ASTM E468-18

(Practice)Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

SIGNIFICANCE AND USE

4.1 Fatigue test results may be significantly influenced by the properties and history of the parent material, the operations performed during the preparation of the fatigue specimens, and the testing machine and test procedures used during the generation of the data. The presentation of fatigue test results should include citation of basic information on the material, specimens, and testing to increase the utility of the results and to reduce to a minimum the possibility of misinterpretation or improper application of those results.

SCOPE

1.1 This practice covers the desirable and minimum information to be communicated between the originator and the user of data derived from constant-force amplitude axial, bending, or torsion fatigue tests of metallic materials tested in air and at room temperature.

Note 1: Practice E466, although not directly referenced in the text, is considered important enough to be listed in this standard.

1.2 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E468 − 18

Standard Practice for

Presentation of Constant Amplitude Fatigue Test Results for

1

Metallic Materials

This standard is issued under the fixed designation E468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology Definitions and Nomenclature

1.1 This practice covers the desirable and minimum infor- 3.1 The terms and abbreviations used in this practice are

mation to be communicated between the originator and the user defined in Terminology E6 and in Terminology E1823.

of data derived from constant-force amplitude axial, bending,

or torsion fatigue tests of metallic materials tested in air and at 4. Significance and Use

room temperature.

4.1 Fatigue test results may be significantly influenced by

the properties and history of the parent material, the operations

NOTE 1—Practice E466, although not directly referenced in the text, is

considered important enough to be listed in this standard. performed during the preparation of the fatigue specimens, and

the testing machine and test procedures used during the

1.2 This international standard was developed in accor-

generation of the data. The presentation of fatigue test results

dance with internationally recognized principles on standard-

should include citation of basic information on the material,

ization established in the Decision on Principles for the

specimens, and testing to increase the utility of the results and

Development of International Standards, Guides and Recom-

to reduce to a minimum the possibility of misinterpretation or

mendations issued by the World Trade Organization Technical

improper application of those results.

Barriers to Trade (TBT) Committee.

5. Listing of Basic Information About Fatigue Test

2. Referenced Documents

Specimen

2

2.1 ASTM Standards:

5.1 Specification and Properties of Material:

E6 Terminology Relating to Methods of Mechanical Testing

5.1.1 Material Prior to Fatigue Test Specimen

E8/E8M Test Methods for Tension Testing of Metallic Ma-

Preparation—The minimum information to be presented

terials

should include the designation or specification (for example,

E466 Practice for Conducting Force Controlled Constant

A441, SAE 1070, and so forth) or proprietary grade; form of

Amplitude Axial Fatigue Tests of Metallic Materials

product (for example, plate, bar, casting, and so forth); heat

E467 Practice for Verification of Constant Amplitude Dy-

number; melting practice; last mechanical working and last

namic Forces in an Axial Fatigue Testing System

heat treatment that produced the material in the “as-received”

E1823 Terminology Relating to Fatigue and Fracture Testing

condition (for example, cold-worked and aged, annealed and

2.2 Special Technical Publications:

rolled, and so forth); chemical composition; and surface

STP 91–A A Guide for Fatigue Testing and the Statistical

condition (for example, rolled and descaled, ground, and so

3

Analysis of Fatigue Data

forth).

4

STP 588 Manual on Statistical Planning and Analysis

5.1.1.1 It is desirable but not required (unless by mutual

consent of the originator and user of the data) to list the raw

material production sequence, billet preparation, results of

1

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and

cleanliness analysis, or a combination thereof, when appli-

Fracture and is the direct responsibility of E08.05 E08.05 on Cyclic Deformation

cable.

and Fatigue Crack Formation.

Current edition approved May 1, 2018. Published July 2018. Originally approved 5.1.2 Material in the Fatigue Test Specimen:

in 1972. Last previous edition approved in 2011 as E468 —11. DOI: 10.1520/

5.1.2.1 Mechanical Properties—The minimum data on the

E0468-18.

mechanical properties of the material in a condition identical to

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that of the fatigue test specimen should include the tensile

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

strength, yield point or yield strength at a specified onset;

the ASTM website.

elongation in a specified gage length; reduction of area when

3

A Guide for Fatigue Testing and the Statistical Analysis of Fatigue Data,

applicable; and the designation of the test used to procure the

ASTM International, 1963.

4

Manual on Statistical Planning and Analysis, ASTM International, 1975., mechanical properties (for example, Test Methods E8/E8M,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19

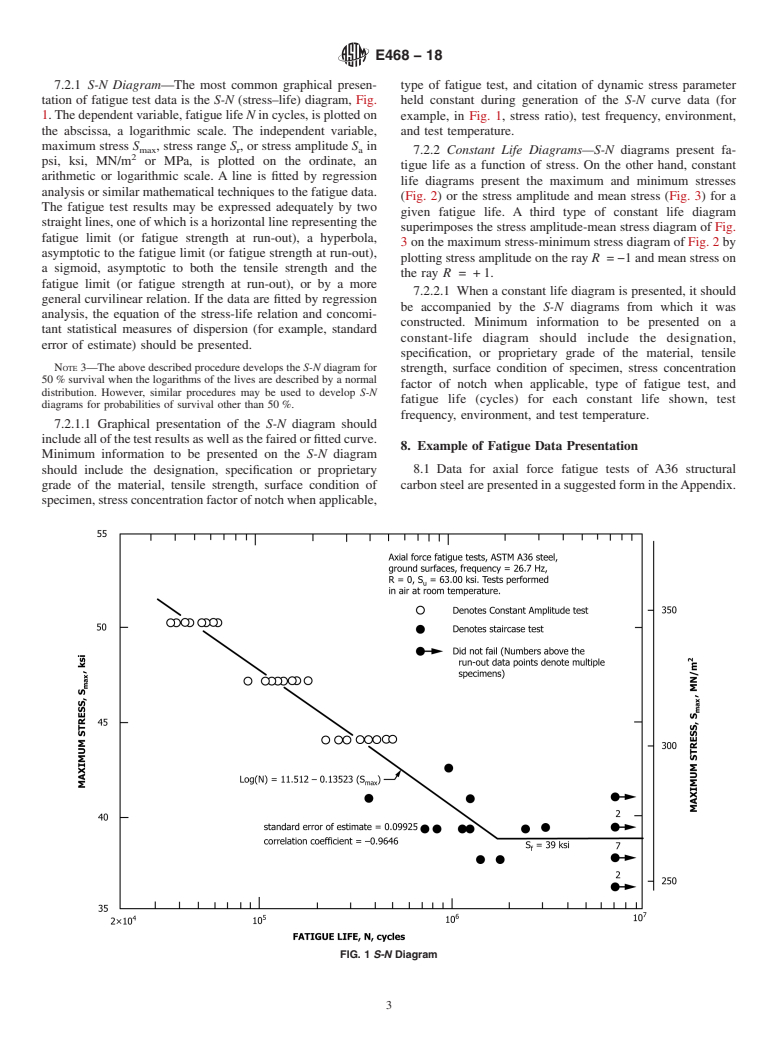

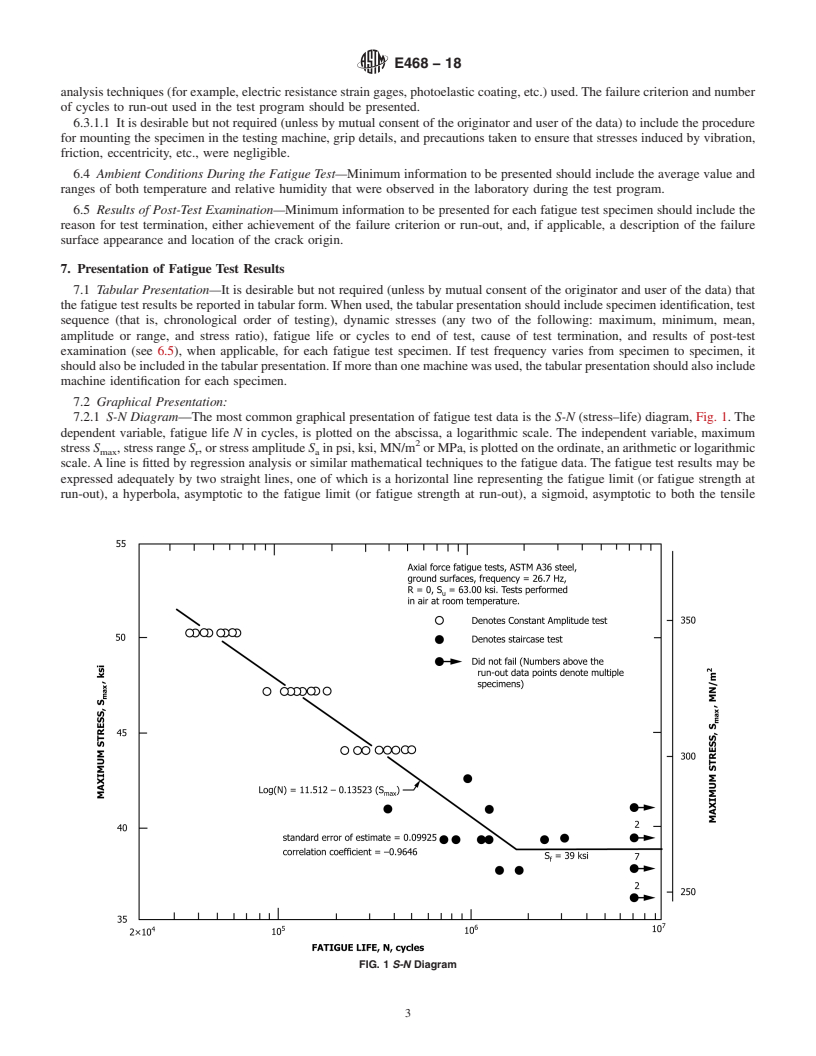

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E468 − 11 E468 − 18

Standard Practice for

Presentation of Constant Amplitude Fatigue Test Results for

1

Metallic Materials

This standard is issued under the fixed designation E468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the desirable and minimum information to be communicated between the originator and the user of data

derived from constant-force amplitude axial, bending, or torsion fatigue tests of metallic materials tested in air and at room

temperature.

NOTE 1—Practice E466, although not directly referenced in the text, is considered important enough to be listed in this standard.

1.2 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E8/E8M Test Methods for Tension Testing of Metallic Materials

E466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E467 Practice for Verification of Constant Amplitude Dynamic Forces in an Axial Fatigue Testing System

E1823 Terminology Relating to Fatigue and Fracture Testing

2.2 Special Technical Publications:

3

STP 91STP 91–A A Guide for Fatigue Testing and the Statistical Analysis of Fatigue Data

4

STP 588 Manual on Statistical Planning and Analysis

3. Terminology Definitions and Nomenclature

3.1 The terms and abbreviations used in this practice are defined in Terminology E6 and in Terminology E1823. In addition,

the following nomenclature is used:

3.2 criterion of failure—complete separation, or the presence of a crack of specified length visible at a specified magnification.

Other criteria may be used but should be clearly defined.

3.3 run-out—no failure at a specified number of loading cycles.

4. Significance and Use

4.1 Fatigue test results may be significantly influenced by the properties and history of the parent material, the operations

performed during the preparation of the fatigue specimens, and the testing machine and test procedures used during the generation

of the data. The presentation of fatigue test results should include citation of basic information on the material, specimens, and

testing to increase the utility of the results and to reduce to a minimum the possibility of misinterpretation or improper application

of those results.

1

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and Fracture and is the direct responsibility of E08.05 E08.05 on Cyclic Deformation and

Fatigue Crack Formation.

Current edition approved Oct. 1, 2011May 1, 2018. Published October 2011July 2018. Originally approved in 1972. Last previous edition approved in 20042011 as

ε1

E468 — 909(2004) —11. . DOI: 10.1520/E0468-11.10.1520/E0468-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

A Guide for Fatigue Testing and the Statistical Analysis of Fatigue Data, ASTM STP 91 A, ASTM International, 1963. Out of print; available from University Micro-

films, Inc., 300 N. Zeeb Rd., Ann Arbor, MI 48106.A Guide for Fatigue Testing and the Statistical Analysis of Fatigue Data, ASTM International, 1963.

4

Manual on Statistical Planning and Analysis, ASTM International, 1975.Manual on Statistical Planning and Analysis, ASTM STP 588,, ASTM International, 1975.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E468 − 18

5. Listing of Basic Information About Fatigue Test Specimen

5.1 Specification and Properties of Material:

5.1.1 Material Prior to Fatigue Test Specimen Preparation—The minimum information to be presented should include the

designation or specification (for example, A441, SAE 1070, and so forth) or proprietary grade; form of product (for example, plate,

bar, casting, and so forth); heat number;

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.