube and contents,

dry in a desiccator.

including test oil,

W = final weight of air tube, sample tube and contents,

9. Procedure

including test oil, and

9.1 Place the specimen hanger onto the air tube and hang

W = initial weight of test oil.

test specimens on their respective hooks.

10.5.2 Change in metal concentration in the used test oil:

9.1.1 Arrange the specimens on the hanger

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.