ASTM D139-95(2001)e1

(Test Method)Standard Test Method for Float Test for Bituminous Materials

Standard Test Method for Float Test for Bituminous Materials

SIGNIFICANCE AND USE

The float test characterizes the flow behavior or consistency of certain bituminous materials.

This test method is useful in determining the consistency of bitumen as one element in establishing the uniformity of certain shipments or sources of supply.

SCOPE

1.1 This test method covers the float test for bituminous materials.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precaution statement, see 6.1

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D139–95 (Reapproved 2001)

Standard Test Method for

Float Test for Bituminous Materials

This standard is issued under the fixed designation D139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made to Sections 2, 5.4.1, 7.4, and 7.7 January 2002.

1. Scope

1.1 This test method covers the float test for bituminous

materials.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For a specific

precaution statement, see 6.1.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

only.

2. Referenced Documents

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

D140 Practice for Sampling Bituminous Materials

D244 Test Methods and Practices for EmulsifiedAsphalts

D2170 Test Method for Kinematic Viscosity of Asphalts

(Bitumens)

E1 Specification for ASTM Thermometers

2.2 IEC Standard:

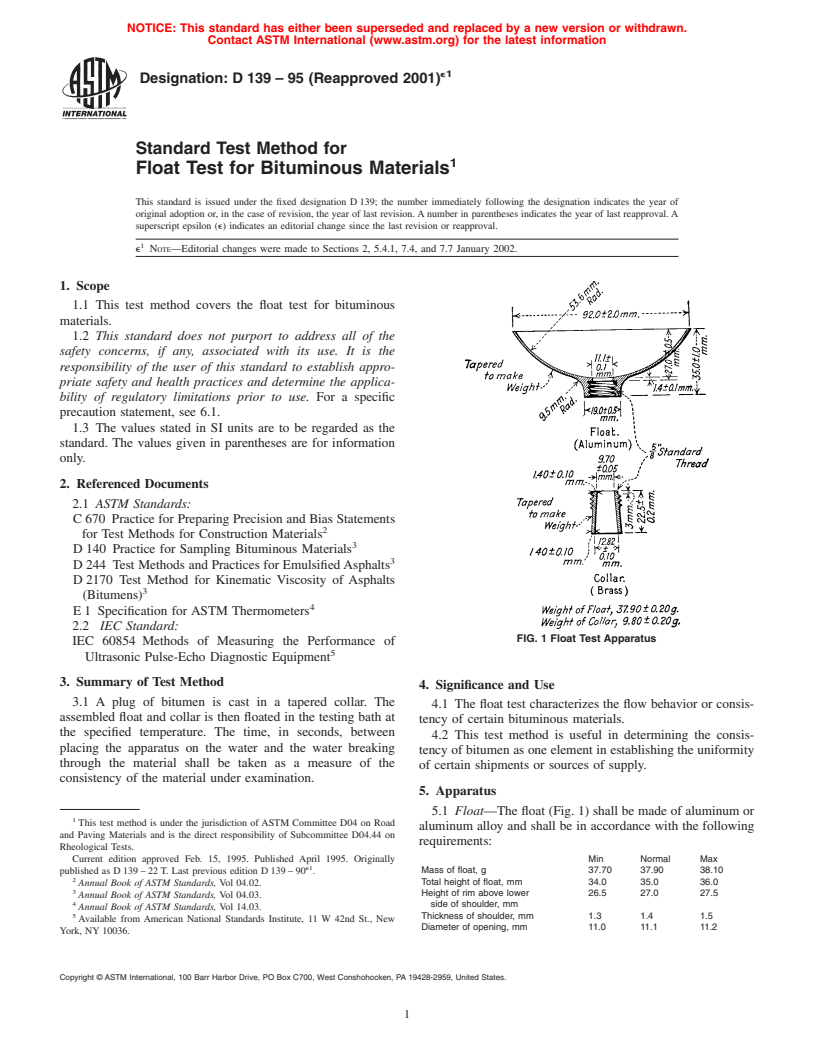

FIG. 1 Float Test Apparatus

IEC 60854 Methods of Measuring the Performance of

Ultrasonic Pulse-Echo Diagnostic Equipment

3. Summary of Test Method

4. Significance and Use

3.1 A plug of bitumen is cast in a tapered collar. The

4.1 The float test characterizes the flow behavior or consis-

assembled float and collar is then floated in the testing bath at

tency of certain bituminous materials.

the specified temperature. The time, in seconds, between

4.2 This test method is useful in determining the consis-

placing the apparatus on the water and the water breaking

tency of bitumen as one element in establishing the uniformity

through the material shall be taken as a measure of the

of certain shipments or sources of supply.

consistency of the material under examination.

5. Apparatus

5.1 Float—The float (Fig. 1) shall be made of aluminum or

This test method is under the jurisdiction of ASTM Committee D04 on Road

aluminum alloy and shall be in accordance with the following

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

requirements:

Rheological Tests.

Current edition approved Feb. 15, 1995. Published April 1995. Originally Min Normal Max

e1

Mass of float, g 37.70 37.90 38.10

published as D139–22T. Last previous edition D139–90 .

Total height of float, mm 34.0 35.0 36.0

Annual Book of ASTM Standards, Vol 04.02.

Height of rim above lower 26.5 27.0 27.5

Annual Book of ASTM Standards, Vol 04.03.

side of shoulder, mm

Annual Book of ASTM Standards, Vol 14.03.

Thickness of shoulder, mm 1.3 1.4 1.5

Available from American National Standards Institute, 11 W 42nd St., New

Diameter of opening, mm 11.0 11.1 11.2

York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D139–95 (2001)

5.2 Collar—The collar (Fig. 1) shall be made of brass and easy pouring, excepting creosote-oil residues, which shall be

shall be in accordance with the following requirements: mixed and poured at a temperature of 100 to 125°C. Stir the

sample thoroughly until it is homogeneous and free from air

Min Normal Max

Mass of collar, g 9.60 9.80 10.00

bubbles.Then pour it into the collar in any convenient manner

Over-all height of collar, mm 22.3 22.5 22.7

until slightly more than level with the top.

Inside diameter at bottom, mm 12.72 12.82 12.92

Inside diameter at top, mm 9.65 9.70 9.75

7.3 Emulsified Asphalts—Test the distillation residue in

accordance with Section 96.1, FloatTest,Test Methods D244.

The top of the collar shall screw up tightly against the lower

The pouring temperature for high float emulsion residues can

side of the shoulder.

be critical. If a high float residue sample fails or appears to be

5.3 Calibration of Assembly—The assembled float and col-

poured at a cooler than specified temperature, the specified

lar, with the collar filled flush with the bottom and weighted to

pouring temperature shall be confirmed in a referee sample by

a total mass of 53.2 g, shall float upon water with the rim 8.5

use of a 30-gage thermocouple probe and instrument. Position

6 1.5 mm above the surface of the water. This adjustment of

the thermocouple probe into the top center of the collar from

the total mass of the assembly is for the purpose only of

above. Record the maximum temperature measured while the

calibrating the depth of immersion in the testing bath.

residue is being poured into the collar. Fill the collar until

5.4 Thermometer—An ASTM Low Softening Point Ther-

slightly more than level with the top, and quickly remove the

mometer, graduated in either Celsius or Fahrenheit degrees as

thermocouple.

specified, having a range from −2 to +80°C or +30 to +180°F

and conforming to the requirements for Thermometer 15°C or

7.3.1 Samples for which the minimum temperature reading

15°F, respectively, as prescribed in Specification E1.

of 218°C (425°F) was not attained shall not be tested for float.

5.4.1 A thermometer consisting of K type 30 AWG gage

7.4 Asphalt and Asphalt Products—Cool asphalt and as-

thermocouple and a meter capable of reading 25°C (77°F) to

phaltproductstoroomtemperaturefor15to60min,thenplace

260°C (500°F). The thermocouple shall be 61 to 76 cm (24 to

them for 5 min in the water bath at 5°C, after which trim the

30 in.) in length. This thermometer sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.