ASTM B919-01

(Specification)Standard Specification for Welded Copper Heat Exchanger Tubes With Internal Enhancement

Standard Specification for Welded Copper Heat Exchanger Tubes With Internal Enhancement

SCOPE

1.1 This specification establishes the requirements for welded, internally enhanced copper tube, in straight lengths or coils, suitable for use in refrigeration and air conditioning products or other heat exchangers.

1.2 UnitsThe values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

1.3 The product shall be produced of the following coppers. Unless otherwise specified, tubes made from any one of these coppers may be supplied:Copper UNS No.Type of MetalC10200Oxygen-free without residual deoxidantsC12200Phosphorized, high residual phosphorus (DHP)

1.4 The following pertains to the test method described in 18.4 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 919 – 01

Standard Specification for

Welded Copper Heat Exchanger Tubes With Internal

Enhancement

This standard is issued under the fixed designation B 919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Determine Conformance with Specifications

E 53 Test Methods for Determination of Copper in Unal-

1.1 This specification establishes the requirements for

loyed Copper by Gravimetry

welded, internally enhanced copper tube, in straight lengths or

E 62 Test Methods for Chemical Analysis of Copper and

coils, suitable for use in refrigeration and air conditioning

Copper Alloys (Photometric Methods)

products or other heat exchangers.

E 112 Test Methods for Determining Average Grain Size

1.2 Units—The values stated in inch-pound units are to be

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

regarded as standard. The values given in parentheses are

nation of Copper and Copper-Alloy Tubes

mathematical conversions to SI units, which are provided for

E 255 Practice for Sampling Copper and CopperAlloys for

information only and are not considered standard.

the Determination of Chemical Composition

1.3 The product shall be produced of the following coppers.

Unless otherwise specified, tubes made from any one of these

3. Terminology

coppers may be supplied:

3.1 For the definition of terms related to copper and copper

Copper UNS No. Type of Metal

alloys refer to Terminology B 846.

C10200 Oxygen-free without residual deoxidants

3.2 Definitions:

C12200 Phosphorized, high residual phosphorus (DHP)

3.2.1 bottom wall, n—the wall thickness measured from the

1.4 The following pertains to the test method described in base of the enhancement to the outside surface.

18.4 of this specification. This standard does not purport to 3.2.2 coil, n—a length of the product wound into a series of

address all of the safety concerns, if any, associated with its connected turns.

use. It is the responsibility of the user of this standard to

3.2.3 enhancement, n—a geometrical feature intentionally

establish appropriate safety and health practices and deter- formed on a tube I.D. surface to improve heat transfer.

mine the applicability of regulatory requirements prior to use. 3.2.4 level wound, adj—a type of coil in which the turns are

wound into layers parallel to the axis of the coil such that

2. Referenced Documents

successive turns in a given layer are next to one another.

2.1 ASTM Standards:

3.3 Definitions of Terms Specific to This Standard:

B 153 Test Method for Expansion (Pin Test) of Copper and 3.3.1 roundness tolerance, n—the roundness tolerance is

Copper-Alloy Pipe and Tubing

defined as the maximum OD at a point minus the minimum

B 577 Test Methods for Detection of Cuprous Oxide (Hy- OD, at the same plane of intersection of the tube, divided by

drogen Embrittlement Susceptibility) in Copper

the specified OD 3 100 %.

B 601 Classification for Temper Designations for Copper 3.3.2 squareness of cut, n—the maximum deviation of one

and Copper Alloys—Wrought and Cast

side of a cross section from the opposite side, when measured

B 846 Terminology for Copper and Copper Alloys against the projected perpendicularity of the plane of the

E 3 Practice for Preparation of Metallographic Specimens

projected center of the tube at the ends.

E 8 Test Methods forTensionTesting of Metallic Materials

4. Classification

E 29 Practice for Using Significant Digits in Test Data to

4.1 The following types of welded tube are manufactured

under the scope of this specification:

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

Current edition approved Oct. 10, 2001. Published December 2001.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 02.01.

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 919

TABLE 1 Chemical Requirements

4.1.1 As-Welded—Welded tube without subsequent heat

treatment or cold work. UNS Alloy Number Copper, wt % Phosphorus, wt %

A

4.1.2 Welded Tube, Subsequently Annealed—Welded tube

C10200 99.95 min

C12200 99.9 min 0.015 - 0.040

annealed to produce a uniform grain size appropriate to the

A

specified annealed temper. Oxygen in C10200 shall be 10 ppm max.

5. Ordering Information

5.1 Include the following information when placing orders

7.2 These compositional limits do not preclude the possible

for product under this specification:

presence of other unnamed elements. When required, limits

5.1.1 ASTM designation number and year of issue,

and analysis for unnamed elements shall be established by

5.1.2 Copper UNS No.,

agreement between the manufacturer and the purchaser.

5.1.3 Tube type (Section 4),

5.1.4 Temper (Section 8),

8. Temper

5.1.5 Length, diameter, bottom-wall thickness, and en-

8.1 Tempers, as defined in Classification B 601, of the

hancement dimensions. Configuration of the enhanced surface

various tube types are as follows:

shall be as agreed upon between the manufacturer, or supplier,

8.1.1 As-Welded:

and purchaser,

8.1.1.1 Annealed strip WM50, subsequently internally en-

5.1.6 How furnished: straight or coils,

hanced by cold working and welded.

5.1.7 Quantity,

8.1.2 Welded and Annealed:

5.1.8 Cuprous oxide test, if required (12.3 and 16.1.4),

8.1.2.1 Annealed strip, internally enhanced by cold work-

5.1.9 Certification, when required (Section 22), and

ing, welded and soft annealed W060, and

5.1.10 Mill test report, if required (Section 23).

8.1.2.2 Annealed strip, internally enhanced by cold work-

ing, welded and light annealed W050.

6. Materials and Manufacture

NOTE 1—By agreement with the purchaser and manufacturer, product

6.1 Material:

in special tempers may be supplied with properties as agreed upon

6.1.1 The material of manufacture shall be sheet or strip, of

between the purchaser and the manufacturer.

the required alloy, and may be either cold worked or annealed.

6.1.2 The material shall be of such purity and soundness as

9. Grain Size for Annealed Tempers

to be suitable for processing into the product prescribed herein.

9.1 Samples of annealed temper tubes shall be examined at

6.2 Manufacture:

a magnification of 75 diameters. The grain size shall be

6.2.1 The welded tube shall be manufactured from either

determined in the wall beneath the internal enhancement. The

coldrolledorannealedsheetorstrip.Thesheetorstripshallbe

microstructure shall show complete recrystallization and shall

formed into a tubular shape on a suitable forming mill.

have an average grain size within the limits specified in Table

6.2.2 Welding shall be accomplished by any process that

2.

producesforgeorfusionweldsleavingnocrevicevisibletothe

9.2 The surface of the test specimen for the microscopical

unaided eye in the weld seam.

examination shall approximate a radial longitudinal section of

6.2.2.1 Forge—Welded Tube—The edges of the strip shall

the tube.

be heated to the required welding temperature, usually by a

high frequency electric current, and be pressed firmly together

10. Mechanical Properties

causing a forged-type joint to be formed with internal and

10.1 WM (as-welded) and WO (annealed) temper shall

external flash.

conform to the mechanical properties as specified in Table 2.

6.2.2.2 Fusion—Welded Tube—The edges of the tube shall

10.2 If disagreement arises between the grain size require-

be brought together and welded, usually by a GTAW welding

ment and the mechanical property requirements for annealed

process, without the addition of filler metal, causing a fusion-

tempers, the mechanical property requirements take precedent.

type joint to be formed with no internal or external flash.

6.2.2.3 Flash Removal—The external flash of forge welded

11. Performance Requirements

tubes, if present, shall be removed by scarfing. The internal

flash shall be treated by one of the following techniques: (1) 11.1 Expansion Requirements:

IFI—internal flash to remain in the as-welded condition, (2)

IFR—internal flash to be removed by scarfing, and (3) IFD—

internal flash displaced by rolling or drawing. TABLE 2 Mechanical Property Requirements of As-Fabricated

and Annealed Tube

6.2.3 The internal enhancement shall be produced by cold

forming. Elongation in

Average Grain Tensile Strength, Yield Strength,

Temper 2 in. (51 mm),

A B

6.2.4 The longitudinal seam from welding shall be free of

Size, mm ksi (Mpa) ksi (Mpa)

min %

filler metal.

WM . . . 30 min (205 min) . . . . . .

WO60 0.040 min. 30 min (205 min) 6 (40) min 35

7. Chemical Composition

WO50 0.040 max 30 min (205 min) 9-15 (60 - 105) 35

7.1 The material shall conform to the requirements in Table A

ksi = 1000 psi.

B

1 for the copper specified in the contract or purchase order. Yield strength to be determined at 0.5 % extension under load.

B 919

11.1.1 The annealed material shall be capable of being that the product does not meet this requirement, the product

expanded in accordance with Test Method B 153 with an shall be subject to either rejection, or recall or both. See 18.4

expansion of the outside diameter in the following percentage:

for the test method.

Outside Diameter, Expansion of Outside

12.3 Cuprous Oxide Requirement:

in. (mm) Diameter, %

12.3.1 Product manufactured from Copper UNS Alloy

0.750 in. (19.0) and under 30

C10200 shall be significantly free of cuprous oxide as deter-

Over 0.750 in. (19.0) 20

mined by Procedure A of Test Methods B 577.

11.1.2 The expanded tube shall show no cracking or rupture

visible to the unaided eye.

13. Dimensions, Mass, and Permissible Variations

13.1 The standard method for specifying tube diameters and

12. Other Requirements

walls shall be decimal fractions of an inch.

12.1 Nondestructive Examination for Defects:

13.2 Tolerances on a given tube are permitted to be speci-

12.1.1 Each tube shall be subjected to an eddy-current test.

fied with respect to any two but not all three of the following:

Tubes shall normally be tested in the fabricated temper;

outside diameter, inside diameter, and bottom-wall thickness.

however, they may be tested in the annealed temper at the

13.3 For the purposes of determining conformance with the

option of the manufacturer.

dimensional requirements in this specification, any measured

12.1.2 Electromagnetic (Eddy-Current) Test:

value outside the specified limiting values for any dimension

12.1.2.1 The testing shall follow the procedures specified in

shall be cause for rejection.

Practice E 243. Unless otherwise agreed upon between the

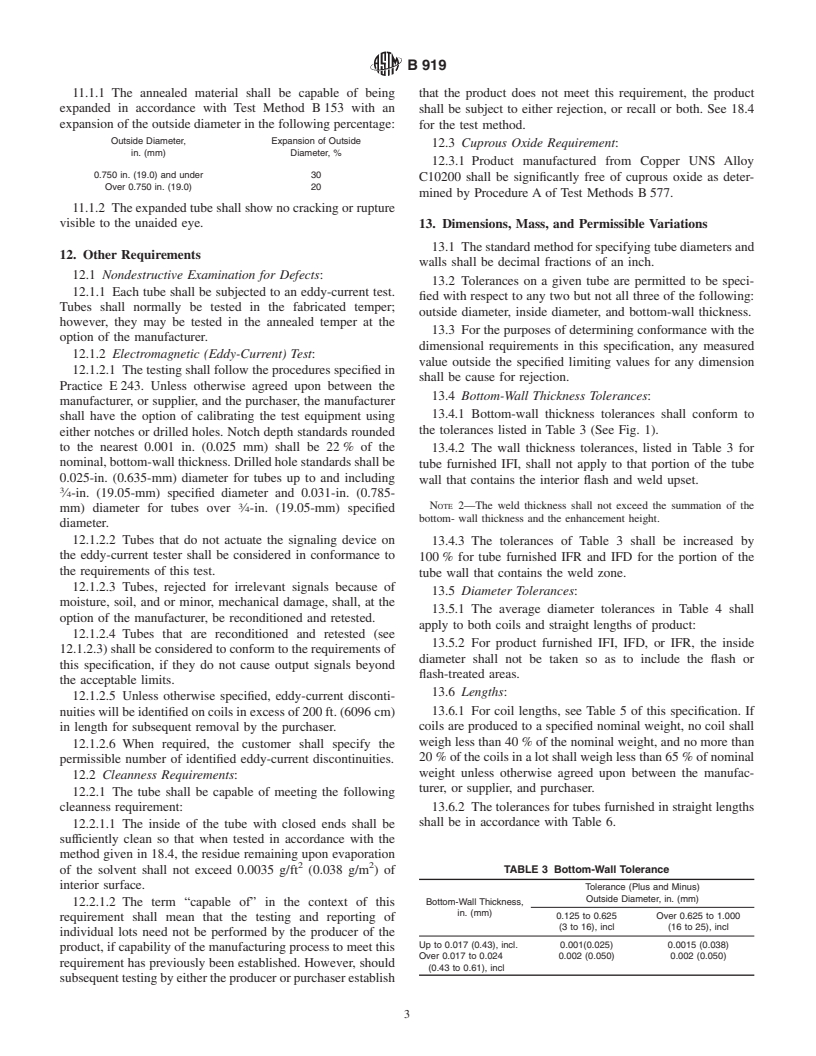

13.4 Bottom-Wall Thickness Tolerances:

manufacturer, or supplier, and the purchaser, the manufacturer

13.4.1 Bottom-wall thickness tolerances shall conform to

shall have the option of calibrating the test equipment using

the tolerances listed in Table 3 (See Fig. 1).

either notches or drilled holes. Notch depth standards rounded

to the nearest 0.001 in. (0.025 mm) shall be 22 % of the

13.4.2 The wall thickness tolerances, listed in Table 3 for

nominal, bottom-wall thickness. Drilled hole standards shall be

tube furnished IFI, shall not apply to that portion of the tube

0.025-in. (0.635-mm) diameter for tubes up to and including

wall that contains the interior flash and weld upset.

⁄4-in. (19.05-mm) specified diameter and 0.031-in. (0.785-

3 NOTE 2—The weld thickness shall not exceed the summation of the

mm) diameter for tubes over ⁄4-in. (19.05-mm) specified

bottom- wall thickness and the enhancement height.

diameter.

12.1.2.2 Tubes that do not actuate the signaling device on

13.4.3 The tolerances of Table 3 shall be increased by

the eddy-current tester shall be considered in conformance to

100 % for tube furnished IFR and IFD for the portion of the

the requirements of this test.

tube wall that contains the weld zone.

12.1.2.3 Tubes, rejected for irrelevant signals because of

13.5 Diameter Tolerances:

moisture, soil, and or minor, mechanical damage, shall, at the

13.5.1 The average diameter tolerances in Table 4 shall

option of the manufacturer, be reconditioned and retested.

apply to both coils and straight lengths of product:

12.1.2.4 Tubes that are reconditioned and retested (see

13.5.2 For product furnished IFI, IFD, or IFR, the inside

12.1.2.3) shall be considered to conform to the requirements of

diameter shall not be taken so as to include the flash or

this specification, if they do not cause output signals beyond

flash-treated areas.

the acceptable limits.

13.6 Lengths:

12.1.2.5 Unless otherwise specified, eddy-current disconti-

13.6.1 For coil lengths, see Table 5 of this specification. If

nuities will be identified on coils in excess of 200 ft. (6096 cm)

coils are produced to a specified nominal weight, no coil shall

in length for subsequent removal by the purchaser.

weigh less than 40 % of the nominal weight, and no more than

12.1.2.6 When required, the customer shall specify the

20 % of the coils in a lot shall weigh less than 65 % of nominal

permissible number of identified eddy-current discontinuities.

weight unless otherwise agreed upon between the manufac-

12.2 Cleanness Requirements:

turer, or supplier, and purchaser.

12.2.1 The tube shall be capable of meeting the following

13.6.2 The tolerances for tubes furnished in straight lengths

cleanness requirement:

shall be in accordance with Table 6.

12.2.1.1 The inside of the tube with closed ends shall be

sufficiently clean so that when tested in accordance with the

method given in 18.4, the residue remaining upon evaporation

2 2

TABLE 3 Bottom-Wall Tolerance

of the solvent shall not exceed 0.0035 g/ft (0.038 g/m)of

interior surface.

Tolerance (Plus and Minus)

Outside Diameter, in. (mm)

Bottom-Wall Thickness,

12.2.1.2 The term “capable of” in the context of this

in. (mm)

0.125 to 0.625 Over 0.625 to 1.000

requirement shall mean that the testing and reporting of

(3 to 16), incl (16 to 25), incl

individual lots need not be performed by the producer of the

Up to 0.017 (0.43), incl. 0.001(0.025) 0.0015 (0.038)

product, if capability of the manufacturing process to meet this

Over 0.017 to 0.024 0.002 (0.050) 0.002 (0.050)

requirement has previously been established. However, should

(0.43 to 0.61), incl

subsequenttestingbyeithertheproducerorpurchaserestablish

B 919

FIG. 1 Bottom-Wall Thickness Tolerances

TABLE 4 Average Diameter Toler

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.