ASTM C834-14

(Specification)Standard Specification for Latex Sealants

Standard Specification for Latex Sealants

ABSTRACT

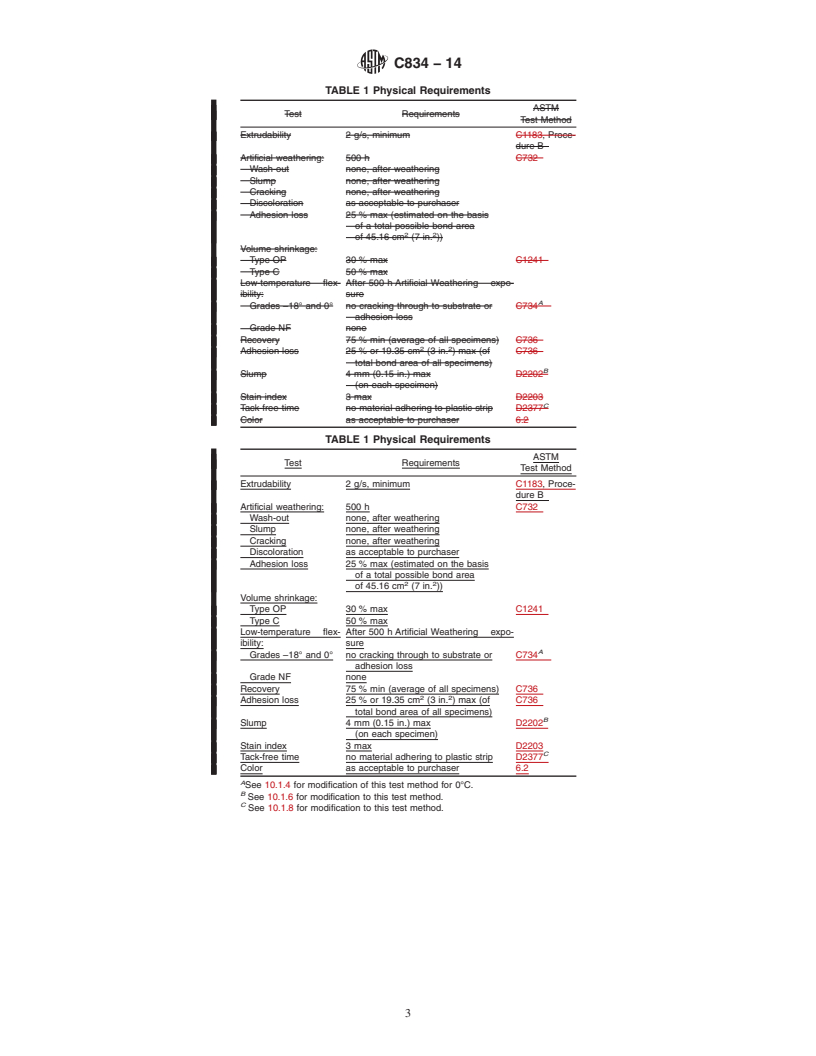

This specification covers latex sealants used for sealing joints in building construction. The following are the type and grade of sealant under this specification: Type OP, Type C, Grade 18°C, Grade 0°C, and Grade NF. The sealant shall be composed of latex formulated with appropriate fillers, pigments, and chemical additives. The physical properties of the sealant shall conform to the specified requirements according to type and grade. The following tests shall be done: extrudability after aging, artificial weathering, volume shrinkage, low-temperature flexibility, extension-recovery and adhesion, slump, staining, and tack-free time.

SIGNIFICANCE AND USE

8.1 This specification covers two types and three grades of latex sealants as described in Section 4 that are formulated for general caulking and sealing operations in building construction. It should be recognized by the user that not all sealants meeting this specification are suitable for all applications and all substrates. It is essential, therefore, that the type and grade be specified for proper description of a sealant. Test methods relate to special standard substrates of glass, wood and aluminum. If tests are required using substrates in addition to or other than standard, they should be so specified for testing.

8.2 Refer to Guide C1193 for information on the proper use of sealants meeting this specification.

SCOPE

1.1 This specification covers one component latex sealants used for sealing joints in building construction.

1.2 A sealant meeting the requirements of this specification shall be classified by the manufacturer to be one of the types and grades defined in Section 4.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound in parenthesis are provided for information purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 10, of this Specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1: Currently, there is no ISO standard similar to this specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C834 −14

Standard Specification for

1

Latex Sealants

This standard is issued under the fixed designation C834; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C1241 Test Method for Volume Shrinkage of Latex Sealants

During Cure

1.1 This specification covers one component latex sealants

D2202 Test Method for Slump of Sealants

used for sealing joints in building construction.

D2203 Test Method for Staining from Sealants

1.2 A sealant meeting the requirements of this specification

D2377 Test Method for Tack-Free Time of Caulking Com-

shall be classified by the manufacturer to be one of the types

pounds and Sealants

and grades defined in Section 4.

3. Terminology

1.3 The values stated in SI units are to be regarded as the

standard. The inch-pound in parenthesis are provided for

3.1 Definitions—Definitions of the following terms apply to

information purposes only. thisspecificationandarefoundinTerminologyC717:adhesive

failure (adhesion loss), cure, joint, latex sealant, sealant,

1.4 The following precautionary caveat pertains only to the

shrinkage (volume), standard conditions, and substrate.

test method portion, Section 10, of this Specification:This

standard does not purport to address all of the safety concerns,

4. Classification of Sealants

if any, associated with its use. It is the responsibility of the user

4.1 A sealant qualifying under this specification shall be

of this standard to establish appropriate safety and health

classified by type and grade as follows:

practices and determine the applicability of regulatory limita-

4.1.1 Type OP—An opaque sealant containing color pig-

tions prior to use.

ments or extender pigments, or both, that has no more than

NOTE 1—Currently, there is no ISO standard similar to this specifica-

30 % volume shrinkage (see 10.1.3).

tion.

4.1.2 Type C—A clear or translucent sealant that has no

more than 50 % volume shrinkage (see 10.1.3).

2. Referenced Documents

4.1.3 Grade –18°C—A sealant that meets the requirements

2

2.1 ASTM Standards:

for low temperature flexibility (see 7.1) when tested at –18°C

C717 Terminology of Building Seals and Sealants

(0°F).

C732 Test Method forAging Effects ofArtificialWeathering

4.1.4 Grade 0°C—Asealant that meets the requirements for

on Latex Sealants

low temperature flexibility (see 7.1) when tested at 0°C (32°F).

C734 Test Method for Low-Temperature Flexibility of Latex

4.1.5 Grade NF—A sealant that does not meet the require-

Sealants After Artificial Weathering

ments for low temperature flexibility of Grade 0°C (see 4.1.4).

C736 Test Method for Extension-Recovery andAdhesion of

Latex Sealants

5. Materials and Manufacture

C1183 Test Method for Extrusion Rate of Elastomeric Seal-

5.1 The sealant shall be composed of latex formulated with

ants

appropriatefillers,pigments,andchemicaladditivestoresultin

C1193 Guide for Use of Joint Sealants

conformance to this specification.

5.2 All material and workmanship shall be in accordance

with good commercial practice. The producer is permitted a

1

This specification is under the jurisdiction of ASTM Committee C24 on

wide latitude in choice of raw materials for making these

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10

on Specifications, Guides and Practices.

products. Consequently, there is no implication that the com-

CurrenteditionapprovedJune1,2014.PublishedJuly2014.Originallyapproved

pounds are equivalent in all physical properties.

in 1976. Last previous edition approved in 2010 as C834 – 10. DOI: 10.1520/

C0834-14.

5.3 The manufacturing process shall be such as will ensure

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

a homogeneous mix, free of defects that would affect

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

serviceability, and provide a consistency suitable for immedi-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ate application.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C834−14

6. General Requirements num. If tests are required using substrates in addition to or

other than standard, they should be so specified for testing.

6.1 The sealant in the original unopened container shall

8.2 Refer to Guide C1193 for information on the proper use

meet the requirements of this specification for at least 12

of sealants meeting this spe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C834 − 10 C834 − 14

Standard Specification for

1

Latex Sealants

This standard is issued under the fixed designation C834; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers one component latex sealants used for sealing joints in building construction.

1.2 A sealant meeting the requirements of this specification shall be classified by the manufacturer to be one of the types and

grades defined in Section 4.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound in parenthesis are provided for information

purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 10, of this Specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—Currently, there is no ISO standard similar to this specification.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

C732 Test Method for Aging Effects of Artificial Weathering on Latex Sealants

C734 Test Method for Low-Temperature Flexibility of Latex Sealants After Artificial Weathering

C736 Test Method for Extension-Recovery and Adhesion of Latex Sealants

C1183 Test Method for Extrusion Rate of Elastomeric Sealants

C1193 Guide for Use of Joint Sealants

C1241 Test Method for Volume Shrinkage of Latex Sealants During Cure

D2202 Test Method for Slump of Sealants

D2203 Test Method for Staining from Sealants

D2377 Test Method for Tack-Free Time of Caulking Compounds and Sealants

3. Terminology

3.1 Definitions—Definitions of the following terms apply to this specification and are found in Terminology C717: adhesive

failure (adhesion loss), cure, joint, latex sealant, sealant, shrinkage (volume), standard conditions, and substrate.

4. Classification of Sealants

4.1 A sealant qualifying under this specification shall be classified by type and grade as follows:

4.1.1 Type OP—An opaque sealant containing color pigments or extender pigments, or both, that has no more than 30 % volume

shrinkage (see 10.1.3).

4.1.2 Type C—A clear or translucent sealant that has no more than 50 % volume shrinkage (see 10.1.3).

4.1.3 Grade –18°C—A sealant that meets the requirements for low temperature flexibility (see 7.1) when tested at –18°C (0°F).

4.1.4 Grade 0°C—A sealant that meets the requirements for low temperature flexibility (see 7.1) when tested at 0°C (32°F).

4.1.5 Grade NF—A sealant that does not meet the requirements for low temperature flexibility of Grade 0°C (see 4.1.4).

1

This specification is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10 on

Specifications, Guides and Practices.

Current edition approved Jan. 1, 2010June 1, 2014. Published February 2010July 2014. Originally approved in 1976. Last previous edition approved in 20052010 as

C834 – 05.C834 – 10. DOI: 10.1520/C0834-10.10.1520/C0834-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C834 − 14

5. Materials and Manufacture

5.1 The sealant shall be composed of latex formulated with appropriate fillers, pigments, and chemical additives to result in

conformance to this specification.

5.2 All material and workmanship shall be in accordance with good commercial practice. The producer is permitted a wide

latitude in choice of raw materials for making these products. Consequently, there is no implication that the compounds are

equivalent in all physical properties.

5.3 The manufacturing process shall be such as will ensure a homogeneous mix, free of defects that would affect serviceability,

and provide a consistency suitable for immediate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.