ASTM D7882-20

(Test Method)Standard Test Method for Determination of 4-Carboxybenzaldehyde and p-Toluic Acid in Purified Terephthalic Acid by Capillary Electrophoresis with Normal Voltage Mode

Standard Test Method for Determination of 4-Carboxybenzaldehyde and <emph type="bdit" >p</emph>-Toluic Acid in Purified Terephthalic Acid by Capillary Electrophoresis with Normal Voltage Mode

SIGNIFICANCE AND USE

5.1 The presence of 4-CBA and p-TOL in PTA used for the production of polyester is undesirable because they can slow down the polymerization process; and 4-CBA is also imparting coloration to the polymer due to thermal instability.

5.2 Determining the amount of 4-CBA and p-TOL remaining from the manufacture of PTA is often required. This test method is suitable for setting specifications and for use as an internal quality control where these products are produced or used.

5.3 This test method is intended as an alternative to the HPLC method for determination of 4-CBA and p-TOL in PTA. The major benefits of CE are speed, simplicity, reduced reagent consumption and operating costs.

SCOPE

1.1 This test method covers the determination of 4-carboxybenzaldehyde (4-CBA) and p-toluic acid (p-TOL) in purified terephthalic acid (PTA) by capillary electrophoresis (CE) with normal voltage mode and UV detection. It is applicable for 4-CBA from 5 to 400 mg/kg and for p-TOL from 10 to 400 mg/kg, respectively.

1.2 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7882 −20

Standard Test Method for

Determination of 4-Carboxybenzaldehyde and p-Toluic Acid

in Purified Terephthalic Acid by Capillary Electrophoresis

1

with Normal Voltage Mode

This standard is issued under the fixed designation D7882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Procedures for Aromatic Hydrocarbons and Related Ma-

terials

1.1 This test method covers the determination of

E29 Practice for Using Significant Digits in Test Data to

4-carboxybenzaldehyde (4-CBA) and p-toluic acid (p-TOL) in

Determine Conformance with Specifications

purified terephthalic acid (PTA) by capillary electrophoresis

E691 Practice for Conducting an Interlaboratory Study to

(CE) with normal voltage mode and UV detection. It is

Determine the Precision of a Test Method

applicablefor4-CBAfrom5to400mg/kgandforp-TOLfrom

3

2.2 ISO Document:

10 to 400 mg/kg, respectively.

EN ISO 8213 Chemical Products for Industrial Use—

1.2 In determining the conformance of the test results using

Sampling Techniques—Solid Chemical Products in the

this method to applicable specifications, results shall be

Form of ParticlesVarying from Powders to Coarse Lumps

4

rounded off in accordance with the rounding-off method of

2.3 Other Document:

Practice E29.

OSHA Regulations 29 CFR paragraphs 1910.1000 and

1.3 The values stated in SI units are to be regarded as 1910.1200

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions of Terms Specific to Normal Voltage Mode in

1.4 This standard does not purport to address all of the

this Standard:

safety concerns, if any, associated with its use. It is the

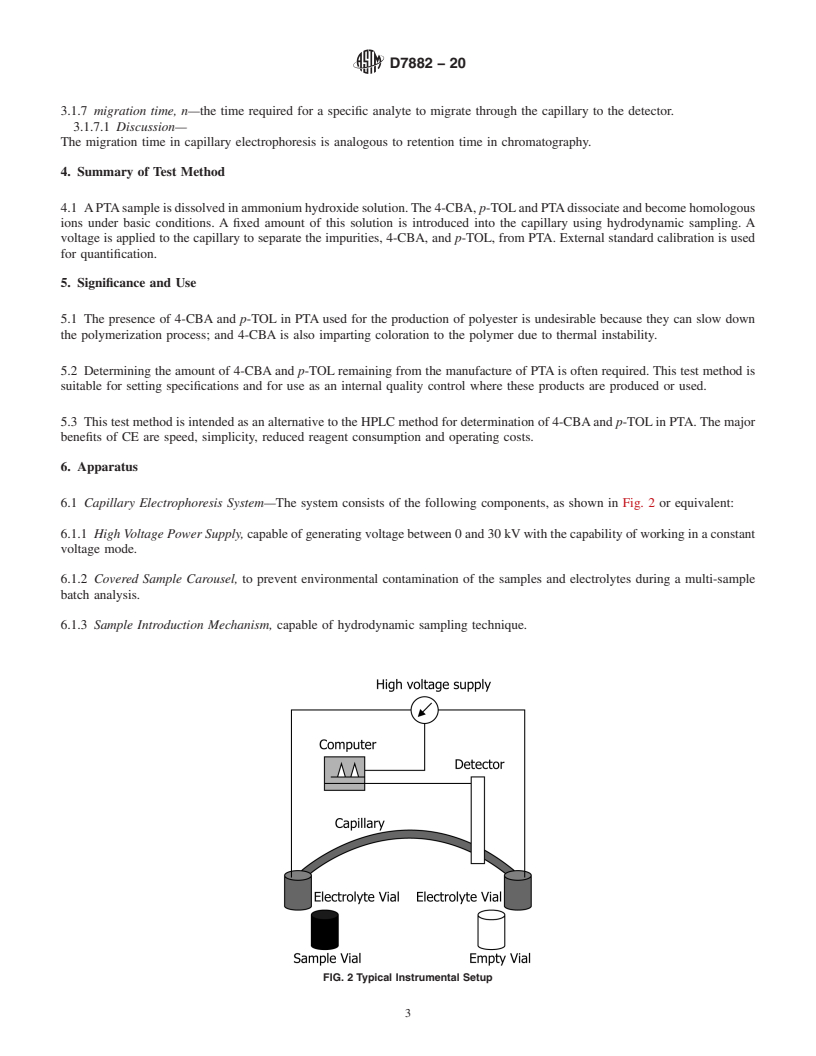

3.1.1 capillary electrophoresis, n—an electrophoretic tech-

responsibility of the user of this standard to establish appro-

nique in which a sample is introduced into a 50 to 100 µm i.d.

priate safety, health, and environmental practices and deter-

fused-silica capillary filled with electrolyte solution and sub-

mine the applicability of regulatory limitations prior to use.

jected to high voltage for separation.

1.5 This international standard was developed in accor-

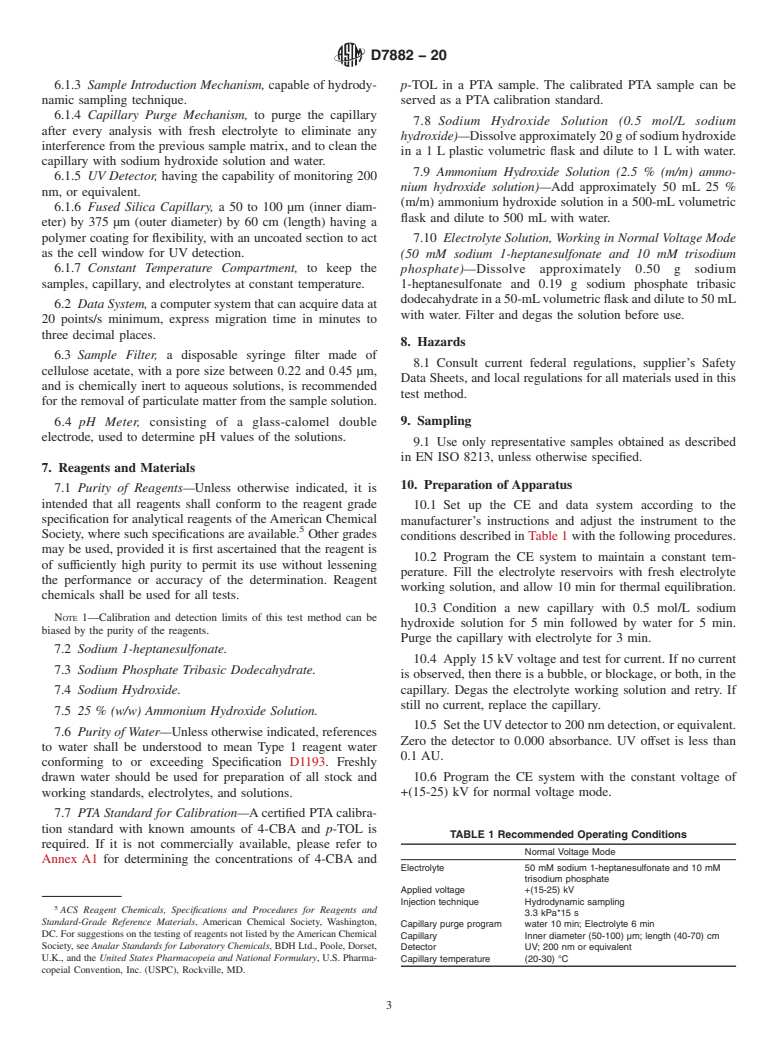

3.1.1.1 Discussion—Normal voltage, with the anode on the

dance with internationally recognized principles on standard-

injection side and the cathode on the detection side, is applied

ization established in the Decision on Principles for the

across the capillary causing electrolyte and analytes to migrate

Development of International Standards, Guides and Recom-

towards the cathode and through the capillary’s UV detector

mendations issued by the World Trade Organization Technical

window. Analytes are separated based on the differential rates

Barriers to Trade (TBT) Committee.

of migration in the electric field. Analyte detection and

quantitation are based on the principles of UV detection.

2. Referenced Documents

2 3.1.2 electrolye,n—acombinationofabufferreagentandan

2.1 ASTM Standards:

ion-pair reagent dissolved in an aqueous solution and placed

D1193 Specification for Reagent Water

inside the capillary, used as a carrier for the analytes.

D6809 Guide for Quality Control and Quality Assurance

3.1.3 electroosmotic flow (EOF), n—the directional velocity

of electrolyte-solution flow within the capillary under an

1

applied voltage; the velocity and direction of flow are deter-

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsi-

mined by electrolyte chemistry, capillary-wall chemistry, and

bility of Subcommittee D16.02 on Oxygenated Aromatics.

applied voltage (see Fig. 1).

Current edition approved Oct. 1, 2020. Published December 2020. Originally

approved in 2013. Last previous edition approved in 2019 as D7882 – 19. DOI:

3

10.1520/D7882-20. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7882 − 19 D7882 − 20

Standard Test Method for

Determination of 4-Carboxybenzaldehyde and p-Toluic Acid

in Purified Terephthalic Acid by Capillary Electrophoresis

1

with Normal Voltage Mode

This standard is issued under the fixed designation D7882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of 4-carboxybenzaldehyde (4-CBA) and p-toluic acid (p-TOL) in purified

terephthalic acid (PTA) by capillary electrophoresis (CE) with normal voltage mode and UV detection. It is applicable for 4-CBA

from 5 to 400 mg/kg and for p-TOL from 10 to 400 mg/kg, respectively.

1.2 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off

in accordance with the rounding-off method of Practice E29.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 ISO Document:

EN ISO 8213 Chemical Products for Industrial Use—Sampling Techniques—Solid Chemical Products in the Form of Particles

Varying from Powders to Coarse Lumps

1

This test method is under the jurisdiction of ASTM Committee D16 on Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsibility of

Subcommittee D16.02 on Oxygenated Aromatics.

Current edition approved Nov. 1, 2019Oct. 1, 2020. Published December 2019December 2020. Originally approved in 2013. Last previous edition approved in 20132019

as D7882 – 13.D7882 – 19. DOI: 10.1520/D7882-19.10.1520/D7882-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7882 − 20

4

2.3 Other Document:

OSHA Regulations 29 CFR paragraphs 1910.1000 and 1910.1200

3. Terminology

3.1 Definitions of Terms Specific to Normal Voltage Mode in this Standard:

3.1.1 capillary electrophoresis, n—an electrophoretic technique in which a sample is introduced into a 50 to 100 μm i.d.

fused-silica capillary filled with electrolyte solution and subjected to high voltage for separation.

3.1.1.1 Discussion—

Normal voltage, with the anode on the injection side and the cathode on the detection side, is applied across the capillary causing

electrolyte and analytes to migrate towards the cathode and through the capillary’s UV detector window. Analytes are separated

based on the differential rates of migration in the electric field. Analyte detection and quantitation are based on the principles of

UV detection.

3.1.2 electrolye, n—a combination of a buffer reagent and an ion-pair reagent dissolved in an aqueous solution and placed inside

the capillary, used as a carrier for the analytes.

3.1.3 electroosmotic flow (EOF), n—the directional velocity of electrolyte-solution flow within the capi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.