ASTM D244-09(2017)

(Test Method)Standard Test Methods and Practices for Emulsified Asphalts

Standard Test Methods and Practices for Emulsified Asphalts

SIGNIFICANCE AND USE

5.1 This test method measures the amount of water present in the emulsified asphalt, as distinguished from either bitumen or petroleum solvent.

SCOPE

1.1 These test methods and practices, given under the headings titled Composition, Consistency, Stability, and Examination of Residue, cover the examination of asphalt emulsions composed principally of a semisolid or liquid asphaltic base, water, and an emulsifying agent. The test methods cover the following tests and practices:

Test

Sections

Composition:

Water Content

4 – 10

Residue and Oil Distillate by Distillation

See Test Method

D6997

Residue by Evaporation

See Test Method

D6934

Particle Charge of Cationic Emulsified Asphalts

See Practice

D7402

Consistency:

Viscosity (Saybolt Furol)

See Test Method

D7496

Stability:

Demulsibility

See Test Method

D6936

Settlement

See Test Method

D6930

Cement Mixing

See Test Method

D6935

Sieve Test

See Test Method

D6933

Aggregate Coating

See Practice

D6998

Miscibility with Water

See Practice

D6999

Freezing

See Practice

D6929

Coating Ability and Water Resistance

11 – 18

Storage Stability of Asphalt Emulsion

See Test Method

D6930

Examination of Residue

19 – 26

Identification Test for Rapid Setting Cationic Emulsified Asphalt

27 – 34

Identification of Cationic Slow Set Emulsions

See Practice

D7402

Field Coating Test on Emulsified Asphalts

35 – 40

Emulsified Asphalt/Job Aggregate Coating Test

41 – 46

Density of Emulsified Asphalt

See Test Method

D6937

Residue by Low-Temperature Vacuum Distillation

See Test Method

D7403

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D244 −09 (Reapproved 2017) American Association State

Highway and Transportation Officials Standard

AASHTO No.: T59

Standard Test Methods and Practices for

Emulsified Asphalts

This standard is issued under the fixed designation D244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

Emulsified Asphalt/Job Aggregate Coating Test 41–46

Density of Emulsified Asphalt See Test Method

1.1 These test methods and practices, given under the

D6937

headings titled Composition, Consistency, Stability, and Ex- Residue by Low-Temperature Vacuum Distillation See Test Method

D7403

amination of Residue, cover the examination of asphalt emul-

1.2 The values stated in SI units are to be regarded as the

sions composed principally of a semisolid or liquid asphaltic

standard. The values given in parentheses are for information

base, water, and an emulsifying agent. The test methods cover

only.

the following tests and practices:

Test Sections 1.3 This standard does not purport to address all of the

Composition:

safety concerns, if any, associated with its use. It is the

Water Content 4–10

responsibility of the user of this standard to establish appro-

Residue and Oil Distillate by Distillation See Test Method

D6997

priate safety, health, and environmental practices and deter-

Residue by Evaporation See Test Method

mine the applicability of regulatory limitations prior to use.

D6934

1.4 This international standard was developed in accor-

Particle Charge of Cationic Emulsified Asphalts See Practice

D7402 dance with internationally recognized principles on standard-

Consistency:

ization established in the Decision on Principles for the

Viscosity (Saybolt Furol) See Test Method

Development of International Standards, Guides and Recom-

D7496

Stability: mendations issued by the World Trade Organization Technical

Demulsibility See Test Method

Barriers to Trade (TBT) Committee.

D6936

Settlement See Test Method

2. Referenced Documents

D6930

Cement Mixing See Test Method 2

2.1 ASTM Standards:

D6935

C778Specification for Standard Sand

Sieve Test See Test Method

D6933

D5Test Method for Penetration of Bituminous Materials

Aggregate Coating See Practice

D70Test Method for Density of Semi-Solid Bituminous

D6998

Materials (Pycnometer Method)

Miscibility with Water See Practice

D6999

D86Test Method for Distillation of Petroleum Products and

Freezing See Practice

Liquid Fuels at Atmospheric Pressure

D6929

D113Test Method for Ductility of Bituminous Materials

Coating Ability and Water Resistance 11–18

Storage Stability of Asphalt Emulsion See Test Method

(Withdrawn 2016)

D6930

D128Test Methods for Analysis of Lubricating Grease

Examination of Residue 19–26

D139Test Method for Float Test for Bituminous Materials

Identification Test for Rapid Setting Cationic Emulsi- 27–34

fied Asphalt

D140Practice for Sampling Bituminous Materials

Identification of Cationic Slow Set Emulsions See Practice

D977Specification for Emulsified Asphalt

D7402

Field Coating Test on Emulsified Asphalts 35–40 D2042Test Method for Solubility of Asphalt Materials in

Trichloroethylene

1 2

These test methods and practices are under the jurisdiction ofASTM Commit- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tee D04 on Road and Paving Materials and are the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D04.42 on Emulsified Asphalt Test. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2017. Published October 2017. Originally the ASTM website.

approved in 1926. Last previous edition approved in 2009 as D244–09. DOI: The last approved version of this historical standard is referenced on

10.1520/D0244-09R17. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D244−09 (2017)

D2397Specification for Cationic Emulsified Asphalt D6999Practice for Miscibility of Emulsified Asphalts

D3289Test Method for Density of Semi-Solid and Solid D7402PracticeforIdentifyingCationicEmulsifiedAsphalts

Asphalt Materials (Nickel Crucible Method) D7403Test Method for Determination of Residue of Emul-

D6929Practice to Evaluate the Effect of Freezing on Emul- sified Asphalt by Low Temperature Vacuum Distillation

D7496Test Method for Viscosity of Emulsified Asphalt by

sified Asphalts

D6930Test Method for Settlement and Storage Stability of Saybolt Furol Viscometer

E1Specification for ASTM Liquid-in-Glass Thermometers

Emulsified Asphalts

D6933Test Method for Oversized Particles in Emulsified E11Specification forWovenWireTest Sieve Cloth andTest

Sieves

Asphalts (Sieve Test)

D6934Test Method for Residue by Evaporation of Emulsi- E145Specification for Gravity-Convection and Forced-

Ventilation Ovens

fied Asphalt

D6935Test Method for Determining Cement Mixing of

3. Sample Conditioning for Testing

Emulsified Asphalt

D6936TestMethodforDeterminingDemulsibilityofEmul- 3.1 All emulsions with viscosity requirements of 50°C

sified Asphalt should be heated to 50 6 3°C in the original sample container

D6937Test Method for Determining Density of Emulsified in a 71°C water bath or oven. The container should be vented

Asphalt torelievepressure.Afterthesamplereaches50 63°C,stirthe

D6997Test Method for Distillation of Emulsified Asphalt sample to achieve homogeneity.

D6998Practice for Evaluating Aggregate Coating using

Emulsified Asphalts

COMPOSITION

WATER CONTENT 6.6 Solvent—Xylol or other petroleum distillate conforming

to the following distillation requirements: 98% distills be-

4. Scope

tween 120 and 250°C. This distillation shall be conducted in

4.1 This test method covers the procedure for determining

accordance with Test Method D86.

the water content of an emulsified asphalt by reflux distillation

7. Sample

using a water trap.

7.1 Obtain a representative sample of the material for test

5. Significance and Use

using standard procedures as specified in Practice D140.

5.1 This test method measures the amount of water present

NOTE 1—The difficulties in obtaining representative samples for this

in the emulsified asphalt, as distinguished from either bitumen

determination are unusually great, so that the importance of sampling

or petroleum solvent.

cannot be too strongly emphasized.

6. Apparatus and Materials

8. Procedure

6.1 MetalStill—Themetalstill(Fig.1(a))shallbeavertical

8.1 When the material to be tested contains less than 25%

cylindrical vessel, preferably of copper, having a faced flange

water, place 100 6 0.1 g of sample in the still. When the

at the top to which the head is tightly attached by means of a

material contains more than 25% water, use a 50 6 0.1-g

clamp. The head shall be made of metal, preferably brass or

sample. Thoroughly mix the sample to be tested with 200 mL

copper,andshallbeprovidedwithatubulation25.4mm(1in.)

of solvent by swirling, taking proper care to avoid any loss of

in inside diameter.

material.

6.2 Glass Still—The glass still (Fig. 1(b)) shall be a short-

8.2 Connect the still, trap, and condenser by means of

neck, round-bottom flask, made of well-annealed glass, and

tight-fitting corks as shown in Fig. 1(a) or (b). Adjust the end

having an approximate capacity of 500 mL.

of the condenser in the trap to a position which will allow the

6.3 Heat Source—The heat source used with the metal still

end to be submerged to a depth of not more than 1 mm below

shall be a ring gas burner of 100-mm (4-in.) inside diameter or

the surface of the liquid in the trap after distillation conditions

an electric mantle heater. The heat source for the glass still

have been established. When using the metal still, insert a

shall be either an ordinary gas burner or an electric heater.

heavy paper gasket, moistened with the solvent, between the

lid and flange before attaching the clamp.

6.4 Condenser—The condenser shall be a water-cooled

reflux glass-tube type, having a jacket not less than 400 mm in

8.3 When the ring burner is used with the metal still, place

length, with an inner tube 9.5 to 12.7 mm in outside diameter.

it about 76.2 mm above the bottom of the still at the beginning

The end of the condenser shall be ground to an angle of 30 6

of the distillation, and gradually lower it as the distillation

5° from the vertical axis of the condenser.

proceeds. Regulate the heat so that the condensate falls from

6.5 Trap—The trap shall be made of annealed glass con- the end of the condenser at a rate of from 2 to 5 drops per

structed in accordance with Fig. 1(c) and shall be graduated in second. Continue the distillation at the specified rate until no

0.10-mL divisions from 0 to 2 mL, and in 0.20-mL divisions water is visible on any part of the apparatus and a constant

from2to25mL. volume of water is obtained in the trap. Remove any persistent

D244−09 (2017)

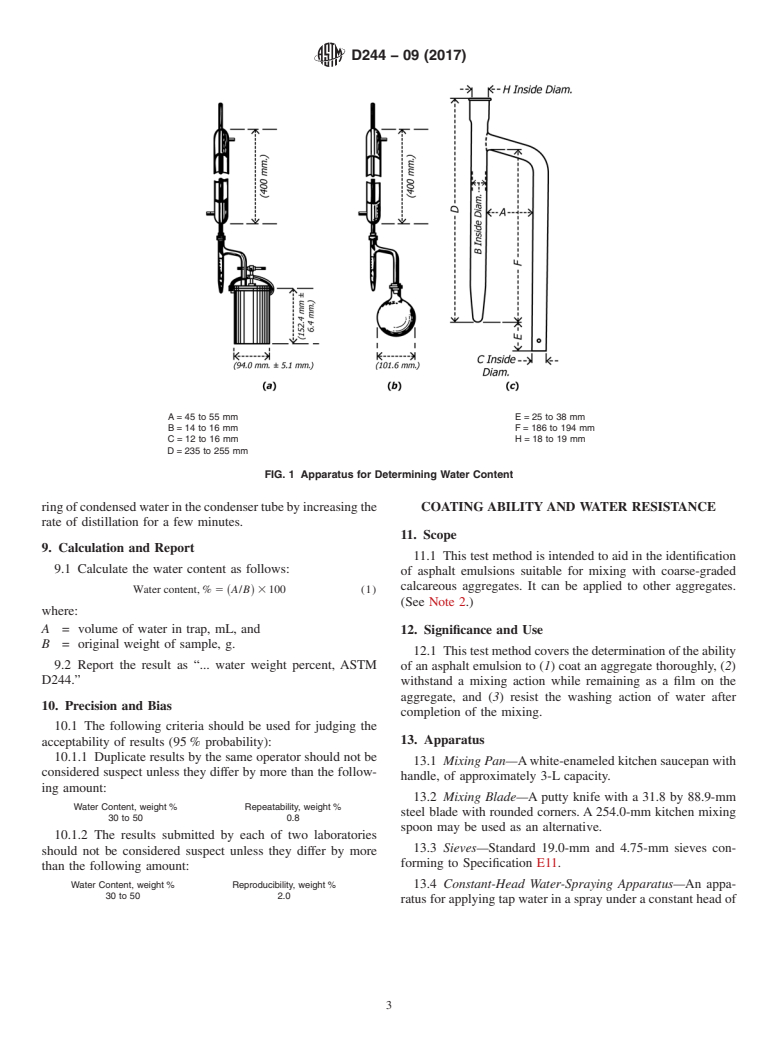

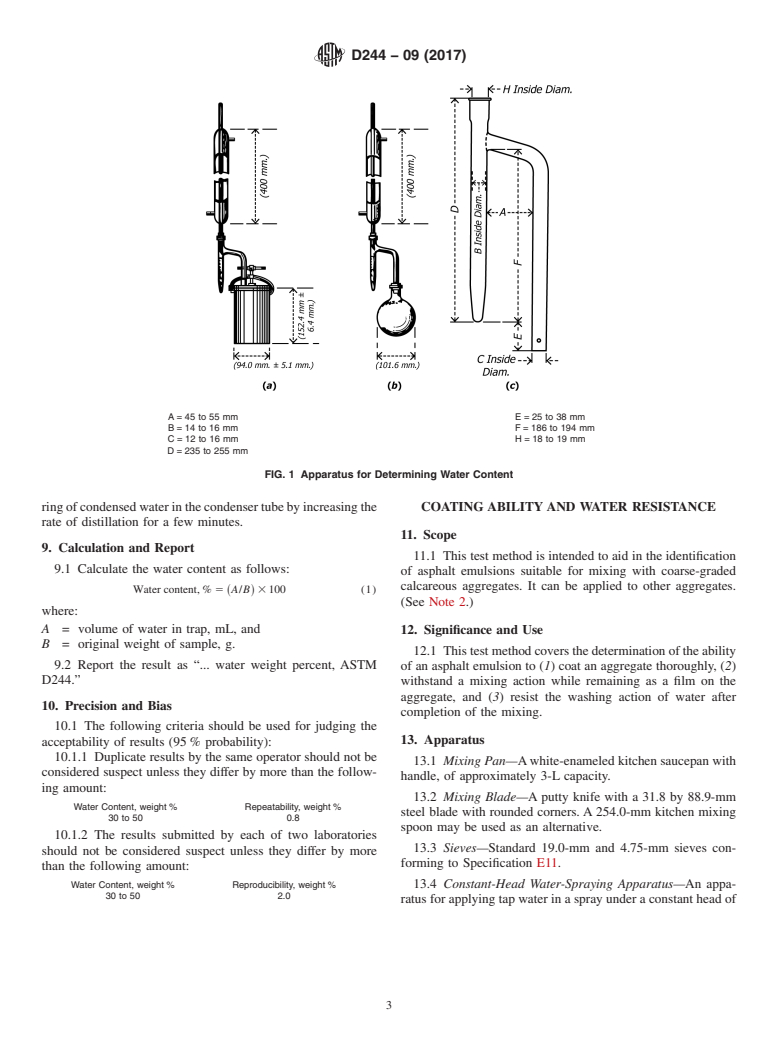

A=45to55mm E=25to38mm

B = 14 to 16 mm F = 186 to 194 mm

C=12to16mm H=18to19mm

D = 235 to 255 mm

FIG. 1 Apparatus for Determining Water Content

ringofcondensedwaterinthecondensertubebyincreasingthe COATING ABILITY AND WATER RESISTANCE

rate of distillation for a few minutes.

11. Scope

9. Calculation and Report

11.1 This test method is intended to aid in the identification

9.1 Calculate the water content as follows:

of asphalt emulsions suitable for mixing with coarse-graded

calcareous aggregates. It can be applied to other aggregates.

Watercontent,% 5 ~A/B! 3100 (1)

(See Note 2.)

where:

A = volume of water in trap, mL, and

12. Significance and Use

B = original weight of sample, g.

12.1 Thistestmethodcoversthedeterminationoftheability

9.2 Report the result as “. water weight percent, ASTM

of an asphalt emulsion to (1) coat an aggregate thoroughly, (2)

D244.”

withstand a mixing action while remaining as a film on the

aggregate, and (3) resist the washing action of water after

10. Precision and Bias

completion of the mixing.

10.1 The following criteria should be used for judging the

13. Apparatus

acceptability of results (95% probability):

10.1.1 Duplicate results by the same operator should not be

13.1 MixingPan—Awhite-enameledkitchensaucepanwith

considered suspect unless they differ by more than the follow-

handle, of approximately 3-L capacity.

ing amount:

13.2 Mixing Blade—A putty knife with a 31.8 by 88.9-mm

Water Content, weight % Repeatability, weight %

steel blade with rounded corners.A254.0-mm kitchen mixing

30 to 50 0.8

spoon may be used as an alternative.

10.1.2 The results submitted by each of two laboratories

13.3 Sieves—Standard 19.0-mm and 4.75-mm sieves con-

should not be considered suspect unless they differ by more

forming to Specification E11.

than the following amount:

Water Content, weight % Reproducibility, weight % 13.4 Constant-Head Water-Spraying Apparatus—An appa-

30 to 50 2.0

ratusforapplyingtapwaterinasprayunderaconstantheadof

D244−09 (2017)

1 in = 25.4 mm 8 in. = 230.2 mm

2 in. = 50.8 mm 1 ft = 304.8 mm

6 in. = 152.4 mm 1 ft 10 ⁄4 in. = 577.9 mm

3 1

7 ⁄4 in = 196.9 mm 2 ft 1 ⁄2 in. = 647.7 mm

2ft6 ⁄2 in. = 774.7 mm

NOTE 1—Use galvanized steel sheeting for the tank.All joints and fitting attachments shall be soldered and shall be watertight.All couplings shall be

standard brass garden hose fittings. The 19-mm pipe valve shall be placed as close as possible to the bottom of the tank, allowing space to shut off the

valve. The tank shall be placed on a suitable stand, so that the distance from the bottom of the spray head to the top of the test sample is 0.914 m 6

25.4 mm.

FIG. 2Constant-Head Flow Tank

774.7 mm (Figs. 2 and 3). The water shall issue from the 14.2 Calcium Carbonate—Chemically pure, precipitated

apparatus in a low-velocity spray. calciumcarbonate(CaCO )shallbeusedasadusttobemixed

with the standard reference aggregate.

13.5 Thermometer—An ASTM low softening point ther-

mometer 15F (or 15C), having a range from −2 to 80°C and 14.3 Water—Tap water of not over 250 ppm CaCO hard-

conforming to the requirements in Specification E1. ness for spraying over the sample.

13.6 Balance,capableofweighing1000gtowithin 60.1g.

15. Sample

13.7 Pipet, of 10-mL capacity.

15.1 The sample shall be representative of the asphalt

emulsion to be tested.

14. Materials

14.1 Aggregate—Standard reference aggregate shall be a

16. Procedure for Tests with Dry Aggregate

laboratory-washed and air-dried limestone aggregate graded to

16.1 Carry out the test at 23.9 6 5.5°C.

pass the 19.0-mm sieve and be retained on the 4.75-mm sieve.

16.2 Weigh 461 g of the air-dried, graded reference aggre-

NOTE 2—Aggregates other than limestone may be used, provided

gate in the mixing pan.

calcium carbonate is omitted throughout the test method. Laboratory

washing and air drying of such aggregates shall also be omitted.

16.3 Weigh 4.0 g of CaCO dust in the mixing pan and mix

with the 461 g of aggregate for approximately 1 min by means

of a mixing blade to obtain a uniform film of dust on the

Limestone from the Monon Stone Co. of Monon, IN, has been found suitable

as reference aggregate. aggregate particles.

D244−09 (2017)

NOTE 1—A Speakman, Model 235S, all brass, fixed shower head has been found acceptable.

NOTE 2—Existing 101.6-mm diameter shower heads may continue to be used.

NOTE 3—0.05 in. = 1.3 mm

6 in. = 152.4 mm

7 ⁄4 in. = 196.9 mm

FIG. 3Spray Nozzle Assembly

NOTE3—Thetotalweightofaggregateanddustshallequal465g.Ifno

overflow water runs clear. Carefully drain off the water in the

calcium carbonate is included, the weight of aggregate alone shall be

pan. Scoop the mixture from the mixing pan on to absorbent

465g.

paper for evaluation of coating retention in the washing test.

16.4 Weigh 35 g of the asphalt emulsion into the aggregate

16.7 Evaluate the mixture immediately by visual estimation

in the pan and mix vigorously with the mixing blade for 5 min

astothetotalaggregatesurfaceareathatiscoatedwithasphalt.

usingatossingactioncreatedbyaback-and-forthmotioninan

16.8 Repeat the evaluation by visual estimation of the

elliptical path of the mixing blade or spoon. At the end of the

coating of aggregate surface area by asphalt after the mixture

mixing period, tilt the pan and permit a

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D244 − 09 (Reapproved 2017) American Association State

Highway and Transportation Officials Standard

AASHTO No.: T59

Standard Test Methods and Practices for

Emulsified Asphalts

This standard is issued under the fixed designation D244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

Emulsified Asphalt/Job Aggregate Coating Test 41 – 46

Density of Emulsified Asphalt See Test Method

1.1 These test methods and practices, given under the

D6937

headings titled Composition, Consistency, Stability, and Ex- Residue by Low-Temperature Vacuum Distillation See Test Method

D7403

amination of Residue, cover the examination of asphalt emul-

1.2 The values stated in SI units are to be regarded as the

sions composed principally of a semisolid or liquid asphaltic

standard. The values given in parentheses are for information

base, water, and an emulsifying agent. The test methods cover

only.

the following tests and practices:

Test Sections 1.3 This standard does not purport to address all of the

Composition:

safety concerns, if any, associated with its use. It is the

Water Content 4 – 10

responsibility of the user of this standard to establish appro-

Residue and Oil Distillate by Distillation See Test Method

D6997 priate safety, health, and environmental practices and deter-

Residue by Evaporation See Test Method

mine the applicability of regulatory limitations prior to use.

D6934

1.4 This international standard was developed in accor-

Particle Charge of Cationic Emulsified Asphalts See Practice

D7402

dance with internationally recognized principles on standard-

Consistency:

ization established in the Decision on Principles for the

Viscosity (Saybolt Furol) See Test Method

Development of International Standards, Guides and Recom-

D7496

Stability:

mendations issued by the World Trade Organization Technical

Demulsibility See Test Method

Barriers to Trade (TBT) Committee.

D6936

Settlement See Test Method

2. Referenced Documents

D6930

Cement Mixing See Test Method 2

2.1 ASTM Standards:

D6935

C778 Specification for Standard Sand

Sieve Test See Test Method

D6933

D5 Test Method for Penetration of Bituminous Materials

Aggregate Coating See Practice

D70 Test Method for Density of Semi-Solid Bituminous

D6998

Materials (Pycnometer Method)

Miscibility with Water See Practice

D6999

D86 Test Method for Distillation of Petroleum Products and

Freezing See Practice

Liquid Fuels at Atmospheric Pressure

D6929

D113 Test Method for Ductility of Bituminous Materials

Coating Ability and Water Resistance 11 – 18

Storage Stability of Asphalt Emulsion See Test Method

(Withdrawn 2016)

D6930

D128 Test Methods for Analysis of Lubricating Grease

Examination of Residue 19 – 26

Identification Test for Rapid Setting Cationic Emulsi- 27 – 34 D139 Test Method for Float Test for Bituminous Materials

fied Asphalt

D140 Practice for Sampling Bituminous Materials

Identification of Cationic Slow Set Emulsions See Practice

D977 Specification for Emulsified Asphalt

D7402

Field Coating Test on Emulsified Asphalts 35 – 40 D2042 Test Method for Solubility of Asphalt Materials in

Trichloroethylene

1 2

These test methods and practices are under the jurisdiction of ASTM Commit- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tee D04 on Road and Paving Materials and are the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D04.42 on Emulsified Asphalt Test. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2017. Published October 2017. Originally the ASTM website.

approved in 1926. Last previous edition approved in 2009 as D244 – 09. DOI: The last approved version of this historical standard is referenced on

10.1520/D0244-09R17. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D244 − 09 (2017)

D2397 Specification for Cationic Emulsified Asphalt D6999 Practice for Miscibility of Emulsified Asphalts

D3289 Test Method for Density of Semi-Solid and Solid D7402 Practice for Identifying Cationic Emulsified Asphalts

Asphalt Materials (Nickel Crucible Method) D7403 Test Method for Determination of Residue of Emul-

sified Asphalt by Low Temperature Vacuum Distillation

D6929 Practice to Evaluate the Effect of Freezing on Emul-

sified Asphalts D7496 Test Method for Viscosity of Emulsified Asphalt by

Saybolt Furol Viscometer

D6930 Test Method for Settlement and Storage Stability of

Emulsified Asphalts E1 Specification for ASTM Liquid-in-Glass Thermometers

E11 Specification for Woven Wire Test Sieve Cloth and Test

D6933 Test Method for Oversized Particles in Emulsified

Asphalts (Sieve Test) Sieves

E145 Specification for Gravity-Convection and Forced-

D6934 Test Method for Residue by Evaporation of Emulsi-

fied Asphalt Ventilation Ovens

D6935 Test Method for Determining Cement Mixing of

3. Sample Conditioning for Testing

Emulsified Asphalt

D6936 Test Method for Determining Demulsibility of Emul- 3.1 All emulsions with viscosity requirements of 50 °C

sified Asphalt should be heated to 50 6 3 °C in the original sample container

D6937 Test Method for Determining Density of Emulsified in a 71 °C water bath or oven. The container should be vented

Asphalt to relieve pressure. After the sample reaches 50 6 3 °C, stir the

D6997 Test Method for Distillation of Emulsified Asphalt sample to achieve homogeneity.

D6998 Practice for Evaluating Aggregate Coating using

Emulsified Asphalts

COMPOSITION

WATER CONTENT 6.6 Solvent—Xylol or other petroleum distillate conforming

to the following distillation requirements: 98 % distills be-

4. Scope

tween 120 and 250 °C. This distillation shall be conducted in

4.1 This test method covers the procedure for determining

accordance with Test Method D86.

the water content of an emulsified asphalt by reflux distillation

7. Sample

using a water trap.

7.1 Obtain a representative sample of the material for test

5. Significance and Use

using standard procedures as specified in Practice D140.

5.1 This test method measures the amount of water present

NOTE 1—The difficulties in obtaining representative samples for this

in the emulsified asphalt, as distinguished from either bitumen

determination are unusually great, so that the importance of sampling

or petroleum solvent.

cannot be too strongly emphasized.

6. Apparatus and Materials

8. Procedure

6.1 Metal Still—The metal still (Fig. 1(a)) shall be a vertical

8.1 When the material to be tested contains less than 25 %

cylindrical vessel, preferably of copper, having a faced flange

water, place 100 6 0.1 g of sample in the still. When the

at the top to which the head is tightly attached by means of a

material contains more than 25 % water, use a 50 6 0.1-g

clamp. The head shall be made of metal, preferably brass or

sample. Thoroughly mix the sample to be tested with 200 mL

copper, and shall be provided with a tubulation 25.4 mm (1 in.)

of solvent by swirling, taking proper care to avoid any loss of

in inside diameter.

material.

6.2 Glass Still—The glass still (Fig. 1(b)) shall be a short-

8.2 Connect the still, trap, and condenser by means of

neck, round-bottom flask, made of well-annealed glass, and

tight-fitting corks as shown in Fig. 1(a) or (b). Adjust the end

having an approximate capacity of 500 mL.

of the condenser in the trap to a position which will allow the

6.3 Heat Source—The heat source used with the metal still

end to be submerged to a depth of not more than 1 mm below

shall be a ring gas burner of 100-mm (4-in.) inside diameter or

the surface of the liquid in the trap after distillation conditions

an electric mantle heater. The heat source for the glass still

have been established. When using the metal still, insert a

shall be either an ordinary gas burner or an electric heater.

heavy paper gasket, moistened with the solvent, between the

lid and flange before attaching the clamp.

6.4 Condenser—The condenser shall be a water-cooled

reflux glass-tube type, having a jacket not less than 400 mm in

8.3 When the ring burner is used with the metal still, place

length, with an inner tube 9.5 to 12.7 mm in outside diameter.

it about 76.2 mm above the bottom of the still at the beginning

The end of the condenser shall be ground to an angle of 30 6

of the distillation, and gradually lower it as the distillation

5° from the vertical axis of the condenser.

proceeds. Regulate the heat so that the condensate falls from

6.5 Trap—The trap shall be made of annealed glass con- the end of the condenser at a rate of from 2 to 5 drops per

structed in accordance with Fig. 1(c) and shall be graduated in second. Continue the distillation at the specified rate until no

0.10-mL divisions from 0 to 2 mL, and in 0.20-mL divisions water is visible on any part of the apparatus and a constant

from 2 to 25 mL. volume of water is obtained in the trap. Remove any persistent

D244 − 09 (2017)

A = 45 to 55 mm E = 25 to 38 mm

B = 14 to 16 mm F = 186 to 194 mm

C = 12 to 16 mm H = 18 to 19 mm

D = 235 to 255 mm

FIG. 1 Apparatus for Determining Water Content

ring of condensed water in the condenser tube by increasing the COATING ABILITY AND WATER RESISTANCE

rate of distillation for a few minutes.

11. Scope

9. Calculation and Report

11.1 This test method is intended to aid in the identification

9.1 Calculate the water content as follows:

of asphalt emulsions suitable for mixing with coarse-graded

calcareous aggregates. It can be applied to other aggregates.

Water content, % 5 A/B 3 100 (1)

~ !

(See Note 2.)

where:

A = volume of water in trap, mL, and 12. Significance and Use

B = original weight of sample, g.

12.1 This test method covers the determination of the ability

9.2 Report the result as “. water weight percent, ASTM

of an asphalt emulsion to (1) coat an aggregate thoroughly, (2)

D244.”

withstand a mixing action while remaining as a film on the

aggregate, and (3) resist the washing action of water after

10. Precision and Bias

completion of the mixing.

10.1 The following criteria should be used for judging the

13. Apparatus

acceptability of results (95 % probability):

10.1.1 Duplicate results by the same operator should not be

13.1 Mixing Pan—A white-enameled kitchen saucepan with

considered suspect unless they differ by more than the follow-

handle, of approximately 3-L capacity.

ing amount:

13.2 Mixing Blade—A putty knife with a 31.8 by 88.9-mm

Water Content, weight % Repeatability, weight %

steel blade with rounded corners. A 254.0-mm kitchen mixing

30 to 50 0.8

spoon may be used as an alternative.

10.1.2 The results submitted by each of two laboratories

13.3 Sieves—Standard 19.0-mm and 4.75-mm sieves con-

should not be considered suspect unless they differ by more

forming to Specification E11.

than the following amount:

Water Content, weight % Reproducibility, weight % 13.4 Constant-Head Water-Spraying Apparatus—An appa-

30 to 50 2.0

ratus for applying tap water in a spray under a constant head of

D244 − 09 (2017)

1 in = 25.4 mm 8 in. = 230.2 mm

2 in. = 50.8 mm 1 ft = 304.8 mm

6 in. = 152.4 mm 1 ft 10 ⁄4 in. = 577.9 mm

3 1

7 ⁄4 in = 196.9 mm 2 ft 1 ⁄2 in. = 647.7 mm

2 ft 6 ⁄2 in. = 774.7 mm

NOTE 1—Use galvanized steel sheeting for the tank. All joints and fitting attachments shall be soldered and shall be watertight. All couplings shall be

standard brass garden hose fittings. The 19-mm pipe valve shall be placed as close as possible to the bottom of the tank, allowing space to shut off the

valve. The tank shall be placed on a suitable stand, so that the distance from the bottom of the spray head to the top of the test sample is 0.914 m 6

25.4 mm.

FIG. 2 Constant-Head Flow Tank

774.7 mm (Figs. 2 and 3). The water shall issue from the 14.2 Calcium Carbonate—Chemically pure, precipitated

apparatus in a low-velocity spray. calcium carbonate (CaCO ) shall be used as a dust to be mixed

with the standard reference aggregate.

13.5 Thermometer—An ASTM low softening point ther-

mometer 15F (or 15C), having a range from −2 to 80 °C and 14.3 Water—Tap water of not over 250 ppm CaCO hard-

conforming to the requirements in Specification E1. ness for spraying over the sample.

13.6 Balance, capable of weighing 1000 g to within 60.1 g.

15. Sample

13.7 Pipet, of 10-mL capacity.

15.1 The sample shall be representative of the asphalt

emulsion to be tested.

14. Materials

14.1 Aggregate—Standard reference aggregate shall be a

16. Procedure for Tests with Dry Aggregate

laboratory-washed and air-dried limestone aggregate graded to

16.1 Carry out the test at 23.9 6 5.5 °C.

pass the 19.0-mm sieve and be retained on the 4.75-mm sieve.

16.2 Weigh 461 g of the air-dried, graded reference aggre-

NOTE 2—Aggregates other than limestone may be used, provided

gate in the mixing pan.

calcium carbonate is omitted throughout the test method. Laboratory

washing and air drying of such aggregates shall also be omitted.

16.3 Weigh 4.0 g of CaCO dust in the mixing pan and mix

with the 461 g of aggregate for approximately 1 min by means

4 of a mixing blade to obtain a uniform film of dust on the

Limestone from the Monon Stone Co. of Monon, IN, has been found suitable

as reference aggregate. aggregate particles.

D244 − 09 (2017)

NOTE 1—A Speakman, Model 235S, all brass, fixed shower head has been found acceptable.

NOTE 2—Existing 101.6-mm diameter shower heads may continue to be used.

NOTE 3—0.05 in. = 1.3 mm

6 in. = 152.4 mm

7 ⁄4 in. = 196.9 mm

FIG. 3 Spray Nozzle Assembly

NOTE 3—The total weight of aggregate and dust shall equal 465 g. If no

overflow water runs clear. Carefully drain off the water in the

calcium carbonate is included, the weight of aggregate alone shall be

pan. Scoop the mixture from the mixing pan on to absorbent

465 g.

paper for evaluation of coating retention in the washing test.

16.4 Weigh 35 g of the asphalt emulsion into the aggregate

16.7 Evaluate the mixture immediately by visual estimation

in the pan and mix vigorously with the mixing blade for 5 min

as to the total aggregate surface area that is coated with asphalt.

using a tossing action created by a back-and-forth motion in an

16.8 Repeat the evaluation by visual estimation of the

elliptical path of the mixing blad

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D244 − 09 D244 − 09 (Reapproved 2017) American Association State

Highway and Transportation Officials Standard

AASHTO No.: T59

Standard Test Methods and Practices for

Emulsified Asphalts

This standard is issued under the fixed designation D244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods and practices, given under the headings titled Composition, Consistency, Stability, and Examination of

Residue, cover the examination of asphalt emulsions composed principally of a semisolid or liquid asphaltic base, water, and an

emulsifying agent. The test methods cover the following tests and practices:

Test Sections

Composition:

Water Content 4 – 10

Residue and Oil Distillate by Distillation See Test Method

D6997

Residue by Evaporation See Test Method

D6934

Particle Charge of Cationic Emulsified Asphalts See Test Method

D7402

Particle Charge of Cationic Emulsified Asphalts See Practice

D7402

Consistency:

Viscosity (Saybolt Furol) See Test Method

D7496

Stability:

Demulsibility See Test Method

D6936

Settlement See Test Method

D6930

Cement Mixing See Test Method

D6935

Sieve Test See Test Method

D6933

Aggregate Coating See Practice

D6998

Miscibility with Water See Test Method

D6999

Miscibility with Water See Practice

D6999

Freezing See Practice

D6929

Coating Ability and Water Resistance 11 – 18

Storage Stability of Asphalt Emulsion See Test Method

D6930

Examination of Residue 19 – 26

Identification Test for Rapid Setting Cationic Emulsi- 27 – 34

fied Asphalt

Identification of Cationic Slow Set Emulsions See Test Method

D7402

Identification of Cationic Slow Set Emulsions See Practice

D7402

Field Coating Test on Emulsified Asphalts 35 – 40

Emulsified Asphalt/Job Aggregate Coating Test 41 – 46

These test methods and practices are under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and are the direct responsibility of Subcommittee

D04.42 on Emulsified Asphalt Test.

Current edition approved June 1, 2009Oct. 1, 2017. Published July 2009October 2017. Originally approved in 1926. Last previous edition approved in 20042009 as

D244 – 04.D244 – 09. DOI: 10.1520/D0244-09.10.1520/D0244-09R17.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D244 − 09 (2017)

Density of Emulsified Asphalt See Test Method

D6937

Residue by Low-Temperature Vacuum Distillation See Test Method

D7403

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C778 Specification for Standard Sand

D5 Test Method for Penetration of Bituminous Materials

D70 Test Method for Density of Semi-Solid Bituminous Materials (Pycnometer Method)

D86 Test Method for Distillation of Petroleum Products and Liquid Fuels at Atmospheric Pressure

D113 Test Method for Ductility of Bituminous Materials (Withdrawn 2016)

D128 Test Methods for Analysis of Lubricating Grease

D139 Test Method for Float Test for Bituminous Materials

D140 Practice for Sampling Bituminous Materials

D977 Specification for Emulsified Asphalt

D2042 Test Method for Solubility of Asphalt Materials in Trichloroethylene

D2397 Specification for Cationic Emulsified Asphalt

D3289 Test Method for Density of Semi-Solid and Solid Asphalt Materials (Nickel Crucible Method)

D6929 Practice to Evaluate the Effect of Freezing on Emulsified Asphalts

D6930 Test Method for Settlement and Storage Stability of Emulsified Asphalts

D6933 Test Method for Oversized Particles in Emulsified Asphalts (Sieve Test)

D6934 Test Method for Residue by Evaporation of Emulsified Asphalt

D6935 Test Method for Determining Cement Mixing of Emulsified Asphalt

D6936 Test Method for Determining Demulsibility of Emulsified Asphalt

D6937 Test Method for Determining Density of Emulsified Asphalt

D6997 Test Method for Distillation of Emulsified Asphalt

D6998 Practice for Evaluating Aggregate Coating using Emulsified Asphalts

D6999 Practice for Miscibility of Emulsified Asphalts

D7402 Practice for Identifying Cationic Emulsified Asphalts

D7403 Test Method for Determination of Residue of Emulsified Asphalt by Low Temperature Vacuum Distillation

D7496 Test Method for Viscosity of Emulsified Asphalt by Saybolt Furol Viscometer

E1 Specification for ASTM Liquid-in-Glass Thermometers

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E145 Specification for Gravity-Convection and Forced-Ventilation Ovens

3. Sample Conditioning for Testing

3.1 All emulsions with viscosity requirements of 50°C50 °C should be heated to 50 6 3°C3 °C in the original sample container

in a 71°C71 °C water bath or oven. The container should be vented to relieve pressure. After the sample reaches 50 6 3°C,3 °C,

stir the sample to achieve homogeneity.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

COMPOSITION

D244 − 09 (2017)

WATER CONTENT

4. Scope

4.1 This test method covers the procedure for determining the water content of an emulsified asphalt by reflux distillation using

a water trap.

4.2 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

4. Scope

4.1 This test method covers the procedure for determining the water content of an emulsified asphalt by reflux distillation using

a water trap.

5. Significance and Use

5.1 This test method measures the amount of water present in the emulsified asphalt, as distinguished from either bitumen or

petroleum solvent.

6. Apparatus and Materials

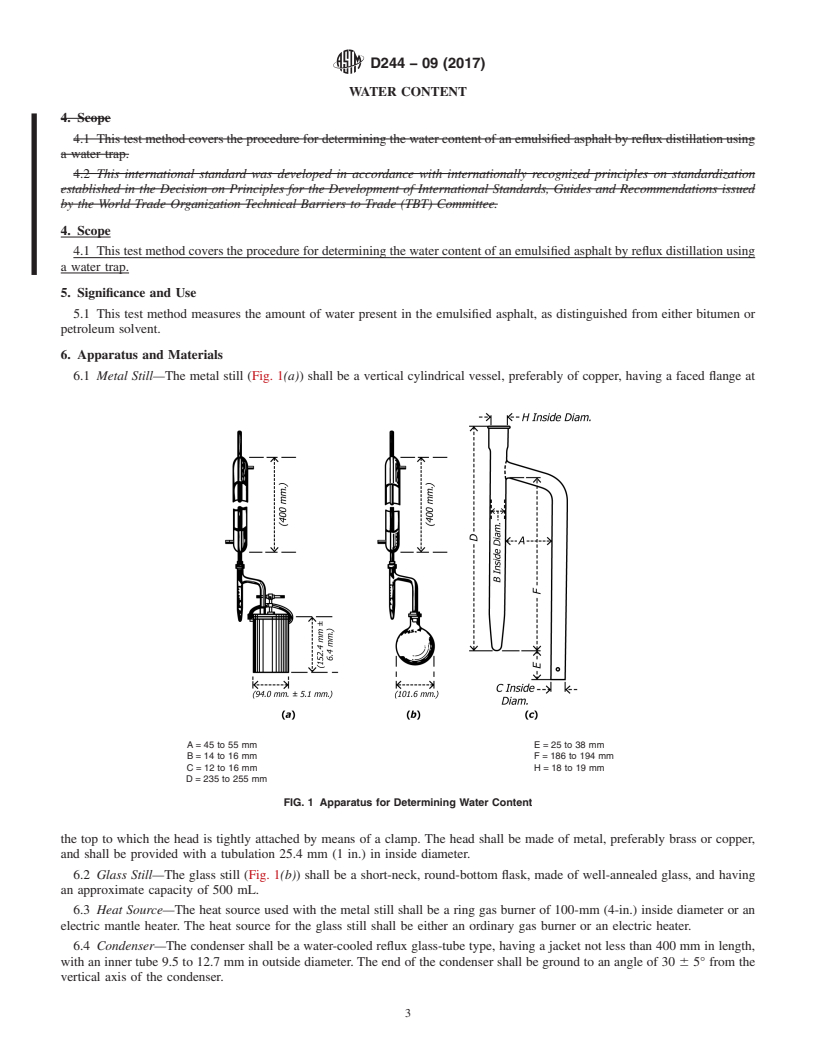

6.1 Metal Still—The metal still (Fig. 1(a)) shall be a vertical cylindrical vessel, preferably of copper, having a faced flange at

A = 45 to 55 mm E = 25 to 38 mm

B = 14 to 16 mm F = 186 to 194 mm

C = 12 to 16 mm H = 18 to 19 mm

D = 235 to 255 mm

FIG. 1 Apparatus for Determining Water Content

the top to which the head is tightly attached by means of a clamp. The head shall be made of metal, preferably brass or copper,

and shall be provided with a tubulation 25.4 mm (1 in.) in inside diameter.

6.2 Glass Still—The glass still (Fig. 1(b)) shall be a short-neck, round-bottom flask, made of well-annealed glass, and having

an approximate capacity of 500 mL.

6.3 Heat Source—The heat source used with the metal still shall be a ring gas burner of 100-mm (4-in.) inside diameter or an

electric mantle heater. The heat source for the glass still shall be either an ordinary gas burner or an electric heater.

6.4 Condenser—The condenser shall be a water-cooled reflux glass-tube type, having a jacket not less than 400 mm in length,

with an inner tube 9.5 to 12.7 mm in outside diameter. The end of the condenser shall be ground to an angle of 30 6 5° from the

vertical axis of the condenser.

D244 − 09 (2017)

6.5 Trap—The trap shall be made of annealed glass constructed in accordance with Fig. 1(c) and shall be graduated in 0.10-mL

divisions from 0 to 2 mL, and in 0.20-mL divisions from 2 to 25 mL.

6.6 Solvent—Xylol or other petroleum distillate conforming to the following distillation requirements: 98 % distills between 120

and 250°C.250 °C. This distillation shall be conducted in accordance with Test Method D86.

7. Sample

7.1 Obtain a representative sample of the material for test using standard procedures as specified in Practice D140.

NOTE 1—The difficulties in obtaining representative samples for this determination are unusually great, so that the importance of sampling cannot be

too strongly emphasized.

8. Procedure

8.1 When the material to be tested contains less than 25 % water, place 100 6 0.1 g of sample in the still. When the material

contains more than 25 % water, use a 50 6 0.1-g sample. Thoroughly mix the sample to be tested with 200 mL of solvent by

swirling, taking proper care to avoid any loss of material.

8.2 Connect the still, trap, and condenser by means of tight-fitting corks as shown in Fig. 1(a) or (b). Adjust the end of the

condenser in the trap to a position which will allow the end to be submerged to a depth of not more than 1 mm below the surface

of the liquid in the trap after distillation conditions have been established. When using the metal still, insert a heavy paper gasket,

moistened with the solvent, between the lid and flange before attaching the clamp.

8.3 When the ring burner is used with the metal still, place it about 76.2 mm above the bottom of the still at the beginning of

the distillation, and gradually lower it as the distillation proceeds. Regulate the heat so that the condensate falls from the end of

the condenser at a rate of from 2 to 5 drops per second. Continue the distillation at the specified rate until no water is visible on

any part of the apparatus and a constant volume of water is obtained in the trap. Remove any persistent ring of condensed water

in the condenser tube by increasing the rate of distillation for a few minutes.

9. Calculation and Report

9.1 Calculate the water content as follows:

Water content,%5 A/B 3100 (1)

~ !

where:

A = volume of water in trap, mL, and

B = original weight of sample, g.

9.2 Report the result as “. water weight percent, ASTM D244.”

10. Precision and Bias

10.1 The following criteria should be used for judging the acceptability of results (95 % probability):

10.1.1 Duplicate results by the same operator should not be considered suspect unless they differ by more than the following

amount:

Water Content, weight % Repeatability, weight %

30 to 50 0.8

10.1.2 The results submitted by each of two laboratories should not be considered suspect unless they differ by more than the

following amount:

Water Content, weight % Reproducibility, weight %

30 to 50 2.0

COATING ABILITY AND WATER RESISTANCE

11. Scope

11.1 This test method is intended to aid in the identification of asphalt emulsions suitable for mixing with coarse graded

calcareous aggregates. It can be applied to other aggregates. (See Note 2).

11.2 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

11. Scope

11.1 This test method is intended to aid in the identification of asphalt emulsions suitable for mixing with coarse-graded

calcareous aggregates. It can be applied to other aggregates. (See Note 2.)

D244 − 09 (2017)

1 in = 25.4 mm 8 in. = 230.2 mm

2 in. = 50.8 mm 1 ft = 304.8 mm

6 in. = 152.4 mm 1 ft 10 ⁄4 in. = 577.9 mm

3 1

7 ⁄4 in = 196.9 mm 2 ft 1 ⁄2 in. = 647.7 mm

2 ft 6 ⁄2 in. = 774.7 mm

NOTE 1—Use galvanized steel sheeting for the tank. All joints and fitting attachments shall be soldered and shall be watertight. All couplings shall be

standard brass garden hose fittings. The 19-mm pipe valve shall be placed as close as possible to the bottom of the tank, allowing space to shut off the

valve. The tank shall be placed on a suitable stand, so that the distance from the bottom of the spray head to the top of the test sample is 0.914 m 6

25.4 mm.

FIG. 2 Constant-Head Flow Tank

12. Significance and Use

12.1 This test method covers the determination of the ability of an asphalt emulsion to (1) coat an aggregate thoroughly, (2)

withstand a mixing action while remaining as a film on the aggregate, and (3) resist the washing action of water after completion

of the mixing.

13. Apparatus

13.1 Mixing Pan—A white-enameled kitchen saucepan with handle, of approximately 3-L capacity.

13.2 Mixing Blade—A putty knife with a 31.8 by 88.9-mm steel blade with rounded corners. A 254.0-mm kitchen mixing spoon

may be used as an alternative.

13.3 Sieves—Standard 19.0-mm and 4.75-mm sieves conforming to Specification E11.

13.4 Constant-Head Water-Spraying Apparatus—An apparatus for applying tap water in a spray under a constant head of 774.7

mm (Figs. 2 and 3). The water shall issue from the apparatus in a low-velocity spray.

13.5 Thermometer—An ASTM Low Softening Point Thermometerlow softening point thermometer 15F (or 15C), having a

range from −2 to 80°C80 °C and conforming to the requirements in Specification E1.

13.6 Balance, capable of weighing 1000 g to within 60.1 g.

13.7 Pipet, of 10-mL capacity.

D244 − 09 (2017)

NOTE 1—A Speakman, Model 235S, all brass, fixed shower head has been found acceptable.

NOTE 2—Existing 101.6-mm diameter shower heads may continue to be used.

NOTE 3—0.05 in. = 1.3 mm

6 in. = 152.4 mm

7 ⁄4 in. = 196.9 mm

FIG. 3 Spray Nozzle Assembly

14. Materials

14.1 Aggregate—Standard reference aggregate shall be a laboratory-washed and air-dried limestone aggregate graded to pass

the 19.0-mm sieve and be retained on the 4.75-mm sieve.

NOTE 2—Aggregates other than limestone may be used, provided calcium carbonate is omitted throughout the test method. Laboratory washing and

air-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.